Are you ready to stand out in your next interview? Understanding and preparing for Experience in Prepress Troubleshooting and Problem-Solving interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Experience in Prepress Troubleshooting and Problem-Solving Interview

Q 1. Explain your experience with color management in prepress.

Color management in prepress is crucial for ensuring that the colors you see on screen accurately represent the colors that will appear in the final printed piece. It involves a complex interplay of color profiles, which are essentially sets of instructions defining how colors are represented in different devices. My experience encompasses a thorough understanding of these profiles, including ICC profiles (International Color Consortium), and their application throughout the workflow.

I’m proficient in using color management tools within software like Adobe Photoshop and InDesign to ensure consistent color reproduction. This includes assigning and converting color spaces (like sRGB, Adobe RGB, and CMYK), soft proofing to preview how colors will look on different substrates, and adjusting color settings to optimize for specific printing presses. For instance, I once worked on a project where the client’s Pantone colors were slightly off in the initial print proof. By carefully analyzing the color profiles and making targeted adjustments in the prepress stage, I was able to achieve the exact Pantone match in the final print, ensuring client satisfaction.

Q 2. Describe your process for identifying and resolving a trapping issue.

Trapping is the intentional overlapping of colors to prevent unsightly gaps between them during printing. Identifying a trapping issue usually involves carefully inspecting proofs for thin white lines or misaligned colors between adjacent elements. My process begins with a thorough visual inspection of the proof, zooming in to pinpoint areas with potential issues.

Once a trapping issue is identified, I determine the cause. This might be due to incorrect trapping settings in the prepress software, an improperly designed file, or even a problem with the printing press itself. I then consult the trapping specifications provided by the client or printing house and use prepress software to adjust the trapping settings, creating a new proof. Sometimes, a specific trapping style might be needed, such as spread or choke trapping. For example, if I notice that fine lines are breaking apart during the printing process, I would adjust the choke trapping settings to ensure a clean overlap. I repeat this process, reviewing proofs, until the trapping is correctly applied and the final print looks satisfactory.

Q 3. How do you handle a file with missing fonts or images?

Missing fonts or images are among the most common prepress problems. My approach involves a systematic process to identify and resolve these issues quickly and efficiently. First, I meticulously check the file for any warnings or error messages generated by the prepress software, which often highlight these missing elements.

If fonts are missing, I attempt to locate them using the font names displayed in the error messages. If they are not available in the system, I contact the designer to obtain the necessary fonts, making sure to use the exact same versions to avoid font substitution issues. Similarly, for missing images, I locate the files using the file paths indicated in the software. If these paths are incorrect or the images are unavailable, I contact the designer to obtain or replace these assets. In some cases, I may need to re-create a missing image based on available design assets or specifications. A detailed record is kept of any font and image replacements to ensure traceability and prevent future issues.

Q 4. What are your strategies for preventing prepress errors?

Preventing errors is far more efficient than fixing them. My strategy involves a multi-faceted approach encompassing thorough preflight checks, adherence to established workflows, and consistent communication. Preflight checks are non-negotiable; I use automated preflight tools within Adobe Acrobat and other software to rigorously examine files for any potential issues, including low-resolution images, missing fonts, incorrect color spaces, and other problems.

I also emphasize the use of standardized templates and style guides, ensuring consistency and minimizing the risk of errors. Clear and frequent communication with designers and clients is key to avoiding problems; ensuring all design elements meet print requirements and are provided in the correct file format at the beginning of the process is crucial. This proactive approach avoids costly delays and rework. Another important aspect is regular software updates. By keeping software updated, I can benefit from bug fixes and performance enhancements, improving the overall stability and accuracy of the prepress process.

Q 5. Explain your experience with different types of image formats (TIFF, JPEG, etc.) and their suitability for print.

Different image formats have varying properties that dictate their suitability for print. TIFF (Tagged Image File Format) is generally preferred for its lossless compression, high image quality, and ability to retain vital image data including color profiles. JPEG (Joint Photographic Experts Group), while widely used for web images, is a lossy format; this means some image data is lost during compression, potentially affecting print quality, especially for images with fine details or subtle color gradients.

For print applications, I almost always recommend TIFF. However, if file size is a critical constraint and the image quality loss can be accepted, JPEG can be used, but always at the highest possible quality setting. Other formats, like PNG (Portable Network Graphics) and GIF (Graphics Interchange Format), might be appropriate for specific elements like logos or illustrations with solid colors but are typically not ideal for high-resolution photographic images. Choosing the right format is essential; a wrong choice might result in unexpected color shifts, pixelation, or other artifacts in the final print, resulting in increased costs and delays.

Q 6. How do you ensure color consistency across different printing methods?

Maintaining color consistency across different printing methods, such as offset, digital, or large-format printing, is a challenge requiring a thorough understanding of color spaces and the capabilities of each printing technology. A key element is using a standardized color profile for the entire workflow – from design to press. I also ensure the use of calibrated monitors and printers to reduce color discrepancies.

I employ color management tools to translate the colors correctly to each output device, but it’s important to understand that there will always be some variation between printing methods. For critical color matching, I recommend creating color proofs and making necessary adjustments during the proofing stage to minimize variations. Communication with the print provider is also crucial; understanding their capabilities and color profiles allows me to adjust the prepress workflow accordingly, reducing the chance of unexpected color shifts. In addition to technical measures, creating accurate color standards, like PANTONE color swatches, helps maintain visual consistency.

Q 7. What software proficiency do you possess for prepress operations (e.g., Adobe Acrobat, Photoshop, InDesign)?

My software proficiency encompasses a wide range of prepress tools. I’m highly skilled in Adobe Creative Suite, particularly Adobe InDesign for page layout, Adobe Photoshop for image editing and retouching, and Adobe Illustrator for vector graphics. I also utilize Adobe Acrobat Pro extensively for PDF creation, preflighting, and the optimization of PDF files for print. Beyond Adobe products, I have experience with other prepress software, including color management solutions and RIP (Raster Image Processor) software, depending on the client’s specific printing needs.

My expertise extends to using these tools to optimize images, correct color profiles, manage fonts, and ensure that files are prepared to the highest standards for various printing processes. This includes knowledge of features like trapping, imposition, and color separation, crucial for producing print-ready files. Continuous learning keeps me updated with new features and industry best practices, so I am always learning and improving my skill set to meet the ever-evolving challenges in prepress.

Q 8. Describe your experience with imposition software and techniques.

Imposition software is crucial for arranging pages in a way that’s ready for printing. Think of it like arranging puzzle pieces to create a larger image – in this case, a print sheet. I’ve extensive experience with various imposition software packages such as Esko, Creo, and Callas software. My expertise extends beyond basic page arrangement; I’m proficient in creating complex imposition schemes for different printing processes like sheetfed, web offset, and digital printing. This includes understanding imposition parameters such as bleed, margins, gutters, and imposition controls to ensure efficient and accurate sheet layout, minimizing waste and maximizing productivity. For instance, I once had to create a unique imposition scheme for a large-format book with intricate folding requirements; using Esko’s advanced features allowed me to optimize the sheet layout, reducing paper waste by 15% and significantly impacting project costs.

I’m well-versed in techniques such as:

- Gang Printing: Combining multiple jobs onto a single sheet to reduce costs.

- N-up Imposition: Creating multiple smaller pages on one sheet.

- Signature Imposition: Arranging pages for folding and binding in a book or booklet.

- Personalized Imposition: Adapting imposition based on individual client requirements, for example variable data printing (VDP) projects.

Q 9. How do you troubleshoot problems related to image resolution and scaling?

Image resolution and scaling issues are common prepress problems. Image resolution refers to the number of pixels or dots per inch (dpi). Scaling changes the image size, and inappropriate scaling can significantly impact print quality. To troubleshoot, I start by checking the image’s resolution. Ideally, images should have a resolution appropriate to their final print size (300 dpi for most offset printing, higher for high-resolution printing). Low-resolution images result in blurry or pixelated prints. I then carefully inspect the scaling method. Enlarging a low-resolution image will only exacerbate the problem, while scaling a high-resolution image down is generally acceptable, provided the correct resampling technique is used (bicubic is often preferred for better quality). I use a combination of visual inspection, and software tools to assess image quality and adjust where necessary. I will often utilize specialized image editing software to check and adjust resolution and perform appropriate resampling to maintain image integrity and sharpness. For example, I once had to deal with a client who provided low-resolution images for a large-format poster. By carefully upscaling the images using advanced resampling methods and by combining images, I managed to achieve an acceptable print quality while minimizing visual artifacts.

Q 10. Explain your understanding of color profiles (e.g., ICC profiles) and their importance.

Color profiles, specifically ICC (International Color Consortium) profiles, are digital descriptions of a color space. Think of them as translators for colors. They ensure consistent color reproduction across different devices—your monitor, printer, and press. Each device has a unique color profile, describing how it renders colors. Without profiles, the same color might appear completely different on different devices, leading to print discrepancies. My understanding of color management is crucial because it ensures consistent color across different stages of the print workflow. I’m experienced in assigning, embedding, and converting color profiles to match the intended output device, ensuring color accuracy and consistency. For example, if a client provides a design file with an sRGB profile, and it needs to be printed on a CMYK press, proper profile conversion ensures the final print matches the onscreen design as closely as possible.

Q 11. What is your approach to identifying and resolving print registration issues?

Print registration refers to the accurate alignment of multiple colors or ink layers on a printed piece. Misregistration occurs when colors are slightly out of alignment, resulting in blurry edges or misaligned images. My approach to solving registration issues begins with careful examination of the press sheets and analysis of the press setup. I investigate several key areas to determine the root cause. Problems can arise from issues in the printing press itself, misaligned plates, or even issues with the pre-press file. I examine the plates for any defects or misalignment using a variety of methods, including physical inspection using magnifying lenses and digital tools to precisely measure plate alignment. Sometimes the problem may be due to incorrect settings within the prepress file itself. For instance, I once had to deal with consistent misregistration on a job. Careful analysis led to the identification of an incorrect setting in the imposition software resulting in an incorrect sheet layout. After correcting the layout and reimposing the job, the misregistration problem was completely resolved. If the issue lies with the printing press, I’d collaborate with the press operators to address mechanical issues or adjust press settings for accurate registration.

Q 12. How do you handle a situation where a client’s supplied files are not print-ready?

When a client provides non-print-ready files, I follow a systematic approach. First, I analyze the files to identify the issues. Common problems include low-resolution images, incorrect color modes, missing fonts, insufficient bleed, and incorrect file formats. Then, I communicate clearly with the client, explaining the problems and their impact on print quality. I provide specific recommendations for correcting the issues. Depending on the complexity, and the client’s requirements, I might offer to correct these issues myself (at a cost). This ensures the job progresses efficiently, and also offers a professional service to the client. For example, if the client’s file lacks bleed, I explain why it’s necessary for clean cuts during printing, and I might either ask them to resupply it or I would handle it on their behalf, adding the required bleed to their files. Always maintaining good communication throughout the process allows me to effectively manage expectations and ensure the finished product meets the client’s expectations. Ultimately, proactive communication and problem-solving are key to resolving such challenges.

Q 13. Describe your experience working with different file formats and their compatibility with various printing devices.

I have extensive experience working with various file formats like PDF, TIFF, EPS, JPEG, and others. Each format has its strengths and weaknesses, and compatibility varies among printing devices. PDF is widely used for its versatility and portability, supporting various color spaces and print settings. TIFF is excellent for high-resolution images, whereas JPEG is known for its smaller file sizes at the cost of some quality. EPS is commonly used for vector graphics, making it ideal for logos and illustrations. Understanding these nuances is critical for selecting the appropriate format. I also know how to handle potential compatibility issues – for instance, color profile differences, embedded fonts, and transparency issues that might be introduced in converting files between various formats. For example, when dealing with older printing devices, I might need to convert a PDF file to TIFF and carefully manage embedded fonts and color profiles to avoid print issues. The key to successfully working with different file formats is a deep understanding of their capabilities and limitations and how they interact with different printing technologies.

Q 14. How do you address issues related to image compression and artifacts?

Image compression and artifacts are often intertwined. Compression reduces file size, but excessive compression can lead to visual artifacts like blockiness, banding, or loss of detail. My approach involves assessing the level of compression and its impact on image quality. For print work, I generally favor lossless compression methods or using compression levels that maintain high quality. If artifacts are already present, my goal is to either correct the image using image editing software (using tools such as noise reduction and sharpening) or to work with the client to source higher-quality images. Sometimes a complete replacement of the image may be necessary. I always prioritize quality over file size when it comes to print, even if it means slightly larger file sizes and longer processing times. For example, a client once provided images with severe JPEG compression artifacts. We had to work together to find higher-resolution source images. This slightly increased our production time, but ensured a high-quality final product free of undesirable artifacts.

Q 15. What are your methods for ensuring the accuracy of barcodes and other critical data in print jobs?

Ensuring the accuracy of barcodes and critical data is paramount in prepress. Think of it like building a house – a single misplaced brick can cause a collapse. My approach involves a multi-layered system of checks and balances. First, I meticulously verify the data source itself, ensuring it’s clean and accurate before even entering the design software. This often involves working directly with the client to confirm details. Then, I use specialized software tools during the design and preflighting stages to verify barcode symbology, check digit accuracy, and overall data integrity. These tools not only identify errors but often suggest solutions. For instance, I use a barcode verifier to check for correct formatting, and a preflight profile that specifically flags any barcode errors. Finally, I implement visual proofing steps, where I visually inspect the barcodes on the proof to catch any unusual distortions or printing problems that might indicate a deeper issue. This combination of automated checks and manual verification significantly reduces the risk of errors reaching the press.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with various types of printing plates and their usage?

My experience encompasses a broad range of printing plates, each with its unique properties and applications. I’m proficient with traditional film-based plates, but my primary expertise lies in Computer-to-Plate (CTP) technologies. I understand the nuances of various plate types, including:

- Thermal plates: These are cost-effective and widely used, especially for shorter runs. I’m experienced with both positive and negative thermal plates and know how to select the right type based on the press and ink system.

- UV plates: These plates offer higher resolution and durability, making them suitable for longer runs and more complex designs, particularly those with fine details. I understand the intricacies of UV exposure and plate processing to optimize performance.

- Waterless plates: These environmentally friendly options require precise processing and handling, which is another area of my expertise. I know how to optimize the workflow to avoid issues like dot gain or ink transfer problems.

My knowledge extends beyond plate type selection to include the proper plate mounting techniques, ensuring optimal registration and print quality. The choice of plate is a crucial decision, impacting everything from cost and turnaround time to print fidelity, and I’m highly adept at making the right choice for each project.

Q 17. Explain your experience with CTP (Computer-to-Plate) workflow.

My CTP workflow experience is extensive, covering all aspects from RIP (Raster Image Processor) setup and color profile management to plate imaging and output. I’m adept at troubleshooting common CTP issues, such as plate defects, registration problems, and color inconsistencies. A recent project involved optimizing the RIP settings for a high-volume client, reducing platemaking time by 15% and improving print consistency. This involved careful analysis of the RIP parameters, color profiles, and plate type to fine-tune the workflow for optimal efficiency and quality. I understand the importance of using appropriate screening angles and frequencies to avoid moiré patterns and ensuring the accuracy of color profiles to match the intended Pantone or CMYK color space.

Q 18. Describe your process for validating print-ready files before sending them to the press.

Validating print-ready files is a crucial stage, and my process is methodical and thorough. It starts with a preflight check using industry-standard software like Acrobat Pro, ensuring the file meets all the necessary technical specifications for the intended press. This involves checking for color spaces, fonts, bleeds, image resolution, and overall file integrity. I then perform a visual inspection of the proof, checking for any discrepancies between the digital file and the physical representation. This often includes examining fine details like kerning, line weight, and image quality. Finally, I generate soft proofs to ensure consistency across various devices and color profiles. Addressing any identified issues early in the process prevents costly reworks later on. I always maintain a detailed log of all preflighting and proofing activities for efficient tracking and auditing.

Q 19. How do you handle emergency situations that require quick problem-solving during a press run?

Emergency situations demand quick thinking and decisive action. My experience has equipped me with the skills to handle such scenarios efficiently. For example, I once encountered a situation where a critical print job experienced a color shift mid-run. By quickly analyzing the press settings, ink densities, and plate condition, I pinpointed the issue to a partially clogged ink fountain. Through prompt cleaning and adjustments, we resumed the press run with minimal downtime and avoided significant financial losses. My problem-solving approach is based on a systematic analysis of the problem, using my experience to identify likely causes, and applying a step-by-step approach to testing and correcting potential issues. I know how to maintain accurate records so that the same mistake does not occur twice.

Q 20. Describe your experience with PDF workflows and preflighting.

PDF workflows are the cornerstone of modern prepress, and I’m highly proficient in their use. I leverage PDF/X standards to ensure color consistency and data integrity. Preflighting, a critical part of this workflow, is implemented using both automated tools and manual checks. I’m familiar with various preflight profiles, customizing them to match the specific requirements of each print job. A recent project involved creating a custom preflight profile to ensure all incoming files adhered to the client’s stringent specifications, significantly reducing the time spent on manual corrections and improving overall efficiency. Understanding how to troubleshoot PDF issues, like font embedding problems or color profile mismatches, is a skill I’ve honed over years of experience.

Q 21. How do you manage and prioritize multiple prepress tasks simultaneously?

Managing multiple prepress tasks simultaneously requires excellent organizational skills and a structured approach. I use project management software to track deadlines, assign priorities, and monitor progress. This allows me to effectively juggle various projects, ensuring each receives the necessary attention without compromising quality. I prioritize tasks based on urgency, complexity, and client deadlines, using a system that balances immediate needs with long-term project goals. I also proactively communicate with clients and team members to manage expectations and address any potential bottlenecks early on. This proactive approach allows me to ensure smooth workflow and timely delivery, even under pressure.

Q 22. Explain your understanding of print finishing considerations relevant to prepress preparation.

Print finishing significantly impacts the final product’s appearance and quality, and prepress preparation must account for this. Understanding finishing considerations ensures the printed piece meets the client’s expectations and is efficiently produced. This includes factors like:

- Die-cutting: If the job involves die-cutting (creating shapes or patterns), the prepress files must include precise die lines, ensuring they are accurately positioned relative to the artwork. Failing to do so could result in misaligned cuts or damaged prints. For instance, a business card with a rounded corner needs precise die lines to ensure the cut is clean and consistent across all cards.

- Folding and Creasing: For brochures or leaflets, accurate crease and fold marks are crucial. These marks guide the folding process, ensuring sharp folds and preventing cracking. Incorrect placement can lead to uneven folds or damaged pieces.

- Perforation: If the project requires perforation (creating tear lines, for example, in tickets or coupons), the prepress files must contain accurate perforation specifications so that the perforations are evenly spaced and tear cleanly. Otherwise, the tear lines might be uneven, making the piece difficult to separate.

- Binding: If the project is bound (like a book), the prepress files should accommodate for binding allowances to prevent content loss after binding. We need to consider spine width, gutter margins (extra space between pages), and appropriate bleed extensions to maintain a cohesive design after the binding process.

In my experience, I always work closely with the finishing department to review the job specifications and ensure the prepress files incorporate all necessary finishing elements accurately and completely, preventing costly reprints and delays.

Q 23. How do you ensure the accuracy and consistency of bleed and trim marks?

Accuracy and consistency of bleed and trim marks are paramount to avoid misprints and wasted materials. I ensure this through several steps:

- Precise Measurement and Placement: I use industry-standard software (like Adobe InDesign or Illustrator) with precise measurement tools to define bleed and trim areas according to the job specifications. Bleed (the extra area extending beyond the trim line) is crucial to prevent white edges after trimming, while trim marks show the final size.

- Templates and Guides: I utilize pre-set templates that incorporate the correct bleed and trim areas, preventing manual errors. These templates are based on the finishing requirements of the printing press and ensure consistency across all projects.

- Proofing and Verification: Before sending the files to the printer, I always perform thorough proofing to visually check the placement of bleed and trim marks. I also often create a soft proof (a digital representation of the final print), which allows me to accurately check the positioning of elements and simulate the appearance of the finished piece before the actual printing.

- Communication with Printers: Clear communication with the printer ensures the specifications are correctly understood. I confirm the bleed and trim dimensions with them, often sending a detailed preflight report outlining all settings and requirements.

Imagine a poster with an image extending to the edge; without proper bleed, the trimmed edges might expose unwanted white borders. My meticulous approach guarantees a professional and flawless final product.

Q 24. Describe your experience with quality control checks at various stages of prepress workflow.

Quality control (QC) is integrated throughout my prepress workflow. It’s not a single stage but a continuous process:

- Initial File Review: I check the client’s files for resolution, color mode (CMYK for print), fonts, images, and overall design integrity before any work begins.

- Preflight Checks: I use automated preflight tools to catch potential errors such as missing fonts, low-resolution images, color inconsistencies, and incorrect bleed and trim settings. This significantly speeds up the error-checking process.

- Proofing: I generate soft proofs for client approval and hard proofs (physical prints) for color accuracy verification and quality control before production.

- Final File Check: Before sending files to the printer, I conduct one last review ensuring everything is in order—all elements are in place, fonts and images are correctly embedded, and output settings align with the printer’s requirements.

For example, I once caught a significant color profile mismatch during the preflight stage, preventing a costly error that would have affected thousands of printed brochures. My rigorous QC approach ensures a consistent level of quality.

Q 25. How do you document and track prepress errors and resolutions?

Thorough documentation and tracking of errors and resolutions are essential for continuous improvement. I use a combination of methods:

- Detailed Error Logs: I maintain a log detailing the type of error, the location in the file, the cause (if known), the resolution implemented, and the date and time of correction. This helps me learn from previous mistakes and identify any recurring issues. I usually use a spreadsheet or a dedicated project management software for this.

- Version Control: I use version control systems (or even simple file naming conventions like adding version numbers) to track changes made to the files, allowing for easy rollback if necessary.

- Client Communication: I document all client communication, particularly regarding identified errors and changes. This ensures transparency and helps prevent future misunderstandings.

- Post-Production Analysis: After print production, I review the final product against the specifications to identify any unresolved issues or areas for improvement in future projects.

Imagine a situation where a font was missing—my detailed log would reveal it, enabling me to implement procedures to prevent this recurring in the future. Such documentation benefits both individual projects and long-term efficiency.

Q 26. What is your experience with working in a team environment to resolve prepress challenges?

Teamwork is crucial in prepress. I’ve worked in various collaborative settings, and effective teamwork involves:

- Clear Communication: Open and consistent communication with designers, printers, and clients ensures everyone is informed about the project status, challenges, and resolutions.

- Collaborative Problem-Solving: I actively participate in brainstorming sessions to find innovative solutions to complex prepress problems. Each team member contributes expertise to overcome obstacles.

- Shared Responsibility: Everyone on the team understands their role in the workflow, taking joint ownership of the project’s quality and timely completion.

- Knowledge Sharing: I actively share my knowledge and experiences with my team, training junior members and helping to improve overall team expertise.

For example, once, a complex color issue needed a combined approach involving my prepress expertise and the printer’s understanding of their equipment. Through open communication, we effectively resolved the problem. It’s not just about my skills; it’s about leveraging the entire team’s capabilities.

Q 27. How do you stay updated with the latest industry standards and technologies in prepress?

Staying updated is vital in the rapidly evolving prepress industry. I use various methods:

- Industry Publications and Websites: I regularly read industry publications, blogs, and websites to stay informed on the latest software, techniques, and trends in prepress.

- Trade Shows and Conferences: Attending trade shows and conferences provides hands-on experience with new technologies and networking opportunities with industry professionals.

- Professional Development Courses and Workshops: Participating in training courses and workshops allows me to deepen my knowledge in specific areas and earn certifications showcasing my commitment to professional development. This includes staying abreast of changes in color management and file formats.

- Networking: I actively engage with other professionals through online forums, groups, and industry events to exchange ideas and learn from their experiences.

The prepress world is constantly innovating, from new software to updated color standards. Continuous learning ensures I maintain a competitive edge and provide the best service possible.

Key Topics to Learn for Prepress Troubleshooting and Problem-Solving Interviews

- Understanding Prepress Workflow: Familiarize yourself with the entire prepress process, from file reception to platemaking. This includes file formats, color management, trapping, and imposition.

- Troubleshooting Common Issues: Practice identifying and resolving issues such as low-resolution images, font problems, color inconsistencies, and trapping errors. Understand the practical implications of these issues on the final printed product.

- Color Management Systems: Demonstrate a strong understanding of color profiles (e.g., ICC profiles), color conversion, and the importance of accurate color representation throughout the prepress workflow.

- File Format Expertise: Become proficient in handling various file formats (PDF, TIFF, JPEG, etc.) and their specific characteristics and limitations in prepress. Be ready to discuss file optimization strategies.

- Imposition and Platemaking: Understand the principles of imposition and how different imposition techniques affect the printing process. Familiarize yourself with various platemaking technologies and their impact on print quality.

- Problem-Solving Methodologies: Showcase your ability to systematically approach and resolve prepress issues. Discuss your experience with troubleshooting techniques, including identifying the root cause, implementing solutions, and verifying results.

- Software Proficiency: Highlight your expertise in relevant prepress software (e.g., Adobe Acrobat, InDesign, Illustrator, Photoshop). Be prepared to discuss specific features and functionalities you’ve used to solve problems.

- Quality Control Procedures: Describe your experience with implementing and adhering to quality control procedures to prevent prepress errors and ensure consistent output.

Next Steps

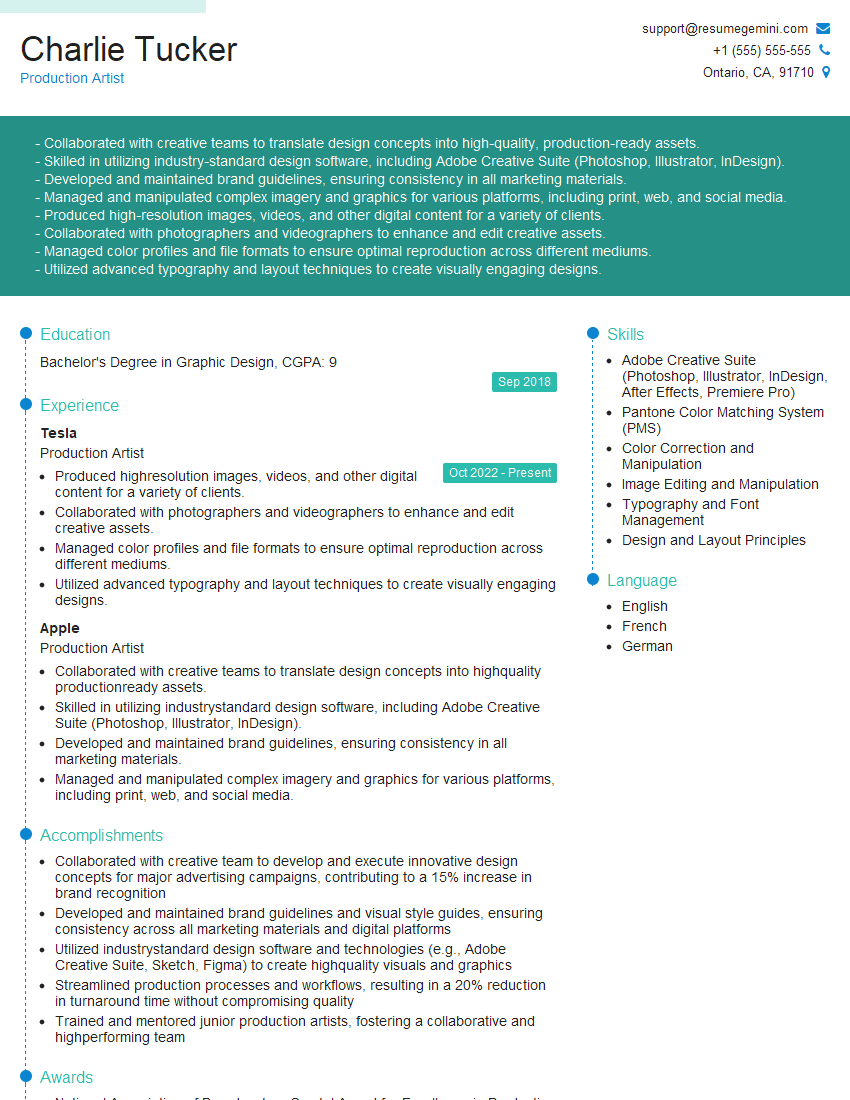

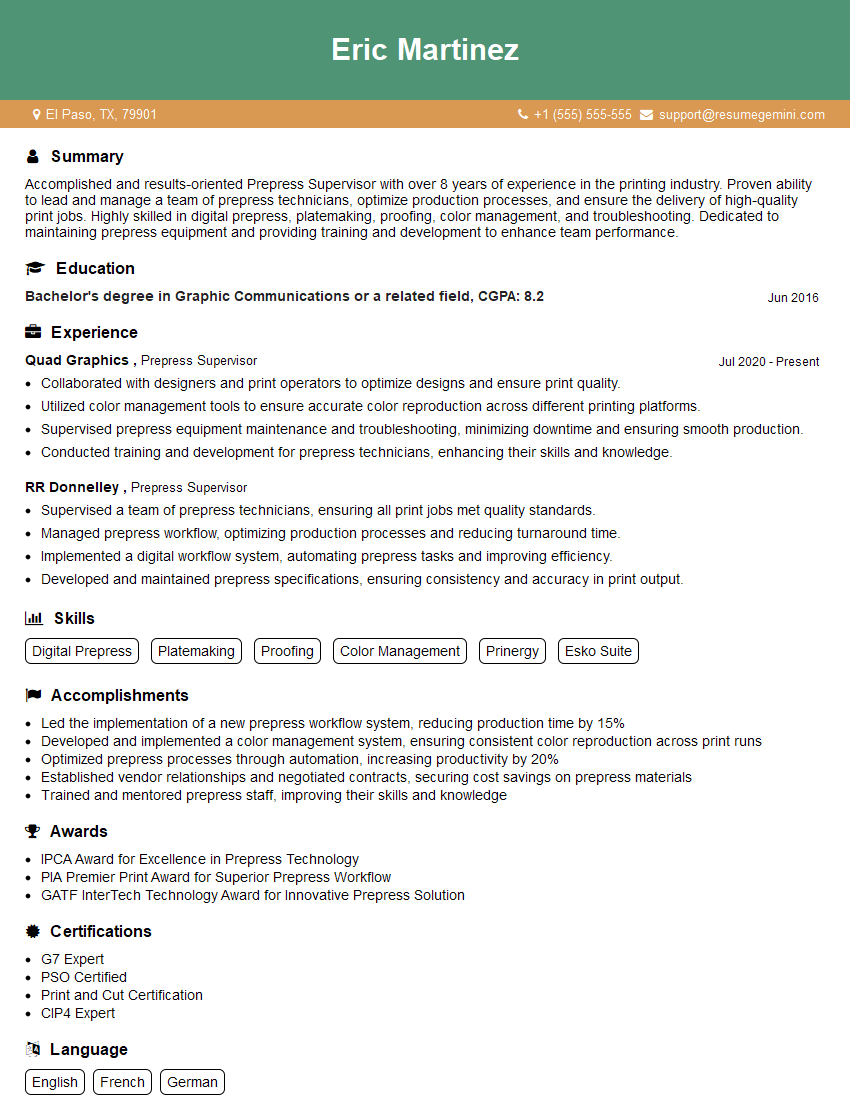

Mastering prepress troubleshooting and problem-solving is crucial for career advancement in the printing industry. It demonstrates a high level of technical skill and problem-solving ability, essential for success in this field. To significantly improve your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored specifically to highlight experience in prepress troubleshooting and problem-solving to guide you in crafting yours. Take the next step toward your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good