Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Experience with a variety of clothing items and fabrics interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Experience with a variety of clothing items and fabrics Interview

Q 1. Describe the differences between natural and synthetic fibers.

Natural fibers are derived from natural sources like plants and animals, while synthetic fibers are manufactured from chemical compounds. Think of it like this: natural fibers are gifts from nature (cotton from a plant, wool from a sheep), while synthetic fibers are human-made creations (polyester, nylon).

- Natural Fibers: Generally more breathable, often softer to the touch, and biodegradable. However, they can be more expensive, less durable, and require more care.

- Synthetic Fibers: Typically more durable, wrinkle-resistant, and less expensive. However, they may not be as breathable, can feel less comfortable against the skin, and aren’t biodegradable.

For example, a cotton t-shirt is soft and breathable but might wrinkle easily, whereas a polyester t-shirt is wrinkle-resistant and durable but might feel less comfortable in hot weather.

Q 2. Explain the properties of cotton, silk, wool, and linen.

Each of these natural fibers offers unique properties:

- Cotton: Soft, absorbent, breathable, and relatively inexpensive. It’s a staple in clothing due to its comfort and versatility. However, it wrinkles easily and can shrink after washing.

- Silk: Luxurious, soft, lustrous, and highly breathable. It drapes beautifully but is delicate and requires special care. Its high cost reflects its luxurious feel and the labor-intensive process of silk production.

- Wool: Warm, insulating, moisture-wicking, and naturally crease-resistant. It’s excellent for colder climates but can be itchy for some people and requires careful cleaning to avoid shrinkage or felting. Think of a cozy wool sweater keeping you warm on a winter’s day.

- Linen: Strong, durable, breathable, and naturally wrinkle-resistant. It has a slightly stiff, crisp hand-feel. It’s known for its coolness and is often used in summer clothing. However, it wrinkles easily and can be prone to creasing.

Q 3. What are the advantages and disadvantages of using polyester in clothing?

Polyester is a widely used synthetic fiber offering both advantages and disadvantages:

- Advantages: Durable, wrinkle-resistant, water-resistant, quick-drying, and relatively inexpensive. It’s a popular choice for sportswear and performance wear due to its moisture-wicking properties.

- Disadvantages: Not as breathable as natural fibers, can feel clammy against the skin, can retain static electricity, and is not biodegradable. It also might not drape as well as some natural fibers.

A classic example is a polyester fleece jacket; it’s warm, durable, and water-resistant, ideal for outdoor activities. However, it’s not the best choice for hot, humid days due to its low breathability.

Q 4. How does the weave of a fabric affect its drape and durability?

The weave of a fabric significantly impacts its drape and durability. The weave refers to how the warp (lengthwise) and weft (crosswise) yarns are interlaced.

- Drape: Loose weaves, like those in chiffon or georgette, create a flowing, soft drape. Tight weaves, like those in denim or canvas, result in a stiffer, more structured drape.

- Durability: Tightly woven fabrics, such as twill or satin, are generally more durable and resistant to wear and tear compared to loosely woven fabrics. The type of yarn also affects durability; thicker yarns yield stronger fabrics.

Think of a flowing silk scarf (loose weave, excellent drape, less durable) compared to a sturdy pair of jeans (tight weave, strong drape, high durability).

Q 5. What are common fabric finishes and their purpose?

Fabric finishes are treatments applied to enhance the fabric’s properties. Common finishes include:

- Mercerization: Enhances luster and strength in cotton.

- Sanforizing: Prevents shrinkage in cotton.

- Water-repellent finishes: Make fabrics resistant to water.

- Flame-retardant finishes: Enhance fire safety.

- Anti-static finishes: Reduce static cling.

- Softening finishes: Improve the hand-feel of the fabric.

These finishes cater to specific needs. For instance, a water-repellent finish on a raincoat ensures it keeps you dry, while a wrinkle-resistant finish on a dress shirt minimizes ironing.

Q 6. Explain the difference between knit and woven fabrics.

Knit and woven fabrics differ fundamentally in their construction:

- Woven fabrics: Created by interlacing warp and weft yarns at right angles. They tend to be more durable and less stretchy than knit fabrics. Examples include denim, cotton poplin, and silk charmeuse.

- Knit fabrics: Made by interlocking loops of yarn. They are usually more stretchy and flexible than woven fabrics but can be less durable. Examples include jersey, rib knit, and double knit.

A woven shirt is often more structured and less stretchy than a knit t-shirt. This difference in construction affects the drape, durability, and overall feel of the garment.

Q 7. Describe the process of garment construction.

Garment construction involves a series of steps to transform a flat pattern into a three-dimensional garment. The process generally includes:

- Pattern Making: Creating the design templates.

- Cutting: Cutting fabric according to the patterns.

- Sewing: Joining fabric pieces together using various sewing techniques.

- Finishing: Adding details such as seams, hems, buttons, and zippers.

- Pressing: Shaping the garment using heat and pressure.

- Quality Control: Checking for defects and ensuring consistent quality.

Each step requires precision and skill. For example, proper seam finishing prevents fraying and adds durability, while precise pressing enhances the garment’s shape and appearance. The entire process involves a skilled understanding of materials, techniques and design.

Q 8. How do you identify different types of stitching?

Identifying different types of stitching involves examining several key features: stitch length, stitch type, and thread count. Stitch length refers to the distance between individual stitches. Shorter stitches generally indicate higher quality and durability. Different stitch types serve various purposes; for example, a straight stitch is commonly used for seams, while a zig-zag stitch is often used for finishing edges to prevent fraying. Finally, thread count refers to the number of threads used per inch. A higher thread count usually means a stronger and more durable stitch.

- Straight Stitch: A simple, strong stitch ideal for seams. Think of the seams on your favorite pair of jeans.

- Zig-zag Stitch: A versatile stitch used for finishing edges, creating decorative effects, and attaching elastic. It’s often used on the hems of t-shirts.

- Overlock Stitch (Serger Stitch): A stitch that simultaneously sews, trims, and finishes the edge of fabric, preventing fraying and creating a neat, professional finish. Commonly seen on knitwear.

- Blind Stitch: A nearly invisible stitch used for hemming, particularly on delicate fabrics. It’s ideal for professional-looking hems on dress pants or skirts.

By carefully observing these aspects, one can distinguish between different stitching techniques and assess the quality of the garment’s construction.

Q 9. What are the common fabric defects and how are they identified?

Common fabric defects can significantly impact the quality and aesthetics of a garment. Identifying them requires a keen eye and a good understanding of fabric properties. Here are some common defects and how to spot them:

- Weave Defects: These include slubs (thickened areas of yarn), holes, and broken ends. They can be easily spotted by visually inspecting the fabric’s surface.

- Color Defects: Uneven dyeing, shade variation, and color bleeding are common issues. These are best observed under consistent lighting conditions.

- Structural Defects: These involve inconsistencies in the fabric’s construction, such as crooked selvedges (finished edges), puckering, or shrinkage. Careful measuring and inspection during pattern cutting and construction reveals these.

- Fiber Defects: These can include short fibers, weak fibers, or foreign matter embedded in the fabric. Often, a magnifying glass can help in identifying these.

Identifying these defects is crucial. For example, a large hole or a significant color variation might render the fabric unusable. Careful pre-production inspection minimizes waste and ensures the final product meets quality standards.

Q 10. Explain the importance of quality control in apparel manufacturing.

Quality control in apparel manufacturing is paramount. It ensures that the final product meets the required standards of quality, fit, and finish. A robust quality control system includes several key steps:

- Raw Material Inspection: Checking the quality of the fabric, thread, and other materials before production begins.

- In-Process Inspection: Monitoring the manufacturing process at various stages to identify and correct defects early on.

- Finished Goods Inspection: Thoroughly examining the finished garments to ensure they meet the specified quality standards, including measurements, stitching, and overall appearance. This often involves visual inspection, measurements, and sometimes, functional testing.

- Sampling and Testing: Regularly testing samples to ensure consistency and meet relevant safety and quality standards.

Without a strong quality control process, you risk producing defective garments, damaging your brand reputation, and incurring significant financial losses. Think of a high-end brand: their commitment to quality control is a key part of their brand identity and justifies the premium price point.

Q 11. How do you determine the appropriate fabric for a specific garment?

Choosing the right fabric for a garment depends on several factors, including the garment’s intended use, the desired aesthetic, and the wearer’s comfort needs. Consider these aspects:

- Garment Type: A lightweight cotton is ideal for a summer dress, while a heavier wool is better suited for a winter coat.

- Intended Use: Fabrics need to be durable enough to withstand the wear and tear of their intended use. Workwear needs durability, while evening wear might prioritize elegance and drape.

- Aesthetic: The fabric’s drape, texture, and sheen contribute to the overall look of the garment. A flowing silk creates a different aesthetic than a structured linen.

- Comfort and Breathability: Natural fibers like cotton and linen generally offer better breathability than synthetics, making them suitable for warmer climates or active wear.

- Care Instructions: The fabric’s care requirements (e.g., dry clean only vs. machine washable) affect practicality and consumer appeal.

For instance, designing a raincoat requires a waterproof and breathable fabric like nylon or Gore-Tex. Conversely, a delicate evening gown might utilize a luxurious silk or satin.

Q 12. Describe your experience with different types of pattern making.

My experience encompasses various pattern-making techniques, including draping, flat pattern making, and computer-aided design (CAD). Draping involves manipulating fabric on a dress form to create a three-dimensional pattern. This method is excellent for creating unique and flowing designs, often used in haute couture. Flat pattern making involves creating a two-dimensional pattern on paper using measurements and calculations. This is a more precise and reproducible method, suitable for mass production. CAD software allows for digital pattern design and manipulation, offering speed, precision, and the ability to create complex designs.

I’ve worked extensively with all three methods, adapting my approach based on the garment’s design, the desired level of precision, and the production scale. For example, a highly individualized, bespoke garment might necessitate draping, whereas a large-scale production run would benefit from the efficiency of CAD.

Q 13. How do you choose the right needle and thread for different fabrics?

The correct needle and thread are crucial for achieving high-quality stitching and preventing fabric damage. Different fabrics require different needle sizes and thread types to ensure proper penetration and minimize snagging or breakage.

- Needle Size: Heavier fabrics require larger needles, while finer fabrics require smaller needles. Needle size is typically denoted by a number, with larger numbers indicating larger needles.

- Needle Type: Different needle types are designed for specific fabric types. For example, ballpoint needles are ideal for knit fabrics, while sharp needles are best for woven fabrics. Using the wrong needle can lead to skipped stitches or damaged fabric.

- Thread Type: The thread’s material, weight, and strength should match the fabric and needle. Cotton thread is a versatile option for many fabrics, while silk thread is more suitable for delicate materials.

For example, sewing heavy denim requires a strong, heavy-duty needle and thread. Conversely, delicate silk requires a fine needle and lightweight thread to avoid piercing or damaging the fabric.

Q 14. What are the standard measurements used in apparel design?

Standard measurements used in apparel design vary depending on the garment type and the target market (e.g., men’s, women’s, children’s). However, some common measurements include:

- Body Measurements: These include bust, waist, hip, shoulder width, sleeve length, and inseam. These are crucial for creating well-fitting garments.

- Garment Measurements: These are taken from the finished garment and include measurements such as chest circumference, waist circumference, and garment length. These measurements verify the final product conforms to the design specifications.

Different measurement systems exist, including metric (centimeters) and imperial (inches). Accurate measurement is essential for creating well-fitting garments that meet customer expectations. Inconsistent or inaccurate measurements result in ill-fitting clothes and potential returns.

Q 15. Explain the concept of grading in apparel manufacturing.

Grading in apparel manufacturing is the process of scaling a garment pattern to create different sizes. Think of it like enlarging or reducing a photograph – you’re maintaining the proportions, but adjusting the overall dimensions. It’s crucial for producing a range of sizes, from XS to XXL, ensuring a consistent fit across the size spectrum.

The process typically involves using specialized software or manual techniques to systematically increase or decrease the pattern pieces’ measurements based on pre-determined size specifications. These specifications often come from body measurement charts, considering factors like chest circumference, waist circumference, hip circumference, and height. For instance, if you’re grading a shirt pattern from a size medium to a large, you’d increase the width and length of the pattern pieces according to the size chart, ensuring the larger size still maintains the original design’s aesthetic and functional aspects.

In practice, inaccuracies can arise if the grading isn’t done precisely, leading to ill-fitting garments. Experienced graders understand how different body parts scale relative to each other – for example, sleeve length adjustments might not be directly proportional to the body length increase.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software are you familiar with for apparel design and production?

I’m proficient in several software packages used in apparel design and production. My expertise includes industry-standard programs like Adobe Illustrator for creating and manipulating vector graphics of patterns and designs, and CLO 3D for 3D garment modeling and virtual prototyping. This allows for detailed visualization and adjustments before physical sampling. I also have experience using Pattern Design Software, such as Optitex and Lectra, for advanced pattern making, grading, and marker making (optimizing fabric placement for cutting).

Beyond design, I’m familiar with PLM (Product Lifecycle Management) systems which help manage the entire product lifecycle, from design conception to production and delivery. These systems are essential for managing data, collaborating with teams, and tracking progress.

Q 17. How do you handle discrepancies between design specifications and final product?

Discrepancies between design specifications and the final product are unfortunately common. My approach to handling them is systematic and collaborative. First, I carefully analyze the discrepancy to identify its root cause. Is it a design flaw? A manufacturing error? A material issue? I carefully compare the technical specifications of the design with the actual product measurements and quality checks. This often involves comparing the physical garment to the approved tech pack (a detailed document outlining all aspects of the garment).

Once the source is identified, I work closely with the design team, the production team, and the relevant quality control personnel to rectify the issue. This may involve revising the pattern, adjusting the manufacturing process, or replacing faulty materials. Detailed documentation is crucial throughout this process to prevent similar errors in future productions. I firmly believe in proactive measures and utilize quality control checkpoints throughout the production cycle to prevent major discrepancies from occurring in the first place.

Q 18. Describe your experience working with different types of sewing machines.

My experience encompasses a wide range of sewing machines, from basic single-needle machines used for straight stitching to industrial machines specialized for specific tasks like overlocking (serging), buttonhole stitching, and embroidery. I’m adept at using flatbed, cylindrical, and walking foot machines, each suited for different fabrics and garment types. For example, a walking foot machine is invaluable when sewing multiple layers of thick fabric, preventing slippage. Industrial overlock machines are crucial for creating professional-looking seams that are both durable and aesthetically pleasing.

Beyond the mechanics of operating the machines, I understand the importance of proper maintenance and troubleshooting. I can identify and address common issues, such as broken needles, timing belt problems, or tension adjustments. This hands-on experience is essential for efficient and high-quality production.

Q 19. What is your experience in sourcing fabrics from different suppliers?

I have extensive experience sourcing fabrics from diverse suppliers globally. This includes working with both domestic and international suppliers, negotiating pricing, and managing the logistics of fabric procurement. My experience covers a broad spectrum of fabrics, from natural fibers like cotton, silk, wool, and linen to synthetics such as polyester, nylon, and rayon. I also have expertise working with specialty fabrics like performance fabrics (moisture-wicking, stretch) and eco-friendly options.

Choosing a supplier involves meticulous research, including assessing their quality control processes, ethical practices, and lead times. I often conduct site visits to evaluate suppliers firsthand, ensuring that the materials meet our quality standards and production deadlines. Developing strong relationships with reliable suppliers is key to maintain consistent supply and quality.

Q 20. How do you ensure the ethical and sustainable sourcing of fabrics?

Ethical and sustainable sourcing of fabrics is paramount. My approach involves careful consideration of several key factors:

- Traceability: I prioritize suppliers who can provide clear documentation about their supply chain, ensuring transparency about the origin of their raw materials and the manufacturing processes. This helps in identifying and avoiding potential human rights violations or environmental damage.

- Certifications: I look for certifications like GOTS (Global Organic Textile Standard) or OEKO-TEX Standard 100, which confirm the fabric’s adherence to strict environmental and social standards.

- Environmental Impact: I favor suppliers using sustainable practices, such as minimizing water usage, reducing carbon emissions, and employing recycled or biodegradable materials.

- Fair Labor Practices: I ensure that the suppliers comply with fair labor standards, guaranteeing safe and ethical working conditions for their employees.

By actively engaging with our suppliers and demanding transparency, we contribute to building a more ethical and sustainable apparel industry.

Q 21. Explain your understanding of different fabric dyeing techniques.

My understanding of fabric dyeing techniques is comprehensive. I’m familiar with various methods, including:

- Reactive dyeing: This process is commonly used for cellulosic fibers like cotton and is known for its excellent colorfastness (resistance to fading).

- Disperse dyeing: Suitable for synthetic fibers like polyester, this technique utilizes dyes that are soluble in the fiber.

- Acid dyeing: Used for natural fibers like wool and silk, this method produces vibrant colors with good wash fastness.

- Vat dyeing: This technique is especially useful for producing deep, intense colors on cotton, but involves a more complex process than reactive dyeing.

Beyond the basic types, I’m also aware of more specialized dyeing methods, such as pigment dyeing, which offers a wide range of colors but often has lower wash fastness. The choice of dyeing technique depends on the fiber type, desired color, and required wash fastness. I consider all of these aspects when choosing the best method for each garment and fabric.

Q 22. Describe your experience with different types of printing on fabric.

My experience encompasses a wide range of fabric printing techniques, each with its own unique characteristics and applications. I’ve worked extensively with screen printing, a time-tested method ideal for bold, high-opacity designs on various fabrics like cotton and polyester. This process involves creating stencils for each color and manually applying ink, offering excellent control over color saturation and detail. For large-scale production, however, it can be less efficient than other methods.

Digital printing, using inkjet or direct-to-garment (DTG) technology, has become increasingly popular. It offers unparalleled design flexibility, enabling complex patterns and photorealistic images with incredible precision. DTG, for instance, is perfect for personalized apparel or small batch production, but can be more expensive per unit for large orders. Sublimation printing, ideal for polyester fabrics, uses heat to transfer dye into the fibers, resulting in a vibrant, long-lasting print that’s part of the fabric itself, rather than a layer on top. Finally, I’ve also worked with block printing, a more traditional and artisanal method, perfect for unique, handmade designs.

- Screen Printing: Best for large runs of simple designs, vibrant colors.

- Digital Printing: Versatile, perfect for custom designs, smaller runs, photo-realistic images.

- Sublimation Printing: Ideal for polyester fabrics, produces vibrant, long-lasting prints.

- Block Printing: Artisanal method for unique, handmade designs.

Q 23. What are the environmental impacts of different fabric production methods?

The environmental impact of fabric production is significant, varying greatly depending on the chosen fibers and manufacturing processes. Conventional cotton farming, for instance, is water-intensive and often relies heavily on pesticides, contributing to soil degradation and water pollution. Synthetic fibers like polyester, derived from petroleum, have a substantial carbon footprint due to their production and the non-biodegradable nature of the resulting waste.

More sustainable alternatives include organically grown cotton, which minimizes the use of harmful chemicals, and recycled fibers such as recycled polyester (rPET), which reduces reliance on virgin resources. Innovative technologies like using closed-loop water systems in production and exploring bio-based materials like Tencel (derived from wood pulp) are paving the way for a more environmentally responsible textile industry. The choice of dye also matters; low-impact dyes that minimize water pollution are becoming increasingly crucial.

- Conventional Cotton: High water usage, pesticide use, soil degradation.

- Polyester: High carbon footprint, non-biodegradable.

- Organic Cotton: Reduced chemical use, lower environmental impact.

- Recycled Polyester: Reduces reliance on virgin resources.

Q 24. How do you stay updated with current trends in fabric technology?

Staying current in fabric technology involves a multi-pronged approach. I regularly attend industry trade shows like Première Vision and Texworld, where I can see firsthand the latest innovations in fibers, finishes, and printing technologies. I subscribe to industry publications like Textile Today and subscribe to relevant newsletters from textile companies and research institutions.

Online resources such as academic databases and industry blogs provide invaluable insights into emerging trends. Networking with other professionals through industry conferences and online communities is another vital aspect. This keeps me updated on sustainable materials, innovative production methods, and shifts in consumer preferences.

Q 25. Describe your experience in troubleshooting problems during apparel production.

Troubleshooting in apparel production often requires a systematic approach. For example, I once encountered a situation where the colorfastness of a newly sourced fabric was significantly lower than expected, leading to unacceptable color bleeding in the finished garment. My process involved a series of steps:

- Identify the Problem: Precisely determine the nature and extent of the issue—in this case, the color bleeding during washing.

- Gather Data: Collect all relevant information, including fabric testing reports, dye specifications, and production records.

- Analyze the Cause: Determine the root cause of the issue – here, it was an incompatibility between the dye and the fabric treatment.

- Develop Solutions: Explore potential solutions: switching to a different dye, pre-treating the fabric, or changing the washing process.

- Implement and Test: Implement the chosen solution and thoroughly test it to ensure the problem is resolved.

- Document Findings: Record all findings and lessons learned to prevent similar issues in the future.

Q 26. How do you manage your time effectively to meet deadlines in a fast-paced environment?

Time management in a fast-paced environment is crucial. My approach relies on a combination of planning, prioritization, and efficient task management. I utilize project management tools to track deadlines, assign tasks, and monitor progress. This allows me to visualize the entire workflow and promptly address potential delays. Prioritization is key; I focus on the most critical tasks first and delegate where possible.

Effective communication with team members is essential to ensure everyone is on the same page. I also prioritize regular breaks to maintain focus and avoid burnout. This structured approach, along with proactive communication, ensures I consistently meet deadlines without compromising quality.

Q 27. Describe a time you had to adapt to a change in fabric or garment design.

A memorable instance involved a last-minute change in fabric for a large order. The originally specified fabric became unavailable due to unforeseen supply chain issues. I had to quickly find a suitable replacement, focusing on maintaining the drape, weight, and color consistency as closely as possible.

This involved working closely with the designers and sourcing team to identify alternative fabrics. We conducted rigorous testing to ensure the replacement fabric met the quality standards and wouldn’t necessitate major alterations to the garment’s construction. Through effective communication and quick decision-making, we successfully launched the collection on time with minimal disruptions.

Q 28. How do you communicate effectively with designers, manufacturers, and clients?

Effective communication is paramount in my role. With designers, it involves understanding their creative vision and translating it into practical production requirements. This involves clear and concise discussions, utilizing sketches, swatches, and technical specifications to ensure everyone is aligned. With manufacturers, clear and detailed communication of specifications, quality standards, and deadlines is essential.

Regular updates and open communication channels are crucial to ensure seamless production. With clients, I focus on clear, non-technical explanations of the production process, managing their expectations and keeping them updated on progress. Active listening and proactive communication are central to all interactions to ensure a smooth workflow and successful outcomes.

Key Topics to Learn for Experience with a Variety of Clothing Items and Fabrics Interview

- Fabric Identification and Properties: Understanding different fiber types (natural vs. synthetic), their properties (drape, texture, durability, breathability), and appropriate care instructions.

- Garment Construction and Manufacturing: Knowledge of various sewing techniques, pattern making principles, and the manufacturing process, including different production methods and their impact on quality and cost.

- Clothing Styles and Trends: Familiarity with different clothing styles across various eras and cultures, current fashion trends, and the factors influencing design choices.

- Quality Control and Assessment: Ability to identify defects in fabrics and garments, understanding quality standards, and implementing effective quality control measures.

- Sustainability and Ethical Sourcing: Awareness of sustainable materials, ethical manufacturing practices, and the environmental impact of the fashion industry.

- Problem-Solving and Troubleshooting: Experience in addressing challenges related to fabric selection, garment construction, or manufacturing processes, and finding creative solutions.

- Technical Specifications and Documentation: Understanding and interpreting technical drawings, specifications, and other relevant documentation used in the apparel industry.

Next Steps

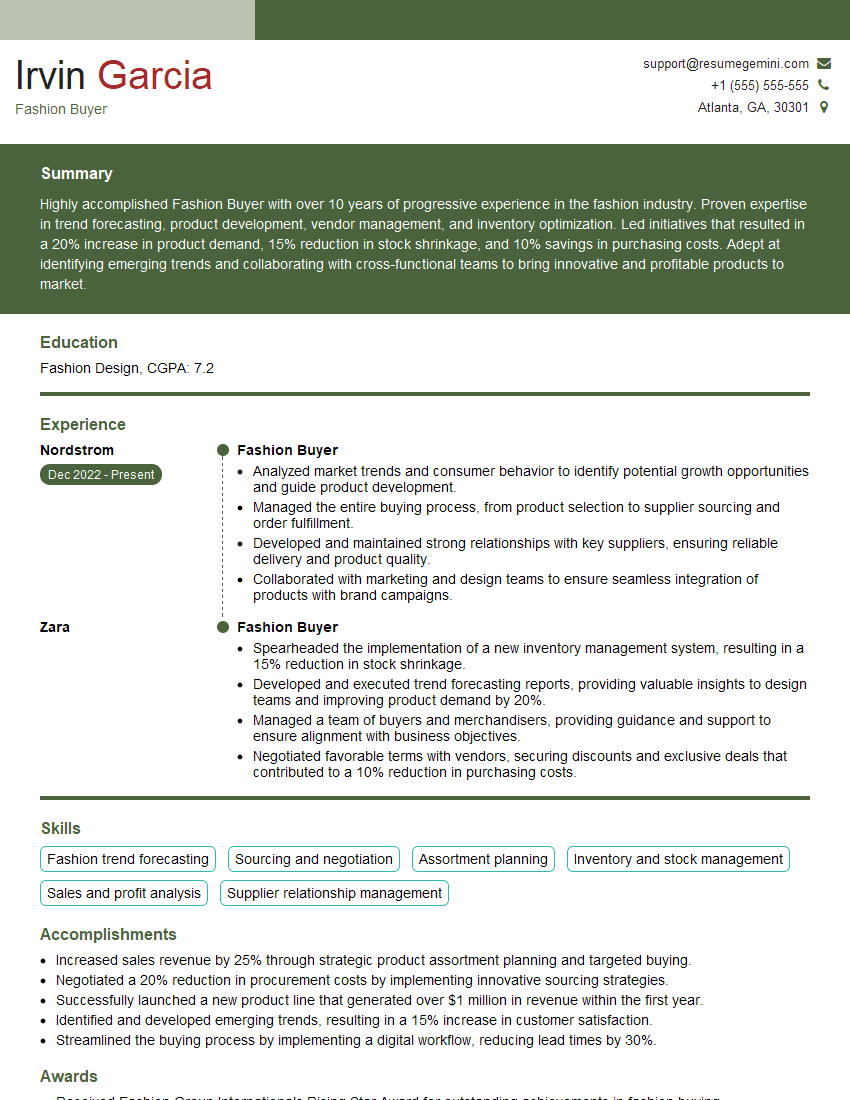

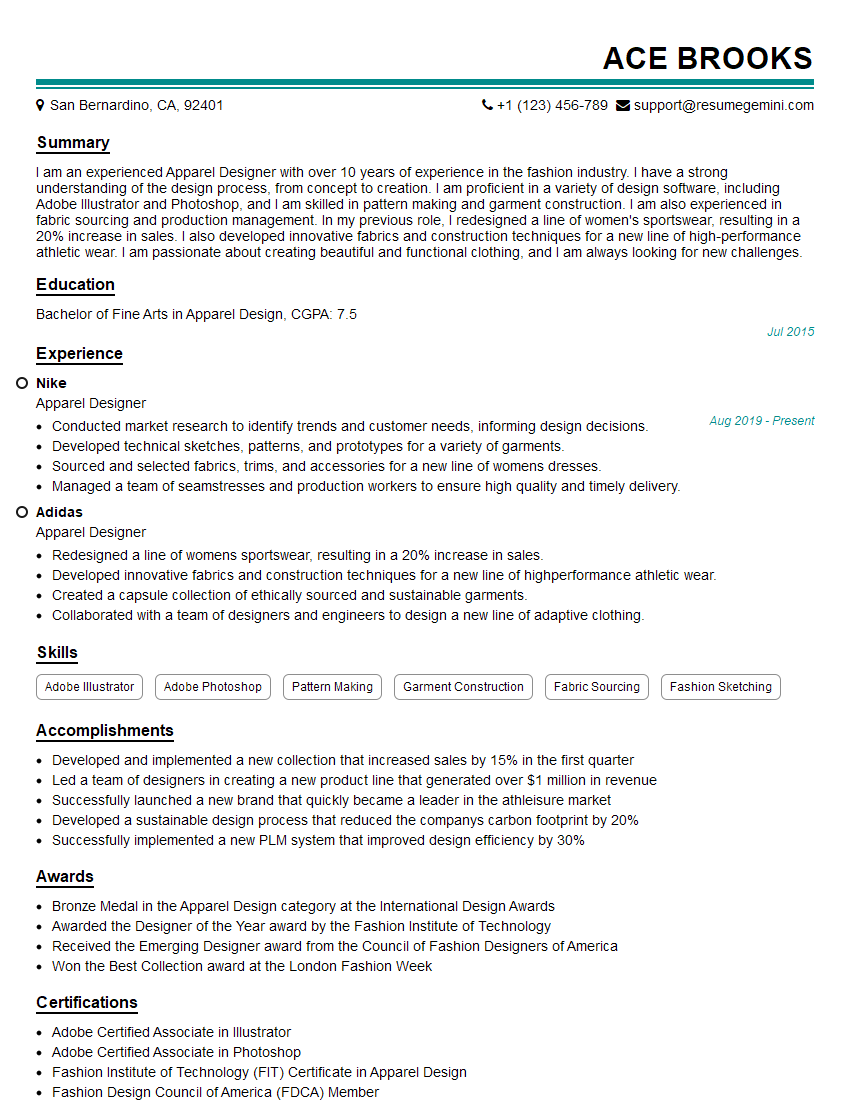

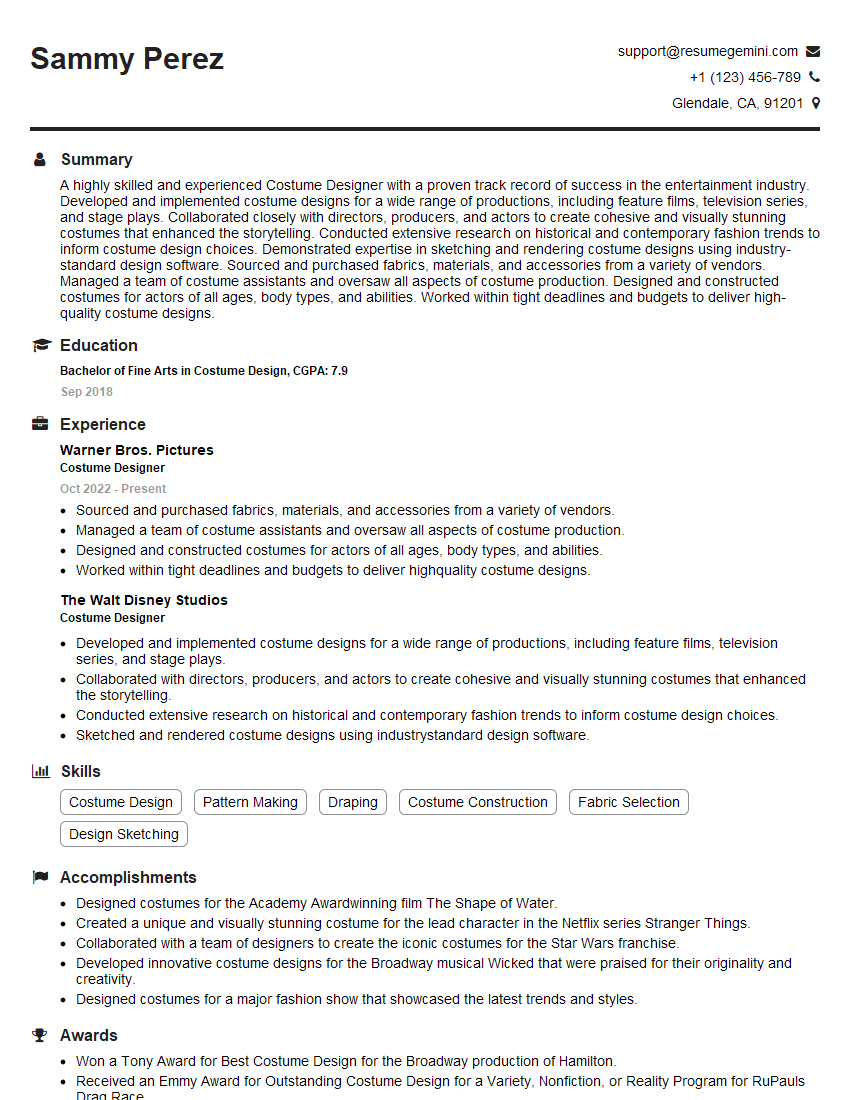

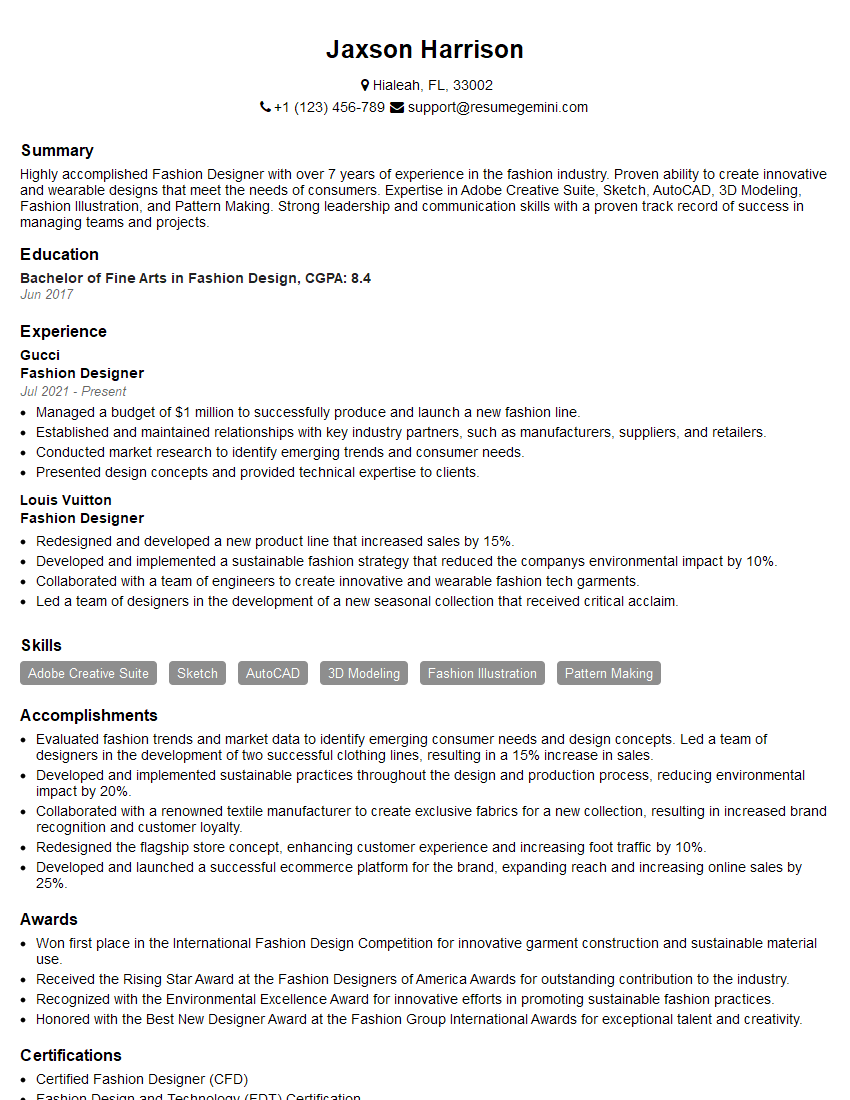

Mastering your knowledge of clothing items and fabrics is crucial for career advancement in the fashion and apparel industry. A strong understanding of these topics demonstrates your expertise and opens doors to exciting opportunities. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to showcase experience with a variety of clothing items and fabrics, helping you present your qualifications in the best possible light. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good