Cracking a skill-specific interview, like one for Elevator System Analysis, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Elevator System Analysis Interview

Q 1. Explain the difference between traction and hydraulic elevator systems.

The core difference between traction and hydraulic elevator systems lies in how they achieve vertical movement. Think of it like this: traction elevators are like a rope and pulley system, while hydraulic elevators are like a giant lift powered by fluid pressure.

Traction Elevators: These use a motor to rotate a sheave (a large grooved wheel), which in turn moves cables attached to the elevator car. These cables run over the sheave and counterweight system, balancing the car’s weight and reducing the energy needed for movement. They’re common in taller buildings because they’re more energy-efficient at greater heights.

Hydraulic Elevators: These utilize a hydraulic piston or ram that pushes the elevator car upward. A pump pressurizes hydraulic fluid, which acts on the piston. They are generally more suitable for lower-rise buildings because the hydraulic system becomes less efficient and more expensive as the building height increases. The maximum travel distance is limited by the length of the hydraulic cylinder. Also, they tend to be slower than traction elevators.

- Traction Advantages: Higher speeds, taller building suitability, lower energy consumption at high rises.

- Traction Disadvantages: More complex mechanical systems, higher initial cost.

- Hydraulic Advantages: Simpler mechanical design, lower initial cost (for low-rise buildings), smoother start and stop.

- Hydraulic Disadvantages: Lower speeds, limited height, potential environmental concerns due to hydraulic fluid.

Q 2. Describe the function of a governor in an elevator system.

The governor is a critical safety device in an elevator system. Imagine it as a failsafe mechanism that prevents catastrophic accidents. Its primary function is to automatically stop the elevator car if it exceeds a predetermined speed, typically during a runaway situation. This could be caused by cable breakage, mechanical failure, or other unforeseen circumstances.

When the elevator car travels too fast, the governor activates a safety mechanism, typically a clamping device, which engages with the guide rails, bringing the car to a rapid but controlled stop. This prevents the car from plummeting. Modern systems often incorporate sophisticated electronic monitoring and feedback mechanisms to enhance governor performance and provide early warnings of potential problems.

In essence, the governor ensures that even in the event of a major mechanical failure, the elevator car is prevented from free-falling, significantly enhancing passenger safety.

Q 3. What are the common causes of elevator malfunctions?

Elevator malfunctions can stem from a variety of causes, ranging from simple issues to more complex mechanical and electrical problems. Here are some common culprits:

- Mechanical Issues: Worn cables, damaged pulleys, malfunctioning brakes, problems with the hoisting mechanism (in traction elevators), or issues within the hydraulic system (in hydraulic elevators).

- Electrical Problems: Power outages, faulty wiring, motor failures, malfunctioning control circuits, or problems with the safety systems (such as limit switches or sensors).

- Software Glitches: Errors in the elevator’s control system software can cause unpredictable behavior, leading to malfunctions. This is increasingly common in modern elevators with sophisticated computerized controls.

- Door Problems: Problems with the elevator doors, such as sensor failures or mechanical jams, are frequent causes of service interruptions.

- Overload: Exceeding the elevator’s weight capacity can trigger safety mechanisms, causing the elevator to stop.

Regular maintenance and inspections are crucial in preventing many of these malfunctions.

Q 4. How do you troubleshoot a stuck elevator?

Troubleshooting a stuck elevator requires a systematic approach, prioritizing safety. Never attempt to repair an elevator yourself unless you’re a qualified technician. The first step is always to ensure the safety of any occupants.

- Assess the Situation: Determine if anyone is trapped and their condition. Contact emergency services if necessary.

- Communicate: Maintain communication with the occupants, reassuring them and providing updates. Use the emergency phone or intercom system.

- Check the Control Panel: Look for any error codes or indications of the problem displayed on the elevator’s control panel. This might give clues to the cause.

- Check for Obstructions: Inspect the elevator car and shaft for any obstructions that may be preventing movement.

- Attempt to Restart the Elevator: Once you’ve ruled out any immediate safety concerns, carefully attempt to restart the elevator using the emergency controls (following established safety protocols).

- Contact Elevator Maintenance: If the elevator cannot be restarted or if there are any safety concerns, immediately contact the elevator maintenance company or a qualified technician. Only qualified personnel should attempt repairs.

Q 5. Explain the role of safety features in elevator systems (e.g., buffers, limit switches).

Safety features in elevators are paramount. They are designed to protect passengers and prevent accidents, even in the event of failures. These features work together to form a comprehensive safety system.

- Buffers: These are large springs or hydraulic systems located at the bottom of the elevator shaft. They act as a final safety net, absorbing the impact of the elevator car if it falls unexpectedly, minimizing damage and injuries.

- Limit Switches: These are electrical switches that detect when the elevator car has reached the top or bottom of the shaft, preventing overtravel and ensuring the car stops within its designated boundaries.

- Safety Gears (in traction elevators): These mechanically engage with the guide rails to stop the car if it travels too fast, often working in conjunction with the governor.

- Doors and Door Sensors: These prevent the elevator from moving while the doors are open or improperly closed. Sensors detect obstructions in the doorway, preventing the doors from closing on anything.

- Emergency Brakes: These automatically engage to stop the elevator in case of power failure or other malfunctions.

- Emergency Lighting and Communication Systems: These ensure occupants can see and communicate in case of an emergency.

The interplay of all these systems ensures a high level of safety in elevator operation.

Q 6. Describe different types of elevator control systems (e.g., collective, destination dispatch).

Elevator control systems manage the efficient and safe movement of elevator cars. Several types exist, each with its advantages and disadvantages.

- Collective Control: This is a traditional system that prioritizes requests based on their arrival time and direction. It’s simple but can be inefficient in high-traffic situations, leading to longer wait times.

- Destination Dispatch Control: This more advanced system allows passengers to select their destination floor before entering the elevator. The system then assigns them to a car that will take them directly to their floor, minimizing travel time and improving efficiency. Think of it as a smart, optimized traffic system for elevators.

- Group Supervisory Control: This system manages multiple elevators in a building, optimizing their operation and reducing wait times. It dynamically assigns cars to requests, improving overall efficiency.

The choice of control system depends on factors such as the building’s size, passenger traffic, and the desired level of efficiency and sophistication.

Q 7. What are the key components of an elevator’s electrical system?

The electrical system of an elevator is complex and essential for its operation. Here are some key components:

- Motor: The motor provides the power to drive the elevator car (traction elevators) or the hydraulic pump (hydraulic elevators). It can be AC or DC, depending on the system.

- Controller: This is the ‘brain’ of the elevator, managing the motor speed, direction, and overall operation based on passenger requests and safety protocols. Modern controllers are often computer-based.

- Power Supply: Provides the electricity needed for the elevator’s operation, including the motor, lights, and control systems.

- Wiring and Cabling: Complex network of wires and cables transmits power and signals throughout the elevator system.

- Limit Switches and Safety Devices: Electrical switches and sensors that monitor the elevator’s position and operation, triggering safety mechanisms if necessary.

- Emergency Power System: Backup power system to ensure safe operation in case of power outages.

- Lighting and Communication Systems: Electrical systems providing illumination and communication capabilities within the elevator car.

The design and implementation of the electrical system are critical to ensuring safe and reliable elevator operation.

Q 8. How do you perform a safety inspection of an elevator system?

A comprehensive elevator safety inspection is a multi-stage process crucial for preventing accidents and ensuring regulatory compliance. It’s like a thorough health check for your building’s vertical transportation system.

Visual Inspection: This involves a detailed examination of all components, from the hoistway and machinery room to the car itself. We look for signs of wear and tear, corrosion, loose parts, and any damage to cables, ropes, or safety devices. Think of it as a visual scan for any potential issues.

Functional Testing: This step involves operating the elevator under various conditions to assess its performance. This includes testing emergency stops, door mechanisms, safety brakes, and the overall operational smoothness. We’re essentially stress-testing the system to see how it handles different scenarios.

Mechanical Checks: We meticulously inspect the elevator’s mechanical components, such as the motor, gears, brakes, and counterweights. This often involves precise measurements and checks against manufacturer specifications. We’re looking for any signs of malfunction or wear exceeding permissible limits.

Electrical Checks: This includes testing the electrical wiring, control systems, and safety circuits to identify any potential electrical hazards. We’re looking for issues that could lead to electrical shorts, fires, or malfunctions.

Documentation: All findings are meticulously documented, including photos, measurements, and observations. This detailed report is essential for maintenance scheduling and regulatory compliance. This ensures a clear record of the elevator’s health.

For example, during a recent inspection, I noticed a slight misalignment in the guide rails, which could potentially lead to increased friction and wear. This was promptly reported and addressed, preventing a potential future failure.

Q 9. Explain the process of elevator modernization.

Elevator modernization is the process of upgrading an existing elevator system to improve its efficiency, safety, and aesthetics. It’s like giving your old elevator a complete makeover, both inside and out.

Needs Assessment: The process begins with a thorough assessment of the current system’s condition, identifying areas for improvement. This includes evaluating the age, condition, and capacity of the existing equipment.

Design and Planning: Based on the assessment, a detailed plan is developed. This plan specifies the upgrades to be implemented, such as replacing old control systems, installing new cabs, adding energy-efficient components, or upgrading safety features.

Implementation: This phase involves the actual installation of new equipment and the removal of outdated components. This requires careful coordination and skilled technicians.

Testing and Commissioning: After installation, the modernized system undergoes rigorous testing to ensure it meets safety standards and performs as expected. This is a crucial phase to verify everything is working correctly.

Documentation and Handover: Finally, comprehensive documentation is provided, including operational manuals, maintenance schedules, and compliance certificates. This ensures the smooth handover of the system to the building management.

For instance, I recently led a project where we modernized an old hydraulic elevator by replacing its outdated control system with a microprocessor-based one, resulting in a significant improvement in energy efficiency and response time.

Q 10. What are the common regulatory requirements for elevator maintenance and safety?

Elevator maintenance and safety regulations vary depending on location, but there are common themes. They’re designed to protect building occupants and ensure the safe operation of the equipment.

Regular Inspections: Frequent inspections are mandated, typically annually or biannually, depending on the elevator type and usage. These inspections are performed by qualified elevator technicians and ensure the system remains compliant with safety standards.

Maintenance Records: Detailed maintenance records must be kept, showing the history of inspections, repairs, and replacements. These records are crucial for demonstrating compliance and tracking the elevator’s operational history.

Safety Devices: Elevators must be equipped with various safety devices, including emergency brakes, overspeed governors, and safety gears. These are designed to prevent accidents and ensure the safe operation of the equipment.

Emergency Procedures: Clear emergency procedures must be established and documented, ensuring occupants know how to safely evacuate in case of malfunction. This includes clear signage and instructions.

Compliance with Codes: The elevator system must comply with all applicable local and national safety codes and standards. These standards are regularly updated to reflect advancements in technology and safety practices.

Failure to comply with these regulations can result in significant fines and potential legal liabilities. It’s crucial to stay informed about the latest code changes and ensure your elevator systems are regularly updated and inspected.

Q 11. Describe your experience with elevator control system programming.

My experience with elevator control system programming spans several platforms and programming languages. I’m proficient in PLC programming (using languages like ladder logic), as well as microcontroller programming (using C or C++). This expertise enables me to design, implement, and troubleshoot complex elevator control systems.

I’ve worked extensively with various elevator control systems, including those using VVVF (Variable Voltage Variable Frequency) drives for precise speed control and energy efficiency. I’ve also programmed systems for optimizing traffic flow, predicting passenger demand, and implementing advanced features like destination dispatch.

Example: In a recent project, I implemented a destination dispatch system using a PLC and a customized algorithm. This system significantly reduced waiting times and improved overall elevator efficiency by directing passengers to the most appropriate car based on their destination floor. The code involved intricate logic to manage car assignments, optimize travel routes, and dynamically adjust to changes in passenger demand.

My programming skills extend beyond just implementation; I’m adept at debugging, testing, and maintaining these systems, ensuring they function reliably and safely over their operational lifespan.

Q 12. How do you handle emergency situations involving elevators?

Handling elevator emergencies requires a calm, methodical approach and adherence to established safety procedures. It’s like being a first responder, but for vertical transportation.

Assess the Situation: First, assess the nature of the emergency. Is someone trapped? Is there a fire? Is the elevator malfunctioning? Understanding the situation dictates the next steps.

Contact Emergency Services: Immediately contact emergency services (fire department, rescue services). This is the most crucial initial step.

Secure the Area: If possible, secure the area around the elevator to prevent accidents or further injuries.

Communicate with Trapped Passengers: If someone is trapped, reassure them and provide updates about rescue efforts. Maintain clear communication.

Follow Established Protocols: Adhere strictly to established emergency protocols and procedures, utilizing any available communication systems (intercoms, emergency phones) within the elevator and building.

Cooperate with Rescue Personnel: Cooperate fully with emergency response personnel, providing them with relevant information about the elevator system and its specifications.

For instance, I once responded to an emergency where an elevator was stuck between floors. By calmly communicating with the trapped passengers, contacting emergency services, and providing information to the rescue team, we ensured a safe and timely rescue, minimizing passenger anxiety and potential harm.

Q 13. Explain the principles of elevator load balancing.

Elevator load balancing aims to distribute the passenger load evenly across multiple elevators in a group, optimizing traffic flow and minimizing waiting times. It’s like a traffic controller for vertical movement.

Sophisticated elevator control systems employ various algorithms for load balancing. These algorithms consider factors such as:

Number of passengers waiting: The system assesses the number of passengers waiting at each floor.

Elevator direction and occupancy: The system tracks the direction (up or down) and current occupancy of each elevator.

Elevator speed and location: The system considers the current speed and location of each elevator.

The goal is to assign passengers to elevators in a way that minimizes waiting time and maximizes throughput. For instance, if one elevator is heading up with a full load, the system might direct passengers waiting on lower floors to a different elevator heading upward with more capacity. This prevents overcrowding and minimizes wait times.

Modern systems often use predictive algorithms to anticipate passenger demand, making load balancing even more efficient. This preemptive approach prevents potential bottlenecks during peak hours, improving overall system performance.

Q 14. What are the different types of elevator doors and their safety mechanisms?

Elevator doors come in various types, each with specific safety mechanisms. These mechanisms are critical for preventing accidents.

Center-Opening Doors: These doors open in the middle and are commonly found in high-rise buildings. Safety features typically include interlocks that prevent the elevator from moving while the doors are open, and pressure sensors to detect obstructions.

Side-Opening Doors: These doors open to the side, often seen in smaller buildings or those with limited space. Similar safety mechanisms as center-opening doors apply here, such as interlocks and pressure sensors.

Telescopic Doors: These doors consist of multiple sections that slide past each other to save space. They require more intricate safety mechanisms to ensure smooth operation and prevent pinching.

Safety Mechanisms: Common safety features include:

- Interlocks: These prevent the elevator from moving unless the doors are fully closed.

- Pressure Sensors: These detect obstructions in the doorway and prevent the doors from closing.

- Emergency Release Mechanisms: These allow the doors to be opened manually in case of emergencies.

- Door Operators: These control the opening and closing of the doors, often with programmable features for speed and safety.

For example, telescopic doors in high traffic areas frequently utilize multiple sensors and a complex control system to guarantee that no part of the door mechanism creates a risk of injury.

Q 15. How do you diagnose and repair elevator hydraulic system problems?

Diagnosing and repairing hydraulic elevator system problems requires a systematic approach. First, we need to identify the specific issue. Is the elevator stuck, moving erratically, or experiencing leaks? This often involves a careful visual inspection, checking for obvious leaks in the hydraulic lines, hoses, or cylinder seals. We’d also check the hydraulic fluid level and quality; low fluid or contaminated fluid is a common culprit.

Once the problem is identified, troubleshooting begins. This might involve checking the hydraulic pump for proper operation – measuring pressure and flow rates are crucial. We’ll also inspect the control valves for proper function, ensuring they are directing hydraulic fluid correctly. Testing pressure sensors and limit switches is vital to ensure the elevator’s safety mechanisms are working. For instance, if the safety valves aren’t operating correctly, it could lead to overpressure and system failure.

Repairs can range from simple tasks like replacing a leaky hose or topping off the hydraulic fluid to more complex procedures such as repairing or replacing a faulty hydraulic pump, control valves, or even the hydraulic cylinder itself. Safety is paramount; all work must adhere to strict safety protocols and lockout/tagout procedures to prevent injury. For instance, when working with high-pressure hydraulic systems, we always ensure the system is depressurized before any repairs are carried out. After repairs are complete, rigorous testing and inspection are performed to ensure the elevator is functioning correctly and safely before returning it to service.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different elevator manufacturers and their systems.

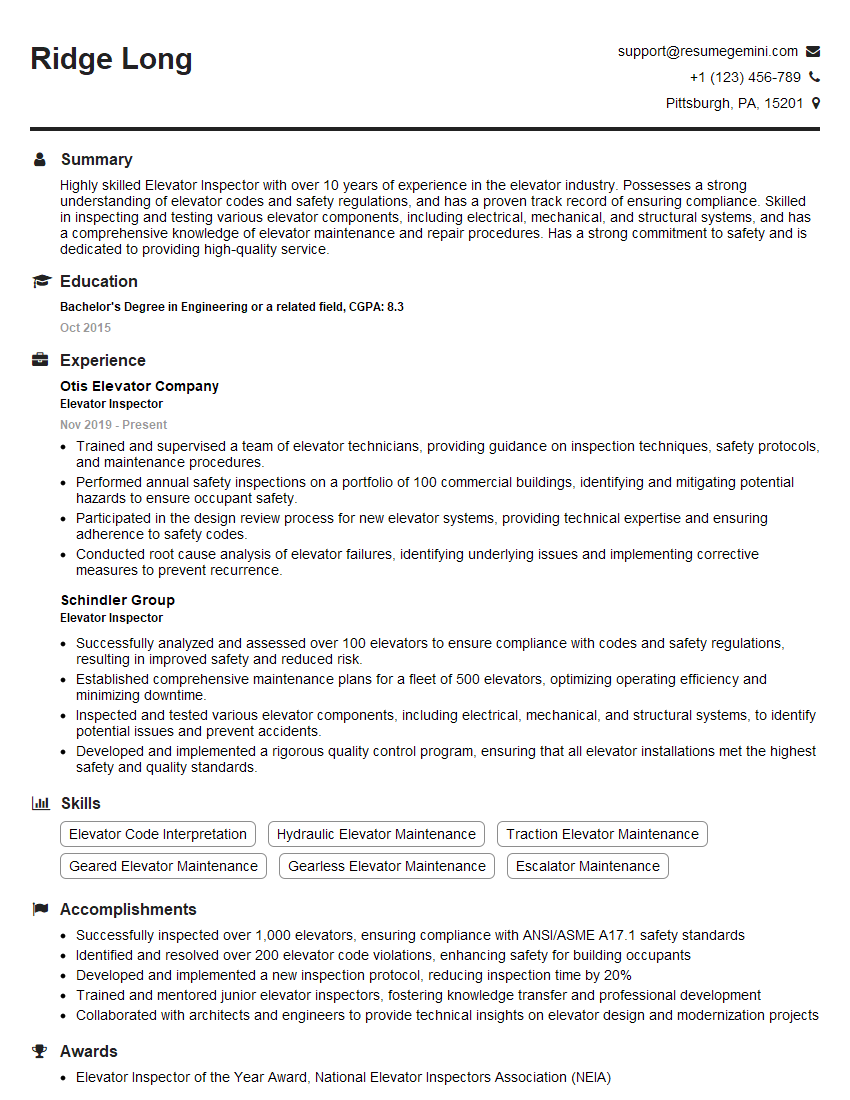

Throughout my career, I’ve worked extensively with various elevator manufacturers, including Otis, Schindler, Kone, and ThyssenKrupp. Each manufacturer has its unique design philosophies and system architectures. Otis, for instance, is known for its robust and reliable systems, often featuring advanced control systems and sophisticated safety features. Schindler, on the other hand, emphasizes energy efficiency in their designs. Kone is known for its innovative technologies, often integrating advanced monitoring and maintenance systems. ThyssenKrupp is at the forefront of developing and implementing multi-directional elevator technology.

My experience spans across different elevator types, including hydraulic, traction, and machine-room-less systems from these manufacturers. This experience enables me to understand the nuances of each system, troubleshoot problems effectively, and implement maintenance strategies tailored to each manufacturer’s specific requirements. For instance, I’ve diagnosed and repaired a hydraulic valve issue in an Otis elevator that required a specific part sourced directly from Otis, which emphasized the need to understand each manufacturer’s specific components and repair procedures.

Q 17. What are the key performance indicators (KPIs) for elevator system efficiency?

Key Performance Indicators (KPIs) for elevator system efficiency focus on uptime, energy consumption, and maintenance costs. These KPIs help us assess the overall performance and identify areas for improvement. Here are some key metrics:

- Uptime: The percentage of time the elevator is operational. A high uptime percentage indicates efficient operation and minimal downtime. We aim for 99% or higher.

- Mean Time Between Failures (MTBF): The average time between elevator breakdowns. A higher MTBF value shows improved reliability.

- Mean Time To Repair (MTTR): The average time taken to repair a malfunction. Lower MTTR values signify efficient maintenance and repair processes.

- Energy Consumption: Kilowatt-hours (kWh) consumed per passenger trip or per hour of operation. Modern, energy-efficient systems significantly reduce this metric.

- Maintenance Costs: Total cost of preventative and corrective maintenance per year or per elevator. Efficient maintenance programs minimize these costs.

By tracking these KPIs and analyzing trends, we can make data-driven decisions to enhance elevator efficiency, reduce operating costs, and improve passenger satisfaction. For example, identifying a recurring fault in a specific elevator model across multiple buildings allows for proactive preventative measures, reducing downtime and maintenance costs.

Q 18. How do you ensure compliance with elevator safety codes and regulations?

Ensuring compliance with elevator safety codes and regulations is crucial. This involves meticulous adherence to local, state, and national codes (such as ASME A17.1 in the US, or equivalent standards in other countries). This begins with regular inspections and testing. We conduct thorough visual inspections, functional tests, and safety device tests – for example, testing emergency brakes, safety gears, and limit switches.

Documentation is paramount. All inspection findings, maintenance records, and repair history are meticulously documented to ensure traceability and compliance. We maintain detailed logs of all activities, including dates, times, and personnel involved. This documentation aids in complying with regulatory audits. Any identified non-compliances are immediately addressed through corrective actions, and follow-up inspections are conducted to verify that the issues have been resolved and the elevator is operating safely.

Training is another critical aspect. Our technicians receive ongoing training to stay updated on the latest safety codes, regulations, and best practices. This ensures they can perform their duties competently and safely. Regular refresher courses are integral to this commitment to safety.

Q 19. Describe your experience with elevator preventative maintenance programs.

Preventative maintenance programs are vital for ensuring elevator reliability and safety. They involve a scheduled program of routine inspections, lubrication, cleaning, and adjustments. These programs are tailored to the specific elevator system and manufacturer’s recommendations, aiming to identify and rectify potential problems before they escalate into major failures. A typical program includes:

- Regular inspections: Visual checks for wear and tear, loose components, and potential hazards.

- Lubrication: Applying lubricants to moving parts to reduce friction and wear.

- Cleaning: Keeping the elevator car, hoistway, and machine room clean and free of debris.

- Adjustments: Fine-tuning the elevator system to optimize performance and efficiency.

- Functional testing: Periodically testing the elevator’s safety features and operational systems.

Implementing a robust preventative maintenance program significantly reduces the risk of breakdowns, minimizes repair costs, prolongs the lifespan of the elevator, and ultimately improves safety and passenger satisfaction. We use computerized maintenance management systems (CMMS) to track maintenance activities, schedule inspections, and manage spare parts inventory – this contributes to a more proactive and efficient maintenance operation. For instance, early detection of a worn brake system through our preventative maintenance program allows for timely replacement, avoiding costly repairs or even potential accidents.

Q 20. Explain the process of commissioning a new elevator system.

Commissioning a new elevator system is a multi-stage process that involves verifying that the elevator system meets the design specifications, safety codes, and operational requirements. It begins with a thorough inspection of all components upon installation. This includes verifying that all components are correctly installed and wired according to the manufacturer’s instructions. Next, functional testing is performed to ensure all systems are working correctly, from the control system to the safety devices.

The process involves rigorous testing of safety features – emergency stops, overspeed governors, and safety gears. Detailed documentation is compiled, recording the results of all tests and inspections. We also conduct load tests to verify that the elevator can handle its rated capacity safely. Once all testing is complete and all deficiencies are rectified, a final inspection is carried out, and the elevator is certified for operation. The commissioning process involves close collaboration with the building owners, architects, and other stakeholders to ensure smooth integration with the building’s infrastructure and compliance with all applicable building codes and regulations.

After commissioning, a comprehensive training program is provided to the building personnel responsible for operating and maintaining the elevator. This includes safety procedures, basic troubleshooting, and regular maintenance tasks. Post-commissioning monitoring and feedback are collected to address any issues that might arise.

Q 21. How do you manage elevator system upgrades and retrofits?

Managing elevator system upgrades and retrofits requires careful planning and execution. First, a comprehensive assessment of the existing system is conducted to determine the scope of the upgrade or retrofit. This involves analyzing the current system’s limitations, identifying areas for improvement, and assessing the feasibility of different upgrade options. For example, an upgrade might involve replacing an outdated control system with a modern, energy-efficient one, or upgrading the elevator’s cab and doors to improve aesthetics and accessibility.

Next, we develop a detailed plan that includes timelines, budgets, and resource allocation. This plan outlines the specific tasks involved in the upgrade or retrofit, along with the necessary materials, equipment, and personnel. The plan should also take into account potential disruptions to building operations and measures to mitigate any inconveniences. During the upgrade or retrofit process, we adhere strictly to safety regulations, employing lockout/tagout procedures to ensure the safety of personnel working on the elevator. Thorough testing and inspection are conducted following the completion of the upgrade or retrofit to verify that the system meets the required safety standards and performance specifications.

Finally, comprehensive documentation is prepared, including ‘as-built’ drawings and operational manuals, for future maintenance and upgrades. This ensures the longevity of the system and its safe and efficient operation for years to come.

Q 22. What are the common types of elevator malfunctions and their solutions?

Elevator malfunctions are unfortunately common, ranging from minor inconveniences to serious safety hazards. Understanding the common types and their solutions is crucial for ensuring safe and efficient operation.

- Door Problems: These are frequent, including doors failing to close properly, opening unexpectedly, or becoming obstructed. Solutions range from simple adjustments and lubrication to replacing faulty sensors or door motors. For example, a faulty safety edge sensor, which detects obstructions, can be replaced to resolve unexpected door openings.

- Mechanical Issues: These can involve problems with the hoisting ropes, counterweights, or the motor itself. A broken rope, for instance, requires a full system inspection and potentially a complete rope replacement, a costly and time-consuming process. Regular lubrication and inspections are key preventative measures.

- Electrical Malfunctions: These can encompass issues with the control system, power supply, or lighting. A faulty control board might lead to erratic elevator behavior, requiring diagnostics and potentially a board replacement. Regular electrical checks are essential for safety and longevity.

- Overload Issues: Elevators have weight limits. Exceeding this limit triggers safety mechanisms which can require resetting after the overload is resolved. Clear weight limit indicators and enforcement are necessary solutions.

- Communication System Failures: Modern elevators rely on sophisticated communication systems for monitoring and control. Failures in these systems can result in the elevator becoming unresponsive. Troubleshooting these involves checking cabling, network connectivity, and the communication module itself.

Effective solutions often involve a combination of preventative maintenance (regular inspections, lubrication, and component checks), diagnostic tools to identify the root cause, and prompt repairs using high-quality replacement parts.

Q 23. How do you interpret elevator system schematics and blueprints?

Reading elevator system schematics and blueprints requires a solid understanding of electrical, mechanical, and hydraulic systems. These documents are crucial for planning maintenance, troubleshooting, and installation. Think of them as detailed maps of the elevator’s inner workings.

I approach schematics systematically. I start by identifying the key components: the hoistway, the car, the counterweights, the motor, the control panel, and the safety systems. Then, I follow the flow of power and signals through the system, tracing wires and hydraulic lines. Blueprints show the physical layout of the elevator, its position within the building, and its relationship to other building systems.

For example, a schematic might show the wiring diagram for the safety circuit, highlighting the interconnections between the limit switches, safety edges, and the motor braking system. This allows me to trace the path of a signal and identify potential points of failure. Blueprints would show the dimensions of the hoistway, the location of the machine room, and the positioning of the elevator shaft relative to the building’s structural elements.

Experience is key. I’ve worked with various manufacturers’ documentation, each with its own conventions and symbols. However, the fundamental principles of interpreting these documents remain consistent.

Q 24. Explain the importance of data logging in elevator system maintenance.

Data logging in elevator system maintenance is incredibly important for preventative maintenance, predictive maintenance, and regulatory compliance. Think of it as a detailed health record for the elevator.

Data loggers record various parameters, including door operations, speed, acceleration, motor current, and temperature. This information reveals patterns and trends that can be used to identify potential issues before they escalate into major problems. For example, a gradual increase in motor current might indicate impending motor failure, allowing for preventative maintenance before a breakdown.

Furthermore, data logging provides a valuable audit trail for compliance with safety regulations. This ensures all the necessary checks and inspections were performed and provides evidence for regulatory authorities. It also assists with warranty claims, as a verifiable history of the system’s performance is available.

I have personally used data logging systems to pinpoint recurring problems in several high-rise buildings. In one instance, data indicated frequent stops due to an intermittent door sensor issue. This led to its timely replacement, preventing a potential safety risk and inconvenience to building occupants.

Q 25. Describe your experience working with different elevator control panels.

My experience encompasses a variety of elevator control panels, from older, electromechanical systems to modern microprocessor-based systems. Understanding the intricacies of different control panels is essential for effective troubleshooting and maintenance.

Older systems often rely on relays, contactors, and timers, requiring a deep understanding of electrical circuits and logic. Troubleshooting these systems involves systematic checking of components and wiring diagrams, using multimeters and other diagnostic tools. I’ve worked extensively with these panels, often needing to replace faulty relays or troubleshoot wiring issues.

Modern microprocessor-based systems are considerably more sophisticated, utilizing programmable logic controllers (PLCs) and sophisticated diagnostic software. These panels provide extensive diagnostic information, often displaying error codes and detailed operational data. My experience with these panels includes programming PLCs to modify elevator operation parameters and diagnosing problems using the manufacturer’s software tools. I’ve worked with panels from various manufacturers, including Otis, Schindler, and Kone, mastering their unique interfaces and diagnostic capabilities.

Each panel presents unique challenges. The older systems require a more hands-on, component-level approach while newer systems leverage sophisticated software tools for diagnostics and repairs. My expertise lies in adapting my approach to the specific system at hand.

Q 26. How do you assess the energy efficiency of an elevator system?

Assessing the energy efficiency of an elevator system involves a multi-faceted approach, focusing on various aspects of its operation. It’s about minimizing energy consumption without compromising safety or performance.

Key factors include:

- Motor Efficiency: Modern, high-efficiency motors consume less energy than older models. Evaluating the motor’s efficiency rating (often expressed as a percentage) is crucial.

- Regenerative Drive Systems: These systems recapture energy during braking and return it to the building’s power supply, significantly reducing energy consumption. Their presence and effectiveness are key assessment points.

- Control System Optimization: A well-designed control system can significantly impact energy usage. This includes factors like destination dispatch algorithms (which optimize car movements) and sleep modes during periods of low usage.

- Lighting and Ventilation: The energy consumed by elevator cab lighting and ventilation systems should also be considered. LED lighting and efficient ventilation systems can significantly reduce energy waste.

- Standby Power Consumption: Elevators consume some power even when not in use. Minimizing this standby consumption is vital for energy efficiency.

Assessment involves data logging to measure energy usage under various operating conditions, analyzing the system’s components and their efficiency, and comparing performance to industry best practices. Using specialized software and performing energy audits allows for precise quantification of energy usage and identification of potential improvements.

Q 27. What are your experiences with elevator system testing and inspection procedures?

Elevator system testing and inspection procedures are critical for ensuring safety and compliance. They’re designed to uncover potential issues before they cause accidents or breakdowns.

My experience includes performing a wide range of tests, including:

- Safety Tests: These involve checking the operation of emergency brakes, safety switches, and other safety features to ensure they function as designed.

- Performance Tests: These evaluate the elevator’s speed, acceleration, deceleration, and stopping accuracy, comparing them to manufacturer specifications.

- Door and Gate Tests: This involves verifying that the doors open and close smoothly and safely, and that the safety features prevent accidental operation.

- Visual Inspections: Regular visual inspections are crucial for identifying signs of wear, damage, or corrosion on cables, ropes, and other components.

- Non-Destructive Testing (NDT): For critical components like hoisting ropes, NDT methods like ultrasonic testing can detect hidden defects.

These tests follow strict industry standards and codes. Detailed reports are generated, documenting findings and recommendations for repairs or replacements. I have consistently adhered to these standards, ensuring the safety and reliability of the systems I’ve worked on. A thorough inspection report provides a clear picture of the elevator’s condition and potential risks.

Q 28. Describe your experience with troubleshooting elevator communication systems.

Modern elevators rely heavily on communication systems for various functions, from controlling the elevator’s movement to providing real-time information about its status and maintenance needs. Troubleshooting these systems requires a blend of electrical, networking, and software expertise.

My experience with elevator communication systems includes:

- Network Troubleshooting: Identifying and resolving issues with network connectivity, such as faulty cables, network configuration problems, or server issues. This often involves using network diagnostic tools to pinpoint the source of the problem.

- Protocol Analysis: Analyzing the communication protocols used by the elevator system to identify errors or inconsistencies in data transmission. Specialized software can decode the communication protocols and help identify the root cause.

- Hardware Diagnostics: Diagnosing hardware faults in communication modules, such as faulty interfaces or damaged components. This often involves using multimeters and oscilloscopes to test the hardware.

- Software Updates and Configuration: Updating firmware and configuring communication parameters on the elevator’s control system to improve reliability and performance. This requires a solid understanding of the software and its interaction with the elevator’s hardware.

One challenging case involved a high-rise building where intermittent communication failures between the elevator cars and the control room were causing unexpected stops. Through systematic analysis of the network traffic and hardware inspection, I discovered a faulty network switch causing data loss. Replacing the switch completely restored reliable communication and eliminated the disruptions.

Key Topics to Learn for Elevator System Analysis Interview

- Elevator System Components and Functionality: Understanding the mechanical, electrical, and control systems within an elevator, including motors, brakes, doors, and safety mechanisms.

- Traffic Analysis and Optimization: Applying algorithms and simulation techniques to analyze passenger flow, optimize elevator dispatching strategies, and minimize waiting times. This includes understanding different dispatching algorithms (e.g., First-Come-First-Served, Scan, Collective).

- Control System Design and Programming: Familiarity with PLC programming, ladder logic, or other control system languages used in elevator systems. Understanding the logic behind elevator control systems and their interaction with building management systems.

- Safety and Regulatory Compliance: Knowledge of relevant safety standards, codes, and regulations governing elevator design, installation, and operation. Understanding risk assessment and mitigation strategies.

- Troubleshooting and Maintenance: Ability to diagnose and resolve common elevator malfunctions, utilizing schematics, diagnostic tools, and maintenance logs. Understanding preventative maintenance schedules.

- Modernization and Upgrades: Knowledge of current trends and technologies in elevator system modernization, such as energy-efficient components, advanced control systems, and accessibility features.

- Simulation and Modeling: Experience using simulation software to model elevator systems, predict performance, and test various scenarios before implementation.

Next Steps

Mastering Elevator System Analysis opens doors to exciting career opportunities in building automation, engineering, and project management. A strong understanding of these concepts is highly valued by employers and will significantly enhance your competitiveness in the job market. To maximize your chances of landing your dream role, focus on crafting an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of Elevator System Analysis roles. Examples of resumes tailored to this field are available to guide you. Investing time in creating a compelling resume is crucial for a successful job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good