Unlock your full potential by mastering the most common Equipment Inspection and Safety Checks interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Equipment Inspection and Safety Checks Interview

Q 1. Describe your experience conducting equipment inspections.

My experience in conducting equipment inspections spans over ten years, encompassing a wide range of machinery across diverse industrial settings. I’ve worked with everything from basic hand tools to complex automated systems, including forklifts, cranes, presses, and conveyor belts. My inspections follow a structured methodology, always beginning with a thorough review of the equipment’s operational manuals and any existing safety protocols. I then perform a visual inspection, checking for wear and tear, loose components, and any signs of damage. This is followed by functional testing, where applicable, to ensure the equipment operates as intended. I meticulously document all findings, including photographs and detailed descriptions, using a standardized reporting system.

For instance, during an inspection of a forklift, I would check the hydraulic fluid levels, tire condition, seatbelt functionality, the horn, lights, and overall structural integrity. Any deviations from the norm are documented and flagged for immediate attention. This systematic approach ensures comprehensive coverage and prevents potential hazards.

Q 2. What safety regulations are you most familiar with?

I’m highly familiar with a broad spectrum of safety regulations, including OSHA (Occupational Safety and Health Administration) standards in the United States, and equivalent regulations in other jurisdictions. This includes regulations pertaining to lockout/tagout procedures (ensuring machinery is properly isolated before maintenance), personal protective equipment (PPE) requirements (ensuring workers use appropriate safety gear), machine guarding (preventing access to hazardous moving parts), and hazard communication (clear labeling of chemicals and potential risks). My knowledge also extends to specific industry regulations and best practices relevant to the equipment being inspected, such as those set by ANSI (American National Standards Institute) for various types of machinery.

Staying updated on these regulations is crucial, as they evolve with technological advancements and safety improvements. I regularly attend industry conferences and training sessions to maintain proficiency and ensure my inspections comply with the latest standards.

Q 3. Explain your process for identifying and reporting safety hazards.

My process for identifying and reporting safety hazards is methodical and thorough. It begins with a keen observation during the inspection process. I look for anything out of the ordinary, any signs of damage, wear, or misuse. For example, frayed electrical cords, damaged guarding, leaking fluids, or improperly stored materials are red flags. Once a potential hazard is identified, I carefully assess its severity and potential impact. This assessment considers factors such as the likelihood of an incident occurring and the potential consequences if it does.

After the assessment, I immediately report the finding using the designated reporting system. This usually involves filling out a detailed report, including photographs or videos as evidence. The report outlines the hazard, its location, severity, and any recommended corrective actions. The report is then escalated to the appropriate personnel for immediate remediation. Timely reporting is critical, especially for critical hazards, to prevent accidents and injuries.

Q 4. How do you prioritize inspections based on risk assessment?

Prioritizing inspections based on risk assessment is paramount. I use a risk matrix to categorize equipment and tasks based on the likelihood of an incident and the severity of its potential consequences. The matrix typically involves assigning numerical scores to both likelihood and severity, multiplying them to determine a risk score. Equipment with higher risk scores receives more frequent and thorough inspections.

For example, equipment with a history of malfunctions or that operates in high-risk environments (like working at heights) will be inspected more frequently than equipment with a low risk profile. This approach ensures that resources are allocated efficiently to address the most significant safety concerns first, minimizing potential harm.

Q 5. What are the key components of a comprehensive equipment inspection checklist?

A comprehensive equipment inspection checklist typically includes several key components. First, it must identify the equipment being inspected and the date of inspection. Second, it includes a section for visual inspection, covering items such as structural integrity, wear and tear on components, and the condition of safety devices (e.g., emergency stops, guards). Third, it includes a section for functional testing, verifying that safety mechanisms work correctly. Next, it should document fluid levels (oil, hydraulic fluid, coolant), electrical systems (wiring, connections, grounding), and moving parts (lubrication, wear). Finally, the checklist provides space for recording observations, findings, and recommendations for corrective actions. It also includes a section for the inspector’s signature and the date of completion. The checklist should be tailored to the specific type of equipment being inspected.

Q 6. How do you ensure the accuracy and reliability of your inspection findings?

Ensuring accuracy and reliability of inspection findings involves several steps. First, I use calibrated measuring instruments whenever possible. Second, I always double-check my measurements and observations, comparing them to relevant standards and specifications. Third, I maintain meticulous documentation, including photographs and detailed descriptions of any identified issues. Fourth, I use a standardized reporting format to maintain consistency and clarity in my findings. Fifth, I regularly review and update my inspection procedures to incorporate any new safety guidelines or technological advancements. Finally, periodically, an independent review of my inspection reports is conducted to ensure accuracy and identify any areas for improvement.

Think of it like a scientific experiment: rigorous methodology, precise measurements, and documented processes ensure reliable results.

Q 7. Describe a situation where you had to make a critical safety decision during an inspection.

During an inspection of a large industrial crane, I noticed significant corrosion on a critical support beam. While the crane was still operational, the level of corrosion was beyond acceptable limits, posing a significant risk of catastrophic failure.

My immediate action was to immediately shut down the crane, preventing further use. I documented my findings extensively, including photographs, and immediately notified my supervisor and the site safety manager. This resulted in the crane being taken out of service for immediate repair. This quick action prevented a potentially serious accident involving heavy lifting operations and considerable potential property damage or even injury. The proactive approach, based on my experience and thorough inspection, prevented a major safety incident. It clearly demonstrated the importance of vigilant inspection and decisive action when critical safety risks are identified.

Q 8. What methods do you use to document your inspection findings?

Documenting inspection findings is crucial for maintaining a clear record of equipment condition and ensuring accountability. My approach involves a multi-faceted system, prioritizing accuracy and ease of access.

Firstly, I always use a standardized checklist, tailored to the specific equipment being inspected. This ensures consistency and avoids overlooking critical areas. Each checklist item includes space for detailed observations, including photographs or sketches where necessary.

Secondly, I utilize digital reporting tools. This might involve a dedicated inspection software application or even a simple spreadsheet, depending on the project. Digital documentation offers benefits like easy sharing, searchability, and version control. For example, I might use a software that allows me to generate reports with embedded images, measurements and automatically create a timestamp of the inspection.

Finally, I maintain a detailed filing system—both digital and physical—to ensure easy retrieval of reports. The system is organized by equipment type, date, and inspector for optimal searchability. This is crucial for tracking equipment history and identifying trends in maintenance needs.

Q 9. How familiar are you with different types of non-destructive testing (NDT)?

My familiarity with Non-Destructive Testing (NDT) methods is extensive. I’m proficient in several techniques, understanding their applications, limitations, and interpretation of results. This includes:

- Visual Inspection (VT): A fundamental method, often the first step, involving a thorough visual examination for surface defects like cracks, corrosion, or wear.

- Liquid Penetrant Testing (LPT): Used to detect surface-breaking flaws in non-porous materials. A penetrant is applied, excess is removed, and a developer reveals any indications of cracks.

- Magnetic Particle Testing (MT): Ideal for ferromagnetic materials, MT uses magnetic fields to detect surface and near-surface flaws. Particles applied to the surface are attracted to magnetic flux leakage around defects.

- Ultrasonic Testing (UT): Employing high-frequency sound waves, UT can detect internal flaws like cracks, voids, or inclusions. It’s particularly valuable for inspecting thicker components.

- Radiographic Testing (RT): Using X-rays or gamma rays, RT allows for the detection of internal flaws. The resulting radiographs provide a visual representation of the internal structure.

I understand the importance of selecting the appropriate NDT method based on the material, component geometry, and type of defect being sought. I also adhere strictly to safety protocols associated with each technique.

Q 10. What are the common causes of equipment failure and how can they be prevented?

Equipment failure stems from various factors, and understanding these is vital for preventative maintenance. Common causes include:

- Wear and Tear: Normal usage leads to gradual degradation of components, especially moving parts. Regular lubrication and component replacement can mitigate this.

- Corrosion: Environmental factors like moisture, chemicals, and temperature fluctuations can cause corrosion, weakening materials and leading to failures. Protective coatings and proper storage are key.

- Overloading: Operating equipment beyond its designed capacity creates excessive stress, leading to premature failure. Careful adherence to operational limits is essential.

- Improper Maintenance: Neglecting regular maintenance tasks significantly increases the risk of failure. A well-defined preventative maintenance program is crucial.

- Operator Error: Incorrect operation or misuse can cause immediate or long-term damage. Proper training and adherence to safety procedures are necessary.

- Material Defects: Flaws in the manufacturing process can lead to weak points in the equipment, increasing the likelihood of failure. Thorough quality control is necessary.

Preventing these failures involves a comprehensive approach that includes regular inspections, preventative maintenance, operator training, and adherence to safety standards. For example, implementing a condition-based maintenance program using vibration analysis to detect wear before it leads to critical failure can avoid costly shutdowns and improve equipment longevity.

Q 11. Explain your experience using inspection tools and equipment (e.g., calipers, gauges, etc.).

I possess extensive experience using a variety of inspection tools and equipment, including:

- Calipers: For precise measurements of dimensions, ensuring components are within tolerance.

- Micrometers: For highly accurate measurements of smaller components and verifying tolerances.

- Gauges: Used for checking specific dimensions, such as bore diameter or shaft diameter, to ensure they meet specifications.

- Thickness Gauges: To measure the thickness of materials, particularly relevant for assessing corrosion or wear.

- Level gauges: For ensuring fluid levels are within the acceptable range in tanks or reservoirs.

- Leak detectors: Used to identify and locate leaks in pipelines or equipment.

I understand the importance of proper calibration of these tools to ensure accurate measurements. My experience includes using both analog and digital instruments, and I am adept at interpreting the readings and documenting them accurately. For example, when inspecting a bearing, I might use a micrometer to measure the shaft diameter and then compare it to the bearing’s internal diameter to check for proper fit and detect any wear. Any discrepancies would be documented and analyzed.

Q 12. How do you handle discrepancies between your inspection findings and documented standards?

Discrepancies between my inspection findings and documented standards are addressed systematically. First, I meticulously re-check my measurements and observations to rule out any errors on my part. I will often enlist a second inspector to double check.

If the discrepancy persists, I thoroughly investigate the potential causes. This could involve reviewing maintenance records, comparing the equipment’s current condition to previous inspections, or even consulting technical documentation. Sometimes, the documented standard itself might need revision or clarification.

Once the cause of the discrepancy is understood, I document all findings and recommendations. This documentation will include detailed explanations, photographs, and suggested corrective actions. This report will then be reviewed by supervisors and the necessary action (repairs, replacement parts, or updates to standards) are prioritized and undertaken. Communication throughout this process is vital to ensure transparency and efficient resolution.

Q 13. How do you ensure effective communication of inspection results to relevant personnel?

Effective communication of inspection results is critical for safety and operational efficiency. My approach involves:

- Clear and concise reporting: Using standardized report formats that highlight key findings and recommendations in an easy-to-understand manner.

- Targeted communication: Directing the report to the appropriate personnel, such as maintenance teams, supervisors, or management, depending on the severity and nature of the findings.

- Visual aids: Incorporating photographs, diagrams, and other visual aids to enhance understanding and clarity.

- Verbal follow-up: When necessary, providing a verbal explanation of the report’s findings, particularly in cases requiring urgent attention or complex issues.

- Formal documentation trail: Maintaining a clear record of all communications, including emails, reports, and meeting minutes to ensure accountability.

For example, if a critical safety issue is identified, I’ll immediately communicate it verbally to the appropriate personnel and follow up with a detailed written report to initiate corrective action. This ensures that timely action is taken to mitigate any risks.

Q 14. What is your experience with preventive maintenance programs?

My experience with preventative maintenance programs is extensive. I understand that preventative maintenance is far more cost-effective and safer than reactive maintenance. My experience involves designing, implementing, and monitoring preventative maintenance programs across various equipment types.

This includes developing schedules based on manufacturers’ recommendations, operational requirements, and risk assessments. I understand the concept of condition-based maintenance which can help avoid unnecessary scheduled work. My work also involves training personnel on proper maintenance procedures and monitoring the effectiveness of the programs through data analysis. The data collected helps refine schedules and allocate resources more efficiently.

I’ve been involved in creating software-based preventative maintenance programs that make tracking maintenance activities, generating reports and managing spare parts much easier. These programs enable proactive measures, reducing downtime and improving overall equipment reliability. For example, using data-driven insights to predict potential equipment failures based on historical data leads to more timely interventions and minimizes unforeseen breakdowns.

Q 15. Describe your knowledge of relevant safety standards (e.g., OSHA, ISO).

My understanding of safety standards is comprehensive, encompassing both national regulations like OSHA (Occupational Safety and Health Administration) in the US and international standards like ISO 45001 (Occupational health and safety management systems). OSHA sets specific requirements for workplace safety, covering aspects relevant to equipment inspection, such as lockout/tagout procedures, personal protective equipment (PPE) usage, and hazard communication. ISO 45001 provides a framework for establishing, implementing, and maintaining an occupational health and safety management system, guiding a proactive approach to risk identification and control. For example, I’m intimately familiar with OSHA’s regulations regarding the inspection and maintenance of powered industrial trucks (forklifts), including pre-operational checks, regular inspections, and operator training requirements. Similarly, I understand how ISO 45001 principles help build a safety culture by ensuring that inspections aren’t just reactive but integrated into a larger safety management system, reducing the likelihood of accidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you stay up-to-date on industry best practices and regulatory changes?

Staying current is crucial in this field. I utilize several methods: I subscribe to industry publications and journals like Occupational Health & Safety and attend relevant conferences and workshops. Membership in professional organizations like the American Society of Safety Professionals (ASSP) provides access to updated resources, webinars, and networking opportunities. Additionally, I actively monitor regulatory agency websites – such as OSHA’s and relevant international bodies’ – for updates to standards and guidance documents. I also engage in continuous learning through online courses and professional development programs focusing on specific equipment types or emerging safety technologies. For instance, recently I completed a course on the inspection and maintenance of drones used in industrial settings, a rapidly evolving area.

Q 17. How do you prioritize your workload when faced with multiple inspection tasks?

Prioritizing inspection tasks involves a structured approach. I use a risk-based methodology, categorizing inspections based on the criticality of the equipment and the potential severity of failure. Equipment crucial for production or safety (e.g., cranes, pressure vessels) takes precedence over less critical equipment. I also consider factors like deadlines and regulatory requirements. I often employ a prioritization matrix, visually representing the risk level and urgency of each task. For example, a critical piece of equipment due for a mandatory inspection next week would be given the highest priority. Using a task management system, with clear timelines and assigned responsibilities, helps maintain organization and visibility of the entire workload.

Q 18. Describe your experience working with different types of equipment.

My experience spans a wide range of equipment, including but not limited to: heavy machinery (cranes, excavators, forklifts), pressure vessels, electrical systems (high and low voltage), HVAC systems, and various types of manufacturing equipment. I’ve worked on both stationary and mobile equipment, both new and aging. Each equipment type demands a specific inspection methodology and understanding of its operational intricacies and potential failure points. For instance, inspecting a crane involves verifying its structural integrity, testing its braking system, and checking its load-bearing capacity, whereas inspecting an electrical system focuses on insulation integrity, grounding, and safety devices like circuit breakers. Experience with diverse equipment ensures that I can adapt my approach to different contexts and identify potential hazards effectively.

Q 19. How do you handle difficult or confrontational situations with equipment operators?

Handling confrontational situations requires a calm and professional approach. I begin by actively listening to the equipment operator’s concerns and validating their perspective. Then, I clearly explain the safety regulations or company policies relevant to the situation, using plain language and avoiding technical jargon. I emphasize the importance of safety for everyone involved, not as a personal attack but as a shared responsibility. If necessary, I involve a supervisor or manager to mediate the conflict. Building trust and rapport with operators is critical; proactive communication and clear expectations can often prevent confrontations. For example, explaining a new safety procedure during a regular inspection, instead of only during an incident, helps improve operator understanding and cooperation.

Q 20. What is your experience with root cause analysis for equipment failures?

I’m proficient in conducting root cause analysis (RCA) using various techniques, including the “5 Whys” method and fault tree analysis. The “5 Whys” method involves repeatedly asking “why” to uncover the underlying causes of an equipment failure. Fault tree analysis, a more formal technique, maps out potential causes and their combinations leading to a specific failure. I meticulously document the findings of the RCA, including photographs and witness statements, to provide concrete evidence and support corrective actions. For example, a pump failure might initially appear to be due to a worn-out impeller (the first “why”). Further questioning reveals that the impeller wore out prematurely because of inadequate lubrication (second “why”), which was caused by a faulty lubrication system (third “why”), due to a lack of regular maintenance (fourth “why”), ultimately stemming from insufficient training for maintenance personnel (fifth “why”). The RCA process helps prevent similar failures in the future.

Q 21. How do you use data from inspections to improve safety and maintenance procedures?

Inspection data is invaluable for improving safety and maintenance procedures. I systematically collect and analyze data from each inspection, noting trends, recurring issues, and near misses. This data informs the development of preventive maintenance schedules, targeted training programs for operators and maintenance personnel, and improvements to safety protocols. For instance, if inspections repeatedly reveal a specific component failing, this might indicate the need for a change in the component’s material, a revision in the maintenance schedule, or enhanced operator training. Data analysis can also help identify equipment nearing the end of its useful life, allowing for proactive replacement planning. Using data-driven insights contributes to a more proactive and effective safety management system, preventing accidents and enhancing operational efficiency.

Q 22. Describe your proficiency in using inspection software or databases.

My proficiency in using inspection software and databases is extensive. I’m adept at utilizing various platforms, from CMMS (Computerized Maintenance Management Systems) like SAP PM and IBM Maximo to more specialized inspection software tailored for specific equipment types. For example, I’ve extensively used a system for tracking inspections of high-pressure vessels, which involved inputting detailed inspection reports, uploading photographic evidence, and generating automated reports based on pre-defined parameters and thresholds. My experience also includes working with relational databases (like SQL Server or Oracle) to query and analyze inspection data, identifying trends and patterns to predict potential failures and optimize maintenance schedules. I understand the importance of data integrity and accuracy in these systems and am proficient in ensuring data validation and consistency.

Beyond proficiency in the software itself, I am skilled in configuring and customizing these systems to best fit the needs of the organization and the specific inspection requirements. I can design and implement custom reports, create automated alerts for critical issues, and develop workflows to streamline the inspection process. My expertise goes beyond simple data entry and retrieval – I use this data effectively to improve overall safety and efficiency.

Q 23. What are your strategies for managing and minimizing inspection risks?

Managing and minimizing inspection risks requires a multi-faceted approach. My strategy begins with a thorough risk assessment, identifying potential hazards associated with each piece of equipment and the inspection process itself. This involves considering factors like the equipment’s criticality, its operating environment, the inherent risks of failure, and the skills and experience of the inspection team. The outcome of this assessment informs the development of a robust inspection plan, specifying the frequency, scope, and methods of inspection for each asset.

Secondly, I focus on effective training and qualification of inspection personnel. Well-trained inspectors are crucial in minimizing risks. This includes not only technical training on specific equipment but also safety training, including the use of appropriate personal protective equipment (PPE) and safe work practices. I implement regular competency assessments to ensure inspectors maintain their skills and knowledge.

Thirdly, I ensure clear documentation and record-keeping. Detailed inspection reports, including photographic evidence and any remedial actions taken, are essential for identifying trends, improving future inspections, and demonstrating compliance with regulatory requirements. Finally, I use data analysis from the inspection software to proactively identify potential issues, enabling timely intervention and preventing catastrophic failures. For example, if we notice a rising number of similar defects across a particular batch of equipment, this points to a potential systemic issue needing addressed proactively.

Q 24. Explain your understanding of different types of equipment failure modes.

My understanding of equipment failure modes is extensive and encompasses various classifications. Failures can be broadly categorized as gradual deterioration (e.g., corrosion, fatigue, creep) or sudden catastrophic events (e.g., fracture, rupture, explosion). Each of these categories has numerous sub-types. For instance, gradual deterioration can include:

- Corrosion: Chemical or electrochemical degradation of materials, often leading to thinning or pitting.

- Fatigue: Progressive damage due to cyclic loading, ultimately resulting in cracks and fracture.

- Creep: Time-dependent deformation under constant load, often seen in high-temperature applications.

Sudden failures, on the other hand, might be caused by:

- Fracture: Separation of a material into two or more pieces due to stress.

- Rupture: Failure due to excessive strain, typically seen in ductile materials.

- Explosion: Sudden and violent expansion of gases, often due to pressure build-up.

Understanding these failure modes is critical for developing effective inspection plans that target the most likely causes of failure. For example, regular ultrasonic testing can detect fatigue cracks in critical components, while visual inspections can identify corrosion. Analyzing historical failure data also helps in predicting future failures and implementing preventative maintenance strategies.

Q 25. How do you maintain your professional competency and skills in this field?

Maintaining professional competency is paramount in this field. I actively pursue continuous professional development through several avenues. This includes attending industry conferences and workshops to stay updated on the latest inspection techniques, technologies, and regulatory changes. I also regularly review relevant industry publications and standards, such as those published by ASME (American Society of Mechanical Engineers) and API (American Petroleum Institute). Furthermore, I actively participate in professional organizations, such as the Society for Maintenance and Reliability Professionals (SMRP), which provides valuable networking opportunities and access to continuing education resources. I also actively seek out opportunities to mentor junior inspectors, which helps consolidate my existing knowledge and learn from their perspectives.

Hands-on experience is equally important. I actively seek opportunities to work with diverse equipment and inspection technologies, ensuring my skills remain sharp and adaptable. I also embrace new software and techniques, furthering my practical skillset and broadening my knowledge of the ever-evolving field of equipment inspection and safety checks.

Q 26. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and skills within the industry. Based on my research of similar roles and my qualifications, I am targeting a salary range between [Insert Lower Bound] and [Insert Upper Bound] annually. However, I am open to discussing this further based on the specific responsibilities and benefits package offered.

Q 27. Do you have any questions for me?

Yes, I have a few questions. Firstly, could you elaborate on the specific types of equipment that will be under my purview in this role? Secondly, what opportunities are there for professional development and advancement within the company? Finally, what are the company’s safety protocols and reporting procedures for critical incidents or near misses?

Key Topics to Learn for Equipment Inspection and Safety Checks Interview

- Regulatory Compliance: Understanding relevant safety regulations, standards (e.g., OSHA, ANSI), and legal implications of non-compliance. Practical application includes knowing how to interpret and apply these regulations to specific equipment.

- Inspection Techniques: Mastering visual inspection methods, using appropriate tools (e.g., gauges, meters), and documenting findings accurately. Practical application includes describing your experience with different inspection methods and the types of equipment you’ve inspected.

- Preventive Maintenance: Identifying potential hazards and recommending preventative maintenance schedules to minimize downtime and risks. Practical application involves explaining how you’ve contributed to preventative maintenance programs and the positive outcomes.

- Risk Assessment and Mitigation: Conducting thorough risk assessments, identifying potential hazards, and implementing effective control measures. Practical application includes describing your experience in identifying and mitigating risks in various equipment inspection scenarios.

- Documentation and Reporting: Maintaining accurate and detailed inspection records, generating clear and concise reports, and communicating findings effectively to relevant stakeholders. Practical application includes describing your experience with different reporting systems and your ability to communicate technical information clearly.

- Troubleshooting and Problem-Solving: Identifying and diagnosing equipment malfunctions, applying problem-solving techniques to resolve issues, and ensuring safe operation. Practical application includes describing a situation where you effectively troubleshooted a problem and the steps you took to resolve it.

- Specific Equipment Knowledge: Demonstrate familiarity with the types of equipment relevant to the specific job description (e.g., cranes, forklifts, power tools). This includes understanding their operational principles, common failure points, and safety features.

Next Steps

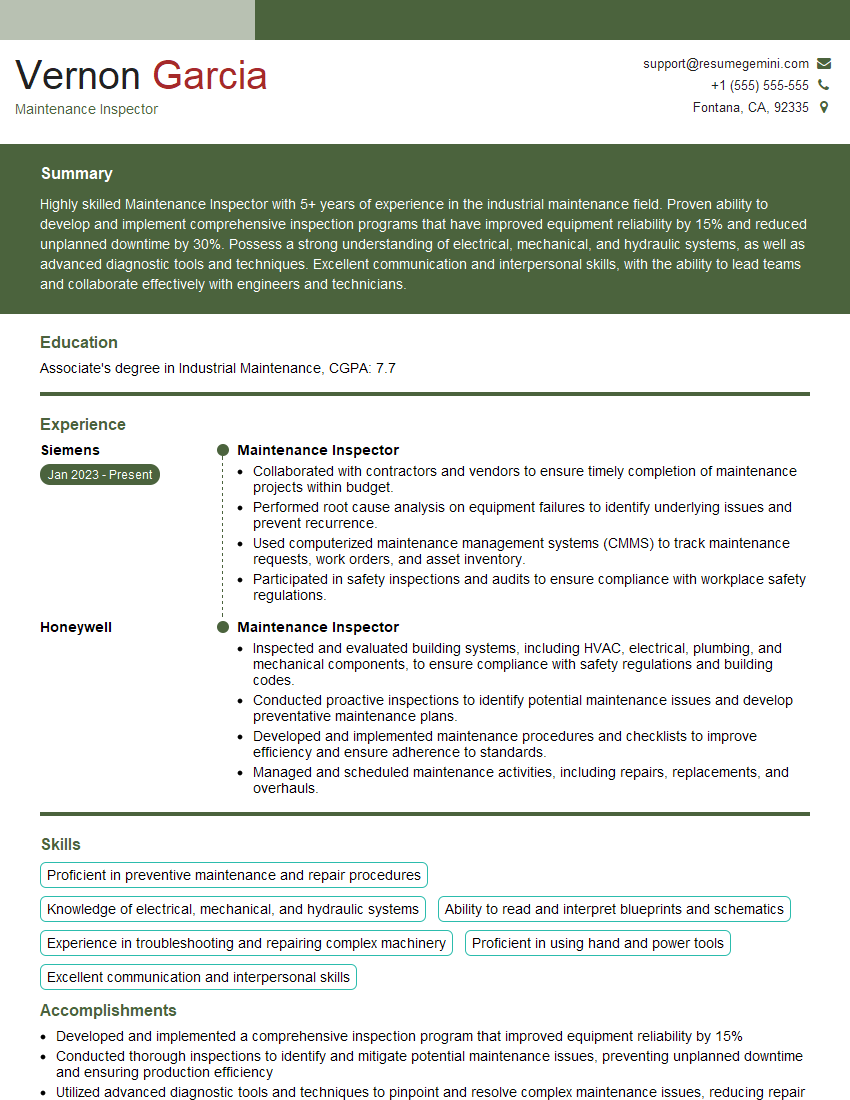

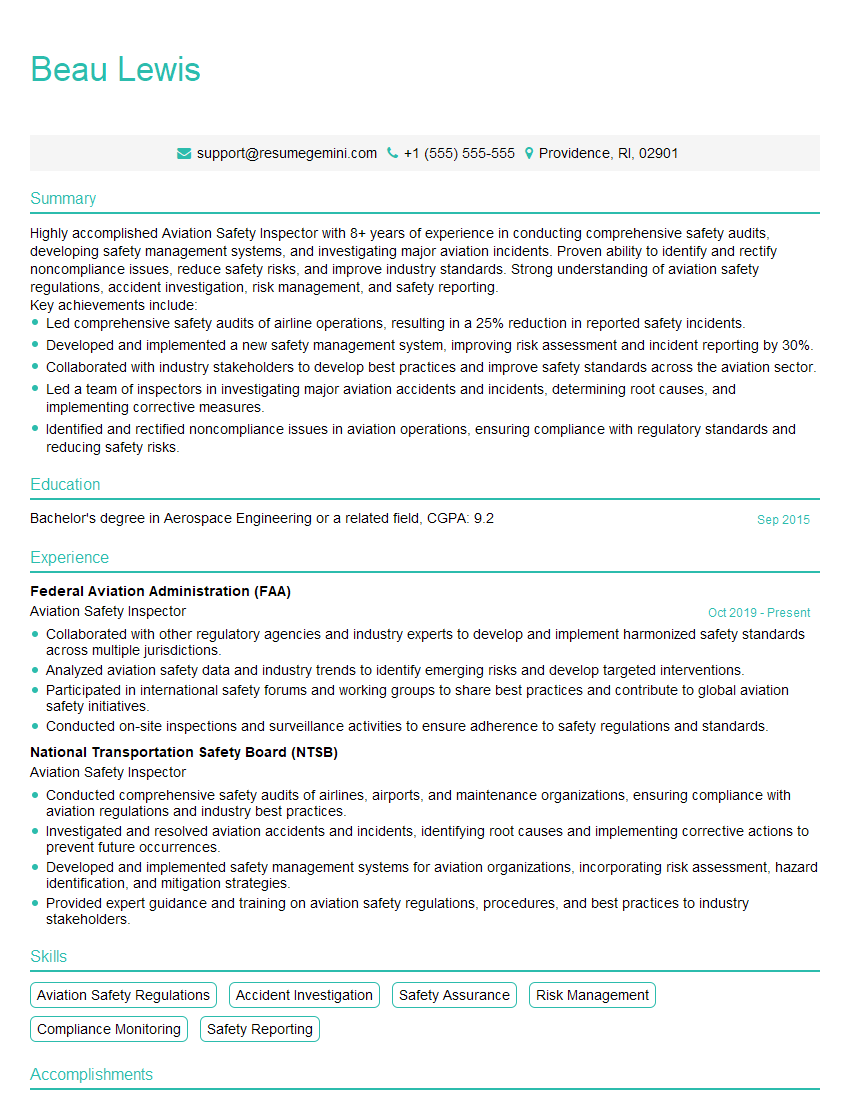

Mastering Equipment Inspection and Safety Checks is crucial for career advancement in many industries, opening doors to leadership roles and higher earning potential. A well-crafted resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential for getting your application noticed by employers. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to Equipment Inspection and Safety Checks are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good