Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Ergonomic assembly techniques interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Ergonomic assembly techniques Interview

Q 1. Define ‘ergonomics’ in the context of assembly line operations.

In assembly line operations, ergonomics is the science of designing the workplace, tasks, and tools to fit the capabilities and limitations of the human body. It’s all about optimizing the work environment to prevent injuries, improve productivity, and enhance worker well-being. Instead of forcing workers to adapt to the job, ergonomics focuses on adapting the job to the worker.

Imagine a scenario where an assembler has to reach awkwardly for parts located too far away. That’s poor ergonomics. Ergonomic principles would dictate moving those parts closer, adjusting the workstation height, or using a tool that minimizes the reach.

Q 2. Explain the relationship between ergonomics and workplace safety in assembly.

Ergonomics and workplace safety in assembly are intrinsically linked. Poor ergonomic design is a major contributor to workplace injuries, particularly musculoskeletal disorders (MSDs). By applying ergonomic principles, we significantly reduce the risk of these injuries. A safe assembly line is, by definition, an ergonomically sound one.

For example, a workstation designed with proper posture support, tool placement, and work surface height minimizes strain on the back, neck, and shoulders. This directly translates to a safer working environment and reduces the likelihood of work-related injuries and lost workdays.

Q 3. Describe common musculoskeletal disorders (MSDs) associated with assembly tasks.

Common musculoskeletal disorders (MSDs) associated with assembly tasks include:

- Carpal Tunnel Syndrome (CTS): Repetitive wrist movements, especially forceful or awkward ones, can compress the median nerve.

- Tendinitis: Inflammation of tendons, often caused by repetitive movements or overuse.

- Back pain and injuries: Prolonged standing, awkward postures, and heavy lifting contribute to back problems.

- Neck pain and injuries: Poor posture, awkward head and neck positions.

- Shoulder pain and injuries: Repetitive reaching, lifting, or overhead work.

- Rotator cuff injuries: Damage to the muscles and tendons around the shoulder joint.

These injuries can lead to significant pain, reduced function, and lost productivity. Early intervention and proactive ergonomic design are crucial in preventing them.

Q 4. What are the key principles of designing an ergonomically sound assembly workstation?

Designing an ergonomically sound assembly workstation involves several key principles:

- Neutral posture: Work surfaces and tool placement should encourage a natural posture, minimizing bending, twisting, and reaching.

- Proper tool design: Tools should be lightweight, well-balanced, and easy to grip. Power tools should minimize vibration.

- Adjustable workstation: Height-adjustable chairs, work surfaces, and tool holders accommodate workers of different sizes and allow for postural adjustments.

- Good lighting and workspace organization: Adequate lighting and well-organized tools and parts reduce strain and improve efficiency.

- Minimize repetitive motions: Design tasks to avoid repetitive movements and prolonged static postures. Incorporate micro-breaks and job rotation.

- Appropriate work surface height: The work surface should be at an optimal height to minimize reaching and strain.

- Sufficient workspace: Ensure ample space around the workstation for movement and to prevent collisions.

Q 5. How do you assess the risk of MSDs in an assembly process?

Risk assessment for MSDs in assembly processes involves a multi-step approach:

- Identify tasks and potential hazards: Observe workers performing their tasks, noting repetitive movements, awkward postures, and forceful exertions.

- Analyze job demands: Quantify the physical demands of the job using tools like RULA or REBA (explained below).

- Identify at-risk workers: Consider factors like age, pre-existing conditions, and individual work habits.

- Develop control measures: Implement solutions such as workstation redesign, tool modifications, or job rotation.

- Monitor and evaluate: Track injury rates and worker feedback to assess the effectiveness of implemented controls and make adjustments as needed.

Thorough observation and data collection are key for a reliable assessment.

Q 6. Explain the use of different ergonomic assessment tools (e.g., RULA, REBA).

RULA (Rapid Upper Limb Assessment) and REBA (Rapid Entire Body Assessment) are widely used ergonomic assessment tools. Both involve observing a worker performing a task and assigning scores based on posture, movement, and force. Higher scores indicate a greater risk of MSDs.

RULA focuses primarily on the upper body (neck, shoulders, arms, wrists), while REBA provides a more holistic assessment of the entire body, including the trunk and legs. Both methods use a systematic scoring system which allows for comparison and prioritization of areas that need immediate improvement.

For example, a high RULA score for a specific assembly task might indicate the need for a redesign of the workstation to reduce wrist extension or the implementation of tools that reduce the force required.

Q 7. How do you incorporate ergonomic considerations into the design of assembly tools?

Ergonomic considerations in assembly tool design focus on minimizing strain and maximizing comfort and control:

- Handle design: Handles should be appropriately sized and shaped for a comfortable grip, minimizing pressure points. Consider using textured surfaces for better grip.

- Weight and balance: Tools should be lightweight and well-balanced to reduce strain on the muscles and joints.

- Tool activation force: The force required to operate the tool should be minimized. Power tools should have easily accessible and comfortable controls.

- Vibration control: Tools generating significant vibration should incorporate vibration-damping mechanisms to protect against hand-arm vibration syndrome.

- Tool positioning: The tool’s position during use should promote a neutral wrist posture and reduce reaching.

An example of good ergonomic design would be a power screwdriver with a lightweight, ergonomic handle, low activation force, and vibration reduction features. Conversely, a heavy, poorly balanced screwdriver requiring excessive force and causing wrist strain is a poor ergonomic design.

Q 8. What are the benefits of implementing ergonomic improvements in an assembly process?

Implementing ergonomic improvements in assembly processes offers a multitude of benefits, impacting both worker well-being and business productivity. At its core, ergonomics aims to fit the job to the person, not the person to the job.

- Reduced Musculoskeletal Disorders (MSDs): Ergonomic interventions significantly lower the risk of MSDs like carpal tunnel syndrome, back pain, and tendonitis, leading to fewer workplace injuries and associated costs. Imagine a worker repeatedly reaching overhead for hours – ergonomic adjustments like lowering the work surface could dramatically reduce strain.

- Increased Productivity and Efficiency: When workers are comfortable and free from pain, they’re more focused and efficient. A well-designed workspace minimizes wasted movements and fatigue, resulting in higher output and improved quality.

- Improved Employee Morale and Retention: Investing in employee well-being shows that the company cares. A comfortable and safe work environment boosts morale, leading to increased job satisfaction and reduced employee turnover.

- Reduced Healthcare Costs: Fewer workplace injuries translate directly to lower healthcare expenses for both the employee and the company. This includes reduced costs associated with workers’ compensation claims.

- Enhanced Company Reputation: A commitment to worker safety and well-being enhances the company’s reputation, attracting and retaining top talent. It demonstrates a proactive approach to risk management.

Q 9. How can job rotation and task variation reduce MSD risk in assembly?

Job rotation and task variation are crucial strategies for mitigating MSD risk in assembly lines. The repetitive nature of many assembly tasks can lead to overuse injuries. By diversifying the tasks workers perform and providing regular breaks, the strain on specific muscle groups is significantly reduced.

- Job Rotation: This involves periodically shifting workers between different assembly tasks or workstations. For example, an employee might spend a portion of their day assembling small components, then switch to installing larger parts, thus preventing prolonged strain on any one set of muscles.

- Task Variation: This involves modifying individual tasks to reduce repetition and static postures. This could involve introducing micro-breaks or changing the tools or techniques used. For instance, using powered tools instead of manual ones, or incorporating varied hand movements.

The effectiveness of job rotation and task variation depends on careful planning and monitoring. It is vital to ensure that the alternative tasks are not equally or more strenuous, and that appropriate training is provided.

Q 10. Explain the importance of proper posture and body mechanics in assembly work.

Proper posture and body mechanics are paramount in preventing MSDs in assembly work. Maintaining a neutral spine, avoiding awkward postures, and using efficient movements are key principles. Think of your body as a finely tuned machine; improper use leads to wear and tear.

- Neutral Spine: The spine should be kept in a natural, slightly curved position, avoiding excessive bending, twisting, or hunching. This minimizes strain on the back muscles and discs.

- Efficient Movements: Movements should be smooth and controlled, avoiding jerky or sudden actions. Using the larger muscle groups of the legs and core instead of solely relying on smaller muscle groups in the arms and hands reduces fatigue and strain.

- Avoid Awkward Postures: Prolonged reaching, twisting, and bending should be minimized. Work surfaces should be positioned at a comfortable height, allowing for a natural posture with minimal strain.

- Proper Lifting Techniques: When lifting heavy objects, use proper lifting techniques, including bending at the knees and keeping the load close to the body. Avoid twisting while lifting.

Training workers on proper posture and body mechanics, coupled with workplace adjustments, is a highly effective approach to injury prevention.

Q 11. What are some common ergonomic hazards in assembly line operations?

Assembly line operations present several common ergonomic hazards, often stemming from the repetitive and often fast-paced nature of the work. Identifying these hazards is crucial for implementing effective preventative measures.

- Repetitive Movements: Repeatedly performing the same motions can lead to overuse injuries like carpal tunnel syndrome and tendonitis.

- Awkward Postures: Prolonged reaching, twisting, bending, or working in cramped spaces puts excessive strain on muscles and joints.

- Forceful Exertion: Using excessive force to perform tasks can lead to muscle strains and injuries.

- Vibration: Operating vibrating tools can cause hand-arm vibration syndrome (HAVS).

- Static Postures: Maintaining the same posture for extended periods can cause fatigue and discomfort.

- Poor Workplace Layout: Poorly designed workstations, inadequate lighting, and cluttered workspaces can contribute to injuries.

- Improper Tool Design: Tools that are too heavy, awkward to use, or poorly designed can increase the risk of injury.

Q 12. How do you measure the effectiveness of ergonomic interventions?

Measuring the effectiveness of ergonomic interventions requires a multi-faceted approach combining quantitative and qualitative data. The goal is to demonstrate a reduction in MSDs and an improvement in worker well-being.

- Injury Rate Tracking: Monitor the number and type of MSDs before and after implementing the interventions. A significant reduction in injury rates is a key indicator of success.

- Worker Surveys: Conduct surveys to assess workers’ perceptions of their comfort, pain levels, and overall satisfaction with the workplace. This provides valuable qualitative insights.

- Productivity Measurement: Track changes in productivity and output to assess the impact of ergonomic improvements on efficiency. Improved productivity may be an indirect result of increased worker comfort and reduced fatigue.

- Observation Studies: Observe workers to identify any remaining ergonomic hazards or areas for improvement, even after interventions are implemented.

- Biomechanical Assessments: Use biomechanical assessments to measure forces and postures during tasks and quantify any reductions in strain after ergonomic changes. This provides objective data on improvement.

Combining these methods provides a comprehensive evaluation of the effectiveness of the interventions.

Q 13. Describe methods for reducing repetitive strain injuries in assembly.

Reducing repetitive strain injuries (RSIs) in assembly requires a proactive approach involving several strategies.

- Reduce Repetitive Motions: Introduce automation, job rotation, and task variation to minimize repetitive tasks. Consider using powered tools or assistive devices.

- Optimize Workspace Design: Ensure workstations are ergonomically designed, with adjustable chairs, proper tool placement, and adequate lighting. This minimizes awkward postures and reduces strain.

- Provide Training on Proper Body Mechanics: Educate workers on proper lifting, posture, and movement techniques to reduce strain on muscles and joints.

- Implement Micro-breaks: Encourage workers to take short, frequent breaks throughout the day to reduce fatigue and allow muscles to rest. These breaks can be incorporated into the work flow.

- Use Appropriate Tools and Equipment: Ensure tools are lightweight, easy to use, and properly maintained. Use anti-vibration gloves or tools to reduce vibration exposure.

- Promote Stretching and Exercise: Encourage regular stretching and exercise to improve flexibility, strength, and range of motion, thus reducing strain.

A holistic approach, combining these strategies, is the most effective method for preventing and managing RSIs in assembly work.

Q 14. How do you design workspaces to accommodate workers of different sizes and abilities?

Designing workspaces to accommodate workers of different sizes and abilities is essential for creating a truly inclusive and ergonomic environment. This requires a flexible and adaptable approach.

- Adjustable Workstations: Use height-adjustable workstations, chairs, and tool holders that can be easily customized to fit individual worker needs. This allows the workspace to adapt to varying heights and reach requirements.

- Adjustable Tools and Equipment: Provide a variety of tools and equipment that can be adjusted to fit the worker, rather than requiring the worker to adapt to the tools. This may include different sizes of handles or grips.

- Consider Anthropometric Data: Design the workstation based on anthropometric data, which are measurements of human body dimensions. This ensures that the workspace accommodates the range of sizes and shapes of potential workers.

- Provide Assistive Devices: For workers with disabilities, provide assistive devices that enable them to perform their tasks safely and efficiently. This may include specialized tools, adaptive equipment, or ergonomic aids.

- Consult with Workers: Involve workers in the design process. Get feedback from workers of different sizes and abilities to ensure the workspace meets their individual needs.

- Use Universal Design Principles: Apply universal design principles, which aim to create products and environments that are usable by people with a wide range of abilities.

By considering these aspects, we can create inclusive and effective workspaces that support workers of all sizes and abilities.

Q 15. What is the role of anthropometry in designing ergonomic workspaces?

Anthropometry is the scientific study of human body measurements. In ergonomic workspace design, it plays a crucial role because it provides the data needed to create workstations that comfortably accommodate the physical dimensions of the workers. This means considering things like average and extreme ranges of height, arm length, hand size, and sitting/standing postures.

For example, if you’re designing an assembly line, you need to know the range of heights your workers fall into to ensure the work surface is adjustable to accommodate everyone. If the work surface is too high, workers may have to hunch over, leading to back pain and fatigue. If it’s too low, they may have to reach up, straining their shoulders and necks. Anthropometric data allows you to design for the 5th percentile (shortest) and 95th percentile (tallest) workers, ensuring the vast majority are comfortably accommodated.

Ignoring anthropometry leads to ill-fitting workstations, resulting in discomfort, musculoskeletal disorders (MSDs) like carpal tunnel syndrome or back pain, reduced productivity, and increased absenteeism. A well-designed workspace, informed by anthropometry, promotes comfort, efficiency, and reduces workplace injuries.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of ‘workplace design for all’ in assembly.

‘Workplace design for all’ in assembly means creating a workspace that is adaptable and inclusive for all workers, regardless of their physical characteristics, abilities, or disabilities. This goes beyond simply accommodating the average worker; it actively considers the needs of individuals with diverse body sizes, strengths, and limitations.

This approach involves designing for adjustability. Imagine an assembly line where tasks require different postures. Adjustable work surfaces, chairs with adjustable height and lumbar support, and tools with interchangeable handles to accommodate different hand sizes are key elements. Furthermore, it might include the implementation of assistive technologies for workers with disabilities. For instance, a worker with limited hand dexterity might need specialized tools or adaptive equipment to perform their tasks comfortably and safely.

Implementing this approach can significantly reduce workplace injuries, improve job satisfaction, and increase the overall productivity and inclusivity of the workforce. It’s about creating a fair and equitable working environment for everyone.

Q 17. Describe different types of adjustable workstations and their applications.

Adjustable workstations are designed to adapt to individual workers’ needs and preferences. Several types exist:

- Sit-stand workstations: These allow workers to switch between sitting and standing positions throughout the day, reducing strain on the back and legs. They can range from simple height-adjustable desks to sophisticated systems with integrated monitor arms and keyboard trays.

- Height-adjustable chairs: These chairs allow workers to adjust the seat height to ensure proper posture and reduce strain on the back and legs. Features like adjustable lumbar support and armrests further enhance comfort and ergonomics.

- Keyboard and monitor arms: These allow workers to position their keyboard and monitor at optimal distances and angles, promoting neutral wrist postures and reducing neck strain. These are often used in conjunction with sit-stand desks.

- Footrests: Footrests can improve posture and circulation when sitting for extended periods, especially for workers with shorter legs. They provide support and alleviate pressure on the lower back and legs.

Applications: These adjustable workstations find application across various assembly settings. For instance, in electronics assembly, sit-stand desks are vital for tasks involving fine motor skills which can cause fatigue if maintained in one posture for prolonged periods. In automotive assembly, height-adjustable chairs are essential for tasks involving repetitive lifting and reaching. The choice of adjustable workstation depends on the specific tasks and individual worker needs.

Q 18. How do you manage ergonomic risks during process changes in assembly?

Managing ergonomic risks during process changes requires a proactive and systematic approach. The key is to conduct a thorough ergonomic risk assessment before, during, and after any changes are implemented.

Before: Analyze the proposed changes and identify potential ergonomic hazards. This might include new tools, equipment, materials, or work processes. Consider the impact on posture, repetitive movements, force exertion, and vibration. Consult with workers to understand their concerns and perspectives.

During: Monitor workers closely during the implementation phase to identify any emerging ergonomic problems. Observe their postures, movements, and any signs of discomfort or strain. Make adjustments as needed.

After: Conduct a post-implementation ergonomic risk assessment to evaluate the effectiveness of the changes and identify any remaining risks. This involves collecting feedback from workers and gathering data on injury rates and lost productivity.

Example: If a new assembly line is introduced, a pre-implementation assessment will identify the need for adjustable work surfaces and ergonomic tools to minimize reaching and repetitive motions. Post-implementation, data on worker fatigue and injury rates will help optimize the design.

Q 19. What are the key considerations when selecting appropriate personal protective equipment (PPE) for assembly workers?

Selecting appropriate PPE for assembly workers requires careful consideration of the specific hazards present. The goal is to protect workers from injury without hindering their ability to perform their tasks safely and efficiently.

- Eye protection: Safety glasses, goggles, or face shields are essential to protect against flying debris, chemicals, or sparks.

- Hearing protection: Earplugs or earmuffs are necessary in environments with high noise levels.

- Hand protection: Gloves should be selected based on the specific hazards, such as cuts, abrasions, chemicals, or vibration. Consider factors like dexterity and comfort.

- Foot protection: Safety shoes or boots are essential to protect against falling objects, punctures, or crushing injuries.

- Respiratory protection: Respirators are required when exposure to dust, fumes, or harmful gases is present.

Key considerations: PPE should be comfortable, fit properly, and not interfere with the worker’s ability to perform their tasks. Workers should be trained on the proper use and maintenance of PPE. Regular inspection and replacement of damaged or worn PPE are crucial.

Q 20. How do you communicate ergonomic guidelines and best practices to assembly workers?

Communicating ergonomic guidelines and best practices requires a multi-faceted approach that ensures information is easily accessible and understood by all assembly workers.

- Training sessions: Conduct interactive training sessions that include demonstrations, practical exercises, and Q&A sessions. Use visual aids and real-life examples to enhance understanding.

- Posters and visual aids: Place posters and visual aids in prominent locations to serve as reminders of proper posture, lifting techniques, and safe work practices.

- Job aids: Create job aids (e.g., checklists, flowcharts) that provide step-by-step instructions for performing tasks ergonomically.

- Regular communication: Regularly communicate updates, changes, and best practices through newsletters, team meetings, and one-on-one conversations.

- Feedback mechanisms: Establish feedback mechanisms (e.g., suggestion boxes, anonymous surveys) to gather worker input and identify areas for improvement.

Make sure communication is clear, concise, and tailored to the literacy level of the workers. Use multiple channels to ensure the message reaches everyone.

Q 21. Describe the importance of training in promoting safe and ergonomic assembly practices.

Training is absolutely paramount in promoting safe and ergonomic assembly practices. It equips workers with the knowledge and skills to identify and mitigate ergonomic risks, preventing injuries and improving productivity.

Comprehensive training should cover topics such as proper posture, lifting techniques, the use of ergonomic tools and equipment, the recognition of early signs of MSDs, and the importance of reporting any discomfort or injuries. Training should be interactive and hands-on, allowing workers to practice proper techniques and ask questions.

Regular refresher training is crucial to reinforce learned behaviors and address any changes in work processes or equipment. Ongoing training helps to maintain a culture of safety and ergonomics within the workplace. This ensures that workers are consistently applying safe and ergonomic practices, leading to a healthier and more productive work environment.

Ignoring training leads to a higher risk of MSDs, increased workers’ compensation claims, and reduced productivity. Investing in effective ergonomic training programs is an investment in the long-term health and well-being of the workforce and the overall success of the business.

Q 22. What are some common ergonomic challenges encountered in automated assembly lines?

Even in automated assembly lines, ergonomic challenges persist, primarily stemming from the interaction between human workers and the automated systems. These challenges often center around repetitive motions, awkward postures, and excessive force exertion, even if the robots are doing the majority of the physical work.

Repetitive tasks: While robots handle many assembly steps, operators often perform repetitive tasks like loading parts into the machine, quality checking, or troubleshooting malfunctions. This can lead to musculoskeletal disorders (MSDs) such as carpal tunnel syndrome or tendonitis.

Awkward postures: Reaching, twisting, and bending to access parts, controls, or malfunctioning machinery can create strain on the back, neck, and shoulders, especially in confined spaces or poorly designed workstations.

Forceful exertions: Even with automation, operators might need to lift heavy components, manage heavy cables, or forcefully manipulate parts that don’t feed smoothly into the automated system. This increases the risk of back injuries and other MSDs.

Visual demands: Constant monitoring of automated processes can lead to eye strain, headaches, and fatigue, particularly if the lighting is inadequate or the screen displays are not ergonomically designed.

Vibration exposure: Operators might be exposed to vibrations from automated machinery, impacting their hands, arms, and whole body.

Q 23. How can you use technology (e.g., exoskeletons) to improve ergonomics in assembly?

Technology plays a crucial role in mitigating ergonomic risks in assembly. Exoskeletons are a prime example, offering passive or active support to reduce physical strain. Other technological solutions include:

Powered exoskeletons: These provide mechanical assistance to reduce the load on the musculoskeletal system, especially during lifting and repetitive tasks. Imagine a lightweight suit that helps you lift heavy objects with less effort, significantly reducing strain on your back and shoulders.

Passive exoskeletons: These offer structural support without powered assistance, helping maintain proper posture and reducing strain from awkward positions. Think of them as external bracing that helps keep your back straight.

Ergonomic tools and equipment: This encompasses everything from adjustable workstations and chairs to specialized hand tools designed to reduce grip force and awkward postures. For example, a tool with a perfectly balanced weight distribution reduces strain on the wrists.

Automated guided vehicles (AGVs): AGVs can transport materials and parts around the assembly line, reducing the need for manual handling and movement by operators.

Robotic assistance: Robots can handle many physically demanding tasks, removing the burden from human workers. This might include performing repetitive movements, lifting heavy components, or performing tasks in hazardous environments.

Q 24. Explain the role of a risk assessment in identifying and mitigating ergonomic hazards.

A risk assessment is the cornerstone of any effective ergonomic intervention. It’s a systematic process of identifying, evaluating, and controlling ergonomic hazards. It involves a structured approach to pinpoint potential problems before they lead to injuries.

Hazard identification: This involves observing the work processes, interviewing workers, and reviewing injury data to identify potential ergonomic hazards like repetitive movements, awkward postures, forceful exertions, and contact stress.

Risk evaluation: This step involves assessing the likelihood of injury and the severity of the potential harm. This might involve using a standardized risk assessment matrix to quantify the risk level.

Control measures: Once risks are identified and evaluated, control measures are developed to eliminate or reduce the hazards. This could include engineering controls (e.g., redesigning workstations), administrative controls (e.g., job rotation), and personal protective equipment (PPE).

Implementation and monitoring: The chosen control measures are implemented, and their effectiveness is monitored over time. Regular reviews ensure that the implemented solutions remain effective and address potential new risks.

For example, a risk assessment might reveal that a specific assembly task requires excessive reaching and twisting. The control measures could involve repositioning the parts, modifying the workstation, providing an adjustable stool, or introducing job rotation to reduce the duration of the task.

Q 25. What are the key performance indicators (KPIs) used to evaluate ergonomic improvements?

Key Performance Indicators (KPIs) for evaluating ergonomic improvements focus on both the reduction of risks and the enhancement of worker well-being and productivity. Some important KPIs include:

Number and severity of musculoskeletal disorders (MSDs): A decrease in MSD reports indicates successful ergonomic interventions. This includes tracking the types of injuries, their severity, and the body parts affected.

Lost time due to injury: Reduction in lost workdays signifies improved worker health and reduced costs associated with worker absence.

Worker absenteeism and presenteeism: Tracking both absence and reduced productivity while at work (presenteeism) provides a more comprehensive picture of employee health.

Worker satisfaction scores (surveys): Employee feedback on comfort, ease of work, and overall satisfaction with workstation design is crucial.

Productivity rates: While not the primary focus, effective ergonomic interventions can lead to increased productivity by reducing fatigue and absenteeism. This must be carefully monitored to avoid prioritising productivity over worker safety.

Return on investment (ROI): Analyzing the costs associated with implementing ergonomic changes against the savings from reduced injuries and increased productivity helps justify ergonomic interventions.

Q 26. How do you balance ergonomic considerations with productivity goals in assembly?

Balancing ergonomic considerations with productivity goals requires a holistic approach. It’s not a trade-off; rather, it’s a synergistic relationship. Good ergonomics actually increases productivity in the long run.

The key lies in designing efficient and comfortable workspaces. This involves:

Lean principles: Applying lean manufacturing techniques can streamline processes, reducing unnecessary movements and fatigue. This increases both productivity and reduces the risk of ergonomic hazards.

Process optimization: Reviewing and redesigning assembly processes to minimize repetitive motions, awkward postures, and forceful exertions while maintaining (or even improving) production rates.

Workstation design: Creating workspaces that are adaptable to individual needs and allow for proper posture, reducing strain on muscles and joints. Adjustable height desks and chairs, appropriate lighting, and optimized tool placement are all vital elements.

Job rotation and task diversification: This strategy helps prevent the repetitive strain injuries associated with monotonous tasks, maintaining worker engagement and productivity.

Training and education: Educating workers on proper lifting techniques, workstation adjustments, and the importance of reporting discomfort helps them stay productive and safe.

By proactively addressing ergonomics, companies can create a win-win situation where workers are healthier, happier, and more productive.

Q 27. Describe your experience with ergonomic software or analysis tools.

I have extensive experience with various ergonomic software and analysis tools. My expertise includes using software for:

3D workstation modeling: Software like

[Software Name Example]allows us to create virtual representations of workstations, allowing us to assess reach distances, postures, and potential hazards before physical implementation, saving time and resources.Rapid Upper Limb Assessment (RULA) and Rapid Entire Body Assessment (REBA): I am proficient in using these standardized assessment tools to analyze postures and identify potential risks during assembly tasks. These tools provide a quantifiable score, helping prioritize areas needing improvement.

Electromyography (EMG) analysis: I’ve worked with equipment and software that measures muscle activity to identify areas of excessive muscle strain during assembly tasks, providing objective data for ergonomic improvements.

Video analysis: I utilize video recording and analysis software to capture and review worker movements, identifying inefficiencies and areas of ergonomic concern that might not be readily apparent during observation.

The combination of these tools provides comprehensive data for improving workplace ergonomics and ensuring the safety and well-being of the assembly line workforce.

Q 28. Explain a time when you identified and solved an ergonomic problem in an assembly setting.

In a previous role, we experienced a high incidence of wrist injuries among operators assembling small electronic components. A thorough risk assessment revealed that the workstation design was a major contributing factor. The operators had to maintain a highly repetitive twisting motion of their wrists while assembling tiny parts under a microscope. It was causing significant discomfort and leading to repetitive strain injuries.

To solve this problem, we implemented a multi-pronged approach:

Workstation redesign: We introduced adjustable height workstations allowing operators to vary their posture. We also redesigned the tool placement to minimize wrist twisting.

Tool modification: We replaced the existing tools with ones that allowed for a more neutral wrist position during assembly. We also explored ergonomic tools with improved grips.

Job rotation: We implemented job rotation, ensuring that no operator performed the same repetitive task for extended periods.

Training and education: We provided training on proper hand posture, breaks, and the importance of reporting any discomfort.

Following these changes, the incidence of wrist injuries significantly decreased. The operators also reported improved comfort and reduced fatigue, which enhanced productivity and morale.

Key Topics to Learn for Ergonomic Assembly Techniques Interview

- Body Mechanics and Posture: Understanding proper lifting techniques, posture adjustments for repetitive tasks, and the impact of workstation setup on musculoskeletal health.

- Workplace Ergonomics Assessment: Applying ergonomic principles to analyze workstations, identify risk factors (e.g., awkward postures, repetitive movements, forceful exertions), and recommend improvements.

- Tool and Equipment Design: Evaluating the ergonomic design of assembly tools and equipment, considering factors like handle size, weight, and force requirements. Understanding how to select and use tools safely and efficiently.

- Workstation Design and Layout: Optimizing workstation layouts to minimize unnecessary movements, reduce strain, and promote a comfortable and efficient work environment. This includes chair adjustments, monitor placement, and tool organization.

- Musculoskeletal Disorders (MSDs) Prevention: Recognizing common MSDs associated with assembly tasks (e.g., carpal tunnel syndrome, tendinitis) and implementing preventative measures through ergonomic design and training.

- Work Process Optimization: Analyzing and improving assembly processes to reduce physical strain and increase efficiency. This includes identifying bottlenecks and implementing lean manufacturing principles.

- Implementation of Ergonomic Solutions: Understanding how to implement recommended ergonomic changes, including training employees on proper techniques and monitoring the effectiveness of implemented solutions.

- Legislation and Regulations: Familiarity with relevant health and safety regulations related to ergonomics and workplace safety.

- Data Analysis and Reporting: Understanding how to collect, analyze, and report on ergonomic data to demonstrate the impact of implemented improvements.

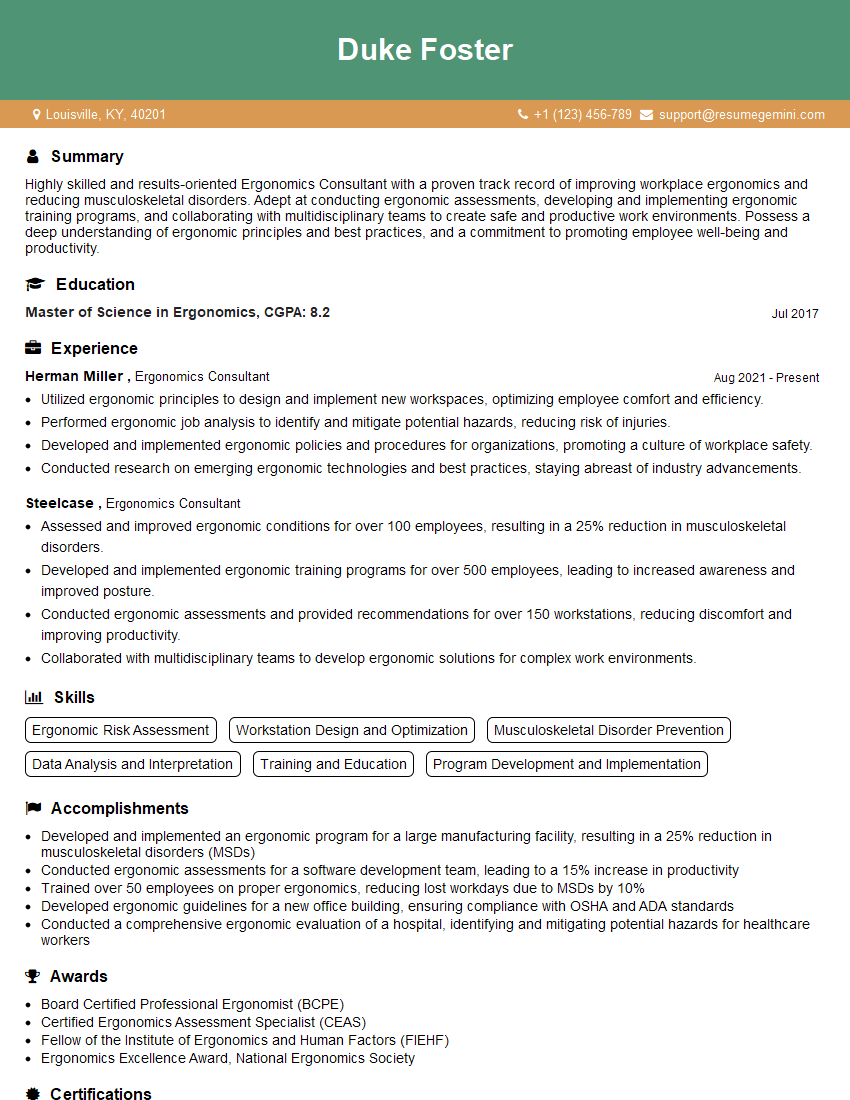

Next Steps

Mastering ergonomic assembly techniques is crucial for career advancement in manufacturing, engineering, and related fields. A strong understanding of these principles demonstrates your commitment to workplace safety and efficiency, making you a highly valuable asset to any team. To significantly enhance your job prospects, it’s essential to create a resume that highlights your skills and experience effectively. An ATS-friendly resume increases your chances of getting noticed by recruiters and landing an interview. We encourage you to leverage ResumeGemini, a trusted resource, to build a professional and impactful resume. Examples of resumes tailored to ergonomic assembly techniques are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good