The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Event and Bridal Gown Pressing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Event and Bridal Gown Pressing Interview

Q 1. What types of fabrics require special pressing techniques?

Certain fabrics demand specialized pressing techniques due to their unique properties. For example, delicate fabrics like silk, chiffon, and lace require a gentler approach to avoid damage. Heavier fabrics such as brocade or velvet need a different touch to prevent unwanted shine or flattening. Synthetic materials, like polyester blends, may melt under high heat, requiring lower temperatures and potentially a press cloth. Similarly, embellished fabrics with beads or sequins necessitate extra care to prevent scorching or dislodging the embellishments.

- Silk and Chiffon: Low heat, steam, and a press cloth are crucial to avoid scorching or creating a shiny surface.

- Lace: Requires a low heat setting and potentially a tailor’s ham for supporting delicate curves and preventing stretching.

- Velvet: Press from the wrong side with a press cloth and low heat to maintain the pile’s integrity and avoid creating unwanted shine.

- Brocade: A steam press may be necessary for heavier brocades, but always test a small inconspicuous area first.

Q 2. Describe your experience with different pressing equipment (e.g., steam press, iron).

My experience encompasses a wide range of pressing equipment, each with its strengths and weaknesses. I’m proficient with both steam irons and professional-grade steam presses. Steam irons are versatile for smaller jobs and touch-ups, offering precise control for delicate areas. However, for larger garments like wedding gowns, a steam press is significantly more efficient, providing even heat distribution and preventing creases from forming. I can expertly adjust the temperature and steam settings on both to suit various fabrics, from the most delicate silk to the heaviest brocade.

For example, I might use a steam iron for delicate beading, working methodically around individual embellishments. For a full-length gown, the steam press saves valuable time and effort, allowing me to efficiently press large areas while maintaining consistency and preventing creases.

Q 3. How do you identify and address common pressing issues like wrinkles, creases, or scorch marks?

Identifying and resolving pressing issues is a key part of my expertise. Wrinkles are often tackled with steam and proper pressure, working methodically from the top to bottom of the garment. Deep creases might require more intense steam and possibly re-pressing. Scorch marks, unfortunately, are harder to remedy. They often indicate that too much heat was used. In such cases, I might try careful dampening and re-pressing with a low heat setting, but sometimes the damage is irreversible.

For instance, if a client points out a wrinkle near a seam, I’ll carefully examine the fabric type, checking its care label. Using the appropriate temperature and steam setting, I’ll apply the iron or press cloth with gentle, even pressure. If the wrinkle persists, I’ll attempt re-pressing or strategically use a tailor’s ham for support in shaping.

Q 4. Explain your process for pressing a delicate beaded or embellished gown.

Pressing a beaded or embellished gown requires the utmost care and precision. My process prioritizes protection of the embellishments. I begin by carefully examining the gown for areas requiring special attention. A tailor’s ham or specialized pressing tools are used to support the fabric underneath the embellishments, preventing flattening or damage during pressing. A press cloth is always employed, acting as a protective barrier between the hot surface and the delicate embellishments. I use a low heat setting and work slowly and methodically around the beads or sequins, lifting and repositioning the press cloth as needed.

For example, I recently pressed a gown heavily embroidered with pearls. To prevent damage to these embellishments, I used a silk press cloth and applied very light pressure, moving the iron in short strokes to avoid undue stress on any part of the delicate embroidery.

Q 5. How do you maintain the integrity of different fabrics during pressing?

Maintaining the integrity of different fabrics during pressing is paramount. This involves careful selection of pressing temperatures, appropriate application of steam, and the use of press cloths where necessary. The fabric’s care label is always consulted to determine the suitable heat setting. For delicate fabrics, low heat and a press cloth are essential. Heavier fabrics may tolerate higher temperatures, but even then, a test on an inconspicuous area is recommended.

For instance, a wool gown requires a lower heat and a steam setting; otherwise, the wool fibres can be damaged. Conversely, a linen garment may require a medium-high setting to achieve crispness. It’s about understanding and adapting to each fabric’s unique characteristics.

Q 6. What safety precautions do you take when using pressing equipment?

Safety is a top priority when using pressing equipment. I always ensure the iron or press is placed on a stable, heat-resistant surface. The area is kept clear of flammable materials. I never leave the equipment unattended while it’s hot and unplug it completely when finished. I always use a press cloth to protect both the garment and myself from burns. I take care to avoid touching hot surfaces directly and use caution when handling steam to prevent burns. Proper ventilation is maintained to avoid breathing in excessive steam.

Q 7. How do you handle urgent requests or last-minute pressing needs?

Handling urgent requests requires efficient time management and prioritization. I assess the garment, the nature of the pressing needs, and available time to formulate a plan. If possible, I break the task into manageable segments to maximize efficiency. Communication with the client is key—keeping them informed of progress and any potential delays. I’ve learned to work quickly without compromising quality by streamlining my processes and focusing on precision. In some cases, for extremely urgent requests, I may need to adjust my schedule and dedicate extra time to fulfill the need, ensuring the client is satisfied.

Q 8. Describe your experience with various pressing techniques (e.g., blocking, pleating, shaping).

Pressing techniques for bridal and event gowns are crucial for achieving a flawless finish. They go beyond simple ironing; they’re about shaping and restoring the garment to its intended design. I’m proficient in several techniques:

- Blocking: This involves using a press cloth and a tailor’s ham or sleeve board to mold the fabric into its correct shape. Think of it as sculpting the garment – you’re carefully pressing sections to remove wrinkles and create sharp creases, like on a bodice or a structured skirt. For instance, I might block a structured bodice to ensure the seams are crisp and the overall shape is perfect.

- Pleating: Pleating requires precision and patience. I use specialized tools like pleating boards and irons to create consistent, even pleats, whether it’s on a skirt, a bodice, or a veil. Each fold must be perfectly aligned to maintain the design’s integrity. I recently pressed a gown with intricate box pleats that required meticulous attention to detail.

- Shaping: This encompasses a range of techniques to enhance the garment’s form. It could involve pressing darts to create a fitted silhouette or using a pressing cloth and a point presser to sharpen the edges of collars or lapels. For example, shaping the shoulders of a gown is vital to create a flattering and elegant look.

My experience spans a wide variety of fabrics and styles, allowing me to adapt my technique to each garment’s unique needs.

Q 9. How do you organize and prioritize pressing tasks for large events?

Organizing pressing tasks for large events demands a systematic approach. Prioritization is key. I begin by reviewing the event schedule and the number of garments, noting their fabrics and complexity. I then:

- Categorize by fabric type: Delicate fabrics like silk and lace require gentler handling and different pressing techniques compared to heavier fabrics like satin or brocade.

- Prioritize by urgency: Garments needed for the ceremony or crucial moments receive priority. I create a timeline that outlines which garments need to be pressed and when.

- Utilize a Pressing Log: I maintain a detailed log tracking each garment, its fabric type, pressing method used, and any specific notes or challenges faced. This ensures consistency and helps in troubleshooting issues if they arise.

- Teamwork (when applicable): For very large events, collaborating with other experienced pressers ensures efficient task completion. We divide tasks based on expertise and urgency.

This structured approach minimizes stress, guarantees timely completion, and ensures that every garment is handled with the care and precision it deserves. For example, at a recent wedding with over 20 garments, this system ensured everything was ready on time without compromising quality.

Q 10. What is your experience with stain removal prior to pressing?

Stain removal is a critical step *before* pressing. Pressing a stained garment can set the stain permanently. My experience encompasses a variety of stain removal techniques, tailored to the fabric type and stain itself. I always test any cleaning solution on an inconspicuous area first.

- Identifying the Stain: I carefully assess the type of stain (wine, grease, makeup, etc.) to determine the appropriate treatment.

- Pre-treatment: I use specialized stain removers and gentle cleaning agents. Knowing the fabric composition is essential—silk requires a far gentler approach than cotton. Sometimes, pre-soaking is necessary; other times, a spot treatment suffices.

- Gentle Cleaning: I use appropriate methods, such as dabbing rather than rubbing, to avoid spreading the stain or damaging the fabric.

For example, I once successfully removed a stubborn red wine stain from a delicate ivory silk gown using a specialized enzyme-based stain remover, followed by a gentle hand-wash and careful air-drying. The gown was then flawlessly pressed without any trace of the stain.

Q 11. How do you identify and correct pressing errors?

Identifying and correcting pressing errors requires a keen eye and a methodical approach. Common errors include scorch marks, creases in the wrong places, and shine.

- Careful Inspection: After pressing each section, I thoroughly inspect the garment for any flaws. Good lighting is essential.

- Re-pressing: Minor wrinkles are usually corrected with a light re-pressing. Using a press cloth prevents additional shine.

- Steam Treatment: Steam can sometimes help to remove minor scorch marks. However, this needs to be done cautiously and quickly to avoid further damage.

- Professional Restoration (in severe cases): If a pressing error is severe, such as a large scorch mark or significant damage, I will refer it to a specialist textile cleaner or restorer for professional repair.

By addressing pressing errors promptly and efficiently, I maintain high quality and client satisfaction. In one instance, I noticed a slight scorching on a satin gown. Using a damp press cloth and careful re-pressing, I was able to remove the mark completely without any visible sign of the error.

Q 12. How do you maintain the quality and consistency of your work?

Maintaining quality and consistency is paramount. I achieve this through a combination of factors:

- Regular Equipment Maintenance: My irons are cleaned regularly to ensure optimal performance and prevent damage to fabrics. I use distilled water to minimize mineral buildup.

- Consistent Techniques: Following standardized techniques ensures that every garment is pressed to the same high standard. I always use a press cloth to protect fabrics and prevent shine.

- Ongoing Professional Development: Staying updated on the latest pressing techniques and advancements ensures my skills remain sharp. This is done through professional development courses, online resources, and ongoing experimentation.

- Quality Control Checks: I always conduct a final quality check before delivering the garments, ensuring everything is pristine and wrinkle-free. I am also diligent in addressing any feedback, as a means of continuous improvement.

This commitment to quality assurance ensures a consistently high level of workmanship that clients can rely on.

Q 13. What are the different types of irons and their appropriate uses?

Different irons serve specific purposes. The choice depends on the fabric type and the pressing task at hand:

- Steam Iron: This is the workhorse for most pressing tasks. It offers both steam and dry heat options, making it versatile for a wide range of fabrics. I use this for most cotton, linen, and heavier fabrics.

- Dry Iron: Used for delicate fabrics that might be damaged by steam. It is important to keep the iron temperature lower when using a dry iron.

- Professional-Grade Steam System: These systems offer powerful, consistent steam, which is vital for large volumes of garments or heavy fabrics, such as those found in bridal gowns. They’re faster and more efficient. I use these for large events.

- Specialty Irons: Certain irons have specialized features like specialized soleplates, which help prevent pressing marks.

Understanding each iron type’s capabilities allows me to select the most appropriate tool for the job, enhancing efficiency and ensuring optimal results. I always test the iron temperature on a scrap piece of fabric before pressing the gown to ensure the setting is correct.

Q 14. How do you handle delicate fabrics like silk or lace?

Delicate fabrics like silk and lace require extra care and specialized pressing techniques. Here’s how I handle them:

- Low Heat and Steam: I always use a low heat setting and a press cloth. High heat can damage these fabrics irreversibly.

- Press Cloth Protection: A silk or muslin press cloth is crucial to protect delicate fibers from direct heat and potential shine.

- Light Touch: Gentle, gliding motions are important. Avoid pressing heavily or leaving the iron in one place for too long.

- Steam Only (sometimes): For some highly delicate fabrics, steam alone may be sufficient for removing wrinkles without any need for direct heat.

- Blocking Techniques: I may utilize blocking techniques, using tailor’s hams and pressing cloths to delicately reshape the fabric while avoiding damage.

Working with delicate fabrics demands a nuanced approach and significant attention to detail. For example, when pressing a silk bridal gown, I frequently use a low heat setting and a silk press cloth to ensure the silk’s luxurious drape and sheen are preserved.

Q 15. Explain your understanding of fabric properties and how they influence pressing methods.

Understanding fabric properties is paramount in successful gown pressing. Different fabrics react differently to heat and moisture, leading to varying pressing techniques. For instance, delicate silks require a low temperature and light touch to avoid scorching, while heavier brocades might tolerate higher heat and more pressure.

- Natural Fibers: Silk, wool, linen, and cotton all have unique responses to heat and moisture. Silk is extremely delicate and prone to scorching, requiring low heat and possibly a press cloth. Linen, on the other hand, is more durable and can withstand higher temperatures. Wool requires careful attention as it can easily become shiny or compressed.

- Synthetic Fibers: Polyester, nylon, and rayon require different approaches. Polyester can melt under high heat, while nylon can become distorted. Rayon, often blended with other fibers, needs a moderate temperature and careful handling to avoid damaging its texture.

- Blends: Many bridal gowns incorporate fabric blends. Understanding the fiber composition – e.g., a silk/polyester blend – is crucial. The pressing technique should prioritize the most delicate fiber in the blend.

For example, a gown with a silk bodice and a polyester skirt would require different pressing techniques and temperatures. I would use a low-temperature setting with a press cloth for the silk and a slightly higher temperature, possibly with a steam setting, for the polyester, always testing in an inconspicuous area first.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with working in a fast-paced environment.

I thrive in fast-paced environments. During peak wedding seasons, our workload dramatically increases. I’ve successfully managed multiple urgent gown pressing requests simultaneously, prioritizing rush orders and communicating effectively with clients and colleagues to ensure timely delivery. My organizational skills and ability to adapt to shifting priorities have been critical in such environments. I recall one instance where we had three wedding gowns come in requiring same-day service – all with different fabrics and intricate beading. Through methodical planning and efficient techniques, I was able to deliver all three gowns flawlessly before their respective ceremonies.

Q 17. How do you manage your time effectively to meet deadlines?

Effective time management is essential. I utilize a combination of techniques, including creating detailed to-do lists, prioritizing tasks based on urgency and complexity, and utilizing time-blocking strategies. For example, I allocate specific time slots for particular types of pressing tasks—delicate fabrics in the morning, heavier fabrics in the afternoon, etc. This allows for efficient workflow and minimizes transitions between equipment and techniques. Furthermore, I regularly review my schedule to identify and address potential bottlenecks or delays proactively. This helps in ensuring that I consistently meet deadlines without compromising on quality.

Q 18. Describe your experience with working independently and as part of a team.

I’m equally comfortable working independently and collaboratively. I’m highly self-motivated and capable of managing my workload efficiently without constant supervision. However, I value teamwork and collaboration, recognizing that exchanging ideas and sharing expertise enhances our overall efficiency and quality of work. In a team, I contribute actively, sharing my knowledge and supporting my colleagues, particularly when faced with complex or unusual fabrics. Conversely, when working independently, I consistently meet deadlines and maintain high standards of work.

Q 19. How do you handle customer complaints or concerns related to pressing services?

Handling customer complaints is crucial. I approach such situations with empathy and professionalism. My first step involves actively listening to the customer’s concern, acknowledging their feelings, and refraining from interrupting. Then, I objectively assess the situation, seeking to understand the root cause of the issue. Depending on the nature of the complaint, I might offer a solution such as re-pressing the garment, providing a partial refund, or offering an alternative service. My goal is always to resolve the issue fairly and to maintain a positive customer relationship. Open communication and a commitment to finding a resolution are paramount.

Q 20. What are the key factors to consider when choosing the right pressing temperature for a fabric?

Selecting the correct pressing temperature is crucial to prevent damage. Several factors must be considered:

- Fabric type: As previously mentioned, delicate fabrics like silk require low temperatures, while more robust fabrics like linen can tolerate higher temperatures.

- Fiber content: The percentage of natural and synthetic fibers in a blend impacts the appropriate temperature. Higher synthetic fiber content usually suggests a lower pressing temperature.

- Fabric color: Darker colors are more prone to scorching, so a lower temperature is generally recommended.

- Embellishments: Beading, sequins, and delicate embroidery require a lower temperature and might necessitate using a press cloth to protect them from direct heat.

Always test the temperature on an inconspicuous area of the garment first. A good starting point is a low setting. If the fabric shows no signs of damage, you can gradually increase the temperature as needed. This cautious approach helps avoid irreversible damage to the gown.

Q 21. How do you keep your pressing equipment clean and well-maintained?

Maintaining clean and well-maintained pressing equipment is critical. I follow a regular cleaning schedule, cleaning the ironing board cover frequently and cleaning my iron’s soleplate after each use. This involves wiping it down with a damp cloth to remove any residue. I also regularly descaling my iron to prevent mineral build-up, ensuring optimal steam performance. For professional irons with multiple settings, I perform thorough maintenance checks according to the manufacturer’s instructions. This preventative maintenance not only extends the lifespan of the equipment but also helps maintain the quality of the pressing service by preventing fabric damage from residue or malfunctioning equipment.

Q 22. What steps do you take to prevent damage to garments during pressing?

Preventing damage during gown pressing is paramount. It’s like handling a priceless piece of art – gentle care is essential. My process begins with a thorough inspection of the garment. I identify delicate areas like beading, embroidery, or lace, and mark them to avoid direct heat or pressure. I always test the iron’s heat setting on an inconspicuous area first to ensure compatibility with the fabric. I use a press cloth, usually a clean cotton sheet or a specialized pressing cloth, between the iron and the garment to act as a buffer and protect against scorching or shine. For delicate fabrics, I often employ a low heat setting and a gentle touch, using steam carefully to avoid damaging the fibers. Finally, I work in small sections, moving systematically to avoid pulling or stretching the fabric. I prefer to press on a well-padded surface such as a tailor’s ham or a sleeve board to help shape the garment and prevent unwanted creases or flatness.

Q 23. Describe your experience working with different types of wedding gowns (e.g., A-line, ballgown, mermaid).

My experience spans a wide range of wedding gown styles. A-line gowns, with their graceful, flowing silhouette, usually require attention to the skirt’s pleats and seams. Ensuring even distribution of heat and steam is crucial here to prevent sticking or unwanted wrinkles. Balloons gowns, known for their dramatic volume, demand careful handling of layers of fabric and intricate details. I often use a specialized pressing technique for these designs to avoid flattening the skirt or altering its intended fullness. Mermaid gowns, fitted close to the body and flaring dramatically at the knee, require precision in pressing the seams and shaping the silhouette. I pay close attention to the form-fitting upper section and ensure a smooth transition to the flare at the bottom. Each style has unique challenges and necessitates a tailor-made approach, allowing me to maintain the integrity of the design and the luxurious quality of the fabric.

Q 24. How do you ensure the longevity and preservation of pressed garments?

Long-term preservation is achieved through careful handling and storage. After pressing, I allow the gown to cool completely before packing it. I recommend using acid-free tissue paper to prevent creasing and protect delicate details. Storage in a breathable garment bag, ideally in a cool, dry, and dark place, protects against light damage and prevents dust accumulation. Avoid using plastic bags or airtight containers, as they can trap moisture and potentially damage the fabric over time. For exceptionally delicate or valuable gowns, professional preservation services that utilize archival-quality materials are an excellent choice.

Q 25. What are some common mistakes to avoid when pressing bridal gowns?

Common mistakes often include using too high a heat setting, causing scorching or shine. Ignoring the fabric type and applying inappropriate pressure can lead to fabric damage or distortion. Pressing directly on delicate embellishments without a press cloth can ruin beading or embroidery. Another frequent error is pressing the entire gown at once instead of working in sections; this can lead to stretching or uneven pressing. Lastly, failing to let the garment cool completely before storing can result in wrinkles or set creases.

Q 26. How do you identify and address pressing issues specific to different gown styles?

Addressing pressing issues specific to gown styles requires a keen understanding of the construction and fabric. For example, a ballgown with many layers needs careful pressing to ensure each layer is smooth without flattening the overall shape. A mermaid gown might have areas where the fabric is tightly fitted and needs attention to prevent puckering or stretching. Lace details require extra care to avoid heat damage or flattening of the delicate fabric. I have learned to adapt my approach depending on the style; sometimes a tailor’s ham is needed to maintain the shape, other times using steam as the primary method for delicate fabrics. Careful observation and experience are crucial in deciding on the best pressing method for each gown.

Q 27. What is your experience with using steam and dry pressing methods?

Steam and dry pressing are both valuable techniques, but I choose the method based on the fabric and design. Steam is ideal for most fabrics, as it gently relaxes fibers and removes wrinkles without direct heat damage. However, steam can be problematic with certain delicate fabrics or those prone to water damage, such as silk or beaded fabrics. Dry pressing, using only the iron’s heat, is more controlled and can be excellent for stubborn creases or heavier fabrics. However, it requires more precision and a lower heat setting to avoid scorching. The choice is not one-size-fits-all; it’s based on the specific characteristics of the wedding gown and the desired outcome.

Q 28. How do you handle alterations requests related to pressing?

Alteration requests related to pressing often involve addressing specific areas needing additional attention. This might include removing stubborn creases from certain sections, lightly pressing specific areas to achieve a more refined look, or ensuring specific design elements maintain a crisp finish. Before making any alterations, I always consult with the client to confirm their expectations and preferences. I work closely with the bridal salon or the client to meet the required specifications, often utilizing a combination of pressing techniques to achieve the perfect outcome. Open communication is key to ensure customer satisfaction and to avoid any misinterpretations.

Key Topics to Learn for Event and Bridal Gown Pressing Interview

- Fabric Identification and Handling: Understanding different fabric types (silk, satin, lace, etc.) and their specific pressing needs. Knowing how to avoid damage based on fabric composition.

- Pressing Techniques: Mastering various pressing techniques, including steaming, pressing with a dry iron, using a pressing cloth, and utilizing specialized equipment like a pressing ham or tailor’s dummy.

- Stain Removal and Pre-Treatment: Identifying and addressing common stains before pressing to prevent setting. Understanding appropriate pre-treatment methods for different fabric types.

- Understanding Garment Construction: Recognizing seams, darts, pleats, and other construction details to effectively press garments without distorting their shape or design.

- Equipment Maintenance and Safety: Proper use and maintenance of irons, steam generators, and other pressing equipment. Adherence to safety protocols to prevent accidents and damage.

- Quality Control and Inspection: Developing a keen eye for detail to identify and correct pressing imperfections, ensuring a polished and professional final product.

- Time Management and Efficiency: Prioritizing tasks and effectively managing time to meet deadlines, especially during peak seasons (weddings, events).

- Problem-Solving and Troubleshooting: Identifying and resolving common pressing issues, such as wrinkles, creases, scorch marks, and fabric damage.

- Professionalism and Communication: Maintaining a professional demeanor and effectively communicating with clients, colleagues, and supervisors.

Next Steps

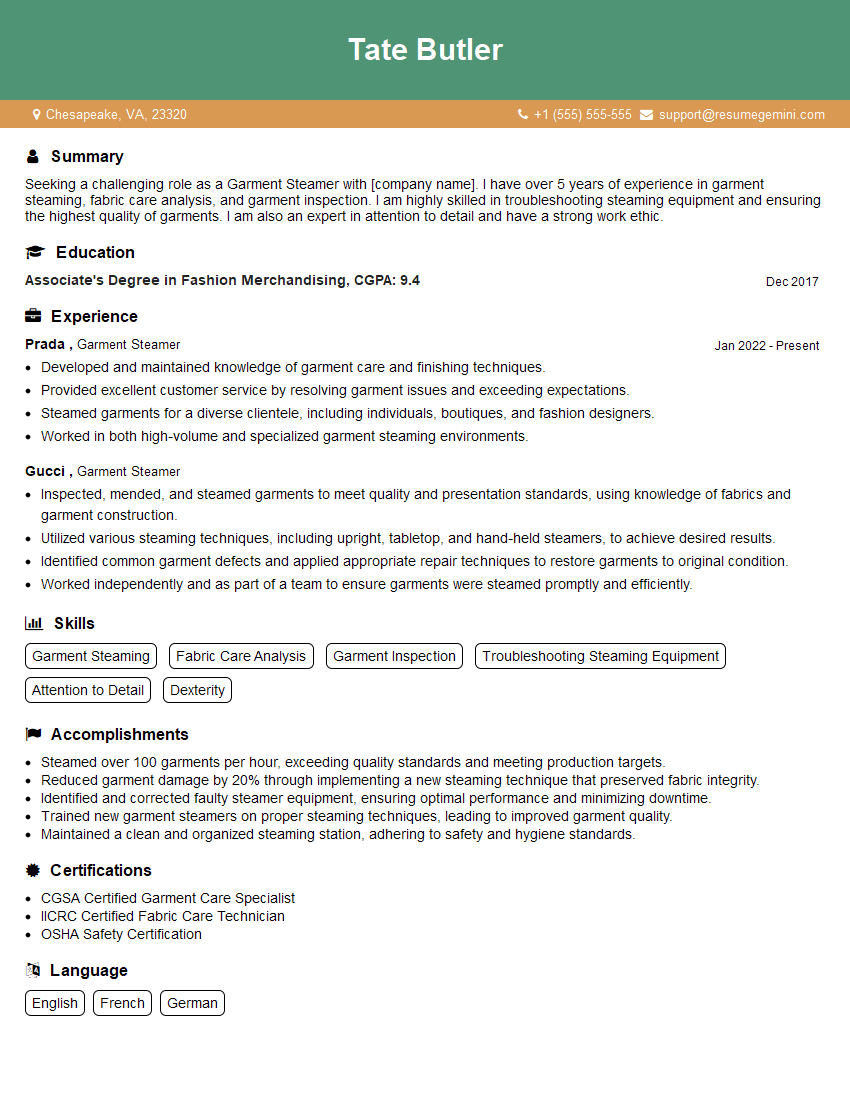

Mastering Event and Bridal Gown Pressing opens doors to exciting career opportunities in the fashion and event industries. It demonstrates a high level of skill and attention to detail, highly valued by employers. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to Event and Bridal Gown Pressing are available to help guide you. Take the next step toward your dream career – invest time in crafting a compelling resume that gets noticed.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good