Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Embroidery Handling interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Embroidery Handling Interview

Q 1. What types of embroidery machines have you worked with?

Throughout my career, I’ve had the opportunity to work with a variety of embroidery machines, ranging from single-head domestic machines to multi-head industrial machines. This experience encompasses both computerized and simpler mechanical models. For instance, I’ve extensively used Tajima embroidery machines, known for their reliability and precision in high-volume production. I’m also proficient with Brother and Singer machines, offering diverse capabilities for different project scales and complexities. My experience extends to machines with various hoop sizes, allowing me to handle projects from small patches to large, intricate designs on garments or textiles. I’m familiar with their operational nuances, maintenance requirements, and troubleshooting techniques for each type.

Q 2. Describe your experience with different embroidery stitches.

My experience with embroidery stitches is quite extensive. I’m familiar with a wide range of stitch types, including the basic satin stitch, fill stitches (like a dense tapestry stitch or a more open running stitch), and outline stitches. I can skillfully execute more complex stitches such as chain stitch, which is great for creating textured outlines, and seed stitch, which adds a beautiful, slightly textured fill. I understand how different stitch densities and stitch lengths affect the final product’s look and durability. For example, a denser satin stitch provides a cleaner, more vibrant finish, while a looser stitch can be better suited for a more rustic or hand-stitched look. My experience also encompasses the application of specialty stitches like applique stitches, used to apply patches or embellishments neatly and securely, and free-motion embroidery for creating unique, freeform designs.

Q 3. How do you troubleshoot common embroidery machine problems?

Troubleshooting embroidery machine problems requires a systematic approach. I typically start by visually inspecting the machine for any obvious issues, like tangled thread, loose connections, or bobbin problems. A common issue is thread breakage; I check the tension settings, thread path, and the condition of the needle and bobbin. If the problem persists, I examine the machine’s error codes or messages to pinpoint the specific fault. For example, a repeated needle breakage might indicate a blunt needle, incorrect tension settings, or a problem with the fabric itself. I also check the hooping process for loose or improperly placed fabric, which can lead to puckering or stitch irregularities. If the problem is beyond basic fixes, I consult the machine’s manual and, if necessary, contact technical support.

Q 4. Explain your process for setting up an embroidery machine for a new job.

Setting up the embroidery machine for a new job involves several key steps. First, I carefully read the design file to understand its size, stitch count, and thread requirements. I then select the appropriate hoop size to accommodate the design, ensuring the fabric is securely and evenly hooped. Next, I thread the machine according to the manufacturer’s instructions, making sure the thread path is clear and free of knots. I also select the correct needle type and size, based on the fabric and thread being used. Then, I load the design into the machine, adjust the tension settings for the chosen threads and fabric type, and perform a test run on a scrap of fabric to verify the settings before starting on the final material. I always double-check the color sequence and thread quantity against the design requirements. This meticulous setup ensures a smooth and efficient embroidery process, minimizing errors and wasted material.

Q 5. What are the key quality control checks you perform during embroidery production?

Quality control is crucial in embroidery production. My checks begin with verifying the design’s accuracy and proper placement on the fabric. I inspect the stitch quality, looking for consistency, evenness, and the absence of skips or breaks. I examine the thread tension, making sure there’s no puckering or looseness. I also check for color accuracy, ensuring the final product matches the design specifications. Finally, I meticulously inspect the finished piece for any defects, like loose threads, fabric damage, or incorrect stitching. These checks are performed at several stages – after the hooping, during the test run, and following the completion of the embroidery process. Maintaining a detailed record of each production run facilitates easy tracing of potential issues and ensures consistent quality.

Q 6. How do you handle thread breaks or other disruptions during embroidery?

Handling thread breaks or other disruptions requires quick, efficient action to minimize downtime and avoid damaging the work. First, I carefully identify the cause of the break—a knotted thread, a faulty needle, incorrect tension, or perhaps a snag in the fabric. I then resolve the issue, whether it’s re-threading, replacing a needle, adjusting the tension, or carefully removing a snag. Once the issue is addressed, I use the machine’s features to resume embroidery from the point of interruption. If the disruption involves significant damage or the embroidery has been compromised, I carefully assess the options: repair, restart or even replace. I always meticulously document the incident and any corrective measures taken, which aids in problem-solving for future production runs. My experience ensures I can address these issues efficiently and effectively.

Q 7. Describe your experience with digitizing embroidery designs.

While I don’t personally digitize embroidery designs, I possess a strong understanding of the digitization process and collaborate effectively with digitizers. I can communicate design requirements clearly, providing feedback on stitch density, color placement, and overall design aesthetics. This helps ensure the digitized design is optimized for efficient and high-quality embroidery on my machines. My understanding of stitch types, fabric behaviors, and machine capabilities allows me to offer valuable input to the digitization process, leading to successful embroidery outcomes. My ability to analyze potential issues in a digitized design before production greatly reduces costly errors and rework.

Q 8. How familiar are you with different embroidery fabrics and their suitability?

Choosing the right fabric is crucial for successful embroidery. Different fabrics have varying weights, weaves, and compositions, each affecting the final embroidered product. Heavier fabrics like denim or canvas require stronger needles and a higher stitch density to prevent puckering, while lighter fabrics like silk or linen require finer needles and a more delicate stitch to avoid damaging the material.

- Cotton: A popular choice, readily available in various weights and weaves. Ideal for many embroidery styles.

- Linen: A beautiful, slightly uneven weave. Needs careful hooping to avoid pulling. Works best with smaller designs.

- Silk: Delicate and requires a very fine needle and low stitch density. Highly susceptible to needle damage.

- Denim: A sturdy fabric requiring heavier needles and a dense stitch. Often requires a tear-away stabilizer to prevent puckering.

- Velvet: A pile fabric that can be challenging. Requires special needles and techniques, often requiring a water-soluble stabilizer.

For example, I once worked on a project requiring delicate floral embroidery on silk. Choosing the wrong needle resulted in significant damage. I learned to use a size 70/10 needle with a lower stitch density and a light stabilizer, resulting in a flawless outcome.

Q 9. What software programs are you proficient in for embroidery design or management?

Proficiency in embroidery design software is essential for creating and managing embroidery files. My expertise spans several programs:

- Wilcom EmbroideryStudio: I’m highly proficient in this industry-standard software, utilizing its advanced digitizing tools for creating complex designs and managing large projects efficiently.

- Embird: I use Embird for its robust editing capabilities, particularly its excellent tools for manipulating existing designs and creating custom lettering.

- Hatch Embroidery: I’m familiar with Hatch, leveraging its user-friendly interface for quicker design modifications and simpler projects.

I can also effectively utilize other vector graphics editors like Adobe Illustrator to create designs that can then be imported into these embroidery software packages. My experience encompasses both design creation and file management, including optimizing stitch density and color changes for production.

Q 10. How do you maintain and clean embroidery machines to ensure optimal performance?

Regular maintenance is crucial for prolonging the life and ensuring optimal performance of embroidery machines. My cleaning routine includes:

- Daily Cleaning: Removing lint and thread trimmings from the bobbin area, needle plate, and feed dogs using a soft brush. I always turn off and unplug the machine before cleaning.

- Weekly Cleaning: A more thorough cleaning, involving removing the bobbin case and cleaning it with a soft brush. Lubricating moving parts as per the manufacturer’s instructions.

- Monthly Cleaning: Deep cleaning of the hook and shuttle assembly, following the manufacturer’s guidelines carefully. This may involve removing and cleaning these components separately.

Ignoring maintenance leads to poor stitch quality, machine malfunction, and ultimately costly repairs. For example, neglecting to clean the bobbin case can lead to thread breakage and inconsistent stitching. A consistent and thorough cleaning regime prevents this and keeps the machines running smoothly.

Q 11. Explain your experience with different types of embroidery hoops and their applications.

Embroidery hoops play a critical role in holding the fabric taut during the embroidery process. Different hoops cater to various fabric types and design sizes.

- Standard Circular Hoops: These are the most common, suitable for most fabrics and designs. The size varies, affecting the maximum design dimensions.

- Magnetic Hoops: These hoops are quicker to use and suitable for delicate fabrics as they avoid the potential damage from clamping. However, they may not be as secure for very large designs.

- Rectangular Hoops: Ideal for larger designs or projects where a specific aspect ratio is required.

- Adjustable Hoops: These hoops allow for adjustments to better accommodate varying fabric thicknesses and create a more even tension.

For instance, when embroidering on a delicate silk scarf, a magnetic hoop prevents fabric damage and allows for quick setup. For large, complex designs on canvas, a rectangular hoop provides the necessary surface area and support to prevent distortion.

Q 12. Describe your experience with multi-needle embroidery machines.

My experience with multi-needle embroidery machines extends to both operation and maintenance. These machines significantly boost production speed by embroidering multiple colors simultaneously. I’m comfortable operating machines with up to 15 needles. Key skills include:

- Thread Management: Efficiently threading multiple needles and ensuring consistent thread tension across all needles is crucial for uniform stitching.

- Color Changes: Swift and accurate color changes are essential for high-throughput production and avoid thread waste.

- Troubleshooting: Identifying and resolving issues like thread breaks or needle misalignments is crucial to maintaining productivity.

For example, in my previous role, I managed a production run requiring intricate logos embroidered on numerous garments. The multi-needle machine dramatically shortened the production time, saving both time and resources.

Q 13. How do you ensure color accuracy in embroidery production?

Color accuracy is paramount in embroidery. I ensure precise color reproduction through several techniques:

- Color Calibration: Regularly calibrating the embroidery machine’s color settings using standardized color charts is essential. This compensates for any slight variations in the machine’s color rendering.

- Thread Selection: Choosing threads from a reputable brand with consistent color matching and using the same dye lot minimizes inconsistencies.

- Proofing: Always producing a test run on a sample fabric before mass production is critical for verifying color accuracy and making adjustments as needed.

- Digital Color Matching: Utilizing color matching software to bridge the gap between digital designs and physical thread colors offers additional accuracy.

In one instance, I discovered a slight color discrepancy during proofing. By adjusting the thread tension and slightly altering the stitch density, I was able to correct the color and avoid a production error.

Q 14. What safety procedures do you follow while operating embroidery equipment?

Safety is my utmost priority when operating embroidery equipment. My procedures include:

- Machine Inspection: Before each use, I carefully inspect the machine for any loose parts, damaged cables, or other potential hazards.

- Proper Clothing: I always wear appropriate clothing—nothing loose or dangling that could get caught in the machine. Long hair is always tied back.

- Emergency Stop: I am thoroughly familiar with the location and operation of the emergency stop button and other safety mechanisms.

- Hand Protection: When changing needles or performing other maintenance, I use protective gloves to prevent needle pricks.

- Eye Protection: Safety glasses are worn to protect my eyes from flying thread or debris.

Following these procedures creates a safe work environment and prevents accidents. By strictly adhering to safety protocols, I’ve maintained a spotless safety record throughout my career.

Q 15. How do you manage embroidery production deadlines and prioritize tasks?

Managing embroidery production deadlines effectively requires a multi-pronged approach combining meticulous planning, efficient task prioritization, and proactive communication. I begin by thoroughly reviewing each order, analyzing its complexity (stitch count, design intricacy, fabric type), and estimating the required production time. This forms the basis of a detailed production schedule, which I then input into a project management system. This system allows me to track progress, identify potential bottlenecks, and allocate resources (machines, threads, personnel) optimally.

Prioritization involves applying a combination of methods. Urgent orders with tight deadlines naturally take precedence. I also consider the value of the order and potential impact on client relationships. A high-value, complex project might demand more attention even if its deadline isn’t immediate. Finally, I factor in the availability of resources; if a certain type of thread or a specific machine is needed for multiple projects, I prioritize tasks accordingly.

Throughout the production process, regular monitoring and progress reporting are crucial. Any deviations from the schedule are flagged immediately, and corrective actions are implemented proactively to minimize delays. This proactive approach, coupled with clear communication with the team and clients, ensures timely delivery and maintains customer satisfaction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different embroidery thread types and their properties.

My experience encompasses a wide range of embroidery thread types, each with unique properties affecting the final product’s aesthetic and durability. I’ve extensively worked with rayon, polyester, metallic, and cotton threads. Rayon threads, known for their lustrous sheen and smooth texture, are ideal for creating elegant designs, but they’re prone to breakage if tension isn’t managed perfectly. Polyester threads, on the other hand, are remarkably strong and colorfast, making them suitable for high-volume production and vibrant designs. Their slight stiffness can sometimes lead to puckering if not handled carefully. Metallic threads, while adding a touch of glamour, require specialized needles and careful handling to avoid fraying or breakage. Finally, cotton threads offer a natural, rustic look, though their durability might be less than polyester, making them more suitable for specific applications.

The choice of thread greatly impacts the outcome. For instance, a delicate design on a lightweight fabric would be best suited to a fine rayon thread, while a bold design on a durable fabric might require the strength of polyester. Understanding these properties is crucial for selecting the right thread for each project, achieving optimal results, and minimizing potential issues.

Q 17. What are the common causes of puckering in embroidery, and how do you address them?

Puckering in embroidery is a common problem arising from several factors. The most frequent culprits are inconsistent fabric tension, improper hooping, incorrect needle and thread selection, and unstable stabilizer. Inconsistent fabric tension occurs when the fabric is not evenly stretched in the hoop, causing the stitches to pull unevenly. Improper hooping, especially too tight or too loose hooping, contributes to the problem. Choosing a needle and thread that are not suitable for the fabric weight can also lead to puckering. Finally, insufficient or inappropriate stabilizer can lead to the fabric stretching and puckering under the tension of the stitching.

Addressing puckering involves a systematic approach. Firstly, I ensure the fabric is properly hooped, using even pressure to prevent wrinkles. I select the correct needle and thread for the fabric and design, and I use the appropriate stabilizer based on fabric type and design complexity. If puckering still occurs, I adjust the embroidery machine’s tension settings, often slightly loosening the top tension, or checking for any underlying inconsistencies in the fabric itself. In some cases, a test run on a scrap fabric is helpful to refine settings before working on the final piece. For very stubborn instances, techniques like pre-washing and carefully pressing the fabric after embroidery might be necessary.

Q 18. Explain your experience with bobbin winding and its importance in embroidery.

Bobbin winding is a seemingly simple yet critical process in embroidery. It involves precisely winding embroidery thread onto the bobbin, ensuring that the thread is evenly distributed and tightly wound to prevent snarling and breakage during stitching. A poorly wound bobbin can lead to thread breakage, uneven stitches, and ultimately, damaged embroidery.

My experience includes working with various bobbin winding methods, both manual and automated. While automated winders offer speed and efficiency, I frequently perform manual winding for smaller batches or for specialized threads requiring specific tension control. I’m meticulous in ensuring the thread is consistently wound, avoiding overlaps or loose areas which can disrupt the stitching process. I regularly check the bobbin’s tightness and ensure it’s correctly inserted into the machine. A properly wound bobbin is crucial because it guarantees consistent tension, prevents skipped stitches, and contributes significantly to the overall quality and efficiency of the embroidery process. Think of it as the foundation upon which the entire embroidery design is built – a stable bobbin equals a stable, beautiful piece of embroidery.

Q 19. How do you ensure consistent tension in your embroidery?

Maintaining consistent tension in embroidery is paramount for achieving high-quality results. Consistent tension ensures even stitch formation, prevents thread breakage, and avoids puckering. Achieving this involves a combination of machine settings, thread selection, and careful monitoring of the stitching process.

I begin by adjusting the machine’s top and bottom tension settings according to the thread type and fabric being used. This is often an iterative process; I might need to make fine adjustments during the stitching process. Regularly checking the stitch formation allows me to detect any inconsistencies in tension and make necessary corrections immediately. I also pay close attention to the thread path – any friction or snagging points can significantly affect tension. Lastly, using appropriate stabilizers and properly hooping the fabric also greatly influences tension consistency. By meticulously attending to these details, I consistently achieve a uniform tension, resulting in flawless, professional-looking embroidery.

Q 20. How do you handle customer complaints or production errors related to embroidery?

Handling customer complaints or production errors requires a calm, professional, and solution-oriented approach. I always begin by actively listening to the customer’s concerns, understanding the nature of the problem, and showing empathy for their frustration. Once I fully grasp the situation, I thoroughly investigate the issue, analyzing the embroidery design, stitching process, and any potential contributing factors. This often involves reviewing the production records, inspecting the finished piece, and even recreating the process to identify the root cause.

Depending on the nature of the problem, solutions can range from minor adjustments to complete re-embroidery. I prioritize finding a quick and satisfactory resolution for the customer. In cases of production errors, internal reviews are conducted to identify areas for improvement and prevent similar issues from recurring. Open communication with the customer throughout the problem-solving process is key, keeping them informed of progress and updates. Building trust and demonstrating commitment to quality builds positive relationships even when dealing with challenging situations.

Q 21. What is your experience with different embroidery density settings and their effects?

Embroidery density settings significantly impact the final appearance and durability of the embroidery. Density refers to the closeness of the stitches; higher density means more stitches per inch, resulting in a denser, more durable, but potentially slower embroidery. Lower density means fewer stitches per inch, leading to a less dense, quicker embroidery, but possibly less durable.

My experience has shown that the optimal density setting depends heavily on the design, fabric type, and desired outcome. Fine details benefit from higher density to ensure crispness and prevent gaps in the stitching. Large, filled areas might tolerate slightly lower density without sacrificing quality. Extremely high density can lead to fabric distortion or damage, especially on delicate materials. Similarly, excessively low density results in a loose, potentially unappealing embroidery. I experiment with different density settings during the design stage, often creating test samples to achieve the perfect balance between visual appeal, durability, and production time. In my experience, understanding the impact of these settings is crucial for producing high-quality embroidery that meets both aesthetic and functional requirements.

Q 22. Describe your experience with various embroidery techniques (e.g., free motion, applique).

My experience spans a wide range of embroidery techniques. I’m proficient in both machine and hand embroidery, with expertise in several styles. Free-motion embroidery, for instance, allows for incredibly fluid designs, almost like drawing with thread. I’ve used this technique extensively to create custom floral patterns and personalize garments. It requires a good understanding of machine control and thread tension to achieve a smooth, consistent stitch. Appliqué, on the other hand, involves applying fabric shapes to a base fabric, creating dimensional effects. I’ve worked with everything from simple shapes to intricate, layered designs, using techniques like blanket stitch and satin stitch to secure the appliqué. Other techniques I’m experienced in include satin stitch, which creates a smooth, shiny surface perfect for lettering; cross-stitch, known for its precise geometric patterns; and shadow work, a beautiful technique employing multiple layers of thread to create a sense of depth.

For example, I once used free-motion embroidery to create a custom landscape design on a denim jacket, and another time employed appliqué to add personalized patches to a collection of children’s clothing. My experience allows me to select the most appropriate technique based on the design, fabric, and desired outcome.

Q 23. How do you measure the quality of an embroidered garment?

Measuring the quality of an embroidered garment is a multi-faceted process. It goes beyond simply looking at the design; it involves a critical examination of several key aspects. First, I assess the stitch quality – are the stitches consistent, even, and secure? Loose stitches, skipped stitches, or uneven tension indicate a lower quality. I also examine the fabric itself; is it damaged or stressed in any way from the embroidery process? Excessive puckering or distortion suggests the stabilizer wasn’t properly used. Then, I check the placement and accuracy of the design – is it perfectly aligned and positioned as intended? Finally, I consider the overall aesthetic appeal – does the embroidery enhance the garment, or does it look cheap or amateurish?

For example, a poorly executed satin stitch will have visible thread gaps, whereas a high-quality one will have a smooth, even surface. Similar to how a painter checks for brushstrokes, I carefully check for any irregularities in the embroidery itself. The longevity of the embroidery is another critical factor: High-quality embroidery will resist wear and tear over time, holding up through multiple washes.

Q 24. What is your experience with repairing damaged embroidery?

Repairing damaged embroidery demands precision and patience. My approach depends heavily on the type and extent of the damage. Minor imperfections like loose threads can be easily secured by hand-sewing. More extensive damage, such as tears in the fabric or missing sections of embroidery, requires a more involved process. This might involve carefully re-stitching the damaged area, matching the existing stitches as closely as possible, using a similar thread and technique. In some cases, it may be necessary to remove and replace a section of embroidery.

For example, I once had to repair a delicate antique sampler where the fabric had become frayed around the edges of an embroidered flower. Using a magnifying glass and fine needles, I painstakingly re-stitched the damaged area, matching the original stitches and thread colour as perfectly as possible. This required skill, precision, and a deep understanding of the original embroidery technique. The goal in any repair is to make the damage as imperceptible as possible.

Q 25. Explain your understanding of different embroidery file formats.

Embroidery file formats are crucial for transferring designs to embroidery machines. The most common formats include .DST (Tajima), .EXP (Janome), .HUS (Husqvarna Viking), .PES (Brother), and .XXX (many machines). Each format has its own specific structure and may contain varying levels of information, such as stitch density, color changes, and underlay information. Understanding these formats is vital for choosing the correct one for your machine and avoiding compatibility issues. A lack of understanding could lead to errors during the digitizing or embroidering process. In addition to these, many machines will accept common graphic file formats like .JPG or .PNG but these need to be converted into a stitch file first using specialized software. This conversion is an important step that requires knowledge of stitch density, colours, and other factors to create a high-quality result.

Q 26. How do you interpret and follow embroidery design specifications?

Interpreting and following embroidery design specifications is paramount to ensuring the successful execution of a design. These specifications usually include information on the stitch count, thread colours, fabric type, stabilizer requirements, and hoop size. They also contain details on the design dimensions, allowing for proper scaling and placement. For example, the design specification may indicate the necessity of using a tear-away stabilizer or a wash-away stabilizer depending on the fabric type and design. Carefully reviewing and understanding these specifications before beginning the embroidery process prevents errors and ensures that the final product matches the intended design. Ignoring them can lead to sizing discrepancies, fabric damage, or unsatisfactory results.

A clear understanding of the specifications – from the thread count to the precise placement of motifs – is crucial for the successful and accurate reproduction of the design. This is especially critical in commercial settings where precision and consistency are crucial.

Q 27. Describe your experience with managing inventory of embroidery supplies.

Managing embroidery supplies inventory is crucial for maintaining efficiency and preventing delays. My approach involves a combination of meticulous record-keeping and regular stock checks. This includes using a digital inventory management system to track thread colours, stabilizer types, needles, and other essential supplies. Regular stock checks ensure we have sufficient supplies on hand to meet demand and to identify any potential shortages before they impact production. I also implement a system for ordering new supplies in advance to minimize downtime. This includes setting reorder points for common supplies and establishing relationships with reliable suppliers. For instance, thread colors are categorized by type and colour number, and then stored in a color-coded system for easy retrieval.

Using an inventory system allows us to track the usage of materials and analyze trends to better forecast future needs. This ultimately reduces waste and minimizes financial losses.

Q 28. How familiar are you with the different types of stabilizer used in embroidery?

Stabilizers are crucial in embroidery to prevent fabric puckering and ensure the integrity of the stitches. I’m familiar with various types, each suited for different fabrics and embroidery styles. Tear-away stabilizers are commonly used and removed after embroidery, while wash-away stabilizers dissolve in water. Cut-away stabilizers remain in the garment, providing additional support for designs on delicate fabrics. I also know the use of water-soluble and heat-away stabilizers, each chosen based on its unique properties and the demands of the project. Choosing the wrong stabilizer can lead to poor stitching quality, fabric damage, or even the complete loss of the embroidered design. The selection is critical, considering the fabric weight, design complexity and final use of the embroidered item.

For example, a heavy-weight cut-away stabilizer would be suitable for denim, providing extra support for dense embroidery, while a lightweight tear-away stabilizer would be appropriate for delicate fabrics like silk to prevent distortion.

Key Topics to Learn for Embroidery Handling Interview

- Machine Operation & Maintenance: Understanding different embroidery machine types, their functionalities, routine maintenance procedures, troubleshooting common mechanical issues, and preventative maintenance strategies.

- Thread Management & Selection: Proper thread handling techniques, understanding thread types (polyester, rayon, metallic), color matching, tension adjustment, and recognizing thread-related problems like breakage or tangling. Practical application includes demonstrating the ability to efficiently change threads and identify the best thread for a specific project.

- Design & Digitization: Familiarity with embroidery designs, understanding stitch types (satin, fill, outline), design editing basics, and the role of digitization software in creating embroidery files. Practical application includes the ability to interpret design specifications and identify potential design flaws.

- Fabric Handling & Hooping: Proper techniques for hooping fabric, understanding different fabric types and their suitability for embroidery, identifying and addressing fabric-related problems such as puckering or stretching. Practical application includes demonstrating efficient and accurate hooping techniques.

- Quality Control & Inspection: Identifying embroidery defects (e.g., skipped stitches, broken threads, incorrect tension), understanding quality standards, and implementing corrective actions. Practical application includes demonstrating a keen eye for detail and the ability to troubleshoot quality issues effectively.

- Safety Procedures & Workplace Practices: Understanding and adhering to safety regulations around machinery operation, proper handling of sharp objects, and maintaining a clean and organized workspace.

- Production Processes & Efficiency: Understanding workflow processes within an embroidery environment, optimizing production time, and meeting deadlines. This includes practical understanding of production planning and scheduling.

Next Steps

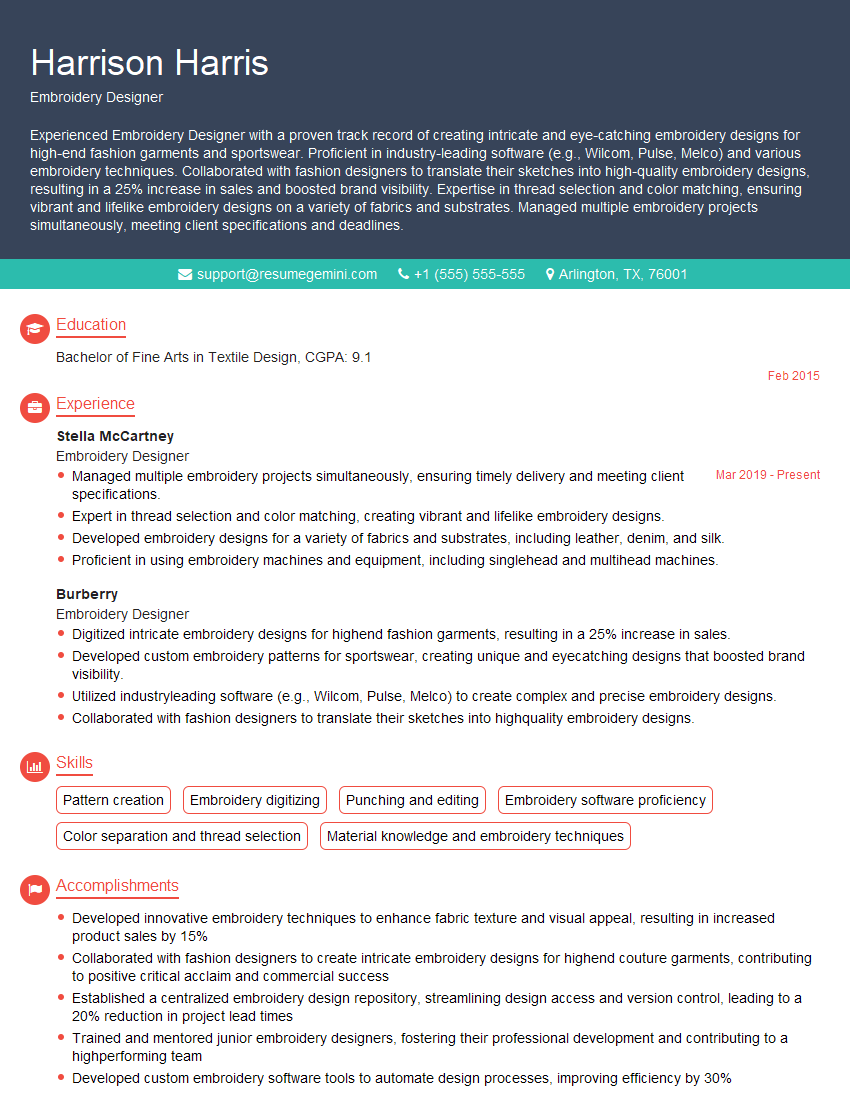

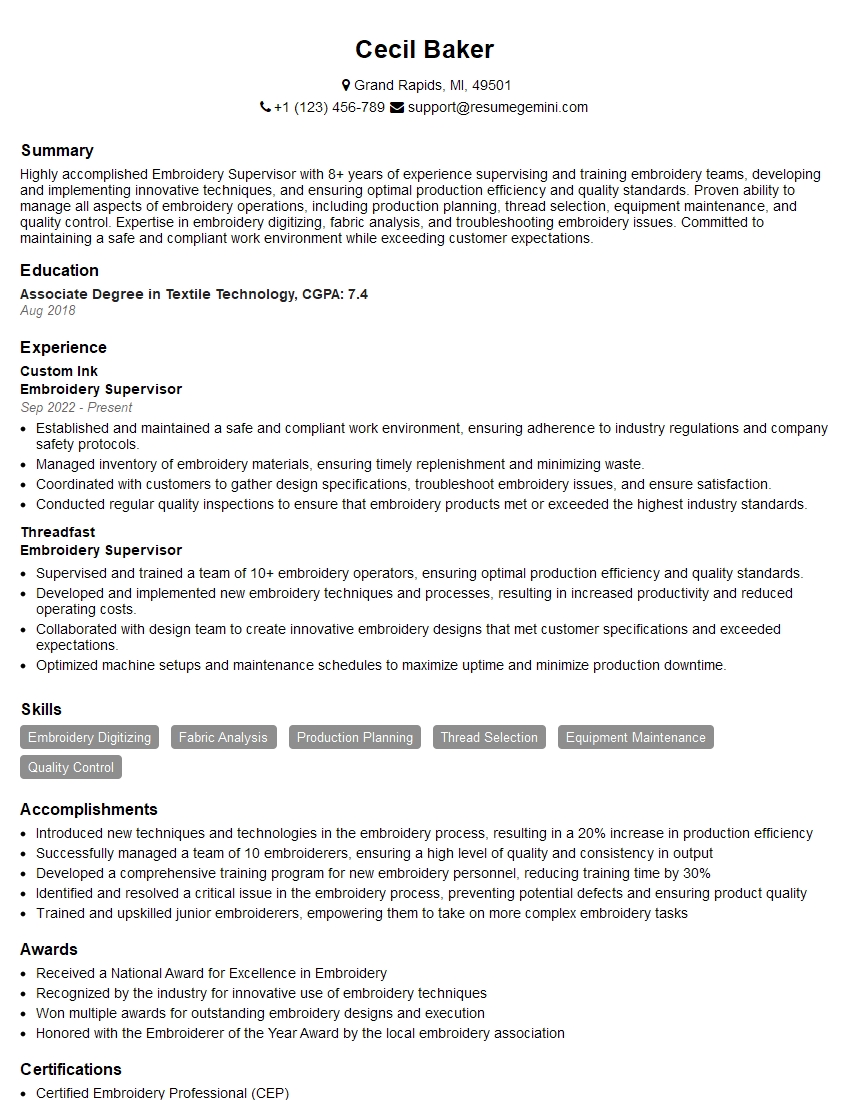

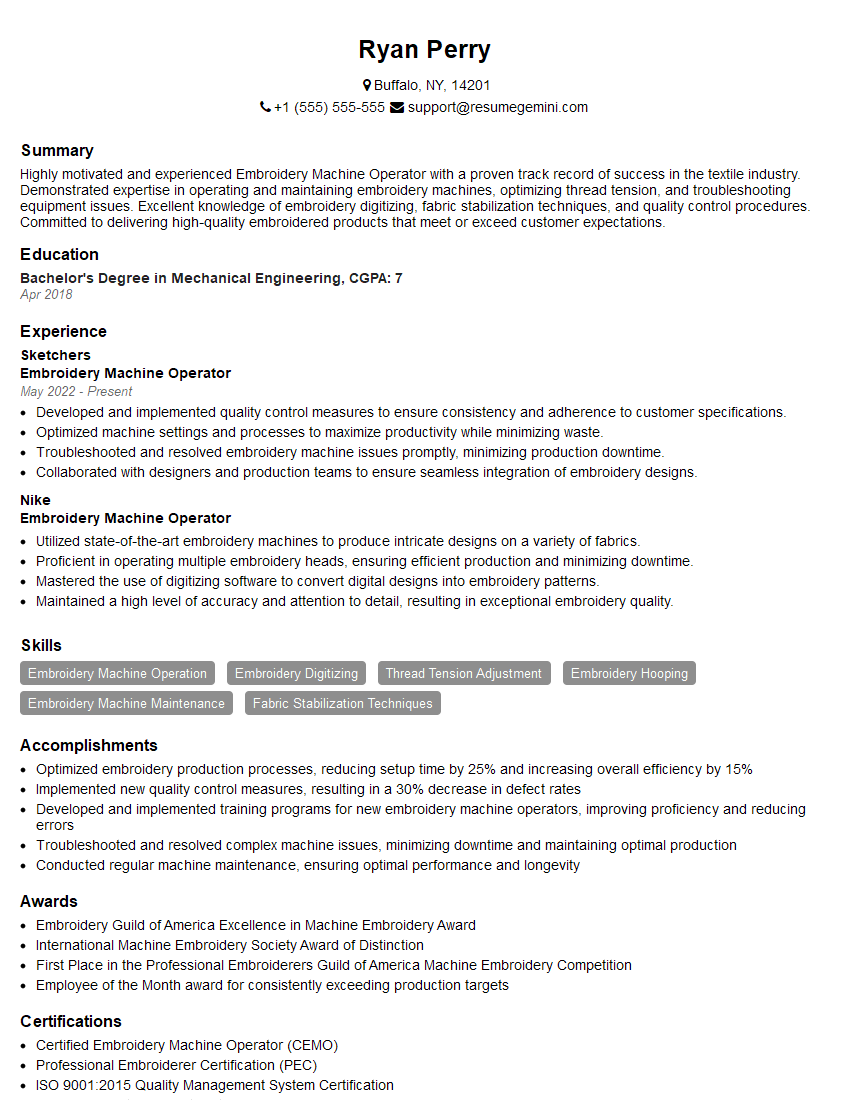

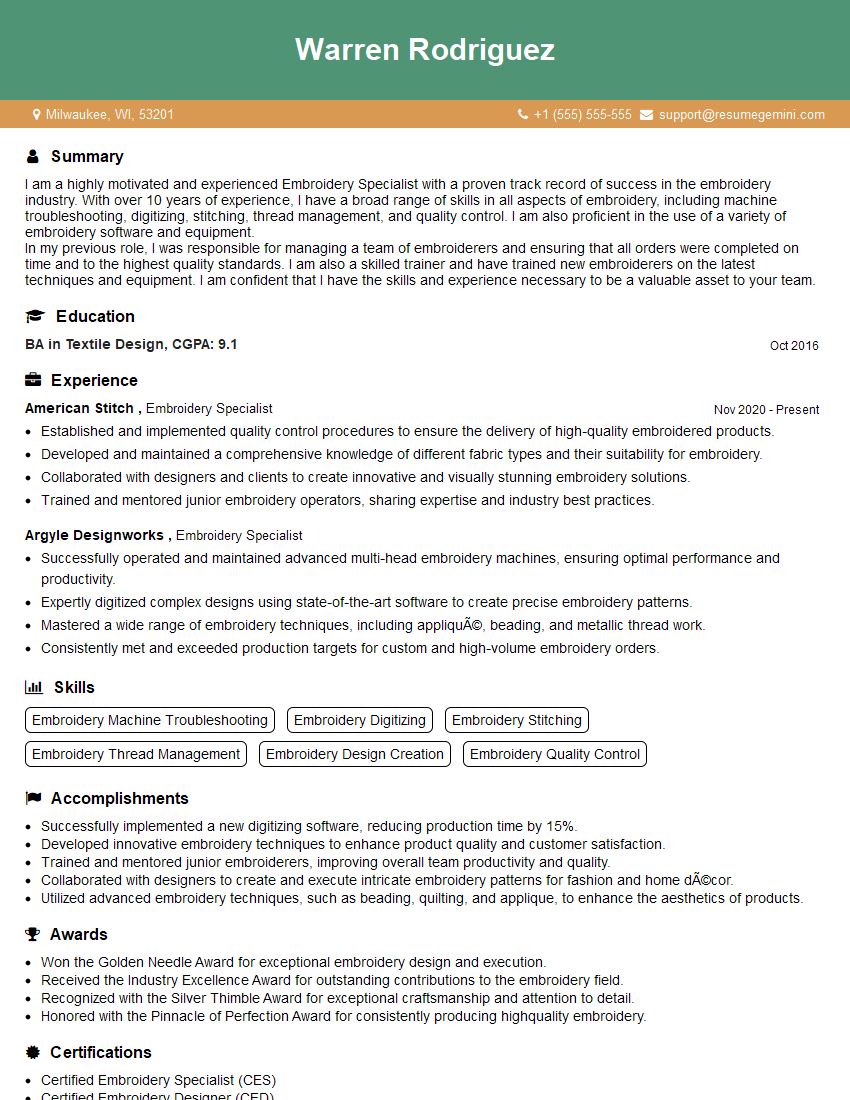

Mastering embroidery handling opens doors to exciting career opportunities with growth potential in production, design, or management roles within the textile industry. To stand out, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that showcases your abilities and gets noticed by recruiters. Examples of resumes tailored to Embroidery Handling are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good