The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Engineering Simulation Tools (e.g., ANSYS, COMSOL) interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Engineering Simulation Tools (e.g., ANSYS, COMSOL) Interview

Q 1. Explain the difference between FEA and CFD.

FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) are both powerful simulation techniques used in engineering, but they address different physical phenomena. FEA is primarily used to analyze stress, strain, and deformation in solid structures subjected to forces and loads. Think of it like virtually testing the strength of a bridge under traffic. CFD, on the other hand, focuses on fluid flow, heat transfer, and mass transport. Imagine simulating the airflow around an airplane wing or the water flow in a pipe.

In simpler terms, FEA deals with solids and their responses to forces, while CFD deals with fluids and their behavior. While they are distinct, there are cases where they’re coupled – for instance, analyzing the interaction between a fluid flowing past a solid structure (like wind loading on a building).

Q 2. Describe your experience with meshing techniques in ANSYS.

My experience with meshing in ANSYS is extensive. I’ve worked with various meshing techniques, including:

- Structured Meshing: Ideal for simple geometries like cubes or cylinders, providing highly organized elements for efficient calculations. I’ve used this extensively for modeling simple components where accuracy in a specific region isn’t critical.

- Unstructured Meshing: More versatile for complex geometries with curved surfaces and intricate details. This is my go-to method for most real-world components, allowing for accurate representation of design features. I’ve often used this for analyzing complex castings or aerodynamic shapes.

- Hybrid Meshing: Combining structured and unstructured meshes to optimize computational efficiency and accuracy. In this approach, I would create a structured mesh in regions where smoothness is important and an unstructured mesh in intricate areas, improving the overall solution.

Beyond the type of mesh, I’m proficient in controlling mesh density to balance accuracy and computational cost. I use mesh refinement techniques, like adaptive meshing, to focus computational effort on regions with high gradients (like stress concentrations), leading to more precise results without unnecessary computation. I frequently leverage ANSYS’s meshing tools to create high-quality meshes efficiently and effectively.

Q 3. How do you handle convergence issues in a simulation?

Convergence issues are a common challenge in simulations. They indicate that the solution isn’t settling down to a stable answer, often resulting in inaccurate results. My approach to handling convergence problems is systematic:

- Check the Mesh Quality: Poor mesh quality (e.g., excessively skewed elements, high aspect ratios) can be the primary cause. I’d refine the mesh in problematic areas or re-mesh completely if necessary.

- Adjust Solver Settings: This involves modifying parameters like the solver type (implicit vs. explicit), under-relaxation factors, and convergence criteria. Experimentation is key here, but I always document changes and results for traceability.

- Examine Boundary Conditions: Incorrectly defined boundary conditions can severely impact convergence. Double-checking for inconsistencies and ensuring appropriate conditions are essential.

- Review the Model: Sometimes, the problem lies within the model itself—e.g., a poorly defined material property or an unrealistic load case. Carefully reviewing the model assumptions is crucial.

- Consider Using a Different Solver: In stubborn cases, switching to a different solver algorithm may help. For instance, moving from a direct to an iterative solver could prove beneficial in specific scenarios.

For example, I once faced convergence problems in a turbulent flow simulation. After numerous attempts, I realized that the mesh near the wall was too coarse, resulting in inaccurate boundary layer resolution. Refining this mesh region quickly solved the convergence problem.

Q 4. What are the different types of boundary conditions in COMSOL?

COMSOL offers a wide range of boundary conditions, tailored to the diverse physics it can simulate. These conditions dictate how the model interacts with its surroundings. Key types include:

- Dirichlet Boundary Conditions: These specify a fixed value for a variable at the boundary. For example, fixing the temperature of a wall in a heat transfer problem.

- Neumann Boundary Conditions: These specify the flux (rate of flow) of a variable at the boundary. A common example is specifying the heat flux across a boundary.

- Periodic Boundary Conditions: Used when the model exhibits repetitive behavior, like in simulations of a section of a long pipe.

- Symmetry Boundary Conditions: Exploited when the model possesses symmetry, reducing computation time by modeling only a portion of the geometry.

- Radiation Boundary Conditions: Important in thermal simulations to model heat transfer through radiation.

The choice of boundary condition depends entirely on the problem being modeled and the physics involved. Incorrect boundary conditions will severely affect the accuracy and reliability of results.

Q 5. Explain the concept of element types in FEA and their applications.

In FEA, element types represent the mathematical approximations of the geometry and the unknown variables within each element. The choice of element significantly affects the accuracy and efficiency of the simulation. Common element types include:

- Linear Elements: Simplest form, using linear interpolation functions. They’re computationally efficient but may need finer meshing for accurate results in complex geometries. A good choice for preliminary studies.

- Quadratic Elements: More accurate representation compared to linear elements, using quadratic interpolation functions. They require more computational resources but offer better accuracy, particularly for curved geometries.

- Tetrahedral Elements: Suitable for complex 3D geometries. They can easily mesh intricate shapes but can be less efficient than hexahedral elements for the same accuracy.

- Hexahedral Elements: Offer greater accuracy and efficiency than tetrahedral elements, especially for smooth geometries. They are more challenging to generate automatically for complex shapes.

Selecting the appropriate element type depends on factors like the complexity of the geometry, the required accuracy, and computational resources available. For example, I would use quadratic hexahedral elements for a high-fidelity stress analysis of a turbine blade, while linear tetrahedral elements might suffice for a preliminary analysis of a complex casting.

Q 6. How do you validate your simulation results?

Validating simulation results is critical to ensure their reliability. I use a multi-pronged approach:

- Comparison with Experimental Data: The most robust validation method. If experimental data are available (e.g., from physical tests), I compare my simulated results to these measurements. Discrepancies can highlight areas requiring refinement in the model or the simulation setup.

- Mesh Convergence Study: I perform mesh refinement studies to ensure that the solution isn’t sensitive to the mesh density. If refining the mesh doesn’t significantly change the results, it indicates mesh independence, enhancing confidence in the results.

- Benchmarking against Established Solutions: For well-understood problems, I compare my results to established solutions or published data. This helps to identify potential errors or biases.

- Peer Review: Having another engineer review my model and results is invaluable. A fresh perspective can often identify overlooked issues or suggest improvements.

For instance, during a project simulating the heat transfer in a heat exchanger, I compared the simulated temperature profiles with experimental data from a prototype. Minor discrepancies prompted a review of the boundary conditions, leading to a refined model and improved agreement with the experimental data.

Q 7. Describe your experience with different solver types (e.g., implicit, explicit).

I have extensive experience with both implicit and explicit solver types. The choice depends heavily on the nature of the problem:

- Implicit Solvers: Solve for the solution at each time step simultaneously. They’re generally more stable and can handle large time steps. However, each time step requires more computational effort. I typically use implicit solvers for static analyses or quasi-static problems with slow-changing conditions, such as steady-state heat transfer or stress analysis under sustained load.

- Explicit Solvers: Solve for the solution at each time step sequentially. They’re computationally less expensive per time step, making them ideal for problems with short durations or rapid changes, like impact simulations or high-speed fluid flow. However, explicit solvers have stricter stability criteria and often require smaller time steps.

Choosing between them requires careful consideration. An explicit solver might be preferred for a crash simulation due to its efficiency in handling short-duration, high-velocity events. On the other hand, an implicit solver would likely be more appropriate for a long-term creep analysis under sustained load, due to its stability.

Q 8. What are the limitations of FEA?

Finite Element Analysis (FEA) is a powerful tool, but it’s crucial to understand its limitations. It’s a numerical approximation, not an exact solution. Think of it like using LEGOs to build a replica of the Eiffel Tower – you can get pretty close, but it won’t be perfectly identical. The accuracy depends heavily on several factors.

- Model Simplifications: Real-world geometries are complex. FEA often requires simplifying these geometries, potentially leading to inaccuracies. For example, a complex casting might be simplified to a more basic shape.

- Material Properties: The accuracy of the simulation is directly tied to the accuracy of the material properties used. Using inaccurate or incomplete material data will result in inaccurate results.

- Meshing: The quality and density of the mesh directly impact the accuracy of the results. A poorly meshed model can lead to significant errors. This will be discussed further in the next question.

- Boundary Conditions: Improperly defined boundary conditions (how the model interacts with its environment) can significantly skew the results. For instance, incorrectly specifying a fixed support can lead to an overestimation of stiffness.

- Software Limitations: The software itself has limitations in terms of the types of problems it can solve and the level of accuracy it can achieve. Some non-linear phenomena might be difficult to model accurately.

In essence, FEA provides valuable insights, but it’s crucial to validate the results through experimental testing or other verification methods. Understanding and acknowledging these limitations ensures that the results are interpreted responsibly and used appropriately in the design process.

Q 9. How do you choose the appropriate mesh density for a simulation?

Choosing the appropriate mesh density is a critical aspect of FEA. It’s a balance between accuracy and computational cost. A finer mesh (more elements) generally leads to greater accuracy but requires significantly more computational resources and time. A coarser mesh is faster but can sacrifice accuracy. The process typically involves iterative refinement.

Here’s a common approach:

- Start with a coarse mesh: Perform a preliminary simulation to get a general understanding of the stress and strain distribution.

- Refine the mesh in critical areas: Identify regions of high stress gradients or complex geometry. Focus mesh refinement in these areas, leaving coarser meshes in less critical regions.

- Mesh Independence Study: This is crucial! Perform multiple simulations with progressively finer meshes. Compare the results. If the results converge (meaning the changes become negligible with further refinement), you’ve achieved mesh independence – a key indicator that your mesh is sufficiently refined.

- Consider element type: The type of element used (linear, quadratic, etc.) impacts accuracy. Higher-order elements generally provide better accuracy but require more computational resources.

Imagine trying to map a mountain range. A coarse mesh would only capture the broad features. A finer mesh reveals the details of valleys and peaks. The mesh density should reflect the level of detail needed for accurate results. Software often provides tools to visualize mesh quality, aiding in identifying potential issues.

Q 10. Explain the concept of mesh independence.

Mesh independence means that the solution obtained from an FEA simulation is no longer significantly affected by further mesh refinement. It ensures that the results are not artifacts of the mesh itself but rather a true reflection of the underlying physics. Think of it as reaching a point of diminishing returns.

To achieve mesh independence, you conduct a series of simulations with increasingly finer meshes. You then compare key results (e.g., stress values at critical points, displacements) from these simulations. If the differences between the results from successively finer meshes are negligible (typically within a pre-defined tolerance), then you’ve achieved mesh independence. This indicates that your solution has converged, and further refinement is unnecessary.

A mesh independence study is a crucial step in validating FEA results and is essential for demonstrating the reliability and credibility of your analysis.

Q 11. Describe your experience with post-processing simulation results.

Post-processing is where the real insights from an FEA simulation are extracted. My experience spans various software packages like ANSYS and COMSOL, and I’m proficient in extracting meaningful data and visualizing it effectively. This typically involves:

- Data Extraction: Extracting key data points, such as maximum stress, displacement, or temperature, from specific regions of interest.

- Visualization: Creating contour plots, deformed shapes, and animations to visually represent the simulation results and help understand complex phenomena.

- Data Analysis: Analyzing the extracted data to identify critical areas, potential failure points, or areas for design optimization.

- Report Generation: Preparing comprehensive reports with graphical visualizations and detailed analysis to communicate the findings to engineers and stakeholders.

For example, in a recent project analyzing stress in a turbine blade, I used ANSYS to generate contour plots of von Mises stress. This helped pinpoint high-stress regions, enabling design modifications to improve the blade’s fatigue life. I also generated animations demonstrating the blade’s deformation under load, providing a clearer understanding of its dynamic behavior.

Q 12. How do you handle non-linearity in a simulation?

Non-linearity in FEA simulations arises when the material behavior, boundary conditions, or geometry changes significantly during the simulation. This contrasts with linear analysis, where the relationship between cause and effect remains constant. Examples include large deformations, material plasticity (permanent deformation), and contact interactions.

Handling non-linearity requires specialized techniques:

- Non-linear solvers: Using iterative solvers capable of handling the changing relationships during the simulation. These solvers gradually adjust their approach based on the changing conditions.

- Incremental loading: Applying loads in small increments, allowing the solution to converge at each step. This avoids large jumps that can lead to instability.

- Appropriate material models: Utilizing material models that account for non-linear behavior (e.g., plasticity models for metals, hyperelastic models for rubber). The selection of the appropriate material model is crucial for the accuracy of the results.

- Convergence criteria: Defining appropriate convergence criteria to ensure the solution is sufficiently accurate. This often involves monitoring the residuals and ensuring they fall below a specified tolerance.

Imagine bending a paperclip – initially, the relationship between force and deformation is relatively linear. However, as you bend it further, the material starts to yield, demonstrating non-linear behavior. Accurately simulating this requires a non-linear analysis.

Q 13. What are some common errors encountered in FEA/CFD simulations?

Common errors in FEA/CFD simulations often stem from seemingly small mistakes with significant consequences. Some frequent issues include:

- Meshing errors: Poorly shaped elements (e.g., highly skewed or distorted elements), insufficient mesh density in critical areas, or improper element type selection. These can introduce numerical errors and affect the solution’s accuracy.

- Boundary condition errors: Incorrectly specified boundary conditions (e.g., wrong support conditions, incorrect loads, or inappropriate symmetry assumptions) can drastically change the results. A simple mistake here can lead to completely unreliable results.

- Material property errors: Using incorrect material properties, neglecting temperature dependence, or failing to account for anisotropy can lead to inaccurate results. The material model used is crucial and a wrong choice will invalidate the results.

- Solver convergence issues: The simulation may fail to converge due to the model’s complexity, poor mesh quality, or inappropriate solver settings. This requires careful examination of the model and the solver parameters.

- Interpretation errors: Misinterpreting the results due to lack of understanding of the underlying physics or limitations of the simulation. This requires a solid understanding of both the simulation software and the physical phenomenon being analyzed.

Rigorous quality checks, thorough validation, and a deep understanding of the simulation process are crucial to minimize these errors and ensure the reliability of FEA/CFD results.

Q 14. How do you determine the appropriate material properties for your simulation?

Determining appropriate material properties is paramount for accurate simulation. The process involves careful consideration of several factors:

- Material Selection: First, you need to identify the exact material being used in the real-world component. This often involves checking material datasheets or conducting experimental tests.

- Material Properties: Once the material is identified, gather its relevant properties. These vary depending on the simulation type. For structural analysis, you’ll need Young’s modulus (elasticity), Poisson’s ratio, yield strength, and density. For thermal analysis, you’ll need thermal conductivity, specific heat, and thermal expansion coefficient.

- Temperature Dependence: Many material properties are temperature-dependent. Account for these variations if the simulation involves significant temperature changes. Interpolation of data might be necessary here.

- Non-linear Behavior: If non-linear material behavior is expected (plasticity, creep, etc.), utilize appropriate material models that capture this behavior accurately. For example, the Johnson-Cook model is often used for high-strain-rate applications.

- Data Validation: Whenever possible, compare the chosen material properties with experimental data to verify their accuracy. This cross-validation is critical for building confidence in the simulation results.

For instance, simulating a plastic part requires accurate values for its yield strength and Young’s modulus. Using inaccurate values could lead to an overestimation or underestimation of the part’s deformation under load, potentially resulting in incorrect design decisions.

Q 15. Describe your experience with scripting or automation in ANSYS or COMSOL.

Scripting and automation are crucial for efficiency and repeatability in FEA. In ANSYS, I extensively use APDL (ANSYS Parametric Design Language) to automate mesh generation, solve multiple simulations with varying parameters, and post-process results. For example, I’ve created APDL scripts to automate the analysis of a series of turbine blades with different airfoil profiles, generating a comprehensive performance comparison report automatically. In COMSOL, the built-in Java scripting capabilities and the Application Builder allow similar automation. I’ve used these to create custom user interfaces for complex multiphysics simulations, simplifying the workflow for less experienced users and streamlining analyses involving coupled phenomena like thermal-structural interactions in electronic devices. Imagine needing to simulate 100 variations of a heat sink design – scripting reduces this from a tedious manual process to an automated overnight run.

For both platforms, I prefer a modular approach, breaking down complex tasks into smaller, reusable functions. This makes debugging and maintenance much easier. Version control is also essential; I utilize Git to track changes and collaborate effectively on large scripting projects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the difference between static and dynamic analysis.

Static analysis simulates structures under constant loads. Think of it like examining a bridge under its own weight and the weight of cars – the loads don’t change over time. The results provide displacements, stresses, and strains at a specific point in time. Dynamic analysis, on the other hand, considers loads that vary with time. This could be an earthquake acting on a building, or the vibrations of an engine component. Dynamic analysis provides time-history responses, allowing us to understand how a structure behaves under transient loads. Further, dynamic analysis can uncover resonant frequencies and mode shapes, which are critical for assessing the structural integrity of systems subject to vibrations.

An example of static analysis would be determining the stress distribution in a bridge under a constant load. In contrast, dynamic analysis would be used to analyze the response of a building during an earthquake, revealing how the structure vibrates and the peak stresses experienced.

Q 17. How do you handle contact problems in FEA?

Contact problems are among the most challenging aspects of FEA. They involve two or more bodies interacting, with forces transmitted across their surfaces. Handling them correctly requires careful consideration of several factors. First, you need to define the contact type: bonded, frictionless, or frictional. Then, you must specify the contact algorithm. ANSYS and COMSOL offer various algorithms (e.g., penalty method, Lagrange multipliers), each with its strengths and weaknesses. The choice depends on the problem’s complexity and the desired accuracy. For example, a penalty method is simpler but might introduce some numerical stiffness, while a Lagrange multiplier method is more accurate but computationally more expensive.

Meshing is also crucial. A fine mesh in the contact region is essential for accurate results. The contact elements themselves should be chosen appropriately to correctly model the interaction. Finally, convergence is often a challenge with contact problems. You might need to adjust solver parameters, such as tolerances and iterative schemes, to obtain reliable solutions. For instance, when simulating the assembly of two parts, careful definition of contact surfaces, appropriate friction coefficients, and iterative solver adjustments are critical to accurately capture the forces and deformations during the assembly process.

Q 18. Explain the concept of modal analysis.

Modal analysis determines the natural frequencies and mode shapes of a structure. Imagine a guitar string – it vibrates at specific frequencies, producing different musical notes. These frequencies are the natural frequencies, and the shape of the vibrating string is its mode shape. In engineering, modal analysis is critical for avoiding resonance, a phenomenon where external vibrations match a structure’s natural frequencies, leading to catastrophic failures. For example, a bridge can collapse if subjected to wind forces that match its natural frequencies. The results of a modal analysis are typically presented as a table of frequencies and a visualization of the corresponding mode shapes.

In practice, I’ve used modal analysis extensively to ensure that the design of a component doesn’t coincide with excitation frequencies that might be present during operation, and to evaluate the robustness of structures under dynamic loads. Imagine designing a turbine blade; modal analysis allows you to verify that no operational frequencies will lead to resonant vibrations and potential damage.

Q 19. Describe your experience with optimization techniques in simulation.

Optimization techniques are used to find the best design parameters that satisfy specific objectives while meeting constraints. I have experience with both gradient-based and gradient-free optimization methods. Gradient-based methods, like those available in ANSYS and COMSOL’s optimization modules, are efficient when gradients are readily available but may get stuck in local optima. Gradient-free methods, such as genetic algorithms, are more robust but can be computationally expensive. The choice depends on the problem’s complexity and the availability of gradient information.

For instance, I’ve used topology optimization to design lightweight yet strong components, achieving significant weight reduction while maintaining structural integrity. In another project, I used parameter optimization to determine the optimal dimensions of a heat exchanger, maximizing its efficiency while satisfying constraints on size and pressure drop. These methodologies reduce reliance on trial-and-error, leading to efficient and optimized designs.

Q 20. What are the advantages and disadvantages of using different element types (e.g., tetrahedral, hexahedral)?

The choice between element types (tetrahedral vs. hexahedral) significantly impacts the accuracy and efficiency of FEA. Hexahedral elements (bricks) are generally preferred because they provide better accuracy with fewer elements due to their regular shape. They offer better stress predictions, particularly in bending-dominated situations. However, hexahedral meshing can be challenging, especially for complex geometries. Tetrahedral elements (pyramids) are easier to generate automatically, even for complex shapes. This makes them convenient for quick mesh generation. However, they require a higher number of elements to achieve the same accuracy as hexahedral elements, potentially increasing computational cost and introducing more numerical error.

Imagine modeling a simple rectangular block: Hexahedral elements would provide more accurate results with fewer elements. However, for a complex shape such as a car chassis, automatically generated tetrahedral elements might be more practical although accuracy might demand more elements and computational resources. The choice often involves a trade-off between accuracy, meshing difficulty, and computational cost.

Q 21. How do you ensure the accuracy of your simulation results?

Ensuring the accuracy of simulation results is paramount. My approach involves a multi-pronged strategy: First, I meticulously check the model’s geometry and mesh quality. Poor mesh quality can introduce significant errors. I examine element aspect ratios, skewness, and Jacobian values. Next, I validate the model against experimental data or analytical solutions whenever possible. This helps determine the reliability of my simulation setup and results. A comparison between experimental and simulation results provides insights into the model’s accuracy.

Mesh convergence studies are crucial; I refine the mesh until the results stabilize, indicating that the solution is not significantly affected by mesh density. Additionally, I carefully select appropriate material properties and boundary conditions. Lastly, I always critically evaluate the results, looking for any anomalies or inconsistencies that might indicate errors in the model or simulation setup. Through this combined approach I build trust in the final results to inform the design and engineering decisions.

Q 22. Describe your experience with multiphysics simulations.

Multiphysics simulations involve solving equations that govern multiple physical phenomena simultaneously. Imagine a scenario where you’re designing a heat sink for an electronic component. It’s not just about heat transfer; the material might deform under thermal stress (structural mechanics) and the heat transfer itself could involve fluid flow (CFD). Multiphysics simulations in tools like ANSYS and COMSOL allow us to couple these different physics together, providing a much more realistic and accurate prediction than solving each individually.

My experience spans several applications, including:

- Fluid-Structure Interaction (FSI): Modeling blood flow through arteries, considering the elasticity of the vessel walls.

- Thermal-Electric Coupling: Simulating the performance of a solar cell, considering both the heat generation and the electrical current produced.

- Electromagnetics-Fluid Dynamics: Analyzing the behavior of a liquid metal under an electromagnetic field, as seen in some fusion reactor designs.

I’ve extensively used COMSOL’s coupled solver capabilities and ANSYS’s Workbench platform for these simulations, leveraging their capabilities to manage complex meshing and solver settings for accurate results.

Q 23. Explain your understanding of different turbulence models in CFD.

Turbulence models in Computational Fluid Dynamics (CFD) are essential for handling turbulent flows, which are chaotic and highly unpredictable. Directly simulating turbulence is computationally extremely expensive, so we use models to approximate its effects. These models are mathematical representations of the turbulent stresses.

Some common turbulence models include:

- Spalart-Allmaras (SA): A one-equation model suitable for aerospace applications, especially boundary layer flows. It’s computationally less expensive but less accurate than other models.

- k-ε (k-epsilon): A two-equation model using turbulence kinetic energy (k) and its dissipation rate (ε). It’s a widely used and relatively robust model suitable for a wide range of flows.

- k-ω (k-omega): Another two-equation model using turbulence kinetic energy (k) and its specific dissipation rate (ω). It’s generally better at resolving near-wall flows than k-ε but can be more sensitive to mesh resolution.

- Reynolds Stress Models (RSM): These are more complex and computationally expensive models that directly solve for the Reynolds stresses. They provide the most accurate predictions but demand significant computational resources.

The choice of model depends heavily on the specific flow characteristics, computational resources, and desired accuracy. For example, I’d use SA for a relatively simple external aerodynamics simulation but opt for k-ω SST (Shear Stress Transport) for a more complex internal flow with strong boundary layers.

Q 24. How do you select appropriate solver settings for a given problem?

Selecting appropriate solver settings is crucial for obtaining accurate and efficient simulation results. It’s like choosing the right tools for a job – the wrong tools can lead to inaccurate or incomplete results.

My approach involves a combination of understanding the problem’s physics, examining the mesh quality, and experimenting with different settings. Here’s a step-by-step guide:

- Understanding the Problem: Identify the dominant physical phenomena and potential numerical challenges (e.g., high Reynolds number, sharp gradients).

- Mesh Assessment: Ensure the mesh is appropriate for the problem. A finer mesh is usually needed in regions with high gradients. Checking mesh quality metrics (skewness, aspect ratio) is critical.

- Solver Type Selection: Choose a suitable solver (e.g., pressure-based or density-based for CFD). Pressure-based is generally more stable for incompressible flows while density-based is more suitable for compressible flows.

- Convergence Criteria: Define appropriate convergence criteria. This could involve monitoring residuals of the governing equations or other relevant quantities. Too loose a criteria can lead to inaccurate results, while too strict could lead to unnecessary computational cost.

- Linear Solver Settings: Select a suitable linear solver (e.g., BiCGSTAB, GMRES) and preconditioner (e.g., ILU, incomplete LU factorization) based on the problem and solver type. Experimentation with different settings is often required.

- Time Stepping (for transient simulations): Choose an appropriate time step size. Too large a time step can lead to instability and inaccurate results; too small a time step can be computationally expensive.

- Iterative Approach: Begin with a simpler setting and progressively refine them based on the results and convergence behavior. Monitor residuals and solution quality closely throughout the simulation.

For instance, when simulating a high-speed compressible flow, I would use a density-based solver with an appropriate scheme for capturing shocks (e.g., Roe’s scheme), a smaller time step, and a robust linear solver.

Q 25. Describe your experience with experimental verification of simulation results.

Experimental verification is essential for validating simulation results and building confidence in their accuracy. It’s like testing a recipe – you need to cook it and taste it to confirm it’s good.

My experience includes various methods, such as:

- Comparing Simulation Data with Experimental Measurements: For example, in a heat transfer simulation, I would compare the predicted temperatures at various locations with experimentally measured temperatures. Any significant discrepancy would trigger a review of the model, mesh, and solver settings.

- Designing Experiments for Validation: This sometimes involves designing specific experiments to gather data needed to validate specific aspects of the simulation. For example, conducting wind tunnel tests to validate a CFD model of an airfoil.

- Uncertainty Quantification: Analyzing the uncertainty in both the simulation and experimental data to quantify the agreement (or disagreement) between them.

I’ve worked on projects where we used particle image velocimetry (PIV) to measure velocity fields in a fluid flow and compared them to our CFD simulations. This comparison highlighted areas where the model needed refinement and gave us valuable insights into the flow physics.

Q 26. Explain the role of boundary layers in CFD simulations.

Boundary layers are thin regions near solid surfaces where the fluid velocity changes rapidly from zero at the wall (no-slip condition) to the free-stream velocity. Imagine a river flowing – the water near the riverbed moves much slower than the water in the middle.

In CFD simulations, accurately resolving the boundary layer is crucial because:

- Drag and Heat Transfer: The boundary layer significantly affects drag and heat transfer between the fluid and the solid surface. Inaccurate boundary layer resolution leads to inaccurate predictions of these important parameters.

- Flow Separation: Boundary layer separation can lead to flow instability and significant changes in drag and lift. Proper resolution is needed to capture this phenomenon.

- Turbulence: Turbulence often originates in the boundary layer, and accurate resolution is vital for using turbulence models correctly.

Mesh refinement near walls is often necessary to properly resolve the boundary layer. Techniques like y+ refinement (ensuring the first cell height satisfies a specific criterion related to the Reynolds number and turbulence model) are commonly used to ensure accurate boundary layer resolution. Failing to resolve the boundary layer adequately can lead to substantial errors in the simulation results.

Q 27. How would you approach simulating a complex geometry?

Simulating complex geometries presents significant challenges in mesh generation and solver performance. A straightforward approach is often insufficient.

My approach to simulating complex geometries involves these steps:

- Geometry Simplification (if appropriate): If the geometry allows, simplifying certain less critical features can significantly reduce the computational cost without compromising accuracy. For example, small fillets or surface details may be simplified.

- Meshing Strategy: The choice of meshing technique is crucial. Structured meshes can be efficient for simple geometries, but unstructured or hybrid meshes are generally needed for complex shapes. Adaptive mesh refinement can also help focus computational resources on critical areas.

- Mesh Quality Control: Thoroughly checking the mesh quality is essential. High-quality meshes with appropriate aspect ratios and skewness are crucial for accurate and stable solutions. Poor mesh quality can lead to inaccurate results or solver convergence issues.

- Solver Settings: Choosing appropriate solver settings (as previously discussed) is equally critical for complex geometries. Robust solvers and preconditioners are often necessary to achieve convergence.

- Mesh Independence Study: Conducting a mesh independence study is a necessary step to ensure the results are not overly dependent on the mesh resolution. This involves running the simulation with successively finer meshes and verifying that the solution converges to a stable value.

- Parallel Computing: For very complex geometries, parallel computing is often essential to reduce computation time.

For example, when simulating the flow through a heat exchanger with intricate internal structures, I’d use an unstructured mesh, adaptive mesh refinement in the critical areas (where flow features change rapidly), and parallel computing on a high-performance cluster.

Q 28. What are your preferred methods for visualizing simulation data?

Effective visualization is key to understanding and interpreting simulation results. It allows us to transform complex numerical data into easily digestible visual representations.

My preferred methods include:

- Contour Plots: These are excellent for visualizing scalar fields (like pressure, temperature, or concentration) over a 2D or 3D domain. They clearly show variations in the quantity of interest.

- Vector Plots: These are useful for visualizing vector fields (like velocity or magnetic fields), showing the magnitude and direction of the field at each point.

- Streamlines and Streaklines: These show the path of fluid particles, providing a clear visualization of flow patterns.

- Slice Plots and Iso-surfaces: These allow for examining the internal structure of a 3D model by extracting data along specific planes or surfaces.

- Animations: Animations provide a dynamic view of transient simulations, showing how quantities evolve over time.

I frequently use ANSYS’s post-processing tools, which offer a wide range of visualization options. I also utilize Python libraries like Matplotlib and Mayavi for creating custom visualizations and generating high-quality figures for reports and presentations.

For example, I might create an animation showing the temperature distribution in a heat sink over time to understand how it cools down, or I might use a contour plot of pressure to identify regions of high pressure buildup in a complex flow.

Key Topics to Learn for Engineering Simulation Tools (e.g., ANSYS, COMSOL) Interview

- Fundamentals of Finite Element Analysis (FEA): Understanding the underlying principles of FEA, meshing techniques, element types, and their applications in different engineering disciplines.

- Software-Specific Modules (ANSYS/COMSOL): Become proficient in at least one core module relevant to your target role (e.g., structural mechanics, fluid dynamics, electromagnetics). Practice setting up simulations, running analyses, and interpreting results.

- Meshing Strategies: Learn about different meshing techniques (structured, unstructured, adaptive), their advantages and disadvantages, and how to optimize meshing for accuracy and efficiency. Understand mesh convergence studies.

- Boundary Conditions and Load Cases: Master the application of appropriate boundary conditions and load cases to accurately represent real-world engineering problems. This includes understanding different types of loads, constraints, and their impact on simulation results.

- Post-Processing and Result Interpretation: Develop strong skills in visualizing and interpreting simulation results. Learn to identify critical data points, trends, and potential design flaws.

- Validation and Verification: Understand the importance of validating simulation results against experimental data and verifying the accuracy of the simulation process itself. Discuss methods for ensuring reliable results.

- Practical Applications: Be prepared to discuss real-world applications of simulation tools in your field of interest, including specific examples from your projects or coursework.

- Problem-Solving Approaches: Highlight your ability to troubleshoot simulation errors, refine models, and interpret complex results to arrive at meaningful conclusions.

- Advanced Topics (depending on the role): Consider exploring topics like optimization techniques, coupled-physics simulations, or specific industry-standard modeling practices.

Next Steps

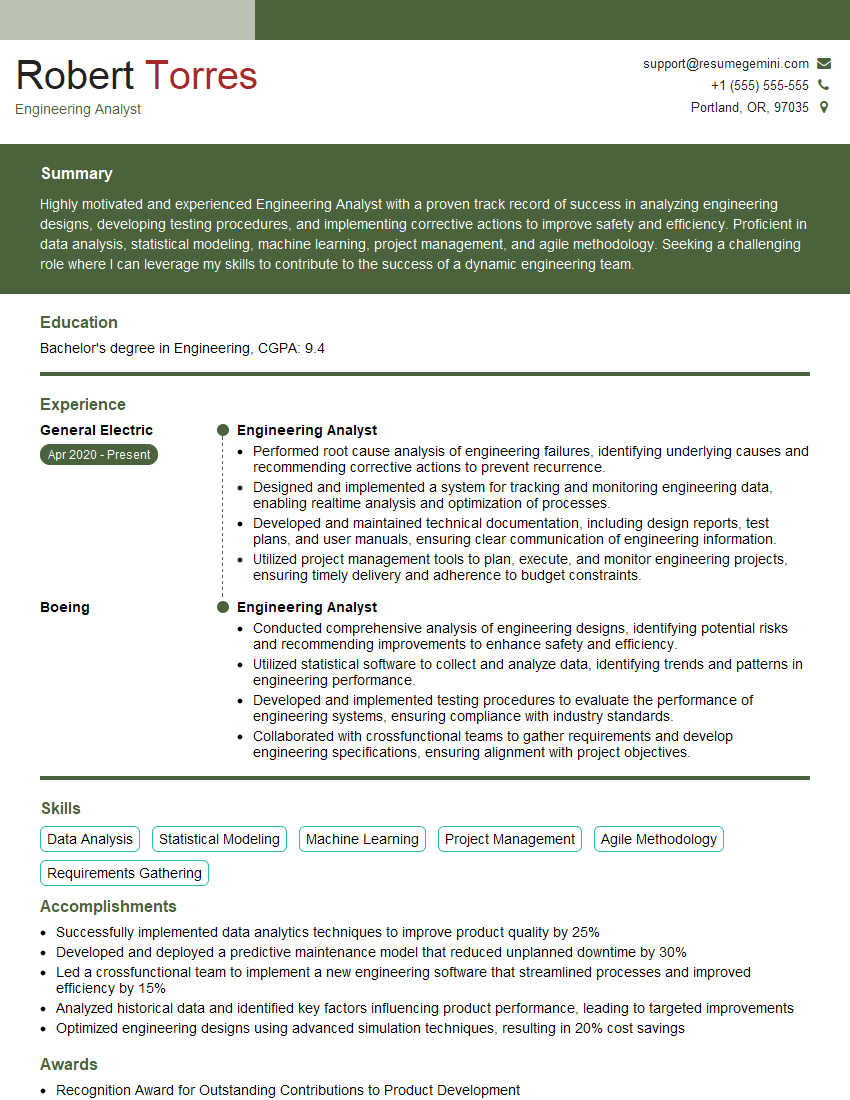

Mastering engineering simulation tools like ANSYS and COMSOL is crucial for career advancement in today’s competitive engineering landscape. These skills demonstrate proficiency in cutting-edge technologies and enable you to contribute significantly to product development and innovation. To maximize your job prospects, create an ATS-friendly resume that clearly highlights your expertise. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your skills and experience. Examples of resumes tailored to Engineering Simulation Tools (e.g., ANSYS, COMSOL) are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good