Are you ready to stand out in your next interview? Understanding and preparing for Energy Testing interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Energy Testing Interview

Q 1. Explain the difference between AC and DC energy systems.

The fundamental difference between AC (Alternating Current) and DC (Direct Current) energy systems lies in the direction of electron flow. In DC systems, electrons flow consistently in one direction, like a river flowing downstream. This is the type of electricity produced by batteries. AC systems, on the other hand, involve electrons that periodically change direction, oscillating back and forth like a wave. This is the electricity that powers our homes and businesses.

Think of it like this: DC is like a water slide – a constant flow in one direction. AC is like a seesaw – the flow changes direction repeatedly. This difference has significant implications for transmission, as AC can be easily transformed to higher voltages for efficient long-distance transmission, a feat more challenging with DC.

AC’s ability to be easily stepped up and down in voltage using transformers is a crucial advantage in power distribution networks. This efficiency makes it the dominant choice for large-scale power grids. DC, while simpler in some respects, is becoming increasingly important in applications like renewable energy integration (solar panels produce DC) and high-power transmission over long distances (HVDC).

Q 2. Describe various types of energy storage technologies and their applications.

Energy storage technologies are crucial for managing the intermittent nature of renewable energy sources and ensuring grid stability. Several types exist, each with its own advantages and drawbacks:

- Batteries: These are the most common form, ranging from lead-acid (used in cars) to lithium-ion (found in phones and electric vehicles), and flow batteries (for large-scale energy storage). Lithium-ion batteries offer high energy density and are widely used in grid-scale applications, though their lifespan and environmental impact are key considerations.

- Pumped hydro storage: This involves pumping water uphill to a reservoir during off-peak hours and releasing it to generate electricity during peak demand. It’s a mature technology, cost-effective for large-scale applications, but geographically limited.

- Compressed air energy storage (CAES): This technology stores energy by compressing air into underground caverns, which is then released to drive turbines. It’s environmentally friendly but requires suitable geological formations.

- Thermal energy storage: This involves storing energy as heat (e.g., molten salt) or cold (e.g., ice) and using it later to generate electricity or provide heating/cooling. This is especially useful for solar thermal power plants.

- Flywheels: These devices store energy by spinning a massive rotor at high speed. They offer fast response times, ideal for stabilizing the grid but have lower energy density compared to batteries.

The choice of energy storage technology depends on factors such as scale, cost, application, and environmental impact. For example, a small-scale residential system might use batteries, while a large utility might opt for pumped hydro storage.

Q 3. What are the key safety precautions when conducting high-voltage testing?

High-voltage testing carries inherent risks, demanding strict adherence to safety protocols. These precautions are paramount to preventing serious injury or death.

- Lockout/Tagout (LOTO): This crucial procedure involves isolating the equipment from the power source and using locks and tags to prevent accidental energization. It is essential before any work begins.

- Personal Protective Equipment (PPE): This includes insulated gloves, safety glasses, arc-flash suits, and safety footwear rated for the voltage levels involved. The PPE must be regularly inspected and certified.

- Trained Personnel: Only qualified and trained personnel should conduct high-voltage testing. Comprehensive training on safety procedures, equipment operation, and emergency response is mandatory.

- Grounding: Proper grounding is vital to dissipate static electricity and prevent dangerous voltage surges. All equipment and personnel should be properly grounded before and during testing.

- Emergency Procedures: A well-defined emergency plan should be in place, including procedures for handling electric shock, arc flashes, and fire. Emergency response teams should be readily available.

- Permit-to-Work System: Formal permits are required for high-voltage work, documenting the safety checks and procedures undertaken before commencement.

Negligence in these precautions can lead to severe consequences. A thorough understanding and diligent application of these safety measures are essential for the safety of personnel and the integrity of the testing process.

Q 4. How do you ensure the accuracy of energy metering equipment?

Ensuring the accuracy of energy metering equipment is crucial for fair billing, efficient energy management, and grid stability. This involves a multi-pronged approach:

- Calibration: Regular calibration against traceable standards is essential. This involves comparing the meter’s readings to those of a known accurate standard, identifying any deviations and applying corrections.

- Verification: Periodic verification checks assess the meter’s performance under operational conditions. This can involve comparing readings with other meters, or using specialized test equipment.

- Maintenance: Proper maintenance, including cleaning and inspection, ensures the meter operates optimally. This minimizes the risk of mechanical failures or environmental influences affecting accuracy.

- Data Logging and Analysis: Regularly logging and analyzing meter data allows for the detection of anomalies or trends indicating potential inaccuracies. Statistical process control techniques can be applied to identify systematic errors.

- Environmental Factors: Account for environmental factors that might affect readings, such as temperature, humidity, and magnetic fields. Compensation may be needed if significant effects are observed.

For instance, a utility company regularly calibrates smart meters to maintain billing accuracy and ensure fair energy pricing to consumers. Neglecting accuracy checks can lead to significant financial losses and operational inefficiencies.

Q 5. What are the common challenges in testing renewable energy systems?

Testing renewable energy systems presents unique challenges compared to traditional power systems:

- Intermittency: The variable nature of solar and wind power makes consistent testing difficult. Specialized equipment and techniques are needed to capture the dynamic behavior of these systems.

- Environmental Factors: Weather conditions significantly impact renewable energy generation. Testing needs to account for these variations, often requiring extensive field testing in different climates.

- System Complexity: Renewable energy systems often involve multiple components (solar panels, inverters, batteries, etc.), requiring comprehensive testing procedures to ensure proper integration and performance.

- Safety: Working with high-voltage DC systems from solar panels requires specialized safety protocols, emphasizing extra precautions for ground fault detection and arc flash hazards.

- Remote Locations: Many renewable energy installations are located in remote areas, requiring specialized testing equipment and logistics planning.

For example, accurately measuring the energy yield of a solar farm requires accounting for cloud cover, solar irradiance variations, and the performance of individual panels. This necessitates advanced monitoring and data acquisition techniques.

Q 6. Explain the concept of power factor and its importance in energy efficiency.

Power factor describes the relationship between the real power (kW) used by a load and the apparent power (kVA) supplied by the source. It’s a measure of how efficiently electrical power is used. A power factor of 1 indicates perfect efficiency – all the supplied power is consumed by the load. Power factors less than 1 indicate that some power is wasted due to reactive loads, such as inductive motors and transformers.

Imagine a water pump. The apparent power is the total amount of water pumped, while the real power is the amount of water that actually reaches its destination. If some water leaks along the way, this represents the reactive power, reducing the overall efficiency (power factor). This reactive power generates heat in transmission lines and equipment, causing energy loss.

Improving power factor is crucial for energy efficiency. It reduces the amount of current drawn from the source, thus minimizing energy loss in transmission lines and equipment. This translates to cost savings and improved grid stability. Techniques for improving power factor include using power factor correction capacitors to compensate for inductive loads.

Q 7. Describe your experience with different types of energy testing equipment.

Throughout my career, I’ve gained extensive experience using a variety of energy testing equipment, including:

- Multimeters: For basic voltage, current, resistance, and continuity measurements.

- Clamp meters: To measure current without breaking the circuit.

- Power quality analyzers: To assess power quality parameters like voltage sags, swells, harmonics, and transients.

- High-voltage testers: For insulation resistance testing, dielectric strength testing, and partial discharge measurements.

- Energy meters: To measure energy consumption.

- Insulation resistance testers (meggers): To test the insulation resistance of cables, motors, and other electrical equipment.

- Oscilloscope: For detailed waveform analysis and troubleshooting.

- Thermal cameras: For detecting overheating components.

I am proficient in using these instruments for various applications, from routine maintenance testing to complex fault diagnosis in high-voltage systems and renewable energy installations. My experience extends to both AC and DC systems across diverse voltage ranges.

Q 8. How do you troubleshoot issues during energy testing procedures?

Troubleshooting energy testing issues involves a systematic approach. Think of it like detective work – you need to gather clues, analyze them, and form a hypothesis to solve the mystery. It begins with careful observation of the test setup and equipment. Are there any obvious problems like loose connections or malfunctioning instruments?

- Check Instrumentation: Verify calibration of all meters, sensors, and data acquisition systems. A faulty instrument can lead to inaccurate readings. For example, if a current clamp is not properly positioned, you’ll get erroneous current measurements.

- Review Test Procedures: Re-examine the test plan and ensure all steps were followed precisely. A simple oversight in the procedure, such as incorrect wiring or incorrect settings on a power supply, can cause significant discrepancies.

- Inspect Connections: Check for loose or corroded connections in the wiring harness and at the test points. These can lead to high resistance, poor contact, and inaccurate results. I always double-check every connection before starting any test.

- Analyze Data Patterns: If the issue is subtle, look for trends or patterns in the acquired data. Unusual spikes or consistent deviations might point to a specific problem. Software tools can help visualize the data to find these anomalies.

- Isolate the Problem: If the problem is complex, isolate sections of the system to pinpoint the source of the error. Start with simple checks, like isolating circuits, then move on to more involved investigations.

For example, during a solar panel array testing, if the total power output is unexpectedly low, I would first check the individual panel voltages and currents. If one panel shows significantly lower output, the problem is likely localized to that panel. Further investigation might reveal a faulty cell or shading issue.

Q 9. What are the key performance indicators (KPIs) you monitor in energy testing?

Key Performance Indicators (KPIs) in energy testing depend on the specific application, but some common ones include:

- Efficiency: This is a crucial metric in many energy systems. For instance, in motor testing, we measure efficiency as the ratio of output power to input power. Low efficiency might point to mechanical friction or electrical losses.

- Power Factor: This represents the ratio of real power to apparent power in AC circuits. A low power factor indicates reactive power consumption and potential energy waste. We strive for a power factor close to unity (1).

- Harmonic Distortion: Non-linear loads introduce harmonic currents, which distort the sinusoidal waveform. Measuring Total Harmonic Distortion (THD) helps assess the impact on the power system and equipment. High THD can damage equipment and reduce efficiency.

- Temperature Rise: Monitoring the temperature rise in components like transformers or motors is critical for safety and lifespan. Excessive temperature can indicate overloads or faults.

- Insulation Resistance: Measuring the insulation resistance helps identify potential insulation degradation, which can lead to electrical failures. Regular checks prevent safety hazards.

- Energy Consumption: We track energy consumption over time to assess energy efficiency and identify potential areas for improvement. This often involves integrating energy meters and monitoring software.

In a building energy audit, for example, we would monitor the energy consumption of different systems (heating, cooling, lighting) to identify which systems are consuming the most energy and whether their efficiency can be improved. For each KPI, we’d compare our measurements against predefined standards or benchmarks.

Q 10. Explain your experience with data acquisition and analysis in energy testing.

Data acquisition and analysis is the backbone of modern energy testing. I’ve extensive experience using various data acquisition systems, from simple multimeters to sophisticated automated test systems that can simultaneously measure multiple parameters. Think of a data acquisition system as the central nervous system of an energy test, collecting all the vital data.

My experience encompasses:

- Hardware: Working with various types of sensors, transducers (like current transformers and voltage transformers), and data loggers. I’m familiar with configuring and calibrating these devices for accurate measurements.

- Software: Proficient in using data acquisition software to control instruments, collect data, and generate reports. I have experience with software packages like LabVIEW and DASYLab for advanced analysis.

- Data Analysis Techniques: I utilize statistical methods and signal processing techniques to analyze the collected data. This includes identifying trends, calculating KPIs, and detecting anomalies.

- Data Visualization: Creating clear and informative visualizations – charts, graphs, and reports – to present the test results in an understandable manner. Effective visualization is critical for conveying insights from the often complex data sets.

For example, in a large-scale wind turbine testing project, we used a sophisticated data acquisition system to monitor multiple parameters such as wind speed, turbine RPM, generator output, and blade pitch angles. We then used specialized software to analyze the data and create a comprehensive report on the turbine’s performance and efficiency.

Q 11. Describe your familiarity with relevant safety standards and regulations (e.g., IEC, IEEE).

Safety is paramount in energy testing. My work always adheres to relevant safety standards and regulations. I’m familiar with standards published by organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE).

Key standards and regulations include:

- IEC 61000: This series covers electromagnetic compatibility (EMC), ensuring that equipment does not interfere with other devices and is resistant to interference. We use these standards to test equipment for compliance.

- IEC 60068: These standards specify environmental testing for electrical equipment, ensuring its ability to withstand various conditions, such as temperature changes and vibration.

- IEC 61850: This standard defines communication networks for substation automation, crucial for the safety and reliability of modern power systems. I’ve worked with systems adhering to this standard.

- IEEE 1547: This standard is for interconnection of distributed generation to utility power systems, important for ensuring the safe integration of renewable energy sources.

- Occupational Safety and Health Administration (OSHA) regulations: These regulations provide a framework for safe working practices in electrical environments, including lockout/tagout procedures, personal protective equipment (PPE) use, and safe working distances.

Before each test, a thorough risk assessment is performed, and appropriate safety measures are implemented. This includes using proper PPE, like insulated gloves and safety glasses, performing lockout/tagout procedures to prevent accidental energization, and ensuring that the testing environment is properly grounded and shielded.

Q 12. How do you validate test results and ensure their reliability?

Validating test results and ensuring reliability requires a multi-faceted approach. It’s not enough to simply record the numbers; you need to be certain they’re accurate and meaningful.

My validation process includes:

- Calibration Verification: All measuring instruments are calibrated regularly and traceability is meticulously maintained. A calibration certificate ensures the accuracy of the instruments.

- Cross-Checking: Data is cross-checked against multiple measurements. For example, we might compare power calculated from voltage and current measurements with direct power measurements using a wattmeter. Discrepancies signal further investigation.

- Repeatability and Reproducibility: Tests are often repeated to verify the consistency of results. Reproducibility is checked by having other engineers repeat the tests to ensure results are not dependent on a particular person’s skills or technique.

- Uncertainty Analysis: Uncertainty in measurements is assessed using statistical methods to determine the range of possible values for the measured quantity. This provides a quantitative measure of the reliability of the results.

- Data Quality Checks: Software tools are used to automatically check for outliers or inconsistencies in the data, which may indicate errors in measurement or data transmission.

- Comparison with Standards: Test results are frequently compared to established standards or benchmarks. For example, efficiency values of a tested motor should be consistent with those published by the manufacturer.

If significant discrepancies are found, a thorough investigation is conducted to identify and correct the source of error. The validation process ensures the integrity and trustworthiness of the test results.

Q 13. Explain your experience with different types of energy testing methodologies.

My experience spans a wide range of energy testing methodologies. I’ve worked on projects involving:

- Power System Testing: This includes testing transformers, circuit breakers, relays, and other power system components. This often involves high-voltage testing to assess insulation strength and withstand capabilities.

- Renewable Energy Testing: Extensive experience testing solar photovoltaic (PV) systems, wind turbines, and energy storage systems (ESS). This includes efficiency measurements, power curve characterization, and grid integration testing.

- Building Energy Audits: Conducting energy audits to identify energy-saving opportunities in buildings and industrial facilities. This involves measuring energy consumption, identifying inefficiencies, and recommending improvements.

- Motor Testing: Assessing the performance, efficiency, and reliability of electric motors. This includes various tests like no-load and full-load tests to determine motor parameters.

- Electrical Appliance Testing: Testing the safety and performance of various electrical appliances in accordance with relevant safety standards. This may involve testing for energy efficiency, safety compliance, and electromagnetic interference.

- Battery Testing: Evaluating the performance, lifespan, and safety of batteries used in electric vehicles, energy storage systems, and portable devices. This involves discharge tests, charge tests, and cycle life testing.

The choice of methodology depends heavily on the specific equipment or system being tested, and the objectives of the test. The process always involves a thorough understanding of the technology involved and a meticulous approach to data acquisition and analysis.

Q 14. How do you handle discrepancies between expected and actual test results?

Discrepancies between expected and actual test results require a systematic investigation. It’s crucial to avoid jumping to conclusions and instead follow a structured approach.

My process:

- Review Test Setup: First, double-check all aspects of the test setup, including the equipment, wiring, connections, and settings. Look for any possible sources of error, such as loose connections, incorrect settings, or faulty equipment.

- Examine Data for Anomalies: Analyze the acquired data for any unusual patterns or outliers. These could point towards specific problems within the tested system.

- Check Calibration: Ensure all measuring instruments were properly calibrated and that the calibration certificates are valid. Calibration errors are a frequent source of discrepancies.

- Re-run Tests: Repeat the tests to determine if the discrepancy was due to random error or a systematic problem. Consistent discrepancies warrant a deeper investigation.

- Investigate Environmental Factors: Assess if environmental conditions (temperature, humidity, etc.) had any impact on the test results. If so, appropriate corrections might be necessary.

- Consult Specifications: Compare the results to the relevant specifications and standards. Understanding the tolerance limits helps in evaluating the significance of the observed discrepancies.

- Document Findings: Thoroughly document the investigation process, including the discrepancies, the troubleshooting steps taken, and the conclusions reached. This documentation is essential for future reference and for improving testing procedures.

For instance, if the efficiency of a motor is significantly lower than expected, I would systematically check the motor’s load, the accuracy of power measurements, and the environmental conditions. I might then consult the motor’s specifications and check for any signs of damage or wear.

Q 15. What is your experience with commissioning and start-up testing of energy systems?

Commissioning and start-up testing of energy systems is crucial for ensuring safe and efficient operation. It involves a systematic process of verifying that all components and systems function as designed and meet specified requirements. This process typically begins with pre-commissioning activities, including reviewing design documents and conducting inspections. Then, individual components are tested, followed by integrated system tests to assess the interaction of various components. Finally, performance testing is done under various operating conditions to validate efficiency and reliability.

In my experience, I’ve led commissioning teams on several large-scale projects, including the start-up of a 50MW solar farm and a 10MW battery energy storage system. For the solar farm, we meticulously tested each inverter, string of panels, and the overall grid connection to ensure optimal energy yield and safe operation. This involved rigorous testing of protection relays and communication systems. For the BESS, we performed extensive testing of the battery management system, power conversion systems, and control algorithms to ensure seamless integration with the grid and smooth charge/discharge cycles. We used detailed checklists and meticulously documented all test results.

The entire process demands meticulous attention to detail and adherence to safety protocols. Any discrepancies or failures are thoroughly investigated and documented before the system is handed over to the client.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with test automation and scripting languages (e.g., LabVIEW, Python).

Test automation and scripting are essential for efficient and repeatable energy system testing. I’m proficient in both LabVIEW and Python. LabVIEW’s graphical programming environment is ideal for real-time data acquisition and control, particularly in the context of complex instrumentation and control systems found in energy systems. I’ve used LabVIEW to develop automated tests for high-voltage equipment and power electronics. For example, I automated the testing of protection relays in a substation using LabVIEW, significantly reducing testing time and improving accuracy compared to manual testing.

Example LabVIEW Code Snippet (Illustrative):

DAQmx Create Task ("MyTask");

DAQmx Create Channel ("MyTask", "Dev1/ai0", "Voltage", DAQmx_Val_RSE);

DAQmx Start Task ("MyTask");

DAQmx Read Analog F64 ("MyTask", 1000, 10.0, DAQmx_Val_GroupByChannel, data, &read);

DAQmx Stop Task ("MyTask");

DAQmx Clear Task ("MyTask");Python, on the other hand, is exceptionally versatile for data analysis, report generation, and integration with various databases and software tools. I’ve used Python extensively to process and analyze large datasets from energy meters, creating custom reports and visualizations to identify trends and anomalies. I’ve also created automated scripts to simulate various fault conditions and assess the performance of protection systems. This automated approach ensures repeatability and allows for thorough testing in a controlled manner.

Q 17. Explain your understanding of different types of energy meters and their functionalities.

Energy meters are vital devices used to measure energy consumption and production. They come in various types, each with specific functionalities:

- Electromechanical Meters: These older meters use a rotating disc to measure energy. They’re relatively simple but less accurate and lack advanced communication capabilities.

- Electronic Meters: These meters use microprocessors to measure energy consumption with greater precision and advanced features like time-of-use metering and remote data access.

- Smart Meters: These advanced electronic meters possess two-way communication capabilities allowing for remote reading, load management, and demand-side management programs. They provide granular data on consumption patterns.

- Power Quality Meters: These meters go beyond simply measuring energy to measure power quality parameters like voltage sags, surges, harmonics, and power factor. They’re used to diagnose power quality issues.

The choice of energy meter depends on the application’s requirements. For example, a smart grid application would necessitate smart meters to enable advanced grid management features, while a simple residential setting might only require a basic electronic meter.

Q 18. How do you ensure the integrity and security of energy systems during testing?

Ensuring the integrity and security of energy systems during testing is paramount. This involves implementing several key strategies:

- Access Control: Limiting access to testing environments to authorized personnel only, using strict password policies and role-based access control.

- Network Security: Implementing firewalls, intrusion detection systems, and other network security measures to protect the system from unauthorized access and cyberattacks.

- Data Encryption: Encrypting sensitive data both in transit and at rest to prevent unauthorized access and data breaches.

- Regular Security Audits: Conducting regular security audits and penetration tests to identify and address vulnerabilities.

- Physical Security: Implementing physical security measures to prevent unauthorized access to testing equipment and facilities.

- Test Data Integrity: Using robust test data management practices to ensure the accuracy and consistency of test data, avoiding data corruption or manipulation.

A layered security approach is essential. Ignoring any one of these areas could leave the system vulnerable to attacks or compromise the integrity of the test results.

Q 19. What are the challenges in testing smart grid technologies?

Testing smart grid technologies presents unique challenges due to their complex and distributed nature. These challenges include:

- Interoperability: Ensuring seamless communication and data exchange between diverse devices and systems from different vendors. This requires standardized protocols and rigorous testing of interoperability.

- Scalability: Smart grid technologies need to be scalable to accommodate the ever-increasing demand for electricity and the integration of renewable energy sources.

- Real-time Performance: Smart grids require real-time data processing and control to ensure stable and efficient operation. Testing real-time performance under various stress conditions is crucial.

- Cybersecurity: The interconnected nature of smart grids makes them susceptible to cyberattacks. Testing the cybersecurity resilience of the system is critical.

- Data Management: Smart grids generate massive amounts of data. Managing, processing, and analyzing this data effectively is a significant challenge.

- Simulation and Emulation: Due to the complexity and scale of smart grids, realistic simulation and emulation are necessary to test various scenarios without directly impacting the live grid.

Addressing these challenges requires a comprehensive testing strategy involving a combination of laboratory testing, field testing, and simulation.

Q 20. Explain your experience with testing battery energy storage systems (BESS).

My experience with testing Battery Energy Storage Systems (BESS) includes a wide range of tests aimed at verifying performance, safety, and reliability. This encompasses:

- Cycle Life Testing: Evaluating the battery’s ability to withstand repeated charge-discharge cycles over its lifetime. This involves subjecting the battery to numerous cycles under various conditions to assess its degradation rate.

- State of Charge (SOC) and State of Health (SOH) Estimation: Verifying the accuracy of the battery management system in estimating SOC and SOH. Inaccurate estimations can lead to premature battery failure or reduced performance.

- Power and Energy Efficiency Testing: Measuring the battery’s power output, energy efficiency, and round-trip efficiency under various operating conditions.

- Safety Testing: Conducting safety tests to ensure that the BESS operates safely and meets all relevant safety standards. This includes tests for over-current, over-voltage, over-temperature, and short-circuit conditions.

- Thermal Management Testing: Evaluating the effectiveness of the battery’s thermal management system in maintaining optimal operating temperatures.

- Grid Integration Testing: Verifying that the BESS seamlessly integrates with the electrical grid and responds appropriately to grid signals.

For example, in one project, I developed a sophisticated automated test system using LabVIEW to perform cycle life testing on a large-scale BESS. This system enabled continuous monitoring and data logging, providing valuable insights into battery performance and degradation patterns. Thorough documentation and analysis are crucial for identifying potential issues and ensuring the long-term reliability of the system.

Q 21. How do you maintain accurate and organized records during energy testing projects?

Maintaining accurate and organized records during energy testing projects is critical for ensuring traceability, compliance, and facilitating future analysis. My approach utilizes a combination of digital and physical tools to ensure comprehensive record-keeping.

- Centralized Database: I use a centralized database (e.g., relational database or cloud-based solution) to store all test data, including raw data, processed data, test reports, and associated documentation.

- Version Control: Version control systems (like Git) are used to manage test scripts, reports, and other documents, allowing for easy tracking of changes and collaboration among team members.

- Detailed Test Plans and Procedures: Comprehensive test plans and procedures clearly outline the scope, methodology, and acceptance criteria for each test. This ensures consistency and reduces ambiguity.

- Automated Reporting: Automated reporting tools are used to generate standardized reports that summarize test results, including key metrics and any identified issues. This saves time and reduces the risk of human error.

- Physical Documentation: Important physical documents, such as calibration certificates for test equipment, are stored securely and are easily accessible. A comprehensive filing system is essential.

This multi-faceted approach guarantees data integrity, facilitates efficient troubleshooting, and ensures regulatory compliance. The well-organized data archives serve as valuable assets for future reference and analysis, supporting continuous improvement and better decision-making.

Q 22. Describe your experience with analyzing energy consumption data.

Analyzing energy consumption data involves more than just looking at numbers; it’s about understanding the story behind the energy usage. My experience spans various methodologies, from simple data visualization using tools like Excel and Power BI to advanced statistical analysis using Python and R. I’m adept at identifying trends, anomalies, and correlations within datasets to pinpoint areas of inefficiency.

For instance, in a recent project for a large manufacturing facility, we analyzed hourly energy consumption data over a year. By visualizing the data, we identified a significant spike in energy use during night shifts. Further investigation, using statistical methods, revealed a malfunctioning HVAC system as the root cause. This wasn’t immediately apparent from a simple glance at the overall energy consumption figures.

My approach always includes data cleaning, validation, and quality control to ensure accurate analysis. This involves handling missing values, identifying outliers, and correcting inconsistencies. I also consider external factors, like weather patterns and production schedules, to provide a holistic interpretation of the data.

Q 23. How do you identify and mitigate risks associated with energy testing activities?

Risk mitigation in energy testing is paramount. It’s about anticipating potential hazards and implementing preventative measures to ensure safety and project success. Risks can range from equipment malfunctions and electrical hazards to data breaches and environmental impacts.

- Safety Protocols: Before any testing begins, we establish strict safety protocols, including lockout/tagout procedures, personal protective equipment (PPE) requirements, and emergency response plans.

- Equipment Calibration and Maintenance: Regular calibration and maintenance of testing equipment are essential for accurate measurements and to prevent malfunctions that could lead to accidents or inaccurate data.

- Data Security: We protect the confidentiality and integrity of energy data using secure data storage and access control measures.

- Environmental Considerations: We assess environmental impacts of testing activities and implement measures to minimize waste and pollution.

- Risk Assessment Matrix: I routinely utilize a risk assessment matrix to identify potential hazards, their likelihood, and their potential consequences. This allows us to prioritize mitigation efforts.

For example, during load testing on a solar farm, we created a detailed plan that accounted for potential weather changes (wind, rain), ensuring equipment was properly grounded to avoid electrical shocks, and had emergency response personnel on standby.

Q 24. Explain your experience working with different types of energy generation systems.

My experience encompasses various energy generation systems, including:

- Fossil Fuel Power Plants: I’ve worked on testing and performance evaluations of coal, natural gas, and oil-fired power plants, focusing on efficiency improvements and emissions reduction.

- Renewable Energy Systems: I have extensive experience with solar PV systems (including different types of solar panels and inverters), wind turbines (assessing energy output and grid stability), and hydroelectric power plants (evaluating dam efficiency and water flow).

- Nuclear Power Plants: While not directly involved in the core nuclear processes, I’ve worked on testing auxiliary systems and instrumentation in nuclear facilities, emphasizing safety and regulatory compliance.

- Combined Heat and Power (CHP) Systems: I have expertise in evaluating the performance and efficiency of CHP systems, focusing on optimizing both electricity and heat generation.

This diverse experience enables me to understand the unique challenges and opportunities associated with each technology and effectively compare their performance and environmental impacts.

Q 25. Describe your experience with root cause analysis in energy testing.

Root cause analysis (RCA) is critical in identifying the underlying reasons for energy system failures or inefficiencies. My approach typically involves the ‘5 Whys’ technique, coupled with data analysis and fault tree analysis (FTA).

The ‘5 Whys’ method involves repeatedly asking ‘why’ to uncover the root cause, drilling down from the initial symptom to the underlying problem. For example, if a building’s energy consumption is unexpectedly high, we might ask:

- Why is energy consumption high? (Answer: HVAC system is running constantly)

- Why is the HVAC system running constantly? (Answer: Thermostat is malfunctioning)

- Why is the thermostat malfunctioning? (Answer: Sensor is faulty)

- Why is the sensor faulty? (Answer: Sensor wasn’t calibrated properly)

- Why wasn’t the sensor calibrated properly? (Answer: Lack of preventative maintenance schedule)

Fault tree analysis provides a more systematic and visual approach, depicting the various potential causes and their relationships. Combining these techniques with data analysis ensures a thorough and accurate RCA.

Q 26. What is your experience with performing load testing on energy systems?

Load testing on energy systems involves simulating various load conditions to assess the system’s response and capacity. This is critical for ensuring the system can handle peak demand and operate reliably. My experience includes both physical and simulated load testing.

Physical load testing often involves using specialized equipment to gradually increase the load on a system, monitoring its performance parameters (voltage, current, frequency, etc.). This can be done on anything from a single inverter in a solar array to an entire power grid. Safety precautions are paramount.

Simulated load testing utilizes software to create virtual load profiles, allowing us to assess system performance under various scenarios without physically stressing the system. This is particularly useful when physical load testing is impractical or too risky. Software tools like ETAP or PSCAD are often employed.

In one project, we performed load testing on a new microgrid to ensure its stability under various load conditions, including sudden changes in demand. The results helped identify areas for improvement in the system’s design and control strategy.

Q 27. Explain your familiarity with various energy efficiency standards and regulations.

Familiarity with energy efficiency standards and regulations is crucial for effective energy testing and consulting. I’m well-versed in various standards, including:

- ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): Standards for building energy efficiency, HVAC systems, and refrigeration.

- IEC (International Electrotechnical Commission): Standards for electrical equipment, including renewable energy systems.

- IEEE (Institute of Electrical and Electronics Engineers): Standards related to power systems and energy management.

- EPA (Environmental Protection Agency): Regulations related to energy consumption, emissions, and environmental impact.

- Local and Regional Building Codes: Specific requirements for energy efficiency in buildings and installations, often referencing national standards.

Understanding these standards allows us to conduct testing that meets regulatory requirements and ensures that the systems we test are compliant and efficient. This also ensures the recommendations we make are feasible and legal.

Q 28. Describe a challenging energy testing project and how you overcame the obstacles.

One particularly challenging project involved diagnosing intermittent power outages in a remote wind farm. The outages were sporadic and difficult to replicate, making it hard to pinpoint the cause. The remoteness added logistical complications. Initial investigations, focused on individual wind turbines, yielded no conclusive results.

To overcome this, we adopted a multi-pronged approach:

- Comprehensive Data Logging: We installed advanced data loggers on multiple turbines and at the substation to capture detailed information on voltage, current, and other parameters during both normal and outage periods.

- Remote Monitoring and Diagnostics: We utilized remote monitoring software to access real-time data, allowing us to observe the system’s behavior during outages.

- Advanced Signal Processing Techniques: We analyzed the collected data using signal processing techniques to identify subtle patterns and anomalies that might indicate the root cause. This revealed a correlation between outages and specific weather patterns.

- Collaboration and Expertise: We collaborated with meteorological experts to analyze weather data in detail and with turbine manufacturers for insights into the equipment’s behavior. This cross-disciplinary approach was essential.

Ultimately, we discovered that the outages were caused by a combination of high winds and unique electrical characteristics of the specific turbine model, exacerbated by aging infrastructure. Implementing a combination of hardware upgrades, software modifications, and operational adjustments resolved the issues permanently.

Key Topics to Learn for Your Energy Testing Interview

- Electrical Power Systems: Understanding AC/DC circuits, power generation principles (renewable and non-renewable), and transmission/distribution networks is fundamental. Consider practical applications like analyzing power flow and identifying potential faults.

- Instrumentation and Measurement: Mastering the use of various testing equipment (multimeters, oscilloscopes, power analyzers) and understanding their limitations is crucial. Explore practical calibration techniques and data interpretation skills.

- Protection Relay Testing: Familiarize yourself with different types of protection relays and their functions. Understand the testing procedures and the importance of accurate relay settings for grid stability and safety. Consider the practical application of diagnosing relay malfunctions.

- High-Voltage Testing: Learn about different high-voltage testing methods and their applications in ensuring the safety and reliability of power systems. Explore dielectric testing, partial discharge analysis, and insulation resistance measurements.

- Renewable Energy Systems Testing: Gain knowledge about the specific testing requirements for solar PV, wind turbines, and other renewable energy sources. Understanding their unique challenges and testing methodologies is becoming increasingly important.

- Data Analysis and Reporting: Develop strong data analysis skills to interpret test results effectively and prepare comprehensive reports. Practice presenting your findings clearly and concisely.

- Safety Regulations and Standards: Familiarize yourself with relevant safety standards and regulations in energy testing. Understanding these is vital for ensuring safe and compliant testing practices.

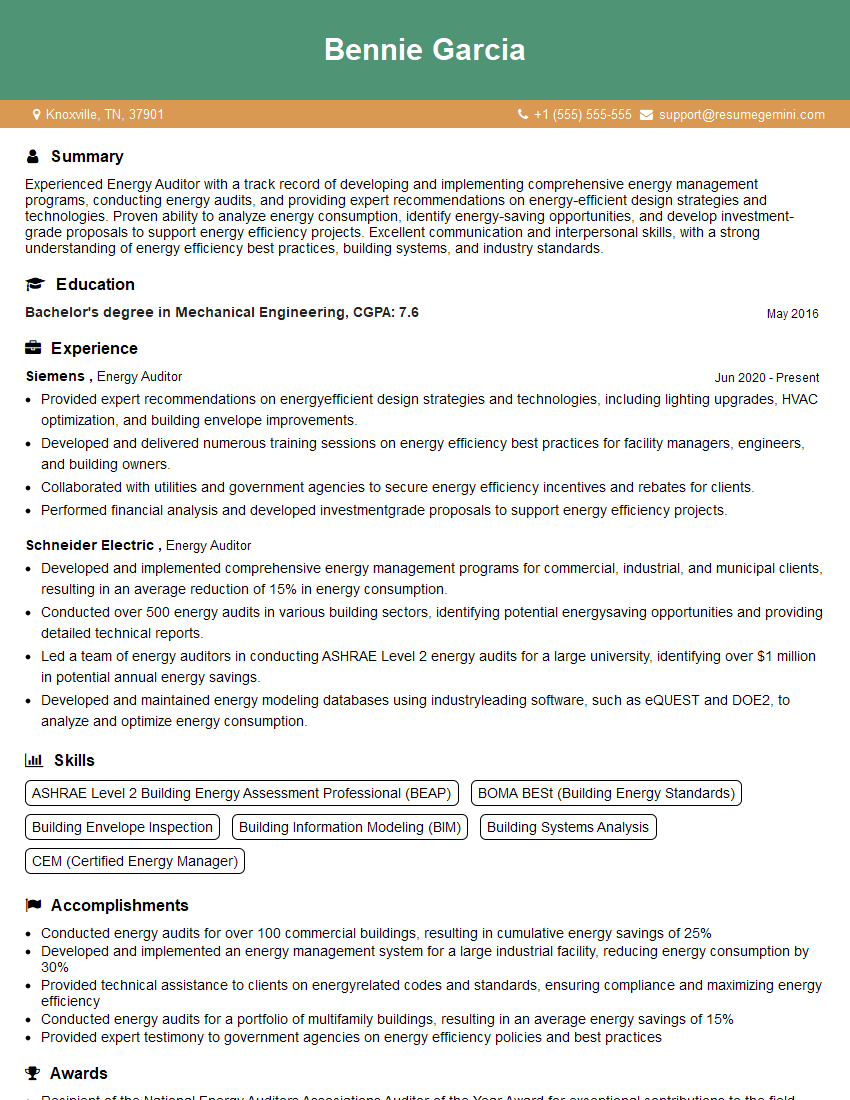

Next Steps: Power Up Your Career

Mastering Energy Testing opens doors to exciting and impactful career opportunities within the rapidly evolving energy sector. To maximize your job prospects, invest in creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that gets noticed. We offer examples of resumes tailored specifically to the Energy Testing field to help you get started. Take the next step towards your dream career – craft a compelling resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good