Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Experience with Advanced Wellbore Surveying Techniques (e.g., Gyro-Surveying) interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Experience with Advanced Wellbore Surveying Techniques (e.g., Gyro-Surveying) Interview

Q 1. Explain the principles of gyro surveying.

Gyro surveying relies on the principle of Newton’s First Law of Motion, specifically inertia. A spinning gyroscope resists changes in its orientation. By measuring the resistance to this change, we can determine the direction and rate of change of the wellbore’s orientation. Imagine a spinning top; it stays upright despite external forces attempting to tilt it. Similarly, a gyroscope in a wellbore measures the forces acting on it as the wellbore curves, allowing us to calculate its trajectory. This is crucial because the gyroscope’s orientation is independent of the Earth’s magnetic field, unlike magnetic tools, making it suitable for navigating in areas with magnetic interference.

In essence, a gyro measures angular velocity – how fast the wellbore is turning. Integrating this angular velocity over time provides the total angular change, allowing us to reconstruct the wellbore path. The accuracy depends on the precision of the angular velocity measurement and the ability to minimize systematic errors like gyro drift.

Q 2. Describe different types of gyro sensors used in wellbore surveying.

Several types of gyro sensors are used in wellbore surveying, each with its strengths and weaknesses:

- Spinning Wheel Gyroscopes (Mechanical Gyros): These traditional gyros use a rapidly spinning rotor to measure angular velocity. They are relatively simple but can be prone to wear and tear and may exhibit significant drift over time. Think of an old-fashioned spinning top – its spin gradually slows down.

- Dynamically Tuned Gyroscopes (DTG): These are more advanced mechanical gyros, offering improved accuracy and stability compared to simple spinning wheel gyros. They use sophisticated tuning mechanisms to minimize drift.

- Ring Laser Gyroscopes (RLG): These employ the interference of laser beams to detect rotation. They are highly accurate and have minimal drift, making them a preferred choice for demanding applications. They operate by measuring the difference in time it takes for light to travel in two opposite directions around a ring, a difference that is proportional to the rotation rate.

- Fiber Optic Gyroscopes (FOG): These operate on the Sagnac effect, which describes how light traveling in opposite directions around a closed path experiences a phase shift if the path rotates. They are robust, compact, and increasingly popular in wellbore surveying due to their high accuracy and stability. They offer a good balance of precision and ruggedness suitable for demanding downhole environments.

The choice of gyro sensor depends on factors such as accuracy requirements, operating environment, cost, and the overall survey design.

Q 3. What are the limitations of gyro surveying?

Despite their advantages, gyro surveying has limitations:

- Gyro Drift: Even the most advanced gyros exhibit some degree of drift – a gradual change in their measured orientation over time, primarily due to factors like thermal effects, vibrations, and imperfections in the sensor. This drift accumulates over time and needs to be accounted for. This is like the spinning top gradually slowing and eventually falling over.

- Temperature Sensitivity: Temperature changes can affect the performance of gyro sensors, introducing errors in the measurements. Proper temperature compensation techniques are necessary to mitigate this issue.

- Cost: Gyro surveying tools, especially those incorporating advanced gyro sensors like RLGs and FOGs, are more expensive than magnetic tools.

- Data Processing: The raw gyro data requires sophisticated processing to account for drift and other errors to obtain accurate wellbore trajectory estimates. This often requires specialized software and expertise.

Q 4. How do you compensate for drift in gyro measurements?

Drift compensation in gyro measurements is crucial for accurate surveying. This is typically achieved through a combination of techniques:

- Calibration: Before deployment, gyros are carefully calibrated to determine their inherent drift characteristics.

- Redundancy: Employing multiple gyro sensors within the surveying tool allows for cross-checking and averaging out individual drift errors. This is analogous to having multiple witnesses to an event for improved reliability.

- Mathematical Models: Sophisticated mathematical models are used to estimate and remove drift from the measured data. These models often incorporate factors like temperature, pressure, and tool orientation.

- Periodic Checks: During the survey, periodic checks may be performed to confirm tool orientation and correct for any accumulated drift.

- Inertial Navigation System (INS) Integration: Advanced techniques combine gyro data with accelerometer data (measuring linear acceleration) through an INS to enhance drift compensation.

The specific drift compensation strategy depends on the type of gyro sensor, the surveying environment, and the desired accuracy level.

Q 5. Explain the concept of tool face and its importance in gyro surveying.

The tool face is the orientation of the wellbore surveying tool within the wellbore. It’s the direction the tool is pointing, usually expressed as an azimuth angle. In gyro surveying, knowing the tool face is essential because the gyroscope’s measurements are referenced to the tool face. It’s like knowing the compass direction a ship is heading. The accurate determination of the tool face is critical for accurate wellbore trajectory determination.

Determining the tool face is often achieved through the use of additional sensors, like magnetic sensors or accelerometers, which complement gyro measurements. The tool face information allows us to correctly interpret the angular rate measurements from the gyroscope, enabling accurate wellbore path reconstruction.

Q 6. How does magnetic surveying differ from gyro surveying?

Magnetic surveying and gyro surveying differ fundamentally in how they determine wellbore orientation:

- Magnetic Surveying: This method relies on measuring the Earth’s magnetic field to determine the inclination and azimuth of the wellbore. It’s a relatively simpler and cheaper technique but is susceptible to magnetic interference from nearby metallic objects or variations in the Earth’s magnetic field. Imagine using a compass to navigate – it’s easy to use but can be affected by magnets nearby.

- Gyro Surveying: This method utilizes gyroscopes to measure angular velocities and determine wellbore orientation independently of the Earth’s magnetic field. It’s more accurate and robust in magnetically complex environments but is more expensive and requires more sophisticated data processing. It is like using a gyroscope – independent of Earth’s magnetic field, thus providing superior accuracy in challenging magnetic environments.

In practice, they are often used in combination to leverage their respective strengths and overcome their limitations. Magnetic surveys can provide an initial orientation estimate, and the data is used to support gyro surveying. The combination results in a more robust and complete picture of the well trajectory.

Q 7. What are the sources of error in wellbore surveying?

Several sources of error can affect wellbore surveying accuracy:

- Gyro Drift (as discussed earlier): This is a major source of error in gyro surveying.

- Magnetic Interference: This is a primary source of error for magnetic surveys, especially in areas with significant metal deposits or man-made structures.

- Temperature Variations: Temperature changes can affect the performance of all sensors used in wellbore surveying.

- Tool Misalignment: If the surveying tool is not properly aligned within the wellbore, it can lead to inaccurate measurements. This is akin to using a tilted level.

- Mechanical Vibrations: Vibrations during the survey can also introduce errors.

- Gravity Anomalies: Local variations in gravity can subtly influence measurements, especially for tools that rely on gravity compensation.

- Measurement Noise: Electronic noise and other random variations can affect the precision of the measurements.

- Data Processing Errors: Errors can be introduced during the data processing stages if incorrect models or assumptions are used.

Minimizing errors requires meticulous attention to detail during the survey design, instrument calibration, data acquisition, and data processing stages. Quality control checks and the use of advanced error correction techniques are essential to ensure the accuracy of wellbore surveys.

Q 8. Describe the process of data processing and quality control in gyro surveying.

Gyro surveying data processing involves several crucial steps to ensure accuracy and reliability. It begins with the raw data from the gyro instrument, which measures the earth’s rotation relative to the wellbore. This raw data is then cleaned to remove spurious readings caused by vibrations or instrument noise. This often involves applying filters and outlier detection techniques.

Next, the data is corrected for various factors like temperature, magnetic fields, and instrument drift. Sophisticated algorithms account for these effects to improve the precision of the calculated wellbore path. The cleaned and corrected data is then used to calculate the wellbore trajectory, typically using a minimum curvature method (discussed in a later question). Finally, a rigorous quality control process is implemented. This involves visually inspecting the survey data for inconsistencies, comparing it against other survey methods if available, and checking for conformance to expected geological formations. Any anomalies require thorough investigation and potentially recalculation.

For instance, a significant deviation in the calculated trajectory compared to geological predictions might indicate a problem with the survey data or faulty instrument calibration. A rigorous QC process would flag this issue and prompt a thorough review of the raw data, the processing steps, and even the instrument’s calibration history. This ensures the delivered survey data is accurate and reliable for subsequent decision-making.

Q 9. How do you handle data discrepancies between different surveying methods?

Data discrepancies between different surveying methods (e.g., gyro, magnetic, and inclinometry) are common and need careful handling. The first step is to understand the limitations and sources of error associated with each method. For example, magnetic surveys can be affected by magnetic anomalies in the formation, while gyro surveys are prone to errors due to instrument drift. Inclinometry, while relatively simple, might not be as accurate over long survey runs.

Discrepancies are usually addressed by a process of reconciliation. This often involves a weighted averaging technique, where the weight assigned to each survey method is determined by its estimated accuracy and reliability for a particular wellbore segment. For instance, in a region known to have significant magnetic interference, the gyro data might receive more weight. Sophisticated software packages are commonly used to perform these weighted averages and resolve conflicting data points.

Visual inspection plays a critical role. Plotting the data from different methods allows for a visual comparison, aiding in identifying potential errors or outliers. In cases of significant and unexplained discrepancies, a thorough investigation, potentially including revisiting the survey site or reviewing the instruments’ operational logs, is often necessary. Ultimately, the goal is to obtain a consistent and reliable representation of the wellbore trajectory.

Q 10. Explain the concept of minimum curvature and its application in wellbore surveying.

Minimum curvature is a mathematical method used to smooth wellbore survey data and create a continuous and realistic representation of the well’s trajectory. It assumes that the wellbore follows a smooth path with the smallest possible total curvature. This is akin to finding the smoothest possible curve that passes through all the measured survey points.

In practice, the minimum curvature method involves solving a series of equations to determine the wellbore’s three-dimensional coordinates at each survey station. This calculation minimizes the overall bending of the wellbore, making the resulting trajectory more realistic and less prone to artificial ‘kinks’ or sharp turns. The application of minimum curvature is essential for accurate well trajectory calculations, particularly when dealing with sparse or noisy data.

For example, if a survey has gaps or some erratic readings, the minimum curvature algorithm generates a plausible well path by finding the shortest path that is consistent with the available data. This results in a much more accurate representation of the wellbore than simply connecting the measured points with straight lines, which would introduce artificial bends and inaccuracies.

Q 11. What is the role of wellbore surveying in directional drilling?

Wellbore surveying is absolutely critical in directional drilling. It provides the real-time position and orientation of the drill bit, allowing operators to steer the drill bit to its target location. Without accurate surveying data, directional drilling would be impossible.

The survey data guides the drilling decisions. By continuously monitoring the wellbore trajectory, operators can make adjustments to the drilling parameters (e.g., weight on bit, rotary speed, directional drilling tools) to steer the drill bit towards the planned path. This ensures that the well reaches its target efficiently and safely, avoiding potential hazards such as intersecting other wells or formations of interest.

Imagine trying to steer a ship across the ocean without knowing its location. Wellbore surveying provides that crucial navigational information for directional drilling, making it a precise and controlled process.

Q 12. How do you interpret wellbore survey data to determine well trajectory?

Interpreting wellbore survey data to determine the well trajectory involves several steps. First, the raw data from the various survey tools must be processed and validated using appropriate software. This process often includes corrections for instrument errors, drift, and environmental factors.

Then, the processed data is used to calculate the wellbore’s three-dimensional coordinates at each survey station. This usually involves using algorithms like minimum curvature, as previously discussed. Once the coordinates are calculated, the data is presented visually, typically as a three-dimensional plot showing the well’s path relative to a defined reference system.

This 3D representation allows geologists and engineers to assess the well’s path and evaluate its conformance to the planned trajectory. They can measure critical parameters such as the well’s total measured depth, inclination, azimuth, and dog-leg severity. Deviations from the planned trajectory may trigger corrective actions during drilling or highlight potential issues that need to be addressed during subsequent operations.

Q 13. Describe the different coordinate systems used in wellbore surveying.

Several coordinate systems are commonly used in wellbore surveying, each serving a specific purpose. The most common are:

- North-East-Up (NEU): This is a Cartesian system where the North direction defines the X-axis, East defines the Y-axis, and Up (vertically upwards) defines the Z-axis. It’s very widely used and is a good system to represent the well’s position relative to the surface location.

- Grid Coordinate System: Similar to NEU, but uses a projected grid system rather than the Earth’s true North. This is often employed when accounting for geographic curvature over larger distances.

- Survey Reference Point (SRP): This is a local coordinate system established near the surface location. The SRP acts as the origin, simplifying calculations and data representation.

- Wellhead/Surface Coordinates: This system locates the well in a global or local map reference frame.

The choice of coordinate system depends on the specific application and the scale of the wellbore trajectory. Often, data is transformed between these different systems during the processing and analysis stages.

Q 14. What are the safety considerations for wellbore surveying operations?

Safety is paramount in wellbore surveying operations. Several critical considerations must be addressed to ensure the safety of personnel and equipment:

- Hydrogen Sulfide (H2S) Detection: H2S is a toxic and flammable gas commonly encountered in oil and gas wells. Continuous monitoring and appropriate safety protocols (including gas detection instruments and personal protective equipment) are crucial.

- High-Pressure/High-Temperature (HPHT) Environments: Wells can operate under extreme pressure and temperature conditions. Equipment must be properly rated, and personnel must be trained on safe operating procedures to avoid accidents.

- Working at Heights: Surveys often involve working on platforms, derricks, or other elevated locations. Fall protection measures and appropriate training are essential.

- Well Control Procedures: Emergency procedures must be in place in case of a well control event (such as a blowout). Personnel involved in surveying need to be well-versed in these procedures.

- Electrical Hazards: Working with electrical equipment near drilling rigs necessitates adherence to strict electrical safety guidelines.

Regular safety audits, training, and adherence to strict safety protocols are paramount to ensure that wellbore surveying operations are conducted safely and efficiently.

Q 15. Explain the use of wellbore surveying in horizontal drilling.

Wellbore surveying is crucial in horizontal drilling, providing the precise location and orientation of the wellbore throughout its trajectory. Imagine trying to navigate a maze without a map – impossible, right? Similarly, without accurate surveying, drilling a horizontal well, which needs to stay within a specific reservoir zone for optimal production, would be extremely difficult and potentially unproductive.

In horizontal drilling, the survey data guides the drilling process, ensuring the wellbore reaches the target formation at the planned depth and azimuth (direction). This involves continuous measurement of inclination (angle from vertical) and azimuth (direction from north), allowing real-time adjustments to the drilling trajectory to stay on course. Without this, the well might miss the target reservoir completely, resulting in significant financial losses.

- Directional Drilling: Survey data allows directional drillers to make adjustments to the drill bit’s angle and direction to steer the wellbore towards the target reservoir zone.

- Well Placement Optimization: Accurate surveys ensure the wellbore is optimally placed within the reservoir, maximizing contact with the hydrocarbon-bearing formations.

- Reservoir Characterization: Data from wellbore surveys combined with other geological information improves our understanding of the reservoir’s structure and properties.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How does wellbore surveying contribute to reservoir management?

Wellbore surveying plays a vital role in reservoir management by providing the critical spatial information needed for various tasks. This data forms the foundation for a comprehensive understanding of the reservoir’s geometry and the distribution of hydrocarbons within it.

For example, accurate wellbore trajectory data helps in optimizing well placement for improved sweep efficiency. Imagine a reservoir as a sponge; we want our wells to effectively extract the fluids from the entire sponge. Wellbore surveys help us place the wells strategically to ensure that we drain the most fluid from the reservoir. Moreover, integrating survey data with seismic and geological models helps us create detailed 3D reservoir models which are crucial for reservoir simulation and forecasting production.

- Reservoir Simulation: Accurate wellbore trajectories are essential input for reservoir simulation models, which predict future production rates and optimize field development strategies.

- Production Optimization: The understanding of well placement relative to reservoir boundaries guides decisions about well completion, stimulation, and production strategies.

- Waterflood Management: Wellbore surveys provide data on injector and producer well locations, which is critical for designing effective waterflooding schemes to enhance oil recovery.

Q 17. How are wellbore surveys used for well completion planning?

Wellbore surveys are indispensable for planning well completions because they provide the accurate geometry of the wellbore which is crucial for designing and deploying the completion equipment. Imagine trying to assemble a complex puzzle without knowing the shape of the pieces – you’d have a very difficult time!

The survey data dictates the length and type of casing required, the placement of perforations to access the reservoir, and the design of any downhole equipment like packers and inflow control devices. Knowing the exact wellbore trajectory allows engineers to optimize completion strategies for maximizing production and minimizing risks.

- Casing Design: Survey data determines the required length and diameter of casing strings to ensure wellbore integrity and prevent collapse.

- Perforation Design: The wellbore path influences the orientation and density of perforations, optimizing contact with the producing reservoir.

- Downhole Equipment Placement: Accurate survey data is crucial for placing downhole tools (such as packers, gravel packs, or inflow control devices) at precise locations along the wellbore.

Q 18. What software packages are you familiar with for wellbore surveying data processing?

I have extensive experience with various wellbore surveying software packages, including:

- Landmark OpenWorks: A comprehensive suite for processing and interpreting wellbore survey data, including quality control, error detection, and trajectory visualization.

- Petrel: A widely used reservoir modeling and simulation platform with integrated wellbore surveying capabilities.

- Roxar RMS: Another industry-standard reservoir modeling and simulation package with strong wellbore survey data handling features.

- DecisionSpace™: Schlumberger’s suite for well planning and operations, which includes advanced wellbore surveying tools and integration with other drilling data.

My proficiency in these software packages allows me to effectively process and analyze survey data, generating accurate wellbore trajectory models and reports used for various applications throughout the well lifecycle.

Q 19. Describe your experience with MWD/LWD tools and their integration with wellbore surveying.

MWD (Measurement While Drilling) and LWD (Logging While Drilling) tools are integral components of modern wellbore surveying. They provide real-time data on the wellbore’s trajectory, allowing for immediate corrections and enhancing operational efficiency. I have extensive experience with various types of MWD/LWD tools, including gyroscopic systems, magnetic systems, and inertial measurement units.

The integration of MWD/LWD data with wellbore surveying involves combining the real-time measurements from the tools with data from other sources (e.g., surface surveys). This integration is crucial for building a comprehensive understanding of the wellbore’s path, improving survey accuracy, and enabling real-time decision-making during drilling operations.

For instance, in one project, integrating MWD data with a gyro-survey allowed us to detect a significant deviation from the planned trajectory early in the drilling process. This early detection allowed for immediate corrective actions, preventing a costly and time-consuming rework of the well.

Q 20. How do you ensure accuracy and precision in wellbore surveying measurements?

Ensuring accuracy and precision in wellbore surveying requires a multi-faceted approach involving rigorous quality control procedures throughout the entire process. This starts with proper tool calibration and maintenance, careful data acquisition practices, and the application of advanced processing techniques.

We use several methods to achieve high accuracy including:

- Redundant Measurements: Employing multiple measurement tools (e.g., gyro and magnetic) to cross-check and validate the data.

- Data Validation and Error Detection: Implementing sophisticated algorithms to identify and correct potential errors in the raw survey data.

- Calibration and Tool Maintenance: Regular calibration and maintenance of surveying tools are crucial for minimizing systematic errors.

- Advanced Processing Techniques: Using sophisticated software to account for various error sources and improve survey accuracy. This often involves the use of advanced algorithms to smooth or adjust the raw survey data and create a more accurate representation of the wellbore’s trajectory.

In practice, this means carefully reviewing the data for anomalies and inconsistencies, implementing rigorous error-checking protocols, and regularly evaluating the accuracy of the survey measurements against known reference points.

Q 21. Explain the concept of wellbore deviation and how it is measured.

Wellbore deviation refers to the extent to which a well deviates from a vertical path. Imagine drilling a straight hole directly down; any deviation from that perfectly vertical line is considered wellbore deviation.

Wellbore deviation is primarily characterized by two parameters:

- Inclination: The angle of the wellbore from the vertical (measured in degrees). An inclination of 0° indicates a vertical well, while 90° represents a horizontal well.

- Azimuth: The direction of the wellbore (measured in degrees from north). This indicates the compass bearing of the wellbore at a given point along its trajectory.

These parameters are measured using various tools, including:

- Inertial Survey Tools (e.g., MWD gyros): These tools measure changes in inclination and azimuth by tracking the wellbore’s movement relative to inertial space.

- Magnetic Survey Tools (MWD magnetometers): These tools use Earth’s magnetic field to determine the wellbore’s azimuth. However, they’re less accurate than gyro systems.

- Gravity Survey Tools: These tools use gravity measurements to determine inclination.

The combination of these measurements allows for the precise determination of the wellbore’s trajectory and the quantification of wellbore deviation.

Q 22. What is the significance of wellbore surveying in reservoir characterization?

Wellbore surveying is absolutely crucial for reservoir characterization because it provides the spatial context for all other subsurface data. Think of it like creating a detailed map of an underground cave system – you need to know the precise location of every passage to understand its overall structure and potential resources.

Specifically, accurate wellbore surveys allow us to:

- Determine the true vertical depth (TVD) and horizontal displacement of the wellbore: This is essential for correlating well logs with seismic data and understanding the reservoir’s geometry.

- Calculate wellbore trajectory: This allows for precise placement of production zones and helps optimize completion strategies.

- Plan for future drilling operations: Accurate surveys inform the design of subsequent wells, minimizing risks and optimizing well spacing.

- Assess reservoir connectivity: By understanding the wellbore path, we can better interpret reservoir compartmentalization and fluid flow patterns.

For example, in a fractured reservoir, the wellbore trajectory data can be used to identify and target specific fractures that enhance production. Without accurate surveying, this targeted approach wouldn’t be possible.

Q 23. Describe your experience with different types of wellbore survey tools.

My experience encompasses a wide range of wellbore survey tools, including:

- Inertial Measurement Units (IMUs): These are the workhorses of many surveys, utilizing accelerometers and gyroscopes to measure changes in inclination and azimuth. I’m proficient in using both single-shot and continuous IMU systems, understanding their respective strengths and limitations.

- Magnetic Measurement Tools (MMTs): These rely on the Earth’s magnetic field to determine the direction of the wellbore. They are typically used in conjunction with IMUs to provide redundancy and improve accuracy. I have extensive experience in correcting magnetic disturbances caused by the wellbore itself and nearby ferrous materials.

- Gyro-Surveying Tools: My expertise includes various gyro-surveying technologies, including high-accuracy gyroscopic systems that offer improved accuracy and reduced drift compared to traditional IMUs, especially in long-reach wells. I’m also familiar with the differences between north-seeking and free-gyro systems.

- Multi-shot Tools: These tools can capture multiple survey measurements during a single trip, offering improved data density and potentially higher precision, especially when combined with a data quality control software suite

My experience extends to handling and calibrating these tools, processing the raw data, and identifying potential errors or anomalies. I have worked with both wireline and logging-while-drilling (LWD) survey tools, adapting my techniques to the specific requirements of each project.

Q 24. How do you handle challenging wellbore conditions during surveying operations?

Challenging wellbore conditions, such as high-angle wells, tortuous trajectories, and magnetic anomalies, require careful planning and specialized techniques. My approach involves:

- Pre-job planning: This includes a thorough review of the planned trajectory, geological information, and anticipated wellbore conditions to select the most appropriate survey tools and techniques. We also plan contingencies for potential problems.

- Real-time monitoring: During the survey operation, I closely monitor the data quality and make adjustments as needed to optimize accuracy. This includes identifying and mitigating issues like tool sticking, excessive vibrations, or magnetic interference.

- Advanced processing techniques: Dealing with challenging data often requires sophisticated processing techniques, such as gyro compass correction, magnetic corrections, and various data smoothing methods. This is where experience with different algorithms and software packages is critical.

- Redundancy and cross-checking: When conditions are particularly challenging, we often use redundant tools and surveying methods to cross-check the data and improve confidence in the results. For example, using both an IMU and a gyro tool simultaneously.

For example, in a high-angle, deviated well with significant magnetic interference, I might utilize a high-accuracy gyro tool and implement advanced processing techniques like Kalman filtering to minimize the impact of noise and drift, ultimately providing a more reliable well trajectory.

Q 25. Explain your understanding of multilateral wellbores and their surveying challenges.

Multilateral wells, with their multiple branches extending from a single wellbore, present unique surveying challenges because of increased complexity. The main challenges are:

- Accurate junction location: Determining the precise location where branches intersect the main wellbore is critical for reservoir management and completion design. This often requires high-resolution surveying techniques.

- Branch trajectory determination: Accurately mapping each branch’s trajectory requires careful planning and execution of surveying operations in often challenging environments. Ensuring tool reliability and data quality are especially important to avoid errors which become magnified when several branches are involved.

- Data integration and visualization: Combining the survey data from the main wellbore and all branches into a coherent 3D model is crucial for effective reservoir modeling and production optimization. Specialized software is necessary for this task.

One strategy I use to overcome these challenges is to employ advanced surveying tools with increased positional accuracy and data density. Also, pre-planning is key. We often use 3D modeling software to simulate the entire multilateral well construction process beforehand to optimize placement of survey tools, ensuring successful data acquisition and reduction of risk.

Q 26. Describe your experience with quality control procedures for wellbore surveying data.

Quality control (QC) for wellbore survey data is paramount to ensure the reliability and accuracy of all subsequent interpretations. My QC procedures include:

- Raw data inspection: I begin by visually inspecting the raw data from all tools for any anomalies or inconsistencies, looking for spikes, jumps, or unusual patterns. This step may involve plotting and examining the data in multiple ways.

- Redundancy checks: When available, I compare data from multiple tools or survey runs to identify discrepancies and verify the accuracy of the measurements.

- Error analysis and correction: I apply appropriate corrections for known error sources, such as magnetic interference or tool drift. This requires deep understanding of the tools and systematic processes.

- Statistical analysis: Statistical methods are used to assess the uncertainty and overall precision of the survey data. This step often includes evaluating the standard deviations, uncertainties, and correlation between various measurements.

- Data validation: The final step involves validating the processed survey data by comparing it with other available data, such as geological information or surface locations. This cross validation increases the confidence in the results.

A robust QC process ensures that the survey data is reliable and fit for purpose. Inaccuracies can lead to significant problems in reservoir characterization, well completion, and subsequent drilling operations. Therefore, a methodical QC approach is essential.

Q 27. How do you use wellbore survey data to optimize drilling operations?

Wellbore survey data is invaluable for optimizing drilling operations in several ways:

- Trajectory control: Real-time survey data allows for dynamic adjustments to the drilling trajectory, ensuring the wellbore reaches its target accurately and efficiently. This reduces non-productive time.

- Drill bit selection: Understanding the wellbore trajectory and geological conditions helps in selecting the most appropriate drill bit, minimizing wear and tear and optimizing drilling rates.

- Mud weight optimization: Accurate survey data can be used to assess the risk of wellbore instability and optimize mud weight to prevent wellbore collapse or other issues.

- Minimizing drilling risks: Real-time survey data helps identify potential problems, such as close proximity to faults or other hazardous geological features, allowing for timely mitigation strategies.

- Production Optimization: Post-drilling, the survey data helps in placement of completions, stimulating the target reservoir zones to maximize production.

For instance, by monitoring the wellbore inclination and azimuth during drilling, we can make small course corrections to avoid encountering unexpected geological formations, thereby saving time and resources.

Q 28. What are the emerging trends in advanced wellbore surveying technologies?

Several emerging trends are shaping the future of advanced wellbore surveying:

- Improved sensor technology: New sensors with higher accuracy, increased sensitivity, and reduced drift are continually being developed, leading to more precise and reliable survey data. This is fueled by advancements in MEMS technology and increased computational capabilities in downhole environments.

- Integration of multiple data sources: There’s a growing trend to integrate wellbore survey data with other subsurface data sources, such as seismic data, well logs, and formation imaging, to create more comprehensive reservoir models. This integration allows for advanced interpretation and more accurate predictions of reservoir properties.

- Automation and real-time data processing: Automation is improving the efficiency and speed of wellbore survey data processing, allowing for real-time interpretation and quicker decision-making during drilling operations.

- Artificial intelligence (AI) and machine learning (ML): AI and ML are playing an increasingly significant role in wellbore survey data analysis, enabling the automated identification of anomalies, improved error correction, and better predictive modeling.

- Wireless data transmission: Wireless communication technologies are allowing for real-time transmission of survey data to the surface, improving monitoring capabilities and reducing the need for wireline retrievals.

These advancements promise to revolutionize wellbore surveying, leading to more efficient drilling operations, improved reservoir characterization, and ultimately, increased production from oil and gas wells.

Key Topics to Learn for Experience with Advanced Wellbore Surveying Techniques (e.g., Gyro-Surveying) Interview

- Fundamentals of Wellbore Surveying: Understanding the different types of wellbore surveys, their limitations, and applications. This includes a solid grasp of directional drilling principles.

- Gyro-Surveying Principles: Mastering the theoretical underpinnings of gyro-surveying, including the physics of gyroscopes and their application in measuring wellbore inclination and azimuth.

- Data Acquisition and Processing: Familiarize yourself with the process of acquiring gyro-surveying data, including sensor calibration, data logging, and quality control measures. Understand how this data is processed and interpreted.

- Error Analysis and Mitigation: Learn to identify potential sources of error in gyro-surveying data and develop strategies to mitigate their impact on survey accuracy. This includes understanding systematic and random errors.

- Advanced Gyro-Surveying Techniques: Explore specialized techniques like Multi-Shot Gyro-Surveying, and their advantages and disadvantages compared to other methods.

- Integration with other Surveying Methods: Understand how gyro-surveying data is integrated with data from other wellbore surveying tools (e.g., magnetic, inclinometer) to create a comprehensive wellbore trajectory model.

- Practical Applications: Be prepared to discuss real-world applications of gyro-surveying, such as horizontal drilling, directional drilling, and well placement optimization. Consider case studies to illustrate your knowledge.

- Software and Tools: Familiarity with common software packages used for processing and interpreting gyro-surveying data is beneficial.

- Troubleshooting and Problem Solving: Prepare to discuss scenarios where gyro-surveying data may be unreliable or incomplete, and how to troubleshoot such issues.

Next Steps

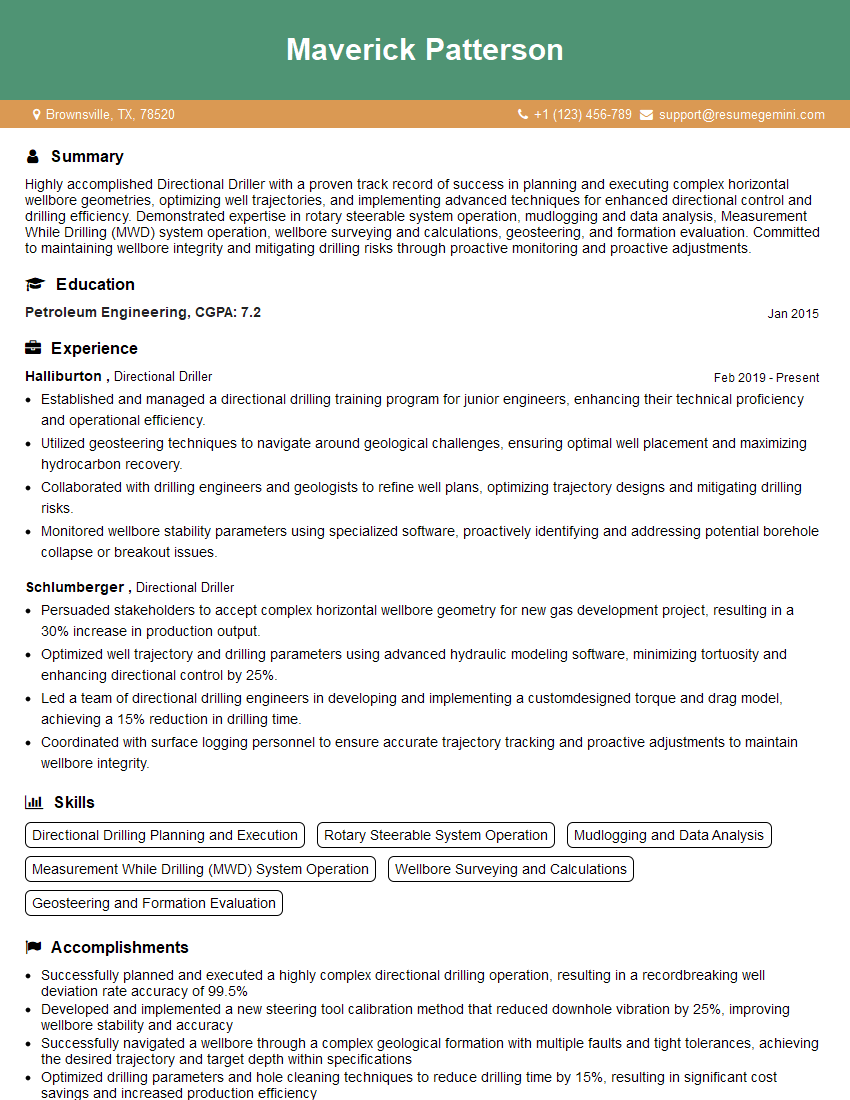

Mastering advanced wellbore surveying techniques, especially gyro-surveying, is crucial for career advancement in the oil and gas, geothermal, or other relevant industries. It demonstrates a high level of technical expertise and problem-solving ability. To maximize your job prospects, it is essential to create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to showcasing experience in advanced wellbore surveying techniques, including gyro-surveying, are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good