Cracking a skill-specific interview, like one for Embroidery machine operation and maintenance, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Embroidery machine operation and maintenance Interview

Q 1. What types of embroidery machines have you operated?

Throughout my career, I’ve had the opportunity to operate a wide range of embroidery machines, from single-head domestic machines like the Brother Innov-is and Janome Memory Craft models to multi-head industrial machines such as Tajima and Barudan machines. My experience encompasses both computerized and simpler mechanical machines. This diverse experience has given me a deep understanding of the nuances of each type, from their programming interfaces to their mechanical workings. For example, working with a Tajima multi-head machine taught me the importance of precise bobbin winding and thread tension control for high-volume production, a skill less critical on a single-head domestic machine. I’ve also worked with machines that utilize various hoop sizes and designs, allowing me to adapt to different project requirements and garment types.

Q 2. Describe your experience with different embroidery stitch types.

My experience with embroidery stitch types is extensive. I’m proficient in all the basic stitches like running stitch, satin stitch, fill stitch, and outline stitch. Beyond the basics, I’m skilled in more complex stitches like chevron fill, cross stitch, and various types of lettering stitches. Understanding stitch properties is crucial for achieving the desired aesthetic. For instance, a satin stitch, ideal for densely filled areas, needs precise tension to avoid puckering, while a running stitch is best suited for outlining or creating delicate details. I can manipulate stitch density, angle, and length to control the look and feel of the embroidery, creating everything from bold, graphic designs to subtle, refined details. I frequently utilize different stitch types in a single design to create texture and visual interest.

Q 3. How do you troubleshoot common embroidery machine errors?

Troubleshooting embroidery machine errors requires a systematic approach. I typically start by identifying the error message or the visible problem. Common issues include thread breaks, needle breakage, bobbin issues, or hooping problems. For thread breaks, I check for proper tension, correct threading, and the condition of the needle and thread itself. Needle breakage often points to a dull needle, improper thread type, or a collision with the material. Bobbin problems usually involve incorrect winding, tension, or a tangled bobbin. Hooping issues usually mean the fabric isn’t securely fastened or is incorrectly centered. If the problem persists after these initial checks, I consult the machine’s manual and may utilize diagnostic tools built into the machine’s software. For example, if I consistently encounter a specific error code, I’ll use the machine’s manual to decode the error and take the appropriate corrective action. My experience allows me to quickly pinpoint the cause of most issues and resolve them effectively. If the problem proves too complex, I know when to seek assistance from a qualified technician.

Q 4. Explain your process for setting up an embroidery machine for a new design.

Setting up an embroidery machine for a new design involves several key steps. First, I transfer the design file to the machine, making sure the format is compatible. Next, I select the appropriate needle, thread type, and hoop size based on the design and fabric. I then carefully hoop the fabric, ensuring it’s taut and wrinkle-free to prevent puckering. The hoop selection is crucial because the size determines how much of the design is embroidered at once, influencing the machine’s stability. After that, I thread the machine, double-checking that it feeds smoothly and that the tension is properly adjusted. The thread tension is critical because uneven tension can lead to broken threads or uneven stitching. Finally, I begin the embroidery process by performing a test run to check for any issues and make any necessary adjustments. This iterative approach—testing and adjusting—ensures the best possible outcome and prevents wasted time and materials.

Q 5. What safety precautions do you follow when operating embroidery machines?

Safety is paramount when operating embroidery machines. I always ensure that my workspace is clean and uncluttered. Loose clothing or jewelry should be avoided to prevent entanglement with moving parts. I never attempt to make adjustments or clean the machine while it’s powered on. Safety glasses are worn to protect my eyes from potential flying debris. Additionally, I always unplug the machine before cleaning or making repairs. Finally, I regularly inspect the machine for signs of wear or damage, such as frayed cables or damaged parts, and report any issues immediately to avoid potential hazards. Treating the machine with respect and following these steps ensure a safe work environment.

Q 6. How do you maintain the needles and hoops of an embroidery machine?

Maintaining the needles and hoops is crucial for high-quality embroidery and machine longevity. I regularly inspect needles for bends, burrs, or dullness, replacing them frequently as needed. A blunt or damaged needle can cause thread breakage or poor stitch quality. The type of needle used also greatly impacts stitch quality. For example, using a sharp needle for dense stitching or a stretch needle for knit fabrics can make a big difference. Hoops should be cleaned after each use to remove fabric lint and debris. This prevents the fabric from sticking or causing irregularities during future embroideries. Proper cleaning extends the life of the hoops and ensures a consistent hold on the fabric. I also carefully inspect the hoops for any damage and replace them if necessary. Storing both needles and hoops properly in a clean and organized place prevents damage and promotes longer lifespans.

Q 7. Describe your experience with digitizing embroidery designs.

While my primary role is machine operation and maintenance, I possess a basic understanding of embroidery digitizing. I’ve collaborated extensively with digitizers, providing feedback on design feasibility and potential machine limitations. This collaboration helps to ensure that the designs are optimized for the specific machines and materials that will be used. I can identify potential problems, such as complex stitches that may not be achievable on a specific machine, or design elements that might lead to fabric damage or thread breakage. This collaborative approach is crucial for achieving high-quality embroidery outcomes. In the future, I am planning to expand my skills in this area.

Q 8. How do you handle bobbin winding and thread changes?

Bobbin winding and thread changes are fundamental to efficient embroidery. Think of the bobbin as the hidden half of the stitch – it needs to be perfectly wound and the thread needs to be of the correct type and quality to create a flawless result.

Bobbin Winding: I always begin by ensuring the correct bobbin is selected for my machine. I then carefully place the bobbin on the winder, thread it correctly (following manufacturer guidelines, which vary slightly between machines), and engage the winder. I monitor the process to ensure even winding and avoid overcrowding. A poorly wound bobbin is a frequent cause of thread breakage and uneven stitching.

Thread Changes: When changing thread, I first trim the existing thread, leaving a short tail. Then, I carefully feed the new thread through the appropriate guides, ensuring it’s taut but not stretched. I use a thread guide to help direct the thread and prevent tangles. I always test the new thread by stitching a few test stitches to confirm there are no issues before proceeding with the full embroidery design. This avoids wasting time and materials.

Practical Example: I once had a problem with inconsistent stitching. It turned out to be a badly wound bobbin causing tension issues. By meticulously winding a new bobbin and carefully threading the machine, I solved the problem immediately.

Q 9. What software programs are you proficient in for embroidery design and operation?

My proficiency in embroidery design and operation software spans several key programs. I’m highly skilled in using industry-standard software like Wilcom EmbroideryStudio and Tajima DG/ML. These programs are powerful tools that allow for intricate design creation, digitization, and machine control. I also have experience with simpler software options such as Hatch Embroidery, which is great for smaller projects and quicker turnaround times.

Wilcom EmbroideryStudio: This is my go-to for complex designs. It offers advanced features for stitch editing, color separation, and even automatic conversion from various design formats. I use its powerful tools to optimize stitch density for different fabric types and achieve high-quality results.

Tajima DG/ML: Excellent for large-scale commercial work, I rely on Tajima’s software for its precision in managing multiple colors, dense stitching and its compatibility with a wide array of industrial machines.

Practical Example: For a recent client’s project that required intricate floral embroidery on silk, I used Wilcom to adjust stitch density for optimum result, preventing puckering and maintaining the delicate nature of the fabric.

Q 10. How do you ensure consistent stitch quality across multiple embroidery pieces?

Maintaining consistent stitch quality across multiple pieces requires a meticulous approach, paying close attention to various factors. It’s like baking a cake – you need the right ingredients and the correct process to get the same delicious result every time.

- Consistent Thread Tension: Properly calibrated tension is crucial. I regularly check and adjust the machine’s tension settings, both on the needle and the bobbin, to ensure a balanced stitch.

- Fabric Preparation: Consistent hooping is vital to avoid puckering or shifting. I use the appropriate hoop size for each project and securely hoop the fabric, making sure it is taut but not overly stretched. Using stabilizer is key as it adds support and prevents distortion.

- Regular Machine Maintenance: Cleaning and lubricating the machine, as per the manufacturer’s guidelines, prevents issues caused by lint buildup or friction which can impact stitch quality. This includes regularly cleaning the bobbin case and ensuring the needle is sharp and correctly seated.

- Consistent Design Settings: I ensure that the stitch density, speed and number of colors in my digitizing file remains constant across multiple embroideries, unless there is a stylistic reason for altering them.

Practical Example: I once had a production run where some pieces had loose stitches. By carefully re-checking the hooping technique and thread tension, I identified the inconsistent hooping as the root cause and corrected the problem for subsequent pieces.

Q 11. Explain your understanding of different embroidery fabric types and their suitability.

Different fabrics require different approaches to embroidery. Choosing the right fabric for a design is critical for achieving the desired outcome, preventing damage to the fabric and the machine. Understanding the fabric’s weight, weave, and composition is important.

- Lightweight Fabrics (e.g., silk, chiffon): These require a softer touch and appropriate stabilizer to prevent puckering and tearing. Reduced stitch density and slower speeds are often necessary.

- Medium-Weight Fabrics (e.g., cotton, linen): These are generally easier to embroider, but still require careful hooping to prevent wrinkles. Medium stitch density is usually suitable.

- Heavyweight Fabrics (e.g., denim, canvas): These may need special needles and potentially a higher stitch density to penetrate the thick fabric. A heavy-duty machine may be necessary.

- Knit Fabrics: These are more prone to stretching. Water-soluble stabilizer or tear-away stabilizer is highly recommended. Use specialized needles and lower stitch density.

Practical Example: Embroidering on delicate silk necessitates using a tear-away stabilizer to help support the fabric and prevent damage during the embroidery process. This is different to embroidering on a heavy cotton canvas, where a heavier weight stabilizer would be selected.

Q 12. How do you calibrate an embroidery machine for accurate stitching?

Calibrating an embroidery machine ensures accurate stitching and prevents common problems like inconsistent stitch length and skipped stitches. It’s like tuning a musical instrument – you need to make sure all the parts work together harmoniously.

Calibration usually involves several steps, and the exact procedure depends on the machine model. However, common steps include:

- Checking the Hook Timing: Many machines have a mechanism to adjust the timing of the bobbin hook. This is often critical for consistent stitch formation.

- Adjusting Needle Height: The needle should be at the optimal height to interact correctly with the bobbin hook. This is frequently a pre-set value, but minor adjustments might be needed.

- Testing Stitch Length and Width: Stitching a test sample allows verification of the stitch dimensions. If incorrect, refer to the machine’s manual to make necessary adjustments.

- Tension Adjustments: Fine-tuning thread tension (both needle and bobbin) is crucial for perfect stitch formation. Usually, a test stitch is used to adjust the tensions until they are balanced.

Practical Example: If your stitches are consistently too long or too short, or if you notice skipped stitches, recalibrating the hook timing and stitch length settings usually fixes the issue.

Q 13. What is your experience with different embroidery machine brands?

My experience encompasses a wide range of embroidery machine brands, from domestic machines to large-scale industrial models. This includes extensive experience with brands such as Tajima, Barudan, Melco, Brother, and Singer. Each brand has its own unique features and operating characteristics. Understanding these nuances is crucial for achieving optimal results.

Tajima and Barudan: These are prominent brands in the industrial embroidery sector, known for their precision, reliability, and speed. I’m well-versed in operating and maintaining their high-speed, multi-needle machines.

Melco: Melco machines are popular for their user-friendly interface and excellent stitch quality. I have experience utilizing their software and troubleshooting common issues.

Brother and Singer: I have experience with Brother and Singer domestic and semi-industrial machines, often used for smaller-scale projects or home-based businesses.

Practical Example: The process for changing bobbins in a Tajima industrial machine is different from that in a Brother domestic machine; understanding these differences is essential for efficient and safe operation.

Q 14. Describe your experience with pre-production sample preparation.

Pre-production sample preparation is a crucial stage that ensures the final product meets the client’s expectations and avoids costly mistakes down the line. It’s like creating a blueprint before building a house – you want to make sure the design works and there are no surprises.

My process typically includes:

- Fabric Selection and Testing: Testing the embroidery design on a sample piece of the client’s chosen fabric to check for issues like color bleeding or fabric distortion. This allows for changes to the design or process before committing to production.

- Stabilizer Selection: Testing the various types of stabilizers to determine which will provide the best results with the chosen fabric and embroidery design.

- Stitch Density and Tension Adjustments: Fine-tuning stitch density and thread tension on the sample to achieve the desired stitch quality.

- Color Matching: Ensuring the colors used in the sample match the client’s specifications.

- Hooping Techniques: Optimizing hooping techniques to minimize puckering or distortions.

- Quality Control: Thoroughly inspecting the sample for any flaws before approving for full production.

Practical Example: I recently prepared a pre-production sample for a client requiring complex embroidery on leather. After several trials using different stabilizers and stitch settings, we finalized a technique that yielded the required results and eliminated problems with the design pulling the leather.

Q 15. How do you identify and resolve thread breaks during embroidery?

Thread breaks are a common frustration in embroidery, but with systematic troubleshooting, they’re usually easily resolved. First, I visually inspect the entire thread path, from the spool to the needle. This includes checking for:

- Spool issues: Is the spool properly seated? Is the thread unwinding smoothly? Is there any damage to the thread itself (knots, tangles)?

- Tension issues: Is the upper and lower thread tension correctly adjusted? Incorrect tension is a major cause of thread breakage. I’ll consult the machine’s manual for optimal settings, or use the machine’s tension adjustment dials to fine-tune it.

- Needle problems: Is the needle the correct size and type for the thread and fabric? Is the needle bent or damaged? A dull or damaged needle can easily snap the thread.

- Bobbin issues: Is the bobbin properly wound and inserted? Is the bobbin thread tension correct? A poorly wound or incorrectly placed bobbin is a frequent culprit.

- Lint and debris: Are there any obstructions in the thread path, such as lint or dust? Regular cleaning prevents these build-ups.

Once I identify the problem, I address it directly. For example, if the tension is off, I’ll adjust it accordingly. If there’s a damaged needle, I’ll replace it. If lint is clogging the mechanism, I’ll carefully remove it using compressed air or a soft brush. I always prioritize safety and power down the machine before any cleaning or maintenance. For stubborn breaks, tracing the thread path carefully, and using a magnifying glass to check for small tangles is key. I’ve found that a little patience and methodical examination almost always leads to identifying the source of the break.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain and clean the embroidery machine’s components?

Maintaining an embroidery machine is crucial for its longevity and consistent performance. My routine cleaning involves:

- Regular dusting: I use compressed air to blow away dust and lint from all accessible areas, including the bobbin case, feed dogs, and the area around the needle. A soft brush can also be useful for more delicate areas.

- Bobbin case cleaning: I regularly clean the bobbin case to remove lint buildup that can interfere with the smooth movement of the bobbin thread. I often use a small brush and sometimes a lint-free cloth for cleaning.

- Needle plate cleaning: The needle plate can accumulate lint and debris, which can cause skipping stitches or thread breakage. I carefully clean this area using a brush or a soft cloth.

- Hook area cleaning: This is a very important area, the hook can get damaged from lint buildup if not cleaned and lubricated properly. I use a brush to clear out lint and debris, taking care not to damage the delicate components. A specialized hook cleaning tool is ideal.

- Lubrication: I use a specialized embroidery machine lubricant sparingly in the recommended areas as specified in the machine’s manual. Over-lubrication can be as damaging as under-lubrication.

I always consult the machine’s manual for specific cleaning and maintenance instructions. This ensures I’m using the correct tools and techniques and avoid causing any damage.

Q 17. What is your experience with performing preventative maintenance on embroidery machines?

Preventative maintenance is paramount for optimal machine performance. My preventative maintenance routine involves a combination of regular cleaning (as described above), and scheduled inspections. This includes:

- Timing Belt Inspection: Regularly checking the timing belt for wear and tear. A worn belt can lead to timing issues and inconsistent stitching.

- Motor and Drive System: Checking for any unusual noises or vibrations that might indicate a problem with the motor or drive system.

- Needle Bar and Hook Timing: Checking the synchronization of the needle bar and hook; misalignment is a source of many issues.

- Tension Adjustment: Regularly checking the upper and lower thread tension. Even slight misalignment can cause puckering or inconsistent stitching.

I also maintain a detailed log of all maintenance activities, noting any issues discovered and actions taken. This helps track the machine’s condition and predict potential problems before they impact productivity. This proactive approach has helped me avoid costly repairs and downtime in my past experiences. One time, a routine inspection revealed a loose screw on a critical component – a simple fix that prevented a major malfunction.

Q 18. How do you handle fabric puckering or tension issues during embroidery?

Fabric puckering and tension issues are common embroidery challenges. To address these:

- Fabric Stabilization: I assess whether the fabric is properly stabilized. Using a stabilizer appropriate for the fabric type is crucial. This often solves most puckering issues.

- Tension Adjustment: Adjusting the upper and lower thread tension is vital. Too much upper tension leads to puckering; too little can cause loose stitches. Experiment with fine adjustments in small increments.

- Needle Size and Type: The incorrect needle size for the fabric can cause puckering. The needle type also impacts tension and stitch quality. Matching the needle to the fabric is crucial.

- Hooping Technique: Proper hooping is essential to avoid fabric distortion. Too much or too little tension in the hoop can cause problems. I check the fabric’s tension within the hoop regularly.

- Stitch Density: High stitch density can contribute to puckering. Reducing the density sometimes helps.

I usually approach these problems systematically. For example, I start by checking the hooping, then the tension, then the needle, and finally the stabilizer. Documenting my adjustments is key for consistency and to be able to go back and repeat successful techniques.

Q 19. Describe your experience with troubleshooting mechanical issues in embroidery machines.

Troubleshooting mechanical issues in embroidery machines requires a blend of technical knowledge and systematic problem-solving. My approach involves:

- Identifying the symptom: Precisely describing the problem (e.g., machine won’t turn on, skipping stitches, inconsistent stitch length) is the first step.

- Checking the obvious: I start by checking simple things: power cord, switches, and any loose connections.

- Consult the manual: The machine’s manual is my go-to resource for troubleshooting common problems. Diagrams and specifications help identify component locations.

- Systematic inspection: If the manual doesn’t provide a solution, I carefully examine all the mechanical components – belts, gears, motors – listening for unusual noises or observing irregular movement.

- Testing components: If possible, I test components individually to isolate the faulty part. For example, if the motor seems suspect, I might try swapping it out with a known working motor (only after disconnecting power).

- Seeking professional help: If I can’t identify and fix the problem, I won’t hesitate to contact qualified service technicians. Attempting advanced repairs without the proper expertise can lead to more damage.

A specific instance involved a machine with irregular stitch length. After eliminating simpler causes, I discovered a slight misalignment in the hook timing. The manual helped guide me to adjust the timing, solving the problem and avoiding the costly replacement of parts.

Q 20. How familiar are you with using different embroidery machine accessories?

I am proficient with a wide range of embroidery machine accessories, including:

- Various types of needles: I know how to select the right needle for different fabrics and threads (e.g., sharp needles for woven fabrics, ballpoint needles for knits).

- Different bobbins: I’m familiar with various bobbin types and sizes compatible with the machine and know how to wind them correctly to avoid issues.

- Stabilizers: I have extensive experience with various stabilizers – tear-away, wash-away, and cut-away – knowing which type is best suited for each project and fabric.

- Hoops: I can use various hoop types and sizes, optimizing hooping techniques for different fabrics and designs to minimize puckering and distortion.

- Specialty feet: I am familiar with specialized embroidery feet, including those designed for free-motion embroidery, applique, or satin stitch.

My experience with these accessories is invaluable for achieving high-quality embroidery results across a wide range of projects. For example, knowing when to use a wash-away stabilizer for delicate fabrics prevents damage and produces a cleaner finish.

Q 21. How do you interpret and follow embroidery design specifications?

Interpreting and following embroidery design specifications is fundamental. This involves understanding the:

- Stitch count: This influences the embroidery time and the amount of thread used.

- Design dimensions: This ensures the design fits the fabric and the embroidery area.

- Thread colors: The design’s color palette dictates the thread selection.

- Stitch types: Understanding the different stitches (satin, fill, running, etc.) helps in selecting the proper needle and stabilizer.

- File format: I’m familiar with various file formats (e.g., .DST, .PES, .EXP) commonly used in embroidery machines.

I use the design specifications to prepare the embroidery process, selecting the correct accessories, setting up the machine, and estimating project completion time. A thorough understanding of the specifications ensures a smooth and successful embroidery process, preventing errors and wasted materials. I’ve learned to always double-check these details before starting, saving myself from costly mistakes in the past.

Q 22. What is your experience with large format embroidery machines?

My experience with large format embroidery machines spans over eight years, encompassing both operational and maintenance aspects. I’ve worked extensively with machines capable of handling designs exceeding 1000mm in width, frequently used for projects like large corporate logos on banners, intricate designs on upholstery, and even customized artwork for automotive interiors. I’m proficient in handling the complexities of these machines, including their intricate setup procedures, multi-needle configurations, and the challenges of managing larger fabric pieces and their associated tension. This includes experience with brands such as Tajima, Barudan, and SWF. I am familiar with their specific software interfaces and troubleshooting methodologies.

For instance, on a recent project embroidering a large company logo onto a set of 2m x 1m promotional banners, I carefully planned the hooping and stitching sequences to minimize fabric distortion and ensure consistent design placement across all banners. This involved meticulous preparation of the fabric, careful selection of stabilizers, and precise adjustments to the machine’s tension settings. The success of this project highlights my ability to efficiently handle large format embroidery challenges.

Q 23. How do you address issues with registration and alignment in embroidery?

Registration and alignment issues in embroidery are common, often stemming from improper hooping, inconsistent fabric tension, or even minor machine calibration errors. Addressing these requires a systematic approach.

- Thorough Inspection: I always begin by meticulously examining the design on the screen alongside the actual stitching on the fabric. This allows for quick identification of the nature of the misalignment – horizontal, vertical, or both.

- Hooping Techniques: Correct hooping is crucial. Ensuring the fabric is taut and evenly distributed within the hoop prevents distortions that lead to misalignment. I use various hooping techniques depending on the fabric type and design complexity. For instance, using tear-away stabilizer allows easy release after embroidery, correcting slight issues.

- Tension Adjustments: Proper top and bottom thread tension is critical. Incorrect tension can cause pulling, leading to distorted designs. I carefully adjust tensions based on the fabric and thread used, often making fine adjustments throughout the process.

- Machine Calibration: In some cases, the issue might lie with the machine itself. I’m trained to check for mechanical alignment issues, such as needle bar positioning or any issues with the shuttle, and perform necessary calibrations or adjustments as needed.

- Software Adjustments: Sometimes, slight adjustments within the embroidery software can compensate for minor misalignments. This involves careful examination of the stitch pattern within the software.

For example, recently, I encountered vertical misalignment on a project. Through careful inspection, I identified an issue with the hooping. By re-hooping and making minor tension adjustments, the misalignment was corrected.

Q 24. Describe your experience with different types of embroidery hoops and their applications.

My experience encompasses a wide range of embroidery hoops, each suited to specific fabrics and applications.

- Standard Circular Hoops: These are the most common, ideal for many fabrics and designs. The size options are crucial – I choose the hoop size that best fits the design while preventing unwanted fabric stretching.

- Rectangular Hoops: Perfect for larger designs or fabrics that aren’t easily accommodated in circular hoops. They are very useful for items like towels or larger apparel.

- Magnetic Hoops: These are particularly useful for delicate fabrics that can be easily damaged by traditional clamping hoops, as they hold the fabric gently, yet firmly.

- Specialty Hoops: I’ve worked with various specialty hoops, including those designed for hats, sleeves, and other challenging areas. Their unique designs and clamping mechanisms are suited to their specific application, reducing issues in those hard-to-reach places.

The choice of hoop is a crucial aspect of the pre-embroidery process. For instance, when embroidering on a delicate lace fabric, I would always opt for magnetic hoops to avoid damaging the fabric. Conversely, for a thick denim jacket, a sturdy, appropriately sized circular or rectangular hoop would be necessary.

Q 25. How do you ensure the proper placement of stabilizer for different fabric types?

Proper stabilizer placement is critical for preventing fabric puckering and achieving professional-looking embroidery. The type of stabilizer needed depends heavily on the fabric type and embroidery design.

- Tear-away Stabilizer: This is a general-purpose stabilizer that is removed after embroidery. Ideal for most medium-weight fabrics.

- Cut-away Stabilizer: A more robust option than tear-away stabilizer, it is used for heavier fabrics or intricate designs. It is partially removed by cutting around the finished design.

- Wash-away Stabilizer: Ideal for delicate fabrics or designs that need exceptional support during the stitching process. The stabilizer dissolves completely after washing.

- Water-soluble Stabilizer: This type of stabilizer is often used for very delicate fabrics. It dissolves immediately upon contact with water.

The placement technique also varies. For instance, with a lightweight fabric, I may use tear-away stabilizer by placing it only under the area to be embroidered. With heavy fabrics and dense designs, I’d use cut-away stabilizer and potentially layer it for extra support. My years of experience help me instinctively choose the correct stabilizer and application for each project.

Q 26. What is your experience with troubleshooting electrical problems in embroidery machines?

Troubleshooting electrical issues in embroidery machines requires a careful and systematic approach, prioritizing safety. I am trained to identify and resolve common electrical problems, following all safety precautions.

- Power Supply Checks: I start with simple checks, ensuring the machine is properly connected to a power source and the circuit breaker isn’t tripped. Then, I would check the machine’s internal fuse box.

- Wiring Inspection: A visual inspection of the internal wiring is performed to look for any loose connections, frayed wires, or signs of damage. This often requires a careful disassembly of certain parts, which I am very familiar with.

- Motor and Component Testing: If the issue isn’t immediately apparent, I might utilize a multimeter to check the voltage and amperage to identify if a specific motor or component is malfunctioning. I would consult the machine’s service manual for testing instructions and safety regulations.

- Professional Assistance: For complex electrical problems that I cannot address safely and efficiently, I know when to contact the qualified service technician and follow procedures for machine shutdown and safety.

For example, I once encountered a situation where the machine’s motor wouldn’t turn on. A thorough inspection revealed a blown fuse in the main power supply, which was safely replaced. This illustrates my practical experience in solving these issues safely and effectively.

Q 27. How do you manage and organize embroidery production workflows?

Efficient embroidery production workflows require meticulous planning and organization. My approach utilizes a combination of digital tools and established practices.

- Design Management: I employ digital design software for organizing and categorizing embroidery files. The files are labelled with specific details, such as the customer name, project description, and fabric information.

- Production Scheduling: I use project management software to schedule tasks efficiently. This involves setting priorities and timelines, factoring in the complexity of each design and the availability of machines and materials.

- Material Management: Maintaining an organized inventory of threads, stabilizers, and other consumables is crucial to avoiding delays. A systematic inventory management system keeps track of materials and their locations.

- Quality Control: A rigorous quality control system is integrated into the workflow. Each completed embroidery is inspected to ensure it meets quality standards before delivery.

For example, during a high-volume order involving diverse designs, I used project management software to ensure each order was progressed according to the set deadlines. This helped optimize workflow and ensure timely project completion without compromising quality.

Q 28. Explain your understanding of different embroidery designs and their complexity.

Embroidery designs vary greatly in their complexity, impacting the stitching time, thread requirements, and overall production process.

- Simple Designs: These often involve basic stitches and limited color changes, making them relatively quick and easy to execute.

- Intermediate Designs: These designs may incorporate more detailed stitching, multiple color changes, and various stitch types. They demand a higher level of skill and attention.

- Complex Designs: These designs often feature intricate detailing, requiring precise stitching, high thread counts, and extensive planning. They might necessitate multiple hoopings and careful stabilizer selection.

For instance, a simple design like a company logo might take only a few minutes to stitch, while a complex piece of artwork with shading and intricate detail might take several hours to complete. Understanding these complexities helps in accurately estimating the project’s time and resource needs.

Key Topics to Learn for Your Embroidery Machine Operation & Maintenance Interview

- Machine Operation: Understanding the different types of embroidery machines (single-head, multi-head, etc.), their functionalities, and safe operating procedures. This includes loading designs, threading needles, adjusting tension, and recognizing common operational errors.

- Design Preparation & Transfer: Familiarize yourself with digital design software, file formats (e.g., DST, PES), and the process of transferring designs onto the machine. Understanding color separation and stitch density is crucial.

- Troubleshooting & Problem Solving: Develop your ability to diagnose and resolve common issues such as broken needles, thread breaks, skipped stitches, and bobbin problems. Practice identifying the root cause and implementing effective solutions.

- Maintenance & Cleaning: Learn about the importance of regular machine maintenance, including cleaning, lubrication, and preventative measures to extend machine lifespan. Know how to identify parts that require replacement and perform basic maintenance tasks.

- Safety Procedures: Demonstrate a strong understanding of safety protocols relevant to operating and maintaining embroidery machines. This includes proper handling of needles, avoiding electrical hazards, and maintaining a clean and organized workspace.

- Understanding Stitch Types & Properties: Become familiar with different stitch types (satin, fill, outline, etc.) and their applications. Knowing how stitch density and underlay affect the final embroidery is essential.

- Fabric Selection & Preparation: Understand how different fabrics impact embroidery results and how to properly prepare fabrics for embroidery (e.g., hooping techniques, stabilizer use).

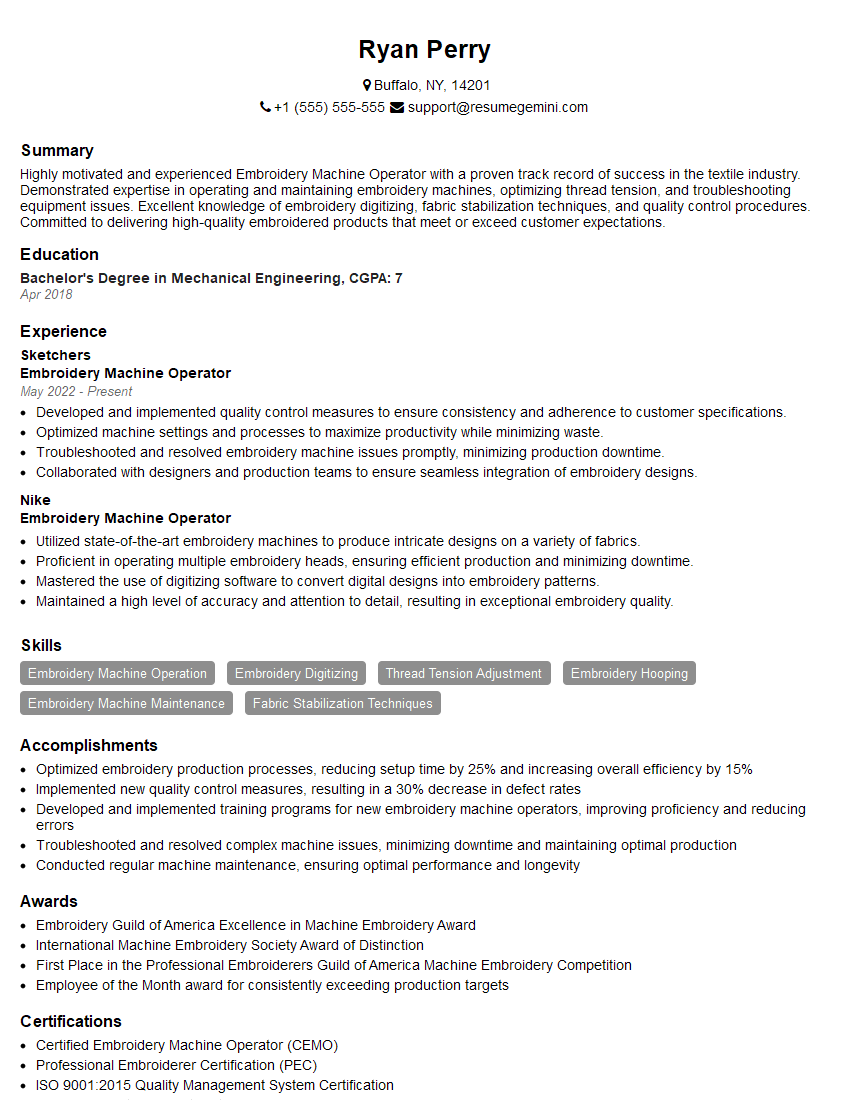

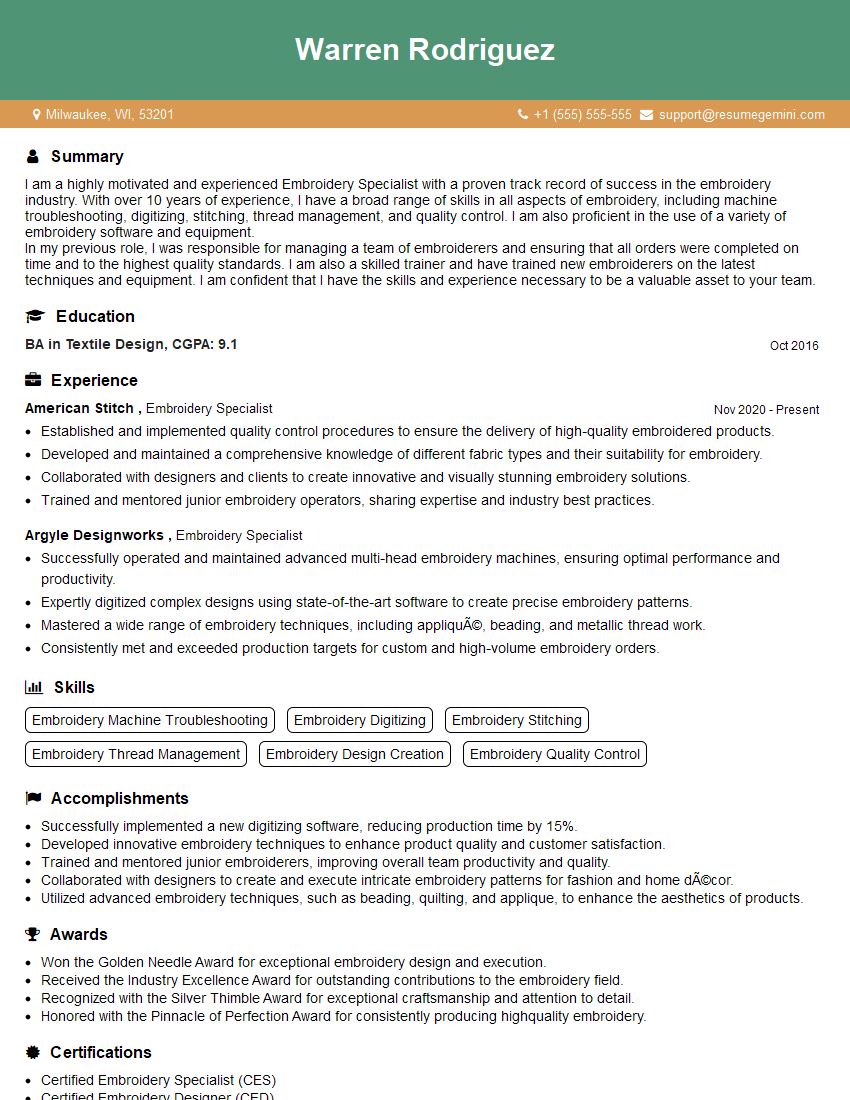

Next Steps: Level Up Your Career

Mastering embroidery machine operation and maintenance is key to unlocking exciting career opportunities and advancing your skills. A strong foundation in these areas will make you a highly sought-after candidate in the industry. To maximize your job prospects, focus on creating a professional and ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource for building impactful resumes, and we offer examples specifically tailored to embroidery machine operation and maintenance professionals. Use these examples to craft a compelling resume that showcases your skills and experience effectively, landing you your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good