Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Experience in Repairing and Replacing Broken Mirrors interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Experience in Repairing and Replacing Broken Mirrors Interview

Q 1. What types of mirrors are most commonly repaired or replaced?

The most common mirrors I repair or replace are those found in bathrooms, bedrooms, and hallways. These are typically framed mirrors, ranging in size from small vanity mirrors to large, full-length mirrors. I also frequently work with mirrors used in commercial settings, such as storefront mirrors or those in gyms and fitness studios. These often require more robust construction and specialized handling. Less frequently, I encounter antique mirrors, which require extra care due to their age and potential fragility. Finally, I occasionally work on specialty mirrors like those with unique shapes, beveling, or decorative elements which present their own set of challenges.

Q 2. Describe your experience with different mirror backing materials.

Mirror backing material is crucial for durability and longevity. My experience spans several types. The most common is copper foil backing, which is relatively inexpensive and easy to work with. It’s also very effective at preventing the silvering from oxidizing and tarnishing. However, it’s not as durable as other options and can be more prone to damage if the mirror is impacted. I’ve also worked with mirrors that use a more robust backing like paint or a composite material; these tend to be used in larger, heavier mirrors where extra protection against damage is needed. When dealing with antique mirrors, you sometimes encounter lead backing, which is now less common due to safety concerns but requires special handling and disposal procedures. Understanding the backing material is key to choosing the best repair method.

Q 3. How do you assess the damage to a broken mirror before repair or replacement?

Assessing damage is the first critical step. I start by visually inspecting the mirror for cracks, chips, and scratches. The location and severity of the damage dictate the repair strategy. For example, small chips or hairline cracks can sometimes be repaired using specialized mirror repair kits. However, if the damage is extensive, such as large cracks or shattered sections, replacement is generally the safest and most effective option. I also check the framing for any damage that might interfere with reinstallation or indicate underlying structural problems. For larger mirrors, I’ll evaluate the mounting system to see if it’s secure enough to support the weight of the new mirror if replacement is necessary.

Q 4. What safety precautions do you take when handling broken glass?

Safety is paramount when handling broken glass. I always wear heavy-duty gloves, eye protection, and a dust mask to prevent cuts, eye injuries, and inhalation of any small glass particles. I use a broom and dustpan, or a shop vacuum (with a HEPA filter) to carefully collect the broken pieces, working slowly to avoid further breakage. Large shards are carefully wrapped in cardboard or heavy-duty paper before disposal. I also take precautions to protect the surrounding area by covering surfaces to prevent further damage or accidental cuts. When handling damaged mirrors in place, I’ll take extra care to avoid putting any pressure that might cause the mirror to break further, especially around already damaged areas.

Q 5. Explain your process for removing and installing a standard-sized mirror.

Removing and installing a standard-sized mirror involves several steps. First, I carefully remove any existing framing or mounting hardware. I then gently loosen the adhesive holding the mirror to the wall or backing, often using a heat gun to soften any adhesive. Once loosened, I support the mirror firmly to prevent damage during removal. After cleaning the surface, I apply fresh adhesive according to the manufacturer’s instructions. I then carefully position the mirror and hold it firmly in place until the adhesive sets. Finally, I reinstall the framing or mounting hardware, ensuring it’s secure and level. The entire process requires precision and patience, particularly when working with larger and heavier mirrors.

Q 6. What tools and equipment are essential for mirror repair and replacement?

Essential tools include a variety of screwdrivers (Phillips and flathead), a utility knife or razor blade for cutting adhesive, a heat gun for loosening adhesive, a sturdy scraper, a level, measuring tape, safety glasses, heavy-duty work gloves, a dust mask, a broom and dustpan, and appropriate adhesive for mirror installation. Depending on the project, I might also use a shop vacuum with a HEPA filter for cleaning up small glass fragments, specialized mirror repair kits (for minor repairs), and even a glass cutter if I’m working with custom-sized replacements. For larger mirrors, I may utilize specialized lifting equipment or a helper to safely maneuver the mirror.

Q 7. How do you handle situations where a mirror is beyond repair?

When a mirror is beyond repair, I advise the client on replacement. This typically involves measuring the existing mirror to ensure a precise fit for the replacement, sourcing a mirror from a supplier that matches the desired size, style and quality, and then proceeding with the removal and installation as described previously. I always discuss options with the client, providing quotes for both repair (if possible) and replacement, allowing them to make an informed decision. Safety and client satisfaction are my top priorities; if repair isn’t feasible, a safe and aesthetically pleasing replacement is the next best solution.

Q 8. Describe your experience with different types of adhesives used in mirror repair.

My experience encompasses a wide range of adhesives suitable for mirror repair, each chosen based on the specific application and the type of mirror. For smaller cracks or chips in standard mirrors, I often use epoxy resins. These are strong, versatile, and provide a clear, durable bond. For larger breaks, or when dealing with more delicate mirrors, I might opt for UV-cured adhesives. These cure quickly under ultraviolet light and offer excellent strength and clarity. In situations requiring a less rigid bond, I’ll use a silicone-based adhesive; this is particularly useful for mirrors with flexible backing or those that require some give.

- Epoxy Resin: Excellent for smaller cracks and chips; offers strong, durable bonding. Think of it like super glue, but designed for more structural integrity.

- UV-cured Adhesive: Ideal for larger breaks, especially when speed is a factor; provides strong, clear bond. This is like a specialized super glue that sets almost instantly with UV light.

- Silicone-based Adhesive: Suitable for mirrors with flexible backing or where some give is needed; offers flexibility and a durable bond. Imagine it as a more forgiving glue suitable for mirrors on moving surfaces.

The choice of adhesive always depends on a careful assessment of the damage and the type of mirror being repaired. Safety precautions like proper ventilation and eye protection are crucial when working with any of these materials.

Q 9. How do you measure and cut a mirror to fit a specific frame?

Accurately measuring and cutting a mirror to fit a specific frame is a critical step that requires precision and patience. I start by meticulously measuring the inside dimensions of the frame, allowing for a small gap (usually 1-2mm) to accommodate the frame’s thickness and ensure a snug fit. This measurement should be done at several points to account for any irregularities in the frame.

Next, I carefully transfer the measurements to the mirror using a marking tool. I use a glass cutter specifically designed for scoring glass and a steady hand; the score is done in one continuous, firm stroke. Following the score line, I use a special tool to snap the glass along the scored line, ensuring a clean break. Once cut, I’ll use fine-grit sandpaper to very carefully smooth out any rough edges. For safety, I always use protective eyewear and gloves throughout this process. This is much like a tailor taking precise measurements before creating a suit, every fraction of an inch matters.

Using templates is very helpful for irregular shapes, as it provides a perfect outline on which to base the cut. Finally, I always double-check my measurements against the frame before installing the mirror to ensure a perfect fit.

Q 10. What are the common causes of mirror breakage?

Mirror breakage is unfortunately common and stems from a variety of causes. The most frequent are:

- Impact: A direct blow from an object is the most obvious cause. This can range from a dropped object to accidental bumping.

- Thermal Stress: Extreme temperature fluctuations can cause internal stress within the glass, leading to cracking or shattering. This is common with mirrors located near fireplaces or in areas with dramatic temperature swings.

- Pressure: Uneven pressure applied to the mirror, such as leaning heavily on it, can cause breakage, especially along the edges. Think of leaning against a mirror that’s not fully supported.

- Manufacturing Defects: Sometimes mirrors have inherent flaws or stresses that weaken the glass and make it more prone to breakage. This is typically uncommon.

- Improper Installation: If a mirror isn’t properly secured or installed, it can be more susceptible to damage.

Understanding these causes helps in both preventing breakage and identifying the best repair or replacement strategies.

Q 11. Describe your experience working with large or unusually shaped mirrors.

Working with large or unusually shaped mirrors presents unique challenges, but also offers rewarding opportunities. The biggest difference lies in the handling and transportation of these mirrors; they require specialized equipment, such as suction cups and protective padding, to prevent damage during movement. Cutting large mirrors also necessitates more precision and planning and often involves specialized cutting tools. For unusual shapes, templates become even more critical for accurate cutting and installation.

I’ve had the experience of working on a very large antique mirror (nearly 8ft tall) for a historical society. The biggest concern was the safe transport from its storage location to the workshop and back. We used a custom-built crate and multiple people to ensure safe handling. The actual repair itself was relatively straightforward; the challenge was preventing further damage during the process. It really highlighted the importance of careful planning and execution.

Q 12. How do you ensure a precise and seamless mirror installation?

A precise and seamless mirror installation involves meticulous attention to detail at every stage. Firstly, the mirror needs to fit perfectly within its frame, as described previously. Then, I use an appropriate adhesive, ensuring an even application to avoid air bubbles or gaps. This is a crucial step for aesthetics and to prevent future issues. Once applied, the mirror is carefully positioned, using spacers to maintain even pressure and alignment. Excess adhesive should be wiped away immediately.

Finally, the mirror is secured with strong but flexible mounting hardware appropriate for both the size and weight of the mirror and the type of wall or surface on which it’s being mounted. The goal is to create a structurally sound and visually appealing installation. Think of it as a delicate balancing act between ensuring proper support and an aesthetically pleasing outcome. After installation, I perform a final check for any movement or misalignment.

Q 13. What are the challenges of repairing antique or vintage mirrors?

Repairing antique or vintage mirrors presents unique challenges due to their age and often delicate condition. The glass itself might be more brittle, and the backing materials may have deteriorated. The original adhesive used might also be difficult to remove or replicate without causing further damage. This is where a deep understanding of historical techniques and materials is crucial. Sometimes, careful cleaning and stabilization are the only viable solutions; in other cases, small repairs may be necessary using compatible adhesives and techniques.

For example, I worked on a beautiful antique mirror with a small crack radiating from its center. Simply gluing it would have damaged the antique patina, so I used a combination of careful surface cleaning and a specialized micro-repair adhesive to consolidate the crack without making it too visible.

In such scenarios, patience, careful planning, and specialized tools and adhesives are paramount to prevent irreversible damage. Preservation is key, not just repair.

Q 14. How do you handle customer complaints or issues related to mirror repair or replacement?

Handling customer complaints is an important part of my work. My approach is always focused on open communication and understanding the root of the issue. I begin by actively listening to the customer’s concerns, ensuring that they feel heard and valued. Then, I assess the situation, inspecting the mirror carefully and determining the next course of action. This might involve further repairs, a replacement, or a discussion of the root cause and what can be done to prevent future issues.

Transparency is key. I explain my findings clearly to the customer and offer various solutions, outlining the pros and cons of each. My aim is always to find a mutually agreeable and satisfactory outcome. If a mistake was made on my part, I take full responsibility and offer a fair resolution. Even if the issue arises from misuse or unforeseen circumstances, I try to find a way to address the customer’s concerns and build their confidence. Good customer service builds trust and is critical for a long-term reputation.

Q 15. Explain your knowledge of different types of glass (e.g., tempered, laminated).

Understanding the different types of glass is crucial for successful mirror repair and replacement. The properties of the glass directly impact its safety, durability, and suitability for a given application. Let’s look at two common types:

- Tempered Glass: This is strengthened glass, typically four to five times stronger than annealed (regular) glass. When it breaks, it shatters into small, relatively harmless, granular pieces, making it safer than annealed glass. It’s often used in applications where safety is paramount, such as shower doors and car side mirrors.

- Laminated Glass: This type consists of two or more layers of glass bonded together by a layer of polyvinyl butyral (PVB) interlayer. If broken, the glass fragments adhere to the PVB, preventing shattering and reducing the risk of injury. This makes it ideal for applications where safety and security are critical, such as windshields and security mirrors.

Beyond these, you’ll also encounter annealed glass (standard window glass), which is fragile and breaks into sharp shards, and various specialized glasses with coatings for enhanced reflectivity, heat resistance, or other properties.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate type of glass for a specific application?

Selecting the right type of glass depends entirely on the application. I always start by carefully assessing the mirror’s location and purpose. For example:

- High-traffic areas: Tempered glass is preferred due to its shatter resistance. Imagine a large mirror in a busy hotel lobby – tempered glass minimizes the risk of serious injury if it breaks.

- Security applications: Laminated glass is the best choice. Its ability to hold together upon breakage prevents easy access through the mirror surface.

- Bathroom mirrors: Often, tempered glass is a good choice for increased safety, though annealed glass might be suitable for smaller, less-impact mirrors.

- Antique mirrors: These might require specialized glass replacement that matches the original’s characteristics. It could involve finding a suitable historical glass type or using techniques to replicate age and appearance.

Safety considerations are paramount. If there’s a risk of impact or breakage, the stronger glass type is essential.

Q 17. What is your experience with beveling or edging mirrors?

Beveling and edging mirrors add a touch of elegance and sophistication. I have extensive experience in these techniques, using both manual and automated tools. Manual beveling involves carefully grinding and polishing the edges of the glass using specialized grinding wheels and polishing compounds. Automated beveling is faster and more precise, typically involving CNC machines that create consistent and accurate bevels. I choose the method based on the mirror’s size, shape, and the desired bevel profile. For intricate designs or smaller mirrors, manual beveling offers more control. For large, uniformly beveled mirrors, automated beveling provides greater efficiency.

For example, a client might request a simple, polished edge for a modern bathroom mirror, while another might want a more ornate, deeply beveled edge for an antique-style vanity mirror. My expertise allows me to cater to different aesthetic preferences and meet the project’s specifications.

Q 18. Describe your experience with using specialized tools like mirror polishing kits.

Mirror polishing kits are essential for achieving a flawless, reflective surface. My experience includes using various kits, each with its own set of polishing compounds and pads. The process usually involves several stages, progressing from coarser to finer abrasives to remove scratches and imperfections, leaving the mirror surface with excellent clarity. I’m proficient with both rotary and hand polishing techniques, selecting the appropriate method based on the mirror’s condition and size. For instance, using a rotary polisher for large mirrors is more efficient than hand polishing, which is often better suited for smaller, intricate mirrors or for delicate restoration work. Understanding the proper pressure and speed for each stage is critical to avoid damaging the glass. Safe practices also include wearing proper safety equipment like eye protection and respirators.

Q 19. How do you dispose of broken glass safely and responsibly?

Safe disposal of broken glass is crucial. I always follow local regulations and best practices. This usually involves sweeping up all glass fragments meticulously, using a dustpan and brush and placing them in a sturdy cardboard box, preferably double-boxed. Each box must be clearly labeled ‘broken glass’ to prevent accidental injury. I then securely tape the box shut and take it to a designated recycling center that accepts broken glass. In some areas, specific hazardous waste collection programs might handle broken glass. It’s vital to check with local authorities for specific guidelines, as regulations can vary by location. Improper disposal puts waste handlers and others at risk.

Q 20. What are the common safety hazards associated with mirror repair?

Mirror repair and replacement involve several safety hazards. The most obvious is the risk of cuts from broken glass. I always wear safety glasses or a face shield, cut-resistant gloves, and closed-toe shoes when handling broken mirrors. In addition to the sharp edges, there’s a risk of eye injury from flying glass fragments during the breakage or removal process. Dust from grinding and polishing can also be harmful, so respiratory protection is necessary when using polishing compounds and other potentially harmful materials. The workspace should also be well-lit and clean to prevent accidents. Using proper techniques, equipment and taking these precautions protects against risk.

Q 21. How do you deal with difficult clients or unexpected problems on a job site?

Dealing with challenging situations is part of the job. If a client is difficult, I maintain a calm and professional demeanor, listening attentively to their concerns. Clear communication is key; I explain the process, options, and any potential challenges clearly and concisely. If unexpected problems arise on a job site – for example, discovering hidden damage or needing specialized tools – I assess the situation objectively, formulate a solution, and communicate it to the client promptly. Transparency is crucial; I always keep clients updated on progress and any changes to the plan. For example, if a repair is unexpectedly more complex, I might discuss the additional work and cost adjustments openly to avoid miscommunication or surprises. Maintaining professionalism throughout the process builds client trust and ensures project success.

Q 22. Describe your experience working from blueprints or specifications.

Working from blueprints or specifications for mirror installation is crucial for ensuring a precise and aesthetically pleasing outcome. I’ve extensively used blueprints and detailed specifications to understand the exact dimensions, placement, and any unique features required for the mirror, like beveling, shape, or integrated lighting. For example, I recently worked on a project where the blueprint detailed a custom-shaped mirror for a curved hallway. The blueprint specified precise angles and radii, which I meticulously followed to create a flawless installation. The success of this project relied heavily on accurately interpreting the design and translating it into a functional and beautiful installation.

I’m proficient in reading both hand-drawn and CAD drawings, interpreting scale, and identifying critical dimensions and specifications like the mirror’s thickness, type of glass, and any special mounting requirements. This ensures that the final installation perfectly matches the client’s vision and the overall design of the space.

Q 23. What is your experience with different installation methods (e.g., adhesive, brackets)?

My experience encompasses a wide range of mirror installation methods, each suited to different situations and mirror types. I’m adept at using adhesives, ranging from specialized mirror adhesive for lighter mirrors to stronger epoxy resins for larger, heavier ones. The choice of adhesive depends on factors such as mirror weight, surface material, and environmental conditions (temperature, humidity). For instance, for a large antique mirror, I would carefully select a strong, UV-resistant epoxy to ensure both structural integrity and longevity.

I’m equally comfortable using various bracketing systems, from simple, pre-fabricated brackets to custom-designed and fabricated ones for unique installation scenarios. This includes utilizing different materials for brackets, such as metal, wood, or even specialized plastic brackets depending on the weight of the mirror and the surrounding material. I always assess the structural integrity of the wall or surface to ensure that the chosen method can securely support the mirror’s weight, preventing accidents.

Q 24. Explain your process for cleaning and preparing a surface for mirror installation.

Proper surface preparation is paramount for a successful and long-lasting mirror installation. The process starts with a thorough cleaning to remove any dust, grease, dirt, or debris that could compromise the adhesive’s bond. I typically use a degreasing agent followed by a clean, lint-free cloth to ensure a completely clean surface. For example, if I’m installing a mirror in a bathroom, I’ll pay special attention to removing any soap residue or moisture before proceeding. This meticulous cleaning is key to preventing later issues such as bubbling or peeling of the adhesive.

After cleaning, I inspect the surface for any imperfections or irregularities. If there are any bumps or unevenness, I take the necessary steps to level the surface to guarantee that the mirror sits flush and prevents stress on the mirror or the adhesive. Depending on the material, this might involve filling imperfections with appropriate fillers or sanding to create a smooth, even surface. Finally, I’ll allow the surface to fully dry before applying the adhesive.

Q 25. How do you ensure the structural integrity of a mirror after repair or replacement?

Ensuring structural integrity after mirror repair or replacement is critical. For repairs, I use high-quality adhesives that are designed to bond with the glass and provide long-lasting support. After the repair, I allow sufficient time for the adhesive to cure completely according to the manufacturer’s instructions. For larger cracks or chips, I may use reinforcing materials such as epoxy backing to strengthen the glass and prevent further damage.

For replacements, I meticulously select the appropriate mounting hardware and adhesive based on the mirror’s size, weight, and the wall material. I always ensure that the mounting points are securely fastened and capable of supporting the weight of the mirror, thereby preventing it from falling or becoming loose over time. I consider factors like potential vibrations or impacts the mirror might encounter in its location. This could involve using additional support structures, such as bracing, for larger mirrors or those in high-traffic areas.

Q 26. What are your preferred techniques for repairing minor scratches or chips in a mirror?

Minor scratches or chips can sometimes be repaired to improve the mirror’s appearance. My preferred method for minor scratches is to use a specialized mirror polishing compound. This compound, applied with a soft cloth in a circular motion, can gently remove superficial scratches, restoring some clarity. The success of this method depends on the depth and type of scratch; deep scratches may be impossible to fully remove.

For small chips, filling materials such as specialized glass fillers can be used. The filler is carefully applied to match the surface and then smoothed and polished to minimize visibility. However, it’s important to be realistic about the limitations of these repair methods. Significant damage will often require a complete mirror replacement to maintain safety and aesthetics.

Q 27. What is your experience working with different types of mirror frames or moldings?

My experience encompasses a wide variety of mirror frames and moldings, including wood, metal, plastic, and resin. I’m familiar with different installation techniques for each type of frame. For example, wood frames might require precise woodworking techniques such as mortise and tenon joints or specialized glue for secure attachment. Metal frames might require drilling and screwing, while plastic frames often utilize simple clips or adhesive.

I understand the importance of matching the frame to the style and overall aesthetic of the environment. I can work with both pre-fabricated frames and custom-designed frames, adapting my techniques as needed to ensure a seamless integration between the mirror and its frame. The proper selection and installation of the frame are key to achieving a polished and professional-looking installation.

Q 28. Describe your problem-solving skills in relation to complex mirror installation challenges.

Problem-solving is an integral part of my work. I’ve encountered various challenges, from misaligned walls to unexpected structural issues. For example, I once encountered a project where the wall behind the intended mirror location was not sufficiently sturdy to support the weight of the mirror. My solution involved reinforcing the wall using additional supports before installing the mirror, ensuring both safety and stability. This involved assessing the existing structure, selecting appropriate reinforcements, and executing the installation in a way that maintained the aesthetic appeal of the final product.

My approach involves careful assessment of the problem, exploring multiple solutions, and selecting the most efficient and safe approach. I always prioritize safety and adhere to all relevant building codes and safety regulations. Communication with clients is also crucial. Keeping them informed throughout the problem-solving process helps to manage expectations and ensure a satisfactory outcome.

Key Topics to Learn for Experience in Repairing and Replacing Broken Mirrors Interview

- Types of Mirror Damage: Understanding different types of damage (cracks, chips, shattering) and their impact on repair feasibility.

- Repair Techniques: Knowledge of various repair methods, including resin repair for minor damage, and when complete replacement is necessary.

- Materials and Tools: Familiarity with the tools and materials used in mirror repair and replacement (e.g., resins, adhesives, specialized blades, safety equipment).

- Safety Procedures: Understanding and adhering to safety protocols when handling broken glass and using repair materials.

- Surface Preparation: Importance of properly cleaning and preparing the mirror surface before repair or replacement.

- Installation Techniques: Knowledge of proper mirror installation methods, including securing the mirror to prevent future damage.

- Troubleshooting: Ability to identify and solve common problems encountered during repair or replacement (e.g., uneven adhesion, air bubbles).

- Cost Estimation: Understanding the factors that influence the cost of repair or replacement (materials, labor, complexity).

- Customer Interaction: Effective communication with customers regarding repair options, timelines, and costs.

- Quality Control: Ensuring the repaired or replaced mirror meets quality standards and is free from defects.

Next Steps

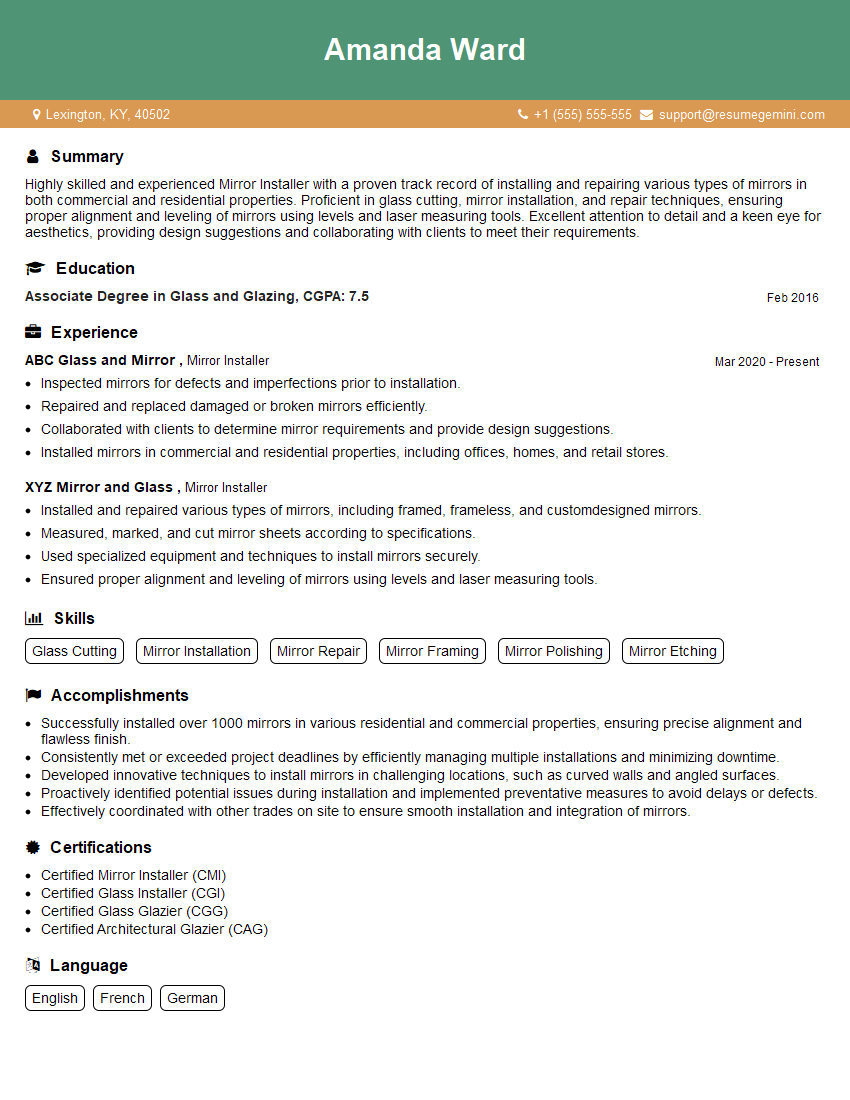

Mastering the skills in repairing and replacing broken mirrors opens doors to various opportunities in the glass repair, construction, and home improvement industries. To maximize your job prospects, it’s crucial to present your experience effectively. Building an ATS-friendly resume is key to getting your application noticed by recruiters. ResumeGemini can help you create a professional and impactful resume that highlights your skills and experience. We offer examples of resumes tailored to this specific experience to guide you through the process. Invest time in crafting a compelling resume—it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good