Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Experience in digital printing interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Experience in digital printing Interview

Q 1. Explain the difference between CMYK and RGB color modes in digital printing.

CMYK and RGB are two different color models used in digital imaging. RGB (Red, Green, Blue) is an additive color model used for screen displays. It works by combining different intensities of red, green, and blue light to create a wide range of colors. Think of your computer monitor or phone screen – it uses RGB. CMYK (Cyan, Magenta, Yellow, Key – Black) is a subtractive color model used in printing. It works by subtracting colors from white light. Ink is applied to a white substrate, and each color subtracts from the white, resulting in the final printed color. The key difference is in how color is created: RGB adds light, while CMYK subtracts light from a white base. This means a color that looks vibrant on screen (RGB) might look slightly different when printed (CMYK) because of this fundamental difference in the way color is represented.

For example, a bright, pure green on your screen (RGB) might appear slightly duller or more muted when printed (CMYK) because inks can’t perfectly replicate the brilliance of light emission. Therefore, accurate color management requires converting RGB files intended for print to CMYK, often involving profiling and color adjustments to ensure the printed output is as close as possible to the screen representation.

Q 2. Describe your experience with different digital printing technologies (e.g., inkjet, toner-based).

My experience encompasses a broad range of digital printing technologies, primarily inkjet and toner-based systems. I’ve worked extensively with inkjet printers, from large-format wide-format machines used for banners and posters to smaller, high-resolution devices for photo prints and fine art reproductions. Inkjet technology offers incredible color gamut and detail, particularly when using pigment-based inks for superior lightfastness and longevity. I’ve also worked with various toner-based printers, including Xerox and HP devices, which are best suited for high-volume, sharp text-based documents and projects where precise linework is critical. Toner-based systems excel in terms of speed and durability but often have a smaller color gamut compared to inkjet.

In a recent project, I used a large-format inkjet printer to produce a series of vibrant, eye-catching posters for a trade show. The high-resolution inkjet technology allowed us to maintain superb image quality even at the large print dimensions. Conversely, for producing a large run of marketing brochures, I opted for a toner-based system to maximize production speed and achieve the consistent sharpness needed for the small text elements within the design.

Q 3. How do you troubleshoot common print quality issues such as banding, color mismatches, or registration problems?

Troubleshooting print quality issues requires a systematic approach. Banding, for instance, often points to a problem with the print head nozzles, insufficient ink, or incorrect print settings. I would first inspect the print head for clogs, run nozzle checks, and clean or replace the head if necessary. I would also examine the print settings, such as print resolution and ink limits, to ensure optimal settings are being used. Color mismatches often stem from incorrect color profiles, inadequate color calibration, or inconsistencies in the media. Addressing this involves checking the color profile used, verifying color calibration using a spectrophotometer, and ensuring the paper used is consistent across the print run. Registration problems, where colors or images are slightly misaligned, are typically caused by issues with the printer’s mechanics or media feeding system. This would involve checking the media path for obstructions, calibrating the registration settings, and perhaps inspecting the rollers for wear and tear.

For example, when encountering banding on a large-format print, I would carefully examine the print head nozzles for any clogs and perform a thorough cleaning, which often resolved the issue. If not, I would check the ink levels and replace the ink cartridges.

Q 4. What is your experience with color calibration and profile management?

Color calibration and profile management are crucial aspects of achieving consistent and accurate color reproduction in digital printing. I have extensive experience using spectrophotometers to measure and profile both printers and monitors. This involves creating ICC (International Color Consortium) profiles that map the color output of a specific device to a standardized color space, such as ISO Coated v2 (for print) or sRGB (for screens). These profiles allow software to accurately translate the digital color values into the closest physical approximation on the printing device. I also regularly check the accuracy of color profiles and update them as necessary due to factors like ink variations and printer wear. My experience extends to utilizing software such as Adobe Color Management Modules (CMM) and other profiling tools for optimal results.

In one instance, color mismatches arose in a large print job. By carefully profiling the printer and ensuring that the client’s design files were set to the appropriate color profile, and by performing a test print to verify the color settings before starting the main print run, we avoided costly reprints and ensured the final product met the client’s exacting color standards.

Q 5. Explain the importance of pre-flighting files before sending them to the digital press.

Preflighting files before sending them to the digital press is essential for preventing costly errors and production delays. Preflighting involves checking the file for potential problems such as missing fonts, incorrect color spaces, low-resolution images, and color management issues. A preflight check ensures that all elements are present, correctly configured, and ready for the printing process. This involves using software that automates various checks such as image resolution, color space, bleed, and other critical specifications. It’s like having a quality control check before you start the job. Without preflighting, you risk encountering unforeseen issues during printing that can lead to substantial time and cost overruns.

For example, a missing font could stop the printing process entirely, which is why a preflight check is crucial to identify this issue early on, allowing you to substitute a similar font or resolve the missing font issue before printing. Similarly, low-resolution images would cause pixelation and degradation in the final print; preflighting can help identify and address these issues before the printing process begins.

Q 6. Describe your experience with different types of substrates (paper, vinyl, canvas, etc.) used in digital printing.

My experience with substrates is quite diverse. I’ve worked with numerous paper types, ranging from standard offset paper and coated papers to specialty stocks like textured papers, recycled papers, and fine art papers. The choice of paper significantly impacts the final print quality, and understanding its characteristics (weight, texture, absorbency) is key to selecting the right one for a given application. I also have experience with vinyl, commonly used for vehicle wraps, signage, and decals. Vinyl’s durability and adaptability make it ideal for outdoor applications. I’ve also worked with canvas, suitable for high-quality fine art reproductions or gallery prints, offering a unique textural appeal and artistic finish. In each case, understanding the substrate’s properties is vital for achieving optimal print results and ensuring the finished product meets the client’s expectations and the project’s demands.

For example, when printing high-quality photographic reproductions, I would choose a fine art paper for its ability to render smooth transitions and subtle color variations. Conversely, for a durable outdoor banner, a robust vinyl substrate would be selected to withstand harsh weather conditions.

Q 7. How familiar are you with different finishing techniques (lamination, cutting, binding)?

I’m very familiar with a variety of finishing techniques that enhance the appearance, durability, and functionality of digitally printed products. Lamination adds a protective layer to printed materials, increasing their resistance to scratches, moisture, and UV damage. There are various types of lamination, including gloss, matte, and soft-touch finishes, each offering a unique aesthetic and functional benefit. Cutting involves precisely trimming printed sheets to specific sizes and shapes, often using automated cutting systems for high-volume jobs. This can include simple rectangular cuts or more complex shapes involving die-cutting. Binding techniques include saddle stitch, perfect binding, and spiral binding, each ideal for different document types. Saddle stitch is suitable for brochures and booklets, while perfect binding is typically used for books, and spiral binding for calendars or notebooks. Selecting the right finishing technique is critical to achieving the desired visual effect and ensuring the final product is functional and durable.

For instance, laminating a poster with a gloss finish adds a professional sheen and protection from the elements. For a high-page-count booklet, perfect binding is used to create a clean, durable, and professional-looking finished product.

Q 8. What is your experience with RIP software and its settings?

RIP software, or Raster Image Processor, is the crucial bridge between my design files and the digital printer. It takes vector-based files (like those from Adobe Illustrator) and converts them into the raster format (pixels) the printer understands. My experience encompasses working with various RIPs, including Onyx, EFI Fiery, and ColorProof. I’m proficient in adjusting settings like color profiles (e.g., ICC profiles for specific substrates and inks), resolution, halftoning techniques (AM, FM screening), and print modes (like overprint or spot colors). For instance, I recently optimized an Onyx RIP to achieve a smoother gradient on a textured canvas by adjusting the halftoning settings and color profile to compensate for the substrate’s absorbency. Understanding the interplay between these settings is critical for achieving the desired print quality and minimizing banding or other artifacts.

I also understand the importance of calibrating the RIP to my specific printer and media. This usually involves creating custom ICC profiles through spectrophotometric measurements to ensure accurate color reproduction. This is akin to calibrating a high-end camera to ensure consistent and accurate color capture, but in the realm of printing.

Q 9. Describe your experience with digital printing workflow management software.

Workflow management software is the backbone of efficient digital printing. My experience includes using various solutions, such as PrintSmith Vision and other custom-built systems. These platforms allow for streamlined job submission, tracking, and management. They facilitate better communication between designers, pre-press operators, and printers. For example, I use these systems to manage client approvals, track material costs and production times, and ultimately optimize our production efficiency. One instance involved streamlining our workflow using a custom-built system that integrated with our ERP, providing real-time inventory management and reducing delays by automating material ordering.

These systems are not just about tracking; they also allow for sophisticated features like automated imposition, which optimizes the arrangement of pages on a sheet for maximum efficiency. It’s like a highly organized assembly line, ensuring that every step is optimized for speed and accuracy.

Q 10. How do you ensure color consistency across different print runs?

Maintaining color consistency across print runs is paramount. My approach involves a multi-faceted strategy starting with consistent color profiling for every project, using spectrophotometers and software like X-Rite i1Profiler to create accurate ICC profiles. This process is regularly checked against industry standards and printer calibration charts. Regular cleaning and maintenance of the printing equipment is critical in preventing color shifts. Additionally, we use color management tools to ensure that the color profile assigned to the file aligns with the printer’s profile, preventing any unexpected variances. For instance, if a client needs 1000 business cards, we would perform test print runs to verify color accuracy and adjust the RIP accordingly to ensure consistency between every card.

We also maintain a comprehensive color library and use color standards to measure the difference between the required color and the printed output, using Delta E values to measure the difference. The goal is to achieve a Delta E value below 1, which represents a visually indistinguishable difference.

Q 11. What is your experience with managing ink levels and maintaining the digital printing equipment?

Managing ink levels and maintaining equipment is crucial for preventing costly downtime and ensuring print quality. I’m proficient in monitoring ink levels through the printer’s interface and implementing a preventative maintenance schedule. This involves regular cleaning of print heads, replacing worn parts promptly, and performing routine checks on all printer components. I’m experienced with various cleaning and maintenance procedures for different printer types (e.g., UV, latex, solvent-based). For example, our preventative maintenance checklist includes cleaning the print heads every morning and running a calibration print before each job to maintain optimal ink flow and color fidelity. This proactive approach minimizes disruptions and enhances print quality.

Regularly scheduled servicing by certified technicians is also a vital component of our maintenance plan. This ensures that any potential issues are identified early, preventing costly repairs in the long term. It’s like servicing a car regularly – preventing major breakdowns is far more economical than fixing a major fault later.

Q 12. How do you handle urgent print jobs and meet tight deadlines?

Handling urgent print jobs and meeting tight deadlines necessitates a well-defined system and prioritization skills. I prioritize urgent jobs immediately, allocating the necessary resources (personnel, equipment, materials) effectively. This often involves coordinating with the pre-press team to expedite file preparation and carefully scheduling print runs to minimize delays. We regularly use project management software to keep track of every step in the process, providing real-time updates to the client. For instance, if an urgent order comes in, I would immediately evaluate the job requirements, assess available resources, and create a revised schedule to accommodate the deadline. Transparent communication with clients is crucial to manage expectations.

Moreover, effective communication within the team helps us to work more efficiently and meet unexpected challenges. This involves daily briefings to track progress and identify any roadblocks that need immediate resolution.

Q 13. Explain your experience with different file formats used in digital printing (PDF, TIFF, etc.).

My experience includes working with a variety of file formats commonly used in digital printing, including PDF, TIFF, EPS, and JPEG. Each format has specific advantages and disadvantages. PDF is a preferred format due to its ability to preserve vector information and embedding fonts, ensuring consistent output across different systems. TIFF offers high-resolution image data, ideal for photographic prints. EPS is suitable for vector-based designs. JPEG, while commonly used, might involve some quality loss during compression. I’m proficient in evaluating each file for its suitability for the intended print job and preparing files for optimal print output. I also use tools like Adobe Acrobat to preflight files, identifying and rectifying any issues that could compromise print quality, such as incorrect color spaces or embedded low-resolution images.

For example, when preparing a client’s design, I check for embedded profiles, image resolutions, and color spaces, making adjustments as necessary to ensure compatibility with our printing equipment and specifications.

Q 14. How do you address customer concerns related to print quality or deadlines?

Addressing customer concerns regarding print quality or deadlines requires a calm and professional approach. I always listen carefully to the customer’s concerns, seeking to understand their perspective. If the issue is related to print quality, I investigate thoroughly, analyzing the print to identify the root cause – whether it’s an issue with the file preparation, printer settings, or materials used. If the problem is due to a deadline miss, I would explain the reasons for the delay and offer a solution, like expedited shipping or a discount on future services. My goal is always to maintain a positive relationship by providing solutions and demonstrating a commitment to customer satisfaction. For example, if a client received prints with a slight color variation, I would explain the technical reason and offer a reprint at no additional cost, while ensuring I have resolved the root issue to prevent a recurrence.

Open communication and transparency are key. By proactively updating clients on the status of their jobs, and keeping them informed, I minimize any potential misunderstandings and maintain a positive working relationship.

Q 15. Describe your experience with quality control procedures in digital printing.

Quality control in digital printing is paramount. It’s a multi-stage process ensuring the final product meets the client’s specifications and our high standards. My experience involves implementing and overseeing procedures at each step, from pre-press to post-press.

- Pre-press Checks: This includes verifying file integrity, color profiles (e.g., ensuring correct CMYK or RGB settings), and resolution. We use color management software to ensure consistent color reproduction. I’ve personally caught several instances of incorrect color profiles leading to significant reprint costs, had we not caught it early.

- Proofing: We utilize both soft proofs (on-screen) and hard proofs (printed samples) for client approval. Soft proofs are great for quick checks and revisions, but hard proofs are crucial for accurate color and texture representation before mass production begins. I’ve found that discrepancies between soft and hard proofs are often due to monitor calibration issues, which we proactively address through regular calibrations.

- In-Press Monitoring: During the printing process, we continuously monitor color accuracy, registration (alignment of colors), and density using colorimeters and densitometers. This ensures that every print is consistent. For instance, a sudden shift in ink density might indicate a problem with the press, which we promptly address to prevent waste.

- Post-Press Inspection: After printing, a rigorous inspection checks for defects like smudges, scratches, and misalignments. This involves both manual inspection and automated systems for large volumes. I’ve established procedures that allow us to swiftly identify and remove faulty prints before packaging, ensuring client satisfaction.

My approach ensures a proactive and preventative quality control system rather than reactive fixing of errors, minimizing waste and maximizing efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with variable data printing?

Variable data printing (VDP) is a powerful technique allowing for personalized elements within each print. My experience with VDP encompasses a wide range of applications, from personalized marketing materials to transactional documents.

- Data Integration: I’m proficient in integrating data from various sources, like databases and spreadsheets, into printing workflows. I understand the importance of data mapping and cleansing to ensure accurate and consistent output. For example, I’ve integrated customer databases with marketing campaign materials, personalizing each piece with the recipient’s name, address, and tailored offers.

- Workflow Management: I’m experienced in managing VDP projects, ensuring efficient data handling and seamless integration with the printing process. This includes using different software solutions for data merging and preflighting before sending to the press. I’ve successfully managed large-scale VDP projects, including hundreds of thousands of personalized mailers.

- Software Proficiency: I’m familiar with various VDP software packages, enabling the creation of dynamic templates and automated print runs. This includes using software like Adobe InDesign and specialized VDP plugins. I’ve developed efficient templates that reduce manual intervention, streamlining the process and allowing for faster turnaround times.

My expertise in VDP ensures that clients can leverage the power of personalization to improve their marketing campaigns and enhance customer engagement.

Q 17. How do you ensure the security and confidentiality of customer data?

Data security and confidentiality are paramount. We adhere to strict protocols to protect client information.

- Data Encryption: We employ strong encryption techniques both during transmission and storage of customer data. This ensures that sensitive information remains inaccessible to unauthorized individuals.

- Access Control: Access to client data is strictly limited to authorized personnel only, with role-based access controls implemented to ensure that only necessary individuals can access specific data.

- Secure Data Disposal: We have secure methods for disposing of client data, including secure shredding and data wiping of electronic media. This ensures that sensitive information is properly destroyed after its use.

- Compliance: We adhere to all relevant data protection regulations, such as GDPR and CCPA, ensuring that we meet legal requirements for handling client information. We regularly update our security protocols to stay ahead of evolving threats.

We treat data security as an ongoing responsibility, constantly evaluating and refining our procedures to maintain the highest standards of confidentiality.

Q 18. What is your experience with different types of digital presses (e.g., HP Indigo, Xerox iGen)?

My experience spans various digital presses, and I’m comfortable operating and maintaining several models.

- HP Indigo: I have extensive experience with the HP Indigo family of presses, particularly their renowned image quality and versatility. I understand their capabilities in handling various substrates and applications, such as photo-quality prints and high-value packaging.

- Xerox iGen: I’m also proficient with the Xerox iGen series, known for its speed and reliability in high-volume printing. I’ve worked with different models of the iGen, understanding their unique features and capabilities. I’m familiar with maintaining optimum print quality and productivity within their specified parameters.

- Other Presses: Beyond HP Indigo and Xerox iGen, I have experience with other digital presses such as those from Konica Minolta and Ricoh. This broader exposure enables me to adapt to different technologies and optimize print jobs for various printing requirements.

My knowledge extends beyond basic operation; I understand the nuances of color calibration, maintenance schedules, and troubleshooting for each press type. This ensures optimal performance and minimal downtime.

Q 19. Describe your experience with large-format digital printing.

Large-format digital printing presents unique challenges and opportunities. My experience includes working with various substrates and applications.

- Applications: I’ve worked on projects ranging from banners and posters to vehicle wraps and trade show displays. My experience extends to various materials like vinyl, canvas, and textiles.

- Software Proficiency: I’m familiar with large-format RIP software and design programs like Adobe Illustrator and Photoshop. I understand the importance of image resolution and file preparation for high-quality large-format prints.

- Media Handling: I’m adept at handling large rolls of media and ensuring proper feeding and alignment on the printers. I understand the nuances of different materials and how they behave on large-format presses.

- Finishing: I’m familiar with finishing techniques such as laminating, mounting, and cutting to enhance the durability and aesthetic appeal of the final product.

My experience with large-format printing includes managing complex projects from design to final installation, ensuring client satisfaction and high-quality results.

Q 20. How do you maintain a clean and organized workspace?

Maintaining a clean and organized workspace is critical for efficiency and safety. My approach focuses on proactive organization and regular cleaning.

- 5S Methodology: I incorporate the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to maintain a clean and efficient workspace. This system promotes a systematic approach to organization and cleanliness.

- Regular Cleaning: I routinely clean equipment, work surfaces, and the surrounding area. This involves using appropriate cleaning solutions for different equipment and materials to prevent damage or contamination.

- Material Organization: I keep materials and supplies organized using clear labeling and designated storage areas. This makes it easy to locate needed items and avoids clutter.

- Waste Management: I follow proper procedures for disposing of ink cartridges, cleaning solvents, and other waste materials, ensuring compliance with environmental regulations.

A well-organized workspace minimizes the risk of accidents and improves workflow, allowing for efficient and error-free operation.

Q 21. What safety procedures do you follow when working with digital printing equipment?

Safety is my top priority. I strictly adhere to all safety procedures when operating digital printing equipment.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, such as safety glasses and gloves, when handling chemicals or operating equipment. This protects against potential injuries from ink spills, cuts, or chemical exposure.

- Equipment Maintenance: I regularly check equipment for any signs of damage or malfunction. I immediately report any issues to prevent potential hazards.

- Lockout/Tagout Procedures: I follow lockout/tagout procedures when performing maintenance or repairs on equipment to prevent accidental start-ups.

- Chemical Handling: I’m trained in the safe handling and disposal of inks, solvents, and other chemicals. I understand the safety data sheets (SDS) for all materials used in the printing process and follow the instructions carefully.

- Emergency Procedures: I’m familiar with emergency procedures, including fire safety and first aid, and I know how to react in case of an accident.

A safe working environment is crucial, and I prioritize safety at every step of the printing process.

Q 22. Explain your experience with troubleshooting and resolving hardware and software issues.

Troubleshooting in digital printing involves a systematic approach combining hardware and software expertise. I’ve handled everything from paper jams and color inconsistencies to driver conflicts and network connectivity issues. For example, I once diagnosed a recurring banding issue on a high-volume Xerox iGen press. Initially, suspected a faulty printhead. However, after meticulously checking the toner supply, fusing unit temperature, and finally, the image transfer roller, I discovered minute scratches on the roller causing uneven toner transfer. Replacing the roller resolved the problem. In software troubleshooting, I’m adept at navigating RIP software (like Fiery or Harlequin) to identify and resolve color profile mismatches or job processing errors. A recent example involved fixing a workflow issue where raster images weren’t properly converting to the desired resolution within the RIP, resulting in blurry prints. By adjusting the image settings within the RIP and fine-tuning the output resolution, I successfully corrected the issue and avoided costly reprint runs. My approach always involves a detailed analysis, starting with simple checks and progressively moving towards more complex investigations. This methodical approach minimizes downtime and ensures the least disruption to production.

Q 23. How do you stay updated on the latest advancements in digital printing technology?

Staying updated in the dynamic field of digital printing requires a multi-pronged strategy. I actively participate in industry conferences like drupa (when held) and local trade shows, attending workshops and seminars to stay current on new technologies and best practices. I subscribe to relevant industry publications such as WhatTheyThink and Printing Impressions, reading articles and case studies to gain insights into emerging trends. Online resources play a vital role. I regularly visit manufacturer websites for updates on their equipment and software. I also actively engage in online forums and communities, sharing knowledge and learning from peers and experts, including participating in webinars and online courses focused on advanced digital printing techniques and software functionalities. This continuous learning keeps me at the forefront of advancements, ensuring I can effectively utilize the latest techniques and technologies in my work.

Q 24. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, and are in line with the market rate for a senior digital printing specialist with my expertise in troubleshooting and workflow optimization. I’m open to discussing a competitive salary package that reflects the value I bring to your team. I am happy to provide specific figures after learning more about the full compensation and benefits offered.

Q 25. What are your long-term career goals?

My long-term career goals center around leadership and innovation within the digital printing industry. I aspire to move into a managerial role where I can leverage my technical expertise to mentor and guide a team while driving operational efficiency and process improvements. Furthermore, I’m interested in exploring opportunities to contribute to the development and implementation of new technologies. Specifically, I’d like to be involved in the integration of Industry 4.0 principles (like automation and data analytics) into digital print workflows. Ultimately, I aim to become a respected leader who contributes significantly to the advancement of sustainable and high-quality digital printing practices.

Q 26. Why are you interested in this position?

I’m highly interested in this position because of [Company Name]’s reputation for innovation and commitment to excellence in digital printing. The opportunity to work with [specific technology or project mentioned in job description] is particularly exciting, aligning perfectly with my skillset and career aspirations. I’m also drawn to [Company Name]’s [mention company culture, values, or mission statement – e.g., commitment to sustainability, collaborative work environment, focus on client satisfaction]. I believe my expertise in troubleshooting and workflow optimization, combined with my passion for digital printing, makes me an ideal candidate to contribute significantly to your team’s success.

Q 27. Why are you leaving your current job?

My decision to leave my current position is driven by my desire to pursue new challenges and opportunities for professional growth. While I’ve valued my experience at [Previous Company Name] and learned a great deal, I believe this opportunity at [Company Name] offers a more significant chance to contribute to a dynamic and innovative team, working with cutting-edge technologies and focusing on the areas that most excite me. I am looking for a role with increased responsibility and opportunities for professional development.

Q 28. What are your strengths and weaknesses?

My strengths lie in my meticulous troubleshooting skills, my deep understanding of digital printing technology and workflows, and my ability to collaborate effectively with cross-functional teams. I am proactive, detail-oriented, and able to maintain a calm and effective approach even under pressure. One area I’m actively working to improve is my delegation skills. While I excel at tackling complex problems independently, I recognize the value of effectively distributing tasks within a team to optimize workflow efficiency. I’m currently implementing strategies to improve this area, including active listening and providing clear, concise instructions to team members. This self-awareness and proactive approach to development are key to my continuous professional growth.

Key Topics to Learn for Digital Printing Interview Success

- Digital Printing Processes: Understanding various digital printing technologies (e.g., inkjet, toner-based, UV printing), their applications, and limitations. Consider the pros and cons of each method for different projects.

- Color Management and Profiles: Learn about color spaces (CMYK, RGB, Pantone), profile creation and application, and how to ensure color consistency across different devices and media.

- Pre-press Preparation: Mastering file preparation for digital printing, including image resolution, color adjustments, trapping, and imposition. Discuss troubleshooting common pre-press errors.

- Print Finishing Techniques: Familiarize yourself with various finishing options like cutting, folding, binding, laminating, and embossing. Understand their impact on the final product and client expectations.

- Substrate Knowledge: Gain expertise in different printing substrates (paper types, vinyl, fabrics, etc.) and their suitability for specific printing methods and applications. Explain how substrate choice affects print quality.

- Troubleshooting and Problem Solving: Develop your ability to identify and resolve common printing issues, such as banding, color inconsistencies, and registration problems. Describe your problem-solving methodology.

- Workflow and Production Management: Understand the overall workflow in a digital printing environment, including job scheduling, file management, and quality control. Discuss how you contribute to efficient production.

- Software Proficiency: Highlight your skills with relevant software (e.g., Adobe Creative Suite, RIP software, print management systems). Be prepared to discuss your experience level and practical application.

- Health and Safety: Demonstrate awareness of safety procedures and regulations related to digital printing equipment and materials.

Next Steps

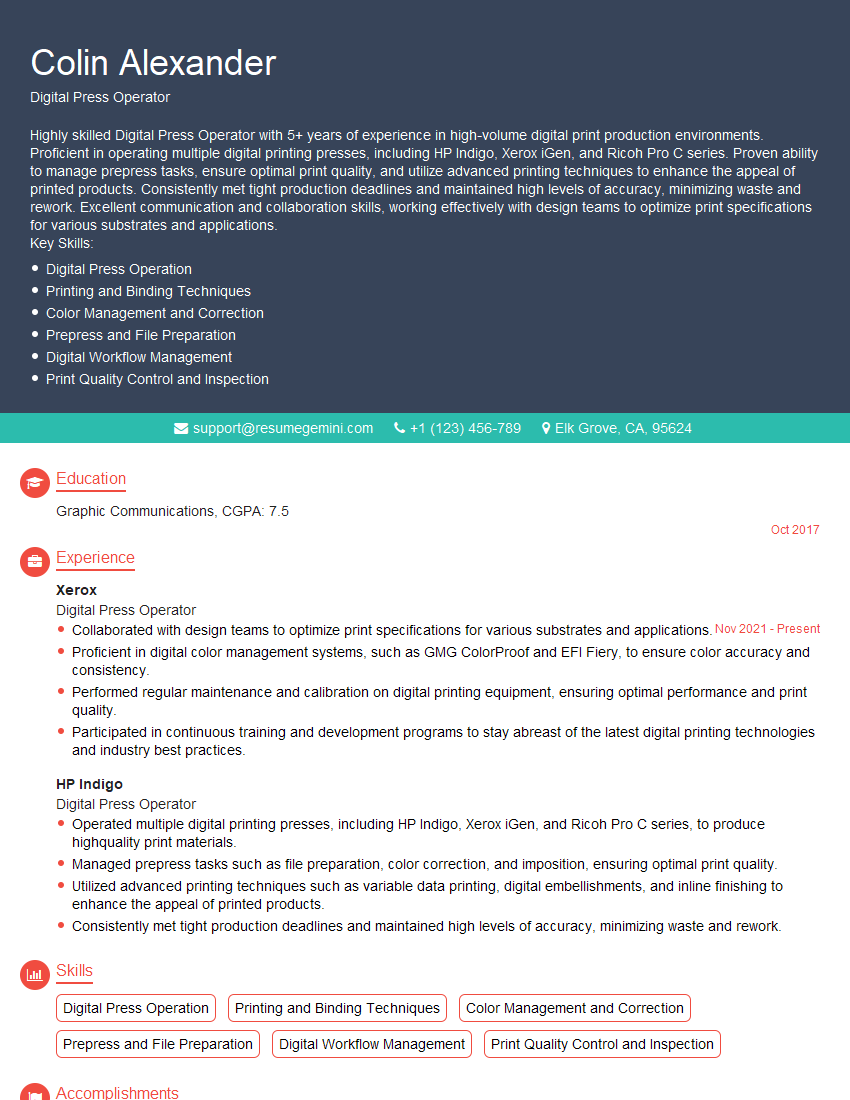

Mastering digital printing techniques is crucial for career advancement in this dynamic field. A strong understanding of these concepts will significantly enhance your interview performance and open doors to exciting opportunities. To maximize your job prospects, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to digital printing experience that you can use as a guide.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).