Cracking a skill-specific interview, like one for Electrode Beveling, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Electrode Beveling Interview

Q 1. Explain the different methods of electrode beveling.

Electrode beveling, a crucial step in welding preparation, involves shaping the end of the welding electrode to optimize weld penetration and create a stronger, more consistent weld. There are several methods to achieve this, each offering advantages depending on the situation and the equipment available.

- Manual Grinding: This is the most common method, using a grinder with various abrasive wheels to shape the electrode to the desired bevel angle. It offers precise control but is labor-intensive and prone to inconsistencies if not done by a skilled welder. For example, a welder might use a grinding wheel to create a specific included angle (e.g., 60 degrees) and a root opening (e.g., 2mm).

- Automated Grinding Machines: These machines provide consistent and repeatable beveling across numerous electrodes, significantly increasing efficiency and improving consistency. They often feature programmable settings for various bevel angles and root openings, minimizing human error. An automotive manufacturing plant, for instance, might use an automated system to prepare thousands of electrodes daily for robotic welding.

- Pre-beveled Electrodes: Some electrodes are manufactured with pre-formed bevels, eliminating the need for separate beveling. This approach saves time and ensures consistency but limits flexibility in terms of bevel angle selection. This is a cost-effective solution when consistent bevel angles are required for high-volume applications.

The choice of method depends heavily on factors such as the number of electrodes to be prepared, the required precision, the available budget, and the overall welding process.

Q 2. What are the benefits of properly beveled electrodes?

Properly beveled electrodes offer several significant advantages in the welding process:

- Improved Weld Penetration: The beveled shape allows for better fusion between the base metal and the electrode filler metal, resulting in a deeper and more complete weld. This leads to stronger and more reliable welds.

- Reduced Weld Defects: A correctly beveled electrode promotes a smoother weld bead, minimizing the risk of porosity, undercutting, and other weld defects. This ensures higher quality welds and reduces rework.

- Better Weld Bead Control: The bevel helps control the molten weld pool, making it easier to maintain a consistent bead width and shape, leading to improved cosmetic appearance and mechanical properties.

- Increased Welding Speed: Proper beveling can sometimes lead to increased welding speed due to improved penetration and heat transfer.

- Reduced Heat Input: With optimized penetration, less heat is required to achieve a sound weld, reducing the risk of distortion or heat-affected zone issues.

Imagine trying to weld two pieces of metal together with a flat electrode – it would be difficult to achieve complete penetration. A beveled electrode is like a funnel, directing the molten metal to effectively fill the joint, creating a strong weld.

Q 3. Describe the factors influencing the choice of bevel angle.

The selection of the bevel angle is a critical decision based on several interacting factors:

- Joint Type: Different joint configurations (butt, fillet, lap) require varying bevel angles to achieve optimal penetration and weld bead geometry. A butt joint, for example, typically requires a larger bevel angle than a fillet weld.

- Plate Thickness: Thicker plates necessitate larger bevel angles to ensure complete penetration. Thinner plates often require smaller angles or even no beveling.

- Welding Process: The welding process being used (e.g., SMAW, GMAW, GTAW) affects the heat input and penetration, influencing the appropriate bevel angle.

- Electrode Type and Size: Different electrode types and sizes have varying capabilities, affecting the choice of bevel angle needed for successful welding.

- Root Opening: The gap between the edges of the base metal before welding (root opening) interacts with the bevel angle to control penetration. A larger root opening sometimes requires a larger bevel angle to ensure the weld bead fills the gap completely.

For instance, welding thick steel plates using SMAW may require a significant bevel angle (e.g., 45 degrees) and a root opening to ensure full penetration. Meanwhile, welding thin aluminum sheets using GTAW may need a smaller bevel angle or no bevel at all.

Q 4. How does electrode beveling affect weld penetration?

Electrode beveling directly influences weld penetration. A properly beveled electrode significantly enhances penetration by:

- Focusing Heat: The beveled shape concentrates the heat from the welding arc, leading to localized melting and deeper penetration into the base metal.

- Increasing Contact Area: The bevel increases the contact area between the electrode and the base metal, improving heat transfer and promoting better fusion.

- Reducing Resistance to Penetration: The angled surface reduces the resistance to molten metal flow, facilitating deeper penetration.

Conversely, improper beveling can lead to insufficient penetration, resulting in incomplete fusion, porosity, or lack of fusion. An example would be trying to weld thick materials without sufficient beveling, resulting in incomplete penetration, creating a weak joint.

Q 5. What are the common defects associated with improper electrode beveling?

Improper electrode beveling can result in various weld defects, including:

- Insufficient Penetration: The weld doesn’t fully penetrate the base metal, leading to a weak and unreliable joint.

- Excessive Penetration: The weld penetrates too deeply, causing burn-through or excessive heat input, potentially leading to distortion or cracking.

- Undercutting: The weld melts away the base metal at the edge of the weld, creating a groove that weakens the joint.

- Porosity: Trapped gas bubbles within the weld bead, caused by insufficient penetration or poor welding technique.

- Incomplete Fusion: The weld metal doesn’t properly fuse with the base metal, creating a weak point in the joint.

These defects can compromise the structural integrity of the weld, resulting in potential failure during service. Identifying and correcting these defects often requires rework, adding cost and time to the project.

Q 6. Explain how to measure electrode bevel angles accurately.

Accurate measurement of electrode bevel angles is essential for consistent and high-quality welds. Several methods can be employed:

- Bevel Gauge: A simple, handheld tool with various angled slots that can be used to check the electrode bevel angle directly.

- Protractor: A standard protractor can be used to measure the angle against a straight edge placed along the electrode’s beveled surface.

- Digital Angle Finder: For higher precision, a digital angle finder provides an accurate reading of the bevel angle.

- Template: A pre-made template with the desired bevel angle can be used for visual comparison and quality control.

To ensure accurate measurements, ensure that the electrode is clean and the measuring surface is smooth and flat. The measurement should be taken in multiple locations along the electrode to ensure consistency across the bevel.

Q 7. What safety precautions should be taken during electrode beveling?

Safety is paramount during electrode beveling. The process involves sharp tools and potentially hazardous materials, necessitating careful attention to safety precautions:

- Eye Protection: Always wear appropriate safety glasses or a face shield to protect against flying debris from grinding.

- Respiratory Protection: Grinding creates dust and fumes that can be harmful; a respirator should be used, especially in poorly ventilated areas.

- Hearing Protection: Grinding can be noisy; earplugs or earmuffs are recommended.

- Proper Clothing: Wear long sleeves, gloves, and closed-toe shoes to prevent injuries from sharp edges and flying debris.

- Secure Work Area: Ensure a stable and well-lit work area to avoid accidents.

- Tool Maintenance: Use properly maintained tools in good working condition to minimize the risk of accidents.

- Regular Breaks: Grinding can be strenuous; take regular breaks to avoid fatigue and maintain focus.

Following these precautions significantly reduces the likelihood of accidents and ensures a safe working environment.

Q 8. How do you determine the appropriate beveling technique for a specific material?

Selecting the right beveling technique hinges on understanding the material’s properties. Factors like thickness, weldability, and desired weld penetration dictate the approach. For instance, a thicker, high-strength steel might necessitate a more aggressive bevel, perhaps a double-V or a U-bevel, to ensure complete penetration and a strong weld. Conversely, thinner materials or those prone to warping might only require a single bevel or even no bevel at all, using a specialized welding process. We need to consider the welding process itself; Gas Metal Arc Welding (GMAW) might tolerate a shallower bevel compared to Shielded Metal Arc Welding (SMAW) for the same material.

Imagine trying to weld two thick pieces of wood together – you wouldn’t just lay them flat; you’d likely cut an angle to ensure the glue or nails penetrate deeply and create a strong join. It’s the same principle. The material’s metallurgical composition also matters; certain alloys might require more precise beveling to avoid cracking or other weld defects.

- Material Thickness: Thicker materials necessitate deeper bevels for complete penetration.

- Material Strength: Higher strength materials often require more aggressive beveling.

- Weldability: Materials with poor weldability might need specialized bevel designs to aid penetration and reduce defects.

- Welding Process: Different welding processes have different penetration capabilities, affecting the necessary bevel angle.

Q 9. Discuss the impact of electrode beveling on weld strength and fatigue life.

Electrode beveling significantly impacts weld strength and fatigue life. Proper beveling ensures complete fusion of the base metals, leading to a stronger and more durable weld. Insufficient penetration due to improper beveling results in incomplete fusion, creating weak points prone to cracking and failure under stress. The geometry of the bevel—the angle and depth—directly influences the stress distribution within the weld joint. A well-designed bevel distributes stress more evenly, improving fatigue resistance. Poorly designed bevels concentrate stress, accelerating fatigue failure.

Think of it like building a bridge: if the connecting beams aren’t properly joined, the whole structure is weaker. Similarly, a weld with poor penetration is vulnerable to failure. Optimized beveling helps distribute the load across the entire weld, maximizing strength and extending its lifespan. A well-executed bevel reduces stress concentration points, thus enhancing the fatigue life—the ability of the weld to withstand repeated cycles of loading and unloading before failure.

Q 10. Describe the process of setting up and operating a beveling machine.

Setting up and operating a beveling machine involves several steps, prioritizing safety and precision. First, the machine needs to be securely mounted and grounded. Next, the workpiece is clamped firmly, ensuring accurate positioning and stability. The beveling parameters – angle, depth, and speed – are then set according to the material and design specifications. This often involves using pre-programmed settings or manual adjustments based on experience and reference tables. A test run on a scrap piece of the same material is highly recommended before proceeding with the actual workpiece. During operation, close monitoring is crucial; ensure the machine runs smoothly, and the cut is consistent and clean. Regular maintenance and tool changes help avoid costly defects and downtime.

Safety protocols are paramount – always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. The machine must be turned off and unplugged before any adjustments or maintenance. Regular checks for wear and tear on the tooling are essential to ensure consistent bevel quality and to prevent accidents.

Q 11. How do you troubleshoot common issues encountered during electrode beveling?

Troubleshooting electrode beveling issues often involves systematic checks. If the bevel is inconsistent or inaccurate, start by inspecting the clamping system, ensuring the workpiece is securely fixed and correctly aligned. Check the cutting tool for wear or damage—a dull or damaged tool produces uneven bevels. Verify the machine’s settings; incorrect parameters can lead to inaccurate cuts. Problems with the power supply or machine mechanics should also be investigated. Examine the material itself; inconsistencies in material thickness or hardness can affect the beveling process. A consistent, clean bevel is a sign of proper operation.

Addressing issues requires a logical approach: check the simplest things first. If the problem persists, consult the machine’s manual or seek help from experienced technicians. Keep a detailed record of any issues encountered and corrective actions taken—this helps prevent future problems.

Q 12. Explain the role of electrode beveling in reducing weld spatter.

Electrode beveling plays a crucial role in reducing weld spatter. A properly beveled electrode creates a more controlled arc and melt flow, minimizing the expulsion of molten metal droplets. The angled surfaces improve the arc stability, leading to a smoother, more consistent weld. The increased penetration from a good bevel also helps consolidate the weld pool, further reducing spatter formation. Spatter is molten metal droplets which are projected from the weld pool, resulting in a less efficient, less aesthetically pleasing weld which requires more clean-up.

Think of it like pouring water from a jug – if the spout is constricted, the water will splatter. Similarly, a poorly beveled electrode constricts the molten metal flow, leading to more spatter.

Q 13. How does automation affect electrode beveling processes?

Automation has revolutionized electrode beveling, improving efficiency, consistency, and precision. Automated beveling machines offer programmable settings, allowing for precise control over bevel angles, depths, and speeds. Automated systems often incorporate robotic arms for precise handling and positioning of workpieces, eliminating human error and ensuring consistent bevel quality. Automated systems also usually provide data logging and tracking, improving quality control. The benefits of automation extend to increased throughput and reduced labor costs.

Imagine transitioning from manually assembling a complex product to using a robotic assembly line – the speed, consistency, and precision are significantly enhanced. Automation in electrode beveling delivers the same advantages, especially in high-volume manufacturing environments.

Q 14. What are the different types of electrode beveling machines?

Several types of electrode beveling machines exist, each suited to different applications and material thicknesses. These include:

- Manual Beveling Machines: These machines offer greater flexibility for smaller or more complex jobs but require more operator skill.

- Semi-automatic Beveling Machines: These combine manual control with automated features like power feed, improving consistency and speed.

- CNC (Computer Numerical Control) Beveling Machines: CNC machines offer the highest level of precision and repeatability, ideal for high-volume production and complex bevel designs.

- Robotic Beveling Systems: These integrated systems combine robotic arms with CNC control, maximizing efficiency and precision, particularly suitable for large or heavy workpieces.

The choice of machine depends on the production volume, desired precision, and budget. Manual machines are cost-effective for smaller projects, whereas automated systems become advantageous for larger-scale operations.

Q 15. Compare and contrast different beveling techniques.

Electrode beveling employs various techniques, each with its strengths and weaknesses. The choice depends on factors like electrode material, desired bevel angle, and production volume.

- Mechanical Beveling: This traditional method uses grinders, lathes, or specialized beveling machines. It’s versatile, suitable for various materials and angles, but requires operator skill for consistent results and can generate burrs or uneven surfaces if not done carefully. Think of it like sharpening a pencil – you need a steady hand and the right tool.

- Electro-Discharge Machining (EDM): EDM uses electrical discharges to erode material, creating precise bevels even on hard-to-machine materials. It’s highly accurate and repeatable but is slower and more expensive than mechanical methods. Imagine a tiny, controlled lightning strike precisely removing material.

- Laser Beveling: Laser technology offers very precise and rapid beveling. It’s ideal for complex geometries and high-volume production but requires specialized equipment and can be sensitive to material properties. This is like using a highly focused heat beam to melt and remove material, creating a very clean edge.

In summary, mechanical beveling is cost-effective and versatile, EDM provides high precision, and laser beveling offers speed and precision, but each has its limitations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure consistent bevel angles across multiple electrodes?

Ensuring consistent bevel angles is crucial for optimal welding performance and consistent part quality. Several strategies can be employed:

- Jigging and Fixturing: Using custom jigs or fixtures holds the electrode at the precise angle during beveling, minimizing variations. This is like using a guide to ensure you draw a perfectly straight line.

- Automated Beveling Machines: CNC-controlled beveling machines offer programmable angle settings and consistent speed, leading to high repeatability. These machines are like robots, precisely following programmed instructions.

- Regular Calibration and Inspection: Regularly check the beveling equipment (e.g., grinder angle, EDM settings, laser alignment) and inspect beveled electrodes using precision measuring tools (e.g., angle gauges, microscopes). This is like regular maintenance on your car – ensuring it’s working as intended.

- Operator Training and Standardization: Well-trained operators using standardized procedures significantly improve consistency. This is like having a well-rehearsed team – everyone knows their role and how to perform it.

Q 17. Explain the importance of electrode preparation before beveling.

Proper electrode preparation is fundamental for successful beveling. This includes cleaning, surface preparation and any necessary pre-machining.

- Cleaning: Removing any contaminants (e.g., grease, oil, oxides) ensures a clean surface for accurate beveling and prevents defects. Imagine trying to sharpen a rusty knife – you need to clean it first.

- Surface Finish: A smooth surface is vital for consistent beveling. Rough surfaces can lead to inconsistencies and premature wear on the beveling tool. A smoother surface makes beveling easier and more accurate.

- Pre-machining (if necessary): For certain geometries or materials, pre-machining might be required to create a suitable starting point for beveling. This is like preparing the ground before building a house.

Neglecting electrode preparation leads to inconsistent bevels, poor weld quality, and potential electrode failure.

Q 18. Discuss the effect of electrode diameter on beveling requirements.

Electrode diameter significantly impacts beveling requirements. Larger diameter electrodes require more material removal and may necessitate different beveling techniques or equipment.

- Increased Material Removal: Larger electrodes require more substantial material removal to achieve the desired bevel angle, potentially increasing processing time and cost.

- Equipment Selection: The choice of beveling equipment (e.g., manual grinder vs. CNC machine) depends on the electrode size. Larger electrodes might need more robust equipment.

- Bevel Angle Considerations: The achievable bevel angle might be constrained by the electrode diameter; excessively steep bevels might be impractical or weaken the electrode.

For example, a small electrode might be easily beveled using a hand-held grinder, while a large electrode may require a CNC machine for precision and efficiency.

Q 19. How do you maintain and calibrate electrode beveling equipment?

Regular maintenance and calibration are essential for accurate and consistent beveling. This involves:

- Regular Cleaning: Regularly clean the beveling equipment to remove debris and prevent clogging (especially for EDM and laser systems).

- Tool Inspection and Replacement: Regularly inspect cutting tools (e.g., grinding wheels, EDM electrodes) for wear and tear and replace them when necessary. A dull tool will produce an uneven bevel.

- Calibration: Calibrate the beveling equipment according to manufacturer instructions using precision measuring tools. This ensures that the machine is producing the desired angle.

- Lubrication: Lubricate moving parts of mechanical beveling equipment to prevent wear and ensure smooth operation.

A preventative maintenance schedule is key to optimizing equipment performance and reducing downtime.

Q 20. What are the common materials used for electrodes requiring beveling?

Electrodes requiring beveling are typically made from materials that offer high conductivity, good weldability, and resistance to wear and erosion. Common materials include:

- Copper (Cu): Widely used due to its high conductivity and excellent weldability.

- Copper Alloys (e.g., brass, bronze): Offer improved mechanical properties compared to pure copper.

- Tungsten (W): Used in high-temperature applications due to its high melting point and resistance to wear.

- Graphite: Used for specific applications, offering good conductivity but lower mechanical strength compared to metals.

The selection of electrode material depends heavily on the specific welding process and application requirements.

Q 21. Describe the inspection criteria for properly beveled electrodes.

Inspection criteria for properly beveled electrodes focus on accuracy, consistency, and surface finish. This typically involves:

- Angle Accuracy: Precise measurement of the bevel angle using angle gauges or other precision measuring instruments to ensure it meets the specified tolerance.

- Surface Finish: Assessment of the surface finish for any defects such as burrs, scratches, or irregularities. A smooth surface is desired for optimal welding.

- Dimensional Consistency: Verification that the bevel dimensions (e.g., width, length) are consistent across multiple electrodes.

- Visual Inspection: A visual check for any obvious defects or imperfections.

Any deviations from the specified requirements indicate a need for corrective actions to improve the beveling process.

Q 22. How do you handle and dispose of waste materials generated during beveling?

Waste management in electrode beveling is crucial for safety and environmental compliance. We meticulously separate waste materials into different categories: metal shavings, grinding dust, and used consumables like grinding wheels or cutting fluids. Metal shavings are typically collected in designated containers and recycled; this is often cost-effective and environmentally responsible. Grinding dust, which can contain hazardous particles depending on the electrode material, is handled with specialized vacuum systems and disposed of according to local regulations. For example, if working with stainless steel electrodes, we’d ensure the dust is collected in a HEPA-filtered system and sent to a facility licensed for hazardous waste disposal. Used consumables are disposed of according to manufacturer guidelines and relevant safety regulations.

A robust waste management plan also includes regular inspections of containers, ensuring proper labeling, and maintaining detailed records of waste generation and disposal. This traceability is crucial for audits and demonstrates our commitment to responsible practices. We regularly review and update our procedures to ensure compliance with the ever-evolving regulations in the industry.

Q 23. Explain the use of jigs and fixtures in electrode beveling.

Jigs and fixtures are indispensable in electrode beveling for ensuring consistency and precision. Think of them as guides that hold the electrode in the exact position needed for the beveling process. This is particularly critical for complex bevel profiles or when dealing with a high volume of identical electrodes. Jigs typically involve clamping mechanisms that securely hold the electrode, preventing movement during machining. Fixtures, on the other hand, can be more sophisticated, often incorporating indexing mechanisms for repeatable positioning and automated processes.

For example, a simple jig might be a custom-made plate with precisely machined holes and clamps to hold a specific electrode size and shape. A more advanced fixture might be integrated into a CNC machining center, allowing for programmed beveling of numerous electrodes with complex geometries. The use of jigs and fixtures significantly reduces errors, improves productivity, and ensures uniform bevel quality across all electrodes.

Q 24. What are the latest advancements in electrode beveling technology?

The field of electrode beveling is constantly evolving. Recent advancements focus on improving precision, speed, and automation. One notable development is the increased use of Computer Numerical Control (CNC) machining, offering programmable control over bevel angle, depth, and finish. This allows for complex bevel profiles to be created with high repeatability. Moreover, advancements in cutting tools, such as the development of more durable and longer-lasting grinding wheels and advanced cutting fluids, lead to significant improvements in efficiency and reduced downtime.

Laser-assisted beveling is gaining traction, offering a high degree of precision and the ability to create intricate bevel shapes. Furthermore, advancements in robotic systems are enabling automated electrode handling and processing, further improving efficiency and reducing labor costs in high-volume manufacturing environments. The integration of data analytics and process monitoring is also becoming increasingly common, enabling proactive maintenance and improved quality control.

Q 25. How do you address variations in material thickness during beveling?

Variations in material thickness present a common challenge in electrode beveling. To address this, we employ several strategies. First, precise measurement of the electrode thickness is vital, using tools like calipers or micrometers to ensure accuracy. This data is then used to adjust the beveling parameters, such as the depth of cut or the feed rate. For instance, if the material is thicker than expected, we might increase the number of passes or adjust the grinding wheel to ensure the desired bevel angle is achieved.

Adaptive control systems in CNC machines can automatically adjust parameters based on real-time feedback from sensors monitoring the electrode thickness. This allows for consistent beveling even with variations in material thickness. In some cases, pre-machining steps might be necessary to level the electrode surface or create a consistent starting point before beveling. Using specialized tooling designed for accommodating thickness variations is another key aspect in maintaining consistent bevel quality across electrodes with differing thicknesses.

Q 26. Describe your experience with different types of beveling tools.

My experience encompasses a wide range of beveling tools. I’m proficient with both manual and automated methods. Manual methods often involve using hand-held grinders or specialized beveling tools, which require skill and precision. I’ve worked extensively with various types of grinding wheels, selecting the appropriate grit and bond for the specific material being machined. For example, coarser grits are used for faster material removal, while finer grits provide a better surface finish. The choice of cutting fluid is also crucial, with different fluids optimized for various materials and machine types.

In automated settings, I have experience with CNC machining centers and robotic systems equipped with specialized grinding heads and milling tools. These systems provide a higher degree of precision and repeatability, particularly crucial for complex bevel profiles. The selection of appropriate tooling is always critical; for example, diamond-coated wheels offer exceptional durability and precision for harder materials, while carbide tools are commonly used for softer materials. Understanding the strengths and limitations of each tool is critical in achieving optimal results.

Q 27. How would you train a new employee on electrode beveling techniques?

Training a new employee involves a structured approach combining theoretical knowledge and practical hands-on experience. It begins with a comprehensive safety briefing emphasizing the importance of personal protective equipment (PPE) and safe operating procedures. Then, I’d provide detailed instruction on the different types of beveling tools, their proper use, and maintenance. We’d cover various beveling techniques and the impact of parameters like angle, depth, and feed rate. Understanding the properties of different electrode materials and their influence on the beveling process is also key.

Hands-on training is crucial. I’d start with simple beveling tasks, gradually increasing complexity as the trainee gains proficiency. Regular assessments and feedback are provided to identify areas needing further development. The training program also includes instruction on quality control procedures, waste management, and troubleshooting common issues. The goal is to ensure the employee understands the entire process, from initial setup to final inspection, and can perform the task independently while maintaining safety and quality standards.

Q 28. What are your preferred methods for quality control in electrode beveling?

Quality control in electrode beveling is paramount. My preferred methods involve a multi-stage approach. First, pre-beveling inspection verifies the electrode’s dimensions and surface quality. This includes checking for defects that could affect the beveling process or the final product. Then, during the beveling process, regular checks are performed to ensure the machine parameters are correct and the bevel is being created according to the specifications.

Post-beveling inspection involves thorough visual examination and measurement using precision tools, like optical comparators or coordinate measuring machines (CMMs), to verify the bevel angle, depth, and surface finish. Statistical Process Control (SPC) techniques are employed to monitor the process and identify any trends that might indicate potential issues. Additionally, regular maintenance of the equipment is crucial for preventing errors and ensuring consistent results. Documentation of all inspections and measurements provides traceability and allows for continuous improvement of our processes. This rigorous quality control ensures consistent, high-quality beveling across all electrodes.

Key Topics to Learn for Electrode Beveling Interview

- Fundamentals of Electrode Beveling: Understanding the process, its purpose, and various techniques employed.

- Equipment and Tooling: Familiarity with different types of electrode beveling machines, their functionalities, and safety protocols.

- Material Selection and Properties: Knowledge of suitable materials for electrode beveling and how material properties influence the process.

- Process Parameters and Optimization: Understanding factors like current, voltage, speed, and their impact on bevel quality and efficiency. Optimizing parameters for different applications.

- Quality Control and Inspection: Methods for inspecting bevel quality, identifying defects, and implementing corrective actions. Understanding relevant quality standards.

- Troubleshooting Common Issues: Recognizing and resolving common problems encountered during electrode beveling, such as uneven bevels, surface defects, or equipment malfunctions.

- Safety Procedures and Regulations: Adherence to safety regulations, proper use of personal protective equipment (PPE), and risk mitigation strategies.

- Practical Applications: Understanding the diverse applications of electrode beveling across various industries, such as welding, fabrication, and manufacturing.

- Advanced Techniques and Technologies: Explore advanced techniques like automated beveling systems and the latest advancements in the field.

Next Steps

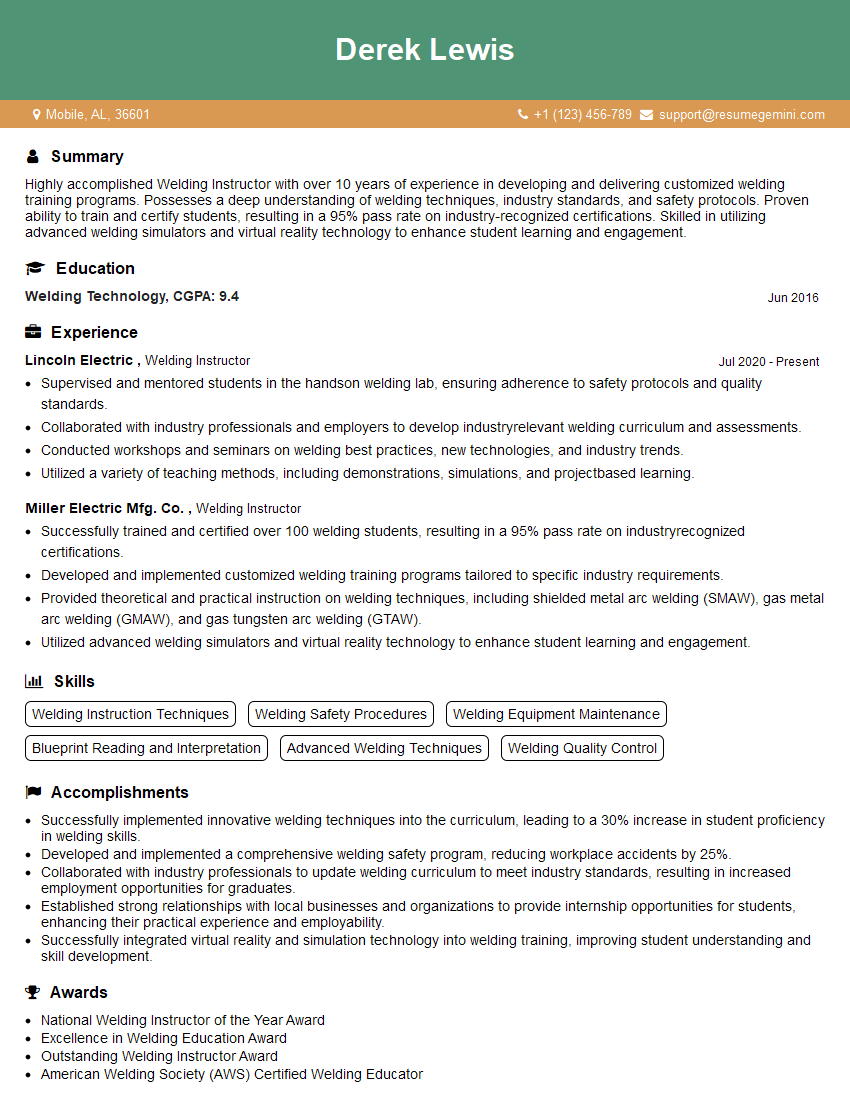

Mastering Electrode Beveling opens doors to exciting career opportunities in high-demand industries. A strong understanding of this crucial skill significantly enhances your value to potential employers. To maximize your chances, focus on creating a professional and ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource for building compelling resumes that stand out. Utilize their tools and resources to craft a powerful document that highlights your expertise in Electrode Beveling. Examples of resumes tailored to this specific skill set are available for your reference.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good