Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Estimating and quoting for joist setting projects interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Estimating and quoting for joist setting projects Interview

Q 1. Explain your experience in estimating materials for joist setting projects.

Estimating materials for joist setting projects requires a meticulous approach. It starts with a thorough review of the project blueprints to determine the exact dimensions and quantities of joists needed. I then consider the type of joist specified – whether it’s engineered wood I-joists, traditional lumber joists, or steel joists – as each has different pricing and material requirements. For example, I-joists require fewer pieces due to their longer spans, but their unit cost is typically higher than dimensional lumber. Next, I account for any necessary additional materials like hangers, connectors, blocking, and fasteners. I always add a contingency of 5-10% to cover potential waste, measurement errors, or unforeseen material needs. Finally, I utilize my preferred estimating software to generate a detailed materials list with accurate quantities and pricing, ensuring all items are sourced from reliable suppliers with competitive pricing.

For instance, on a recent project involving 16-foot I-joists spaced 16 inches on center spanning a 24-foot area, my calculations would involve determining the number of joists needed (24ft / 1.33ft (16 inches) ≈ 18 joists), then multiplying by the necessary quantity of hangers and connectors per joist. I’d then check for any special requirements based on the load specifications and building code requirements.

Q 2. How do you determine the labor costs for joist installation?

Determining labor costs involves a multi-step process. First, I break down the joist installation into distinct tasks: material handling, setting joists, installing hangers and connectors, and any necessary blocking or bridging. For each task, I estimate the time required based on the project’s scale and complexity. My experience allows me to accurately judge productivity rates for different crew sizes and skill levels. I then assign labor rates to each task based on prevailing wages in the region and the specific skill set required. For example, a skilled crew installing complex engineered joists will command a higher rate than one handling simpler installations. Finally, I account for overhead costs, such as insurance, worker’s compensation, and other administrative expenses. I use historical data from completed projects to refine my estimates and maintain accuracy. Often, I build in a buffer for unforeseen delays or difficulties.

For example, if setting joists takes 2 person-hours per joist, and we need 18 joists (as in the prior example), the total labor hours for that specific task alone would be 36 hours. Multiplying this by the hourly rate, and adding additional tasks’ labor costs and overhead will provide the complete labor cost estimate.

Q 3. Describe your process for generating accurate quantity takeoffs for joist projects.

Accurate quantity takeoffs are critical for precise estimating. My process begins with a thorough review of the architectural and structural drawings. I carefully measure all dimensions needed to determine the length, spacing, and quantity of each joist. I use digital takeoff software to assist in this process, ensuring accuracy and speed. I then use the provided specifications to determine the type and size of joists, hangers, and connectors. Next, I account for any waste or extra material, typically 5-10%, considering factors like cutting losses and potential damage during handling. Regularly, I cross-reference my takeoffs with the structural engineer’s calculations to ensure consistency and avoid errors. My quantity takeoff is then organized into a detailed spreadsheet for easy tracking and reference during the project.

Imagine a scenario with multiple spans and varying joist lengths. Using my takeoff software, I’ll automatically calculate the total linear feet of joists required per span and aggregate the results across the entire project, ensuring that no area is overlooked.

Q 4. What software are you proficient in for estimating and quoting?

I’m proficient in several estimating and quoting software packages. My primary software is On-Screen Takeoff, which I use for precise quantity takeoffs, material calculations, and report generation. I’m also experienced with other industry-standard software such as Timberline, and PlanSwift, which enhances my versatility and improves efficiency across different project types.

These programs aid in creating detailed estimates quickly and accurately reducing the potential for human error.

Q 5. How do you account for potential risks and unforeseen circumstances in your estimates?

Accounting for risks and unforeseen circumstances is crucial for accurate and reliable estimates. I incorporate a contingency factor, typically ranging from 5% to 15%, depending on the complexity of the project and site conditions. This contingency covers potential cost overruns due to unexpected site challenges (e.g., hidden obstructions, difficult access), material price fluctuations, or labor shortages. Furthermore, I meticulously review the project drawings and specifications to identify potential risks. This proactive approach helps minimize surprises and ensures the estimate remains viable even with unexpected changes. Detailed risk assessments, including historical data analysis and industry best practices, are integrated into this process.

For example, if a project involves working in a congested urban area with limited access, I’ll increase the contingency to account for potential delays and additional labor costs associated with navigating those challenges.

Q 6. Explain your understanding of different types of joists and their associated costs.

Understanding different joist types and their associated costs is fundamental. The most common types include engineered wood I-joists (strong and lightweight, but generally more expensive), dimensional lumber joists (cost-effective for shorter spans but less efficient for longer ones), and steel joists (strong and suitable for heavy loads but require specialized handling and often have higher upfront costs). Each type has varying material costs, influenced by factors like grade, dimensions, and market conditions. For instance, I-joists come in different depths and spans, each with a corresponding price. Similarly, dimensional lumber’s cost is influenced by the species of wood and its grading. Steel joists are priced based on their weight and dimensions.

Understanding these variances allows me to optimize material selection for each project based on factors like cost, structural requirements, and the client’s budget. For instance, an open-plan design requiring long spans might justify the higher cost of I-joists due to their efficiency in terms of strength and weight.

Q 7. How do you handle changes in scope or design during the estimating phase?

Handling scope changes during the estimating phase requires a systematic approach. Upon receiving a change request, I carefully evaluate its impact on the original estimate. This involves assessing the changes in material quantities, labor hours, and any additional equipment or subcontractor services. I then generate a detailed change order, clearly outlining the revised quantities, costs, and justifications for the adjustments. This revised estimate is then presented to the client for approval, maintaining transparency and accountability throughout the process. Effective communication is key to maintaining the client’s confidence and minimizing any potential conflicts.

For example, if a client decides to change the type of joist mid-project, I would adjust the material costs accordingly, factoring in potential changes in labor time if different installation methods are needed.

Q 8. How do you ensure accuracy and consistency in your estimating process?

Accuracy and consistency in estimating are paramount. My process relies on a structured approach combining detailed plans, accurate material takeoffs, and historical data. I begin by meticulously reviewing architectural and structural drawings to understand the project’s scope completely. This includes identifying the number, size, and type of joists required, as well as any special considerations like complex angles or unusual spans.

Next, I develop a comprehensive material takeoff, quantifying each item needed—joists, connectors, fasteners, and any specialized equipment. This isn’t just a simple count; I account for waste factors (e.g., cutting losses, damaged materials) based on past experience and project specifics. I use specialized software to aid in this process, cross-checking quantities to minimize errors.

Finally, I incorporate historical cost data, adjusting for current market prices and inflation. I maintain a detailed database of past projects, noting material costs, labor rates, equipment rental fees, and unforeseen expenses. This allows for realistic cost predictions, avoiding over- or underestimation. Regularly reviewing and updating this database ensures the estimates remain current and reliable. Think of it as a recipe—the more times you bake the cake, the better you know how to adjust ingredients for a perfect outcome.

Q 9. Describe your experience with different bidding methods (e.g., lump sum, unit price).

I’m experienced with various bidding methods, each suited to different project needs. Lump-sum bidding involves providing a fixed total price for the entire project. This simplifies the process for the client, but necessitates a thorough and accurate initial estimate as changes are costly. For example, a lump-sum bid for setting 100 joists would cover all labor, materials, and equipment for that specific scope.

Unit-price bidding, conversely, assigns a price to each unit of work (e.g., $X per joist set, $Y per linear foot of beam). This is useful for projects with variable scopes or those subject to change orders, as the client pays only for the work performed. A bridge construction project, which might involve setting joists of various types and sizes, is well-suited to unit price bidding.

I also have experience with cost-plus bidding, where the client pays for all direct costs (materials, labor) plus a predetermined markup for overhead and profit. This is appropriate when there’s uncertainty regarding the project’s scope or when precise initial costing is challenging. A historic building restoration, where unforeseen complications are common, might be quoted this way. The chosen bidding method always depends on the project’s complexity, client preferences, and risk tolerance.

Q 10. How do you manage and track your estimates throughout the project lifecycle?

Managing and tracking estimates is crucial for project success. I employ a project management software to maintain a centralized repository for all estimation documents, including the initial bid, detailed cost breakdowns, change orders, and updated cost projections. This software allows me to easily track progress, identify potential cost overruns, and ensure transparency with the client.

For each project, I create a unique file containing all relevant documentation. This includes the original estimate, any revisions made during the project lifecycle, and a record of all approved change orders. This is critical for maintaining a clear audit trail and allows for easy reconciliation of actual costs against the estimated budget.

Regular progress meetings with the project team serve as checkpoints. We review the progress of the work against the budget. Any variances are promptly analyzed, and necessary adjustments are made to the estimate, ensuring everyone remains informed and aligned. This iterative approach ensures a well-managed project, preventing unexpected financial surprises.

Q 11. What are some common challenges faced during joist setting project estimation?

Joist setting estimation presents unique challenges. Accurately predicting material quantities is crucial, as incorrect estimations lead to significant cost overruns or delays. For instance, miscalculating the number of joist hangers or connectors can significantly impact the project timeline and budget.

Another challenge is unforeseen site conditions. Difficulties accessing the work area, unexpected obstructions, or variations in the existing structure can all increase labor costs and project duration. For example, discovering unexpected underground utilities during excavation can dramatically increase costs and delay the schedule.

Lastly, fluctuating material prices and labor rates are significant factors. Accurate cost projections require constant monitoring of market trends and adjusting estimates accordingly. Steel prices, for example, are volatile, requiring estimates to be regularly reviewed and adjusted to reflect current market conditions. Addressing these challenges involves thorough site surveys, detailed planning, and a proactive approach to cost monitoring.

Q 12. How do you handle discrepancies between your estimates and actual costs?

Discrepancies between estimates and actual costs are inevitable. My approach involves a systematic analysis to identify the root cause. I start by comparing the original estimate to the actual costs, item by item, to pinpoint the areas of variance. This detailed comparison helps identify if the differences stem from material cost fluctuations, underestimated labor, unforeseen site conditions, or changes in project scope.

Once the source of the discrepancy is identified, I prepare a variance report outlining the reasons for the differences and suggesting corrective actions for future projects. This report is presented to the client transparently, fostering trust and improving future estimations. For instance, if a delay resulted from a supplier’s failure, this would be clearly documented. Open communication and proactive problem-solving are essential.

Furthermore, learning from past discrepancies is critical. I analyze the reasons behind each variation to identify patterns and adjust my estimating techniques accordingly. This continuous improvement process, based on data-driven insights, reduces the likelihood of similar issues recurring in future projects.

Q 13. How do you incorporate safety measures into your joist setting cost estimations?

Safety is paramount. My estimates incorporate costs associated with all necessary safety measures. This includes providing and maintaining personal protective equipment (PPE) such as hard hats, safety glasses, and high-visibility vests for all personnel. It also covers the cost of fall protection equipment, such as harnesses and safety nets, particularly important when working at heights.

Costs associated with training are also factored in. Ensuring the team is properly trained on safe work practices, including lifting techniques, equipment operation, and hazard identification, is crucial. The costs of safety inspections, pre-job briefings, and any necessary site-specific safety plans are also accounted for. This proactive approach ensures a safe work environment while maintaining project budgets.

Finally, the potential for safety-related incidents and their associated costs (medical expenses, insurance claims, and project delays) are considered. While ideally, accidents never happen, it’s prudent to build in a small contingency for unforeseen situations. This approach demonstrates commitment to a safe working environment and minimizes the risk of escalating costs due to accidents.

Q 14. Explain your understanding of different types of contracts and their impact on estimating.

Understanding different contract types is crucial for accurate estimating. A fixed-price contract, where a lump-sum price is agreed upon upfront, requires a very precise and comprehensive estimate, as changes typically involve costly change orders. Any omissions or inaccuracies in the initial estimate directly impact profitability.

A cost-plus contract, where costs are reimbursed plus a markup, allows for greater flexibility but demands meticulous tracking of all expenses. Accurate record-keeping and regular reporting are crucial to avoid disputes and ensure fair compensation. Estimating for this type of contract focuses on careful costing of individual items and accurate record-keeping.

Time and materials contracts, where payment is based on the time spent and materials used, necessitate a detailed understanding of labor rates and material costs. This requires regular monitoring of both to ensure accurate billing and client satisfaction. Estimating under this structure focuses on hourly rates and material costs. A clear and concise contract is paramount to avoid disputes regarding labor charges and materials used.

Q 15. Describe your process for reviewing and validating your estimates before submission.

My process for reviewing and validating estimates is meticulous and multi-layered. It’s not just about crunching numbers; it’s about ensuring accuracy and mitigating potential risks. First, I perform a thorough self-check, verifying all calculations, material quantities, and labor hours. I use a checklist to ensure nothing is overlooked, from permits to potential site challenges. Second, I conduct a peer review, where another estimator independently verifies my work, catching any errors or inconsistencies I might have missed. This fresh perspective is invaluable. Third, I run a sensitivity analysis, tweaking key variables (like material prices or labor rates) to see how the estimate changes. This helps assess the estimate’s robustness and identify potential cost overruns. Finally, I compare my estimate to historical data for similar projects, ensuring it aligns with market rates and past performance. This entire process is documented, providing a clear audit trail.

For example, on a recent project, the peer review identified a minor oversight in the calculation of transportation costs. This early detection prevented a significant error in the final quote.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you collaborate with other team members (e.g., project managers, engineers) during the estimation process?

Collaboration is key to accurate and efficient estimating. I work closely with project managers to understand project scope, timelines, and potential constraints. This includes discussing potential site access issues, weather delays, and any unique challenges that could impact the schedule and costs. With engineers, I collaborate to understand the joist specifications, load calculations, and any special design features that require specific materials or installation techniques. For instance, we might discuss the use of specialized lifting equipment or the need for specific safety protocols based on the joist design and site conditions. Regular meetings and detailed communication through project management software are crucial to maintain clear communication and ensure all stakeholders are aligned.

Q 17. How do you stay updated on current industry standards and pricing for joist setting materials?

Staying updated on industry standards and pricing is an ongoing process. I subscribe to industry publications like Engineering News-Record (ENR) and relevant trade journals to keep abreast of market trends and material price fluctuations. I actively network with suppliers and subcontractors to get real-time pricing information. Online resources and manufacturer websites are also invaluable for accessing the latest material specifications and price lists. I also maintain a database of historical material costs, labor rates, and subcontractor pricing, which helps me benchmark against current trends and anticipate potential fluctuations. Regularly attending industry conferences and workshops further enhances my knowledge and connections.

Q 18. What is your approach to negotiating with subcontractors on pricing for joist installation?

Negotiating with subcontractors requires a balanced approach. I start by clearly outlining the scope of work, specifications, and payment terms. I present them with a detailed breakdown of the tasks involved and provide them with ample time to review and submit their proposals. I compare multiple bids, assessing not just price but also the subcontractors’ experience, reputation, and insurance coverage. Negotiations focus on clarifying any ambiguities, addressing potential risks, and ensuring a fair and mutually beneficial agreement. Building strong relationships with trusted subcontractors is crucial for consistent, high-quality work and competitive pricing. For example, I might negotiate a slight discount in exchange for a guaranteed completion date or a performance bonus for finishing ahead of schedule.

Q 19. How do you handle complex projects with multiple joist types and configurations?

Handling complex projects with multiple joist types and configurations requires a systematic approach. I break down the project into smaller, manageable segments, each with its own detailed estimate. I use a spreadsheet or estimating software to organize the different joist types, quantities, and associated costs. This allows for clear tracking of materials and labor for each segment. Accurate takeoff of quantities from blueprints is critical here. I cross-reference the specifications with engineering drawings to ensure compatibility and accuracy. Detailed communication with the engineers and the project manager is crucial to resolve any discrepancies and ensure the plan is feasible and cost-effective. Visual aids, such as 3D models or detailed drawings, can be beneficial in visualizing complex configurations and ensuring everyone is on the same page.

Q 20. Describe your experience with using different estimating software (e.g., PlanSwift, On-Screen Takeoff).

I have extensive experience with various estimating software, including PlanSwift and On-Screen Takeoff. Both offer powerful tools for digital takeoff, creating accurate material quantity estimates directly from blueprints. PlanSwift excels in its integration with various pricing databases, which streamlines the pricing process significantly. On-Screen Takeoff provides excellent features for managing complex projects with multiple layers and detailed drawings. My proficiency in these tools allows me to create detailed and accurate estimates efficiently, reducing manual calculation errors and saving time. I am also comfortable using other software like Excel for detailed cost tracking and analysis. Choosing the right software depends on the project complexity and available resources. The key is to leverage technology to enhance accuracy and efficiency.

Q 21. How do you account for waste factors in your material estimations for joist projects?

Accounting for waste factors is crucial for accurate material estimation. Waste percentages vary depending on the joist type, material, and installation method. For example, cutting and fitting losses are higher for custom-length joists compared to standard lengths. I develop waste factors based on historical data, industry best practices, and consultation with experienced installers. These factors are incorporated into my material quantity calculations. For instance, a 5% waste factor might be applied to lumber for standard joists, while a higher percentage might be added for intricate designs or site conditions requiring more cutting. I clearly document the waste factors used in my estimates to ensure transparency and accountability. Overestimating waste is costly, while underestimating leads to potential delays and added expenses. Therefore, using historical data and a cautious approach is essential for effective cost management.

Q 22. What is your approach to value engineering in joist setting projects?

Value engineering in joist setting focuses on optimizing the design and materials while maintaining structural integrity and meeting project requirements. My approach involves a thorough review of the plans, identifying areas where cost savings can be achieved without compromising safety or quality. This might involve exploring alternative joist types, optimizing spacing, or suggesting more efficient installation techniques. For example, if the design specifies heavy-duty steel joists where lighter, engineered wood I-joists would suffice, I’d propose the switch, providing detailed calculations to demonstrate structural adequacy and resulting cost savings. I also consider factors like material availability and lead times to ensure the most cost-effective and timely solution.

I meticulously document all value engineering suggestions, providing clear explanations and quantifiable cost comparisons for the client. This transparent process builds trust and allows for informed decision-making. I’m adept at using specialized software to model different scenarios and compare their performance and cost implications, ensuring the optimal balance of cost and performance.

Q 23. Describe your experience in preparing comprehensive and professional proposals and quotes.

Preparing proposals and quotes is a crucial part of my work. I begin by conducting a thorough site survey to accurately assess the project scope, including the number of joists, their size and type, the complexity of the installation, and any special conditions (e.g., difficult access). I then develop a detailed breakdown of all costs, including materials, labor, equipment rental, permits, and potential contingencies.

My proposals are professionally formatted and include:

- Project Overview: A clear summary of the project scope and objectives.

- Detailed Cost Breakdown: A comprehensive listing of all expenses, categorized for easy understanding.

- Timeline: A realistic schedule for project completion, taking into account potential delays.

- Payment Terms: Clearly defined payment schedule and methods.

- Terms and Conditions: A legally sound document outlining responsibilities and liabilities.

- References: A list of past projects and client testimonials.

Finally, I always present the quote in a clear and concise manner, ensuring the client fully understands all aspects of the project before signing off.

Q 24. How do you present and explain your estimates to clients or stakeholders?

Presenting estimates to clients requires clear communication and a willingness to answer questions thoroughly. I begin by providing a concise overview of the project and the total estimated cost. Then, I walk the client through the detailed cost breakdown, explaining each item in simple terms. Using visuals like diagrams or charts helps illustrate the process and the quantities involved. For instance, I might show a diagram of the joist layout with quantities clearly marked, alongside a chart illustrating the breakdown of material vs labor costs.

I encourage questions and address concerns patiently, ensuring the client fully understands the proposal before agreeing to proceed. I believe that open communication is key to building strong client relationships and ensuring project success. I also emphasize the value proposition – how my expertise and efficient methods translate to a cost-effective and high-quality result for the client.

Q 25. How do you handle conflicting information or unclear specifications in project documents?

Conflicting information or unclear specifications are common challenges in construction projects. My approach involves systematically addressing these issues. First, I carefully review all project documents, identifying inconsistencies or ambiguities. Then, I reach out to the architect, engineer, or project manager to clarify the specifications. I meticulously document all communications and agreements reached during this clarification process. If the discrepancies can’t be resolved through communication, I’ll outline the different interpretations and their cost implications in my estimate, allowing the client to make an informed decision.

For instance, if the drawings show a certain joist type but the specifications mention a different one, I’ll document both and propose the most likely scenario, explaining why, along with the cost impact of the alternative options. This proactive approach ensures that everyone is on the same page and avoids costly rework later in the project.

Q 26. What is your understanding of the role of insurance and bonding in joist setting projects?

Insurance and bonding are essential for protecting both the contractor and the client in joist setting projects. General liability insurance covers potential damages or injuries to third parties during the project. Workers’ compensation insurance protects employees in case of work-related injuries. A surety bond guarantees that the contractor will fulfill the contractual obligations, protecting the client in case of project failure or default.

Understanding and obtaining the appropriate insurance and bonding is crucial for securing projects and ensuring compliance with legal requirements. I always ensure that I have adequate coverage for all projects and provide clients with proof of insurance and bonding as part of the proposal. This demonstrates professionalism and protects both parties involved.

Q 27. How do you ensure your estimates comply with all relevant building codes and regulations?

Compliance with building codes and regulations is paramount. My approach is proactive, beginning with a thorough review of the applicable codes for the project location. I use code-checking software to ensure the proposed joist design meets all relevant standards for load-bearing capacity, span, spacing, and fire resistance.

I stay updated on the latest code changes through continuing education and professional organizations. I also consult with structural engineers when necessary to ensure the design meets all requirements. Before submitting the final proposal, I meticulously check for code compliance to minimize the risk of delays or penalties during inspections. This commitment to compliance minimizes risks and helps build a reputation for reliability and professionalism.

Q 28. Describe a situation where your estimate proved to be particularly accurate or beneficial to a project.

In a recent high-rise residential project, the initial engineer’s estimate for the joist system was significantly higher than anticipated. By employing value engineering techniques, I identified opportunities to utilize lighter, more cost-effective engineered wood I-joists instead of the heavier steel joists originally specified.

Through detailed structural calculations and simulations, I demonstrated that the wood I-joists could adequately meet the project’s structural requirements. This resulted in a 15% reduction in material costs and a 10% reduction in labor costs, saving the client over $50,000 without compromising safety or quality. My accurate estimate, combined with the value engineering strategies, ensured the project remained on budget and timeline, solidifying a strong client relationship.

Key Topics to Learn for Estimating and Quoting for Joist Setting Projects Interview

- Project Planning & Site Assessment: Understanding blueprints, site surveys, and identifying potential challenges (e.g., difficult access, unusual structural requirements).

- Material Quantification: Accurately calculating the required quantity of joists, fasteners, and other materials, considering waste and potential discrepancies.

- Labor Cost Estimation: Determining labor hours needed based on project complexity, crew size, and experience levels. Factoring in potential delays and unforeseen circumstances.

- Equipment Costs: Including the cost of necessary equipment rental or ownership, fuel, and maintenance in the overall estimate.

- Overhead & Profit Margin: Accurately calculating overhead costs (insurance, permits, transportation) and determining a reasonable profit margin to ensure project profitability.

- Software Proficiency: Demonstrating familiarity with estimating software and tools used in the industry for accurate and efficient calculations.

- Risk Assessment & Contingency Planning: Identifying potential risks and incorporating contingency plans into the estimate to mitigate potential cost overruns.

- Pricing Strategies & Proposal Writing: Understanding different pricing models (e.g., hourly rate, fixed price) and crafting clear, professional proposals that effectively communicate the project scope and cost.

- Contract Review & Negotiation: Understanding the terms and conditions of contracts and effectively negotiating favorable terms with clients.

- Communication & Client Management: Demonstrating strong communication skills and the ability to effectively manage client expectations throughout the project lifecycle.

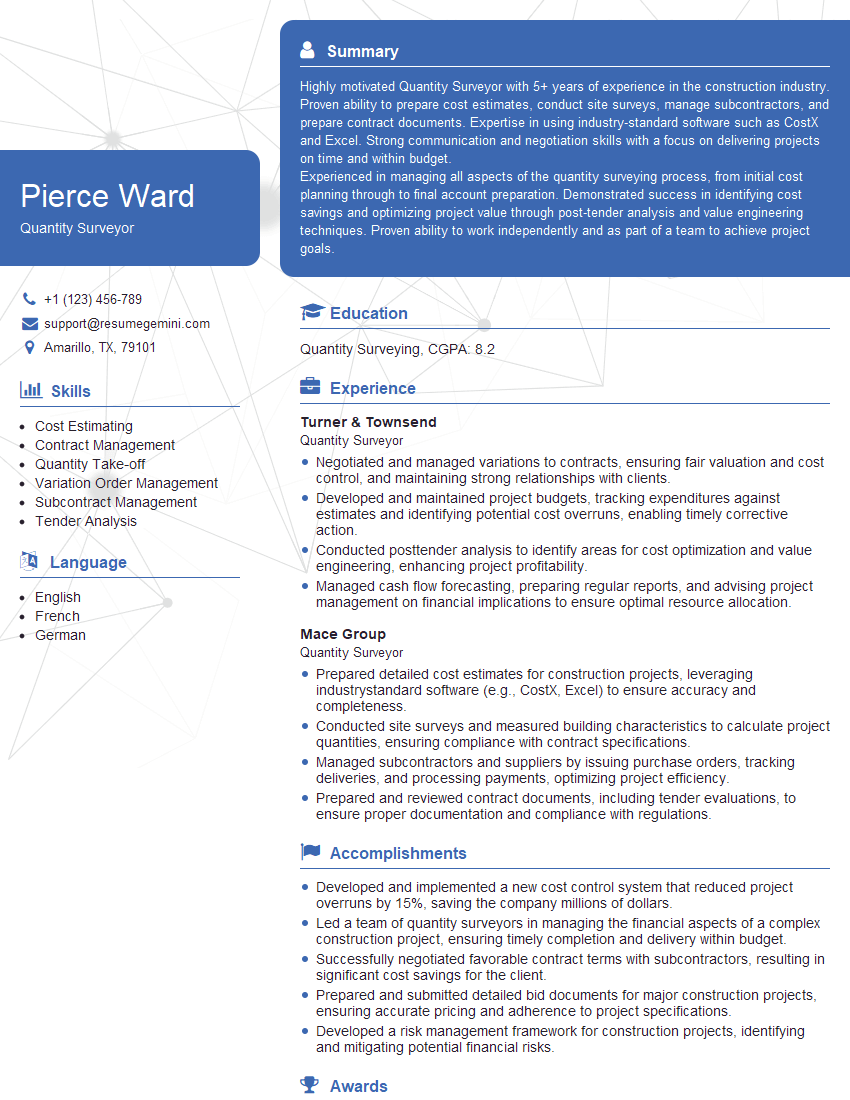

Next Steps

Mastering estimating and quoting for joist setting projects is crucial for career advancement in the construction industry. It demonstrates a valuable skillset, leading to increased responsibility and earning potential. To enhance your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to estimating and quoting for joist setting projects are available to guide you in this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good