Unlock your full potential by mastering the most common Excavating Soil interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Excavating Soil Interview

Q 1. Describe your experience with different types of excavation equipment.

My experience with excavation equipment spans a wide range, from small-scale machinery for delicate tasks to large-scale equipment for major projects. I’m proficient in operating excavators of various sizes – mini excavators ideal for confined spaces, medium excavators for general earthmoving, and large hydraulic excavators for massive projects. I’m also experienced with backhoes, crucial for trenching and digging, and loaders, vital for material handling and site preparation. Furthermore, I have extensive experience with specialized equipment like trenchers for creating precise trenches for utilities, and bulldozers for clearing land and moving large volumes of soil. My expertise extends to understanding the maintenance and safe operation of all this equipment, including preventative maintenance schedules and recognizing signs of potential malfunctions.

For instance, on a recent residential project, a mini-excavator was perfect for digging the foundation without damaging the surrounding landscaping. In contrast, a large hydraulic excavator was necessary for a recent highway project, where we needed to move massive amounts of earth quickly and efficiently. This varied experience allows me to choose the best tool for the job based on project specifics.

Q 2. Explain the process of selecting the appropriate excavation method for a given project.

Selecting the right excavation method is crucial for project success and safety. The process begins with a thorough site analysis, including soil testing and reviewing site plans. Factors to consider include the soil type (e.g., clay, sand, rock), the depth and extent of excavation, the presence of underground utilities, environmental considerations, and the project’s budget and timeline.

- Soil Type: Loose sand might require a different approach than hard clay or bedrock.

- Depth & Extent: Shallow excavations might only need hand tools, while deep excavations require specialized machinery and safety precautions.

- Utilities: Identifying and avoiding underground utilities (power lines, gas pipes, etc.) is paramount. This often requires utility locates and careful excavation techniques.

- Environmental Concerns: Protecting the environment might involve specific excavation methods to minimize disruption and soil erosion.

- Budget & Timeline: The chosen method needs to be cost-effective and meet the project deadlines.

For example, in areas with potential for unstable soil, a top-down excavation method might be safer, and in areas with many underground utilities, hand excavation might be necessary. The selection process involves careful weighing of these factors to determine the optimal approach. This often involves consulting with geotechnical engineers to ensure the safest and most efficient excavation plan.

Q 3. How do you ensure the safety of workers and equipment during excavation?

Worker and equipment safety is my top priority. This involves a multi-faceted approach starting before the first shovel of dirt is moved. It begins with thorough pre-job planning, which includes site surveys to identify hazards, developing a site-specific safety plan, and ensuring all workers receive proper safety training and have the necessary personal protective equipment (PPE).

- Pre-Job Planning: includes risk assessments and developing safety protocols.

- Regular Inspections: daily equipment and site inspections for any potential hazards.

- Proper Training: ensures all personnel understand and follow safety procedures.

- PPE: hard hats, safety glasses, high-visibility clothing, and appropriate footwear are mandatory.

- Emergency Response Plan: must be in place and communicated to everyone on site.

- Communication: clear and frequent communication between workers and supervisors is vital.

For example, we use spotters when operating heavy equipment in close proximity to workers, and we frequently conduct toolbox talks to address specific safety concerns. We adhere strictly to OSHA regulations and implement all necessary safety measures, and maintain detailed safety records to monitor and continuously improve our safety performance.

Q 4. What are the common soil types and their challenges during excavation?

Soil types significantly impact excavation methods and pose unique challenges. Common soil types include:

- Sand: Relatively easy to excavate but can be unstable, especially when wet. It requires careful attention to avoid collapses, particularly in trenches.

- Clay: Sticky and difficult to excavate, often requiring specialized equipment and techniques. It can be prone to swelling and shrinking with changes in moisture content, which can damage structures.

- Silt: Fine-grained soil that can be easily eroded by water. It requires careful water management during excavation.

- Gravel: Well-drained but can contain rocks and boulders, requiring robust equipment.

- Rock: Requires specialized equipment like rock breakers and drilling, and poses significant challenges.

For instance, excavating in clay requires careful management of water to prevent it from becoming overly saturated and unstable. Conversely, sandy soil needs careful shoring to prevent trench collapses.

Q 5. How do you handle unexpected subsurface conditions during excavation?

Unexpected subsurface conditions are a common occurrence in excavation. My approach involves a combination of preparedness, quick thinking, and adherence to safety protocols. When encountering the unexpected, the first step is to stop work immediately and assess the situation.

- Assessment: Determine the nature of the unexpected condition (e.g., rock, water, unstable soil).

- Safety Measures: Implement appropriate safety measures to protect workers and equipment.

- Consultation: Consult with engineers or other specialists to determine the best course of action.

- Revised Plan: Develop a revised excavation plan to account for the unexpected condition.

- Documentation: Thorough documentation of the event, including photos and detailed notes.

For example, if we discover an underground utility not marked on the plans, we immediately stop work, call the utility company, and work with them to ensure the safe relocation or protection of the utility before proceeding.

Q 6. Describe your experience with trench shoring and safety regulations.

Trench shoring is crucial for worker safety, especially in excavations deeper than 5 feet. My experience includes installing various types of shoring systems, including:

- Shoring Systems: These include sheet piling, soldier piles and lagging, and hydraulic shoring systems. The choice depends on factors like soil type, trench depth, and access.

- Safety Regulations: I am intimately familiar with OSHA regulations pertaining to trench safety, including requirements for inspections, soil testing, and the design and installation of protective systems.

- Inspections: Regular inspections are crucial to ensure the integrity of the shoring system.

I always ensure that the shoring system is properly designed and installed, meeting all applicable safety standards. Failure to do so can result in serious accidents. On one project, we encountered unexpectedly unstable soil, requiring us to immediately install a more robust shoring system than initially planned, underscoring the importance of adaptability and rigorous adherence to safety protocols. Proper documentation of each inspection is essential, providing a detailed record of the safety measures taken on the project.

Q 7. Explain your understanding of site surveying and its importance in excavation.

Site surveying is fundamental to successful excavation. It provides crucial information about the site’s topography, the location of underground utilities, and other relevant features. This information is essential for planning and executing safe and efficient excavation work.

- Topographic Survey: Defines the site’s elevation and contours, critical for determining excavation depths and volumes.

- Utility Locates: Identifies the location of underground utilities (gas lines, water pipes, electrical cables), preventing damage and potential accidents.

- Environmental Considerations: Helps identify environmentally sensitive areas that require special precautions.

- Planning & Design: Site survey data is essential for accurate project planning and design, ensuring effective utilization of equipment and resources.

For example, an accurate topographic survey allows for the precise calculation of earthwork quantities, avoiding over- or underestimation of material requirements. A detailed utility locate minimizes the risk of damaging essential underground infrastructure, potentially preventing costly repairs and service disruptions. Without accurate surveying, the entire excavation process becomes significantly riskier and less efficient.

Q 8. How do you manage excavation waste and disposal?

Excavation waste management is crucial for environmental protection and project efficiency. It involves a multi-step process starting with segregation. We carefully separate materials on-site into categories like clean fill (suitable for reuse), contaminated soil (requiring special handling), concrete and asphalt, wood, and other debris. This minimizes disposal costs and maximizes resource recovery.

Next comes transportation. We use designated trucks and containers to transport the segregated waste to appropriate facilities. Clean fill might go to a nearby construction project, while contaminated soil needs a licensed landfill capable of handling hazardous materials. Proper documentation, including manifests tracking waste movement, is critical for compliance.

Finally, we focus on proper disposal. This ensures compliance with all local, state, and federal regulations. This includes following specific procedures for handling potentially hazardous materials, like asbestos or lead paint, which might require specialized permits and disposal methods. We maintain detailed records of all waste disposal activities to demonstrate our commitment to environmental responsibility. For example, on a recent highway project, we successfully diverted over 70% of excavation waste from landfills by reusing clean fill on-site and donating suitable materials to local landscaping projects.

Q 9. What are your experience with GPS guided excavation?

GPS-guided excavation has revolutionized accuracy and efficiency in our projects. We utilize systems that integrate GPS data with excavator control systems, allowing for precise excavation to pre-designed digital models. This minimizes over-excavation, saving both time and money on materials. It’s particularly helpful in complex projects with intricate underground utilities. Imagine trying to dig around a buried gas line – the accuracy GPS provides is critical for safety and minimizing disruption.

My experience includes projects where we used GPS to excavate trenches for fiber optic cable installation within tight tolerances, significantly reducing the risk of damage to the cables. The technology also facilitates real-time monitoring of excavation progress, allowing for immediate adjustments and improved coordination among the team. We typically see a 15-20% reduction in excavation time and a similar reduction in material waste when using GPS-guided excavation compared to traditional methods.

Q 10. How do you ensure compliance with environmental regulations during excavation?

Environmental compliance is paramount in excavation. Before any work begins, we conduct thorough site assessments to identify potential environmental concerns, like wetlands, endangered species habitats, or areas with known contamination. We obtain all necessary permits and approvals from relevant authorities, adhering strictly to regulations concerning stormwater management, erosion control, and hazardous waste handling.

During excavation, we implement measures to minimize environmental impact. This includes using erosion control blankets, installing silt fences, and managing stormwater runoff to prevent soil erosion and pollution of nearby water bodies. We also conduct regular water quality testing and maintain detailed records of all environmental monitoring activities. Failure to comply can result in hefty fines and project delays. For example, on a recent project near a river, we implemented a comprehensive stormwater management plan that included temporary sediment basins and regular water quality monitoring, ensuring no pollutants entered the river system.

Q 11. Describe your experience with different types of backhoes.

My experience encompasses a variety of backhoes, from small, compact excavators ideal for confined spaces to large, powerful machines suited for massive projects. I’m proficient in operating both wheeled and tracked backhoes, each with its own advantages. Wheeled backhoes offer greater mobility on paved surfaces, while tracked backhoes provide superior traction and stability on uneven terrain.

The type of backhoe selected depends heavily on the project’s specific needs. For instance, a smaller, compact backhoe might be used for utility work in a densely populated urban area, while a larger, more powerful machine would be employed for large-scale earthmoving projects. I understand the nuances of various attachments, such as different sized buckets, rippers, and augers, and can select the right tool for the job to optimize efficiency and performance. Knowing how to maintain and troubleshoot different backhoe models is equally crucial for minimizing downtime and ensuring safety.

Q 12. How do you perform a pre-excavation site assessment?

A pre-excavation site assessment is a critical first step, ensuring safety and efficiency. It involves a thorough review of available plans and documents to identify potential underground utilities, such as gas lines, water pipes, electrical cables, and communication lines. We use various methods like utility locates (one-call systems), ground-penetrating radar (GPR), and even historical records to pinpoint the locations of these utilities.

The assessment also considers the soil conditions – its type, composition, and potential instability – which can impact excavation methods and equipment selection. We assess for potential environmental concerns such as contaminated soil or protected habitats. The information gathered informs our excavation plan, including safety measures, equipment selection, and mitigation strategies. For example, on a recent project, a pre-excavation survey revealed an unexpectedly high water table, leading us to adjust our excavation method to prevent flooding and potential damage.

Q 13. Explain your understanding of soil compaction and its importance.

Soil compaction is the process of increasing the density of soil by reducing its pore space. It’s essential for ensuring the stability and load-bearing capacity of foundations and pavements. Insufficient compaction can lead to settlement, cracking, and structural failure. Conversely, over-compaction can damage the soil structure and reduce its permeability, impacting drainage and potentially leading to other problems.

We use various methods to achieve optimal compaction, such as using compactors (vibratory, static, or pneumatic rollers) to compact granular soils (like sand and gravel) or using sheep’s foot rollers to consolidate cohesive soils (like clay). The degree of compaction is determined by specifying a required dry density which is compared to the measured dry density during field tests to ensure that design requirements are met. Regular testing using methods like the nuclear density gauge or sand cone method is crucial to ensure the desired level of compaction is achieved. Think of it like building a house – you wouldn’t want the foundation to settle, and proper compaction is the key to a stable base.

Q 14. How do you calculate cut and fill volumes?

Calculating cut and fill volumes is vital for earthmoving projects. It involves determining the amount of earth to be excavated (cut) and the amount to be placed (fill) to achieve the desired final grade. We use various methods for this calculation, the most common being the use of computer-aided design (CAD) software and surveying techniques.

The process often begins with creating a digital terrain model (DTM) of the existing site and the proposed final grade. The software then calculates the volume difference between these two models, providing precise cut and fill quantities. Traditional methods involve manual calculations using cross-sections and area measurements. Accurate cut and fill calculations are essential for estimating material costs, planning transportation logistics, and ensuring the project stays on budget. For example, on a large highway project, accurate cut and fill calculations enabled us to optimize material transport, minimizing costs and improving project schedule adherence.

Q 15. What are the safety procedures for working near underground utilities?

Safety when working near underground utilities is paramount. Before any excavation begins, we must locate and mark all underground utilities – gas lines, electrical cables, water pipes, etc. This is typically done through calling the local one-call center, also known as 811 in many regions. They will send utility companies to mark the location of their lines with paint or flags.

Once the lines are marked, we establish a safe working distance around them, usually exceeding the minimum distance specified by the utility company. This distance varies depending on the type of utility and the depth. We use hand tools carefully near the marked lines and avoid heavy machinery in that area. If a line is accidentally damaged, work stops immediately, emergency services are contacted, and a thorough investigation follows. Regular safety briefings reinforce these procedures, stressing the importance of careful digging and vigilant monitoring of the work site.

For example, on a recent project near a major highway, we had to excavate next to a high-voltage power line. The utility company marked a 10-foot safety zone. We used only hand tools within that zone, employed spotters to monitor the excavation, and ensured everyone wore high-visibility vests.

Career Expert Tips:

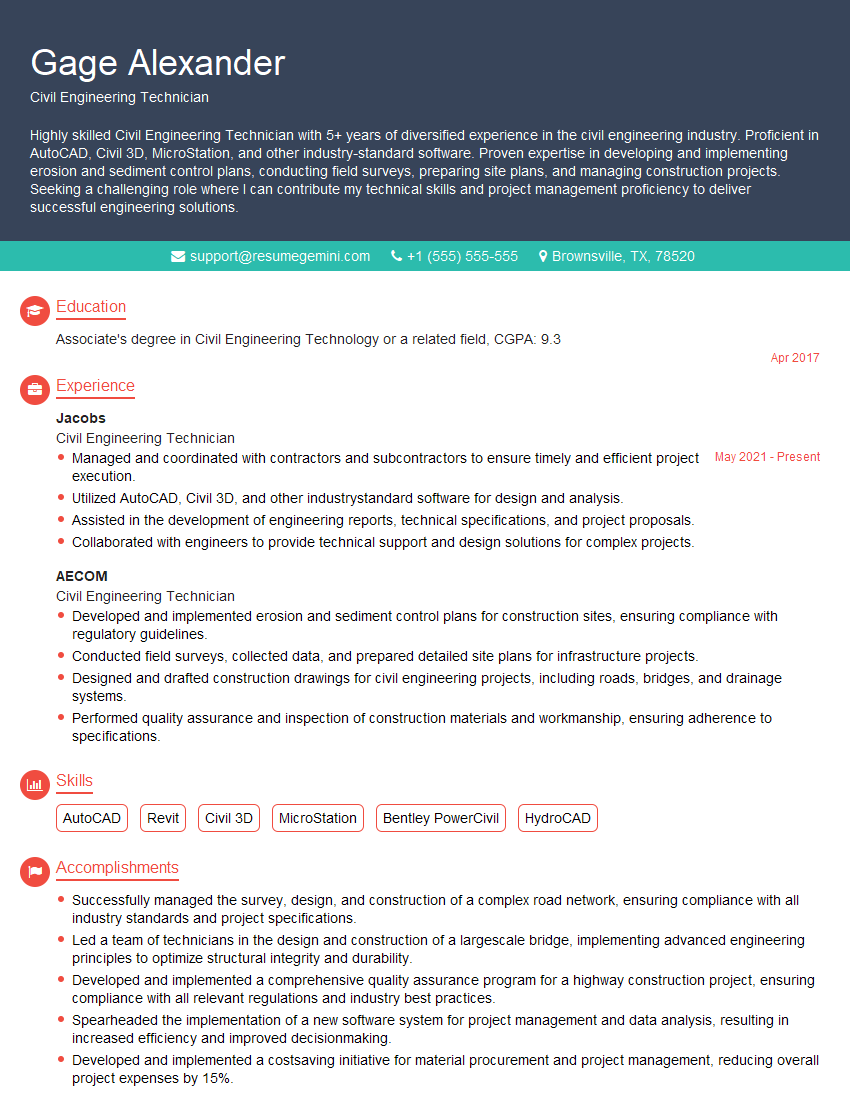

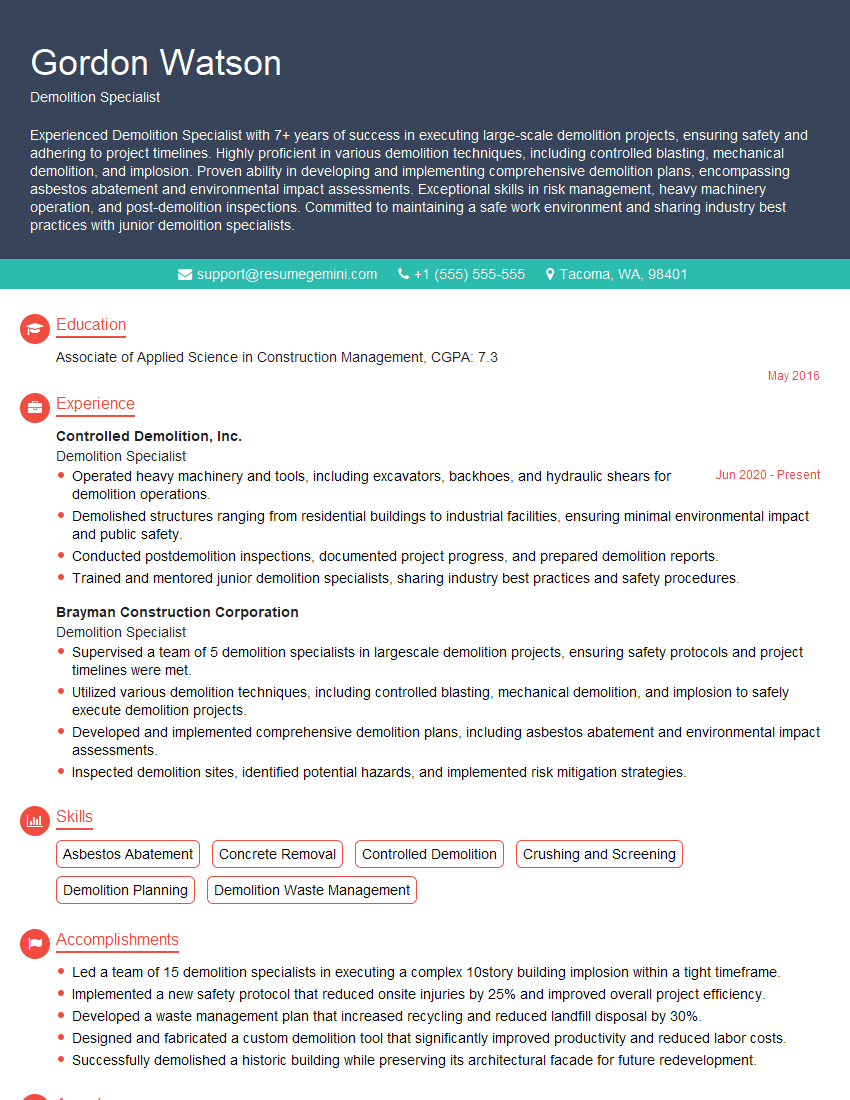

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with working on different types of terrains.

My experience spans various terrains, from stable, compacted soils to challenging, unstable conditions like rocky outcrops and loose, sandy soils. Working on compacted soil is relatively straightforward; however, we might need to employ techniques like pre-watering to reduce dust and improve compaction. In contrast, rocky terrain requires specialized equipment, like rock breakers and possibly explosives (under proper permits and supervision), to break up the rock before excavation. Loose, sandy soils present a risk of collapse, demanding rigorous shoring and support systems to ensure worker safety.

I’ve worked on projects involving expansive clay soils, which are known to swell and shrink with changes in moisture content. This requires careful consideration of foundation design and excavation techniques to avoid damage to structures. For instance, one project involved excavating in a region with expansive clay. We used precise grading techniques and implemented a robust drainage system to manage water infiltration and minimize soil movement.

Q 17. Explain how you would handle a slope stability issue during excavation.

Slope stability is critical. If I encounter a slope stability issue during excavation, the first step is to halt the work immediately. A qualified geotechnical engineer needs to assess the situation and recommend solutions. The engineer will usually conduct a slope stability analysis to determine the factors contributing to the instability, such as excessive water content, steep slopes, or weak soils.

Solutions could range from simple measures like reducing the slope angle to more complex ones such as installing retaining walls, soil nailing, or using anchored earth supports. We may also need to employ methods like benching, which involves creating a series of horizontal platforms to reduce the overall slope height. The choice of solution depends on several factors, including the severity of the instability, the soil type, and the overall project requirements. We always prioritize worker safety and implement the recommendations of the geotechnical engineer meticulously.

Q 18. How do you manage project timelines and budgets during excavation?

Managing project timelines and budgets requires careful planning and execution. We begin with a detailed project schedule, breaking down the excavation into smaller tasks with assigned timelines. This schedule is closely monitored using project management software, which helps track progress and identify potential delays. Budget management involves creating a detailed cost estimate, encompassing equipment rental, labor costs, material procurement, and potential unforeseen expenses. Regular cost tracking ensures that we stay within the allocated budget.

For example, we might use a Gantt chart to visualize the project timeline, assigning specific tasks to teams. Any deviations from the schedule, such as unexpected weather delays or unforeseen ground conditions, are addressed proactively through adjusted schedules and potential budget reallocations. Transparent communication with clients regarding any changes is vital to maintain a collaborative and successful project.

Q 19. What is your experience with different types of excavators (e.g., hydraulic, cable)

I have extensive experience with both hydraulic and cable excavators. Hydraulic excavators are versatile and efficient for most excavation tasks, particularly in confined spaces. Their precise controls allow for intricate work. Cable excavators, on the other hand, are better suited for heavy-duty applications like rock excavation or demolition, where their power and durability are advantageous.

Choosing the right excavator depends on the specific project requirements. For instance, a large-scale infrastructure project might use both hydraulic excavators for finer work and cable excavators for initial clearing and rough excavation. My experience includes operating and maintaining both types, along with a thorough understanding of their limitations and capabilities. Safety procedures for operating these machines are rigorously followed.

Q 20. Explain your experience with using blueprints and specifications for excavation.

Blueprint and specification interpretation is crucial for accurate excavation. We use these documents to understand the project’s scope, including the excavation depths, dimensions, locations, and required tolerances. Blueprints provide a visual representation of the site layout, while specifications detail the technical requirements and material specifications.

For example, a blueprint might show the location of a foundation and its dimensions, along with the depth of the excavation. Specifications would detail the type of soil to be excavated, the required level of compaction, and tolerances for deviations from the planned dimensions. We meticulously verify all measurements and coordinates on-site to ensure alignment with the blueprints and specifications. Any discrepancies are reported immediately to avoid costly mistakes.

Q 21. How do you ensure the accuracy of excavation depths and dimensions?

Ensuring the accuracy of excavation depths and dimensions is achieved through a multi-pronged approach. We utilize various tools, including laser levels, total stations, and GPS technology. Laser levels provide precise vertical measurements, ensuring the correct depth is maintained. Total stations offer accurate horizontal and vertical positioning for precise location and dimension control. GPS technology can be particularly useful on large-scale projects.

Regular checks and measurements are conducted throughout the excavation process to monitor progress and identify any deviations early on. For example, we might establish benchmark points at the start of the project and use these points as references for ongoing measurements. A detailed record of all measurements is kept, ensuring traceability and compliance with the project specifications. In the event of discrepancies, we adjust our procedures accordingly, using the appropriate equipment to correct any deviations, always prioritizing safety.

Q 22. How do you maintain and troubleshoot excavation equipment?

Maintaining and troubleshooting excavation equipment is crucial for safety and efficiency. It involves a proactive approach encompassing daily checks, preventative maintenance, and prompt response to malfunctions.

- Daily Checks: Before each shift, I meticulously inspect all equipment, including excavators, loaders, and backhoes. This involves checking fluid levels (hydraulic oil, engine oil, coolant), tire pressure, wear and tear on buckets and other components, and functionality of safety features like lights, horns, and emergency brakes. Any abnormalities are immediately reported and addressed.

- Preventative Maintenance: Regular scheduled maintenance, as per manufacturer recommendations, is paramount. This includes oil changes, filter replacements, lubrication, and thorough inspections by qualified mechanics. Preventative maintenance significantly reduces the risk of breakdowns and extends the lifespan of equipment. For instance, neglecting regular greasing can lead to costly component failures.

- Troubleshooting: When malfunctions occur, a systematic approach is vital. I start by identifying the problem – is it a hydraulic leak, engine issue, or electrical fault? I then consult manuals, diagnostic tools, and, if necessary, experienced mechanics. A typical troubleshooting process might involve checking fuses, inspecting wiring, or checking pressure readings. For example, if an excavator’s arm isn’t extending correctly, I’d first check the hydraulic pressure and then move on to examine valves and hoses.

Q 23. What is your experience with working in confined spaces during excavation?

Working in confined spaces during excavation requires a heightened awareness of safety protocols. The challenges include limited maneuverability, poor ventilation, and increased risk of cave-ins or equipment damage.

My experience includes projects where we excavated trenches in tight urban areas and utility tunnels. We always followed strict procedures, including:

- Confined Space Entry Permits: Before entering a confined space, we always obtain a permit-to-work, ensuring the space has been properly ventilated, assessed for hazards, and has designated attendants present.

- Atmospheric Monitoring: Regular testing of the air for oxygen levels, harmful gases, and other pollutants is crucial to ensure a safe working environment. We use specialized equipment for this.

- Shoring and Support Systems: To prevent cave-ins, we implemented appropriate shoring systems, such as trench boxes or sheet piling, matching them to the soil conditions.

- Communication Systems: Maintaining clear and constant communication between workers inside and outside the confined space is vital. We use two-way radios for this purpose.

These procedures were essential to ensure the safety and wellbeing of the team and the successful completion of the project.

Q 24. Describe your experience with working at night or in adverse weather conditions.

Working at night or in adverse weather conditions presents unique challenges but is sometimes unavoidable. Safety and efficiency become even more critical.

I’ve worked numerous shifts in both scenarios. Night work required extra lighting, ensuring adequate illumination of the work area and all machinery to avoid accidents. In adverse weather (heavy rain, snow, high winds), we adjusted work methods:

- Enhanced Visibility: We increased lighting levels for night work and used high-visibility clothing and equipment.

- Weather Monitoring: We constantly monitored weather forecasts and suspended work if conditions became dangerously unsafe, like during severe thunderstorms or blizzards.

- Modified Techniques: In wet conditions, we adjusted excavation techniques to avoid soil instability and potential landslides. This might involve slowing down operations, using different excavation methods, or using dewatering techniques to remove excess water.

- Safety Briefings: Before each shift in challenging conditions, we held thorough safety briefings, highlighting specific risks and protective measures.

Careful planning and preparation are crucial for safe and productive work in such environments.

Q 25. How do you communicate effectively with other members of the construction team?

Effective communication is the cornerstone of a successful excavation project. It involves clear, concise, and frequent interactions among team members, including excavators, spotters, surveyors, and supervisors.

I use a variety of methods:

- Pre-shift briefings: Before starting work, we hold briefings where we review the day’s plan, safety procedures, and potential hazards. This ensures everyone is on the same page.

- Hand signals: Precise hand signals are essential for coordinating the operation of excavators and other heavy machinery, especially in noisy environments.

- Two-way radios: These are crucial for maintaining communication between team members, especially in large or complex sites.

- Regular check-ins: Throughout the day, I regularly check in with team members to confirm progress, address concerns, and make adjustments as needed.

- Written communication: For complex instructions or changes to the plan, we use written documentation to ensure clarity and provide a record.

Open communication fosters a collaborative atmosphere, leading to safer and more efficient operations.

Q 26. How do you prevent and handle excavation-related accidents?

Preventing excavation-related accidents is paramount and requires a multi-faceted approach centered on planning, training, and adherence to safety regulations.

My approach includes:

- Site assessment: Thorough assessment of the site before work begins to identify potential hazards, such as underground utilities, unstable soil, and nearby structures.

- Locating underground utilities: Using utility locating services to accurately identify and mark the positions of underground pipelines, cables, and other utilities to avoid damage.

- Soil testing: Conducting appropriate soil testing to determine the soil’s stability and select appropriate excavation and shoring methods.

- Competent personnel: Ensuring all personnel involved in excavation work are properly trained and experienced in safe excavation practices and emergency procedures.

- Emergency procedures: Establishing clear and well-rehearsed emergency procedures to handle accidents, including emergency contacts, evacuation plans, and first-aid protocols.

- Regular inspections: Conducting regular inspections of the excavation site to monitor conditions and identify potential hazards.

- Shoring and slope protection: Implementing appropriate shoring or slope protection techniques based on the soil type and excavation depth to prevent cave-ins.

In case of an accident, immediate actions include securing the site, rendering first aid, contacting emergency services, and conducting a thorough investigation to determine the cause and prevent similar incidents from happening again.

Q 27. Explain your experience with different types of soil testing methods.

Soil testing is critical for determining the type of soil, its stability, and its bearing capacity, which directly impacts excavation methods and safety.

My experience includes various soil testing methods:

- Visual inspection: A preliminary assessment of the soil’s color, texture, and moisture content provides initial information.

- Standard Penetration Test (SPT): A common in-situ test where a weighted sampler is driven into the soil to determine its density and consistency.

- Cone Penetration Test (CPT): This method uses a cone-shaped probe pushed into the soil to measure its resistance, providing information about soil density and strength.

- Laboratory testing: Soil samples are collected and analyzed in a laboratory to determine their grain size distribution, plasticity characteristics, and other geotechnical properties.

- Shear strength testing: Tests performed on soil samples to determine the soil’s ability to resist failure under shear stress, which is vital for slope stability calculations.

The choice of testing method depends on the project requirements and the specific questions needing to be answered.

Q 28. Describe your experience with using and interpreting soil reports.

Soil reports provide crucial information for planning and executing safe and efficient excavation projects. My experience includes interpreting reports to inform design decisions, select appropriate equipment and techniques, and ensure project safety.

I interpret reports by:

- Identifying soil type: The report clearly indicates the type of soil encountered (e.g., clay, sand, gravel), which dictates the excavation methods and the need for shoring or other support systems.

- Assessing soil strength: Soil strength parameters (e.g., cohesion, angle of internal friction) are used to determine the soil’s stability and the likelihood of collapse. This informs decisions on excavation depths, support systems, and slope angles.

- Determining groundwater levels: The report shows the groundwater table, which impacts excavation techniques and may necessitate dewatering measures to prevent water ingress and soil instability.

- Identifying potential hazards: The report can identify potential hazards such as expansive soils, collapsible soils, or the presence of contaminants. This helps us take appropriate safety measures.

- Informing design decisions: Soil reports are vital in designing foundations, retaining walls, and other structures, ensuring they are adequately supported by the underlying soil conditions.

A comprehensive understanding of soil reports is vital for successful and safe excavation projects. I ensure the entire team understands and uses this information to make informed decisions.

Key Topics to Learn for Excavating Soil Interview

- Soil Mechanics: Understanding soil properties like shear strength, compaction, and permeability. This is crucial for selecting the right excavation methods and equipment.

- Excavation Methods: Familiarize yourself with various techniques such as trenching, open-cut, and mass excavation. Be prepared to discuss the advantages and disadvantages of each, considering factors like soil type, project size, and safety.

- Equipment Operation and Maintenance: Demonstrate knowledge of common excavating machinery (e.g., excavators, backhoes, bulldozers) including their capabilities, limitations, and routine maintenance procedures.

- Safety Regulations and Procedures: Showcase your understanding of OSHA (or relevant regional) safety standards pertaining to excavation, including trench shoring, personal protective equipment (PPE), and hazard identification.

- Site Preparation and Layout: Explain your understanding of pre-excavation site assessments, surveying techniques, and the importance of accurate planning to prevent unforeseen complications.

- Environmental Considerations: Discuss best practices for minimizing environmental impact during excavation, including soil erosion control, waste management, and remediation strategies.

- Problem-solving and Decision-Making: Be prepared to describe how you’d handle unexpected challenges during excavation, such as encountering unstable soil conditions or encountering underground utilities.

- Project Management Basics: Demonstrate familiarity with project timelines, budgeting, and coordination with other trades on a construction site.

Next Steps

Mastering the intricacies of excavating soil is paramount for career advancement in the construction and engineering fields. A strong understanding of these principles will significantly enhance your job prospects and open doors to more challenging and rewarding roles. To maximize your chances of landing your dream job, it’s crucial to create a professional, ATS-friendly resume that effectively highlights your skills and experience. We strongly recommend using ResumeGemini to build a compelling resume that stands out from the competition. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to the Excavating Soil field, guiding you in presenting your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good