The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Experience with electrical tools and equipment interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Experience with electrical tools and equipment Interview

Q 1. What safety precautions do you take when working with high-voltage equipment?

Safety is paramount when working with high-voltage equipment. A single mistake can be fatal. My approach involves a layered safety system. First, I always visually inspect the equipment for any visible damage before approaching it. This includes checking for frayed wires, loose connections, or signs of overheating. Then, I meticulously lockout/tagout (LOTO) the power source, ensuring the equipment is completely de-energized. This involves physically disconnecting the power and securing the switch with a lock and tag bearing my name, preventing accidental re-energization. I never trust someone else’s LOTO; I always perform my own. Even with LOTO, I use a non-contact voltage tester to verify the absence of voltage before touching any part of the system. Finally, I use appropriate personal protective equipment (PPE), including insulated gloves, safety glasses, and arc flash protective clothing if the voltage is particularly high. Following these steps consistently minimizes the risk of electrical shock or arc flash injuries.

For instance, during a recent project involving a 480V panel, I meticulously followed the LOTO procedure and even used a voltage detector on every wire before beginning work. This extra precaution, even though it might seem redundant, prevents potential mistakes that could result in serious injury.

Q 2. Explain the difference between AC and DC current.

The main difference between AC (Alternating Current) and DC (Direct Current) lies in the direction of electron flow. DC current flows in one direction consistently, like water flowing downhill. Think of a battery; it provides a constant flow of electrons from the negative to the positive terminal. AC current, on the other hand, periodically reverses its direction. Imagine a water pump pushing water back and forth through a pipe; that’s analogous to AC current. This reversal happens at a specific frequency, typically 50 or 60 Hertz (Hz), depending on the geographical location. AC is advantageous for long-distance power transmission due to its ability to be easily transformed to higher or lower voltages. DC is better suited for low-voltage applications like electronics, as it doesn’t experience the voltage fluctuations inherent to AC.

In practical terms, this difference affects how we work with circuits. DC circuits are often simpler to troubleshoot, as the current always flows in one direction. AC circuits, however, require understanding the sinusoidal waveform and how components like transformers and capacitors interact with it.

Q 3. Describe your experience with various electrical testing instruments (e.g., multimeters, clamp meters).

I’m proficient with a range of electrical testing instruments. The multimeter is my everyday tool; I use it for measuring voltage, current, and resistance. I regularly use it to check the integrity of circuits, verify proper voltage levels, and troubleshoot faulty components. For example, I recently used a multimeter to diagnose a low voltage issue in a building’s lighting circuit, isolating the problem to a faulty connection in a junction box.

The clamp meter is invaluable for measuring current without having to disconnect wires, making it ideal for measuring high currents in live circuits. I’ve used this numerous times for load balancing and ensuring branch circuits aren’t overloaded. For instance, during a motor installation, I used a clamp meter to measure the current draw to verify that the circuit breaker was adequately sized. Other instruments I regularly use include meggers for insulation resistance testing and loop testers for circuit breaker trip time testing. Understanding the limitations and capabilities of each instrument is critical for accurate and safe testing.

Q 4. How do you troubleshoot a faulty circuit?

Troubleshooting a faulty circuit is a systematic process. I start by visually inspecting the circuit for any obvious problems, like loose connections, burnt components, or damaged wiring. Then, I use a multimeter to check the voltage at various points in the circuit, comparing the readings to the expected values. This helps identify whether the problem is related to a voltage drop, an open circuit, or a short circuit. If the problem isn’t immediately apparent, I’ll utilize a combination of systematic testing and logic. This might include checking individual components for continuity and comparing their functionality to known good parts. For instance, if a circuit breaker is tripping frequently, I’ll investigate the load on the circuit, checking for overloading or short circuits. Proper documentation and clear methodology are essential, ensuring the issue is resolved without causing further damage.

Q 5. What are the common causes of electrical shorts?

Electrical shorts occur when there’s an unintended path for current to flow, often bypassing the intended circuit path. Common causes include:

- Damaged insulation: Worn or deteriorated insulation on wires can expose bare conductors, leading to shorts. This often happens due to age, physical damage, or exposure to moisture.

- Loose connections: Poorly tightened connections can create high resistance, causing arcing and eventually a short circuit.

- Foreign objects: Metal objects or debris falling into electrical enclosures can create a short between conductors.

- Overheating: Excessive heat can degrade insulation and lead to shorts.

- Manufacturing defects: Faulty components or wiring can introduce shorts from the moment of installation.

The consequences of a short circuit can range from minor nuisance trips of a circuit breaker to fires and equipment damage. That’s why regular inspections and preventative maintenance are critical.

Q 6. Explain the National Electrical Code (NEC) and its importance.

The National Electrical Code (NEC) is a set of nationally recognized standards for the safe installation and use of electrical systems in the United States. It’s a crucial document that guides electricians and ensures public safety by outlining regulations for wiring methods, equipment installation, and safety procedures. The NEC is regularly updated to reflect advancements in technology and safety practices. Adherence to the NEC is essential; not only does it protect lives, but it also limits liability in case of incidents. During my work, I constantly reference the NEC to ensure installations and repairs comply with all relevant codes and regulations. Ignoring the NEC can result in unsafe conditions, fines, insurance issues and potential legal repercussions.

Q 7. Describe your experience with different types of wiring (e.g., Romex, conduit).

I have extensive experience with various types of wiring. Romex, also known as NM-B cable, is a common type of non-metallic sheathed cable used in residential construction. It’s relatively easy to install, but its limited flexibility can make it challenging in certain situations. Conduit, on the other hand, is more robust and offers better protection for wires in harsh environments. It’s used extensively in commercial and industrial settings, where cables might be subject to physical damage or exposure to chemicals. Within conduit, various types of cables like THHN (heat-resistant, high-voltage) or MC (metal-clad) cables are used. The choice depends on the specific application and environmental conditions. I’m also experienced with other types of wiring, such as BX cable and underground feeder cable, each with its own advantages and limitations and appropriate application.

Choosing the right type of wiring is crucial for safety and longevity. In one recent project, the use of conduit in an area exposed to moisture was critical for preventing corrosion and short circuits.

Q 8. How do you identify different types of electrical components?

Identifying electrical components involves a multi-sensory approach combining visual inspection, understanding of markings, and sometimes even testing with specialized equipment. First, we visually assess the component’s physical characteristics – size, shape, color-coding, and any markings. For example, resistors often have colored bands indicating their resistance value (following a standard color code), while capacitors might have markings indicating their capacitance and voltage rating. Secondly, we look for any manufacturer markings or part numbers, which can be cross-referenced with datasheets to provide detailed specifications. Finally, if necessary and safe to do so, multimeters can be used to measure properties like resistance, capacitance, or voltage to verify the component’s functionality and value.

For instance, a large cylindrical component with a wire coming out at each end is likely an inductor, while a smaller ceramic component with two leads is probably a capacitor. Learning to distinguish components by their physical attributes and markings is crucial for safe and efficient work.

Q 9. What are the different types of electrical motors and their applications?

Electrical motors come in various types, each suited for different applications. The most common include:

- DC Motors: These run on direct current and are simple to control, making them suitable for applications like robotics, toys, and small appliances. They offer good speed control but can be less efficient than AC motors.

- AC Motors: These operate on alternating current, are typically more robust and efficient, and come in various subtypes:

- Induction Motors: These are very common in industrial settings, used in pumps, fans, and compressors due to their ruggedness, reliability, and relatively low cost. They are typically less efficient at low speeds.

- Synchronous Motors: These motors run at a constant speed synchronized with the power supply frequency, and find use in applications requiring precise speed control, such as clocks or timing mechanisms.

- Stepper Motors: These motors move in precise incremental steps, making them perfect for applications requiring precise positioning, such as 3D printers or CNC machines.

- Servo Motors: These motors provide precise control of position, speed and torque, often incorporating feedback mechanisms to maintain accuracy and are widely used in robotics and automation systems.

Choosing the right motor type depends on factors like required torque, speed control needs, efficiency requirements, and budget. In my experience, selecting the correct motor type is critical to system performance and often involves careful consideration of the application’s specific demands.

Q 10. Describe your experience with electrical drawings and schematics.

I have extensive experience interpreting and working with electrical drawings and schematics. My experience ranges from simple circuit diagrams to complex industrial control system schematics. I am proficient in reading and understanding symbols, understanding component values and their connections, and tracing signals through the circuit. This understanding is fundamental to troubleshooting problems, designing new systems and maintaining existing ones.

For example, I’ve worked on projects that involved interpreting single-line diagrams for large power systems, detailed schematics for control panels, and wiring diagrams for complex machinery. The ability to accurately interpret these drawings ensures that work is carried out safely and correctly, avoiding potential hazards and misconnections.

Beyond reading them, I’m comfortable using CAD software to create and modify electrical drawings, ensuring accuracy and consistency in documentation.

Q 11. How do you perform a lockout/tagout procedure?

Lockout/Tagout (LOTO) is a critical safety procedure to prevent accidental energization of equipment during maintenance or repair. It’s a crucial part of my routine. The steps are:

- Preparation: Identify all energy sources (electrical, hydraulic, pneumatic, etc.) that need to be controlled. Gather the necessary lockout/tagout devices (locks, tags, and appropriate tools).

- Notification: Inform all personnel who may be affected by the lockout/tagout procedure.

- Shutdown: Turn off the equipment using the normal shutdown procedures. Verify the equipment is off.

- Isolation: Isolate the equipment from all energy sources. This may involve disconnecting breakers, closing valves, or removing belts.

- Lockout/Tagout: Attach personal lockout devices to the energy isolation points. Ensure that only authorized personnel have keys or can remove the tag.

- Verification: Verify that the equipment is de-energized and cannot be accidentally energized. This often involves using a voltage tester.

- Maintenance/Repair: Perform the necessary maintenance or repair work.

- Removal: After the work is complete, remove the lockout devices in the reverse order they were installed. The person who applied the lockout device is typically the same person who removes it.

- Verification: Verify the equipment operates correctly after the lockout/tagout devices are removed.

Thorough LOTO procedures significantly reduce the risk of electrical shock, burns, or other injuries. I meticulously follow this procedure in every situation requiring it.

Q 12. What are the safety regulations for working at heights involving electrical equipment?

Working at heights with electrical equipment presents significant risks. Safety regulations emphasize several key aspects:

- Fall Protection: Appropriate fall protection is essential, including harnesses, lanyards, and anchor points that meet OSHA standards. This might involve using scaffolding, safety nets, or personal fall arrest systems (PFAS).

- Electrical Safety: Before starting any work, verify that the equipment is de-energized using approved lockout/tagout procedures. Use insulated tools and protective equipment (PPE) like rubber gloves and safety footwear. Always maintain a safe distance from energized conductors.

- Training: Workers must receive thorough training on working at heights and electrical safety procedures. This includes understanding the risks involved, proper use of equipment, emergency procedures, and rescue techniques.

- Site Assessment: A thorough site assessment is crucial to identify potential hazards and plan for safe work practices. This includes checking for overhead power lines and ensuring adequate access and egress.

- Permit-to-Work Systems: In many settings, a permit-to-work system is used to formally authorize and control high-risk activities, including those involving working at height with electrical equipment.

Failure to follow these regulations can lead to serious injury or death. I always prioritize safety by strictly adhering to these regulations and using all the necessary precautions.

Q 13. Explain your experience with grounding and bonding techniques.

Grounding and bonding are fundamental safety techniques that protect against electrical shocks and equipment damage. Grounding connects a conductive part of an electrical system to the earth, providing a low-resistance path for fault currents to flow to the ground, preventing dangerous voltages from building up. Bonding connects multiple conductive parts together to ensure they are at the same electrical potential, preventing voltage differences that could cause arcing or shocks.

My experience includes working with grounding systems in various settings, from simple household installations to complex industrial facilities. I have practical experience installing and verifying ground rods, using ground clamps and bonding jumpers, and testing ground resistance using a ground resistance tester. I understand the importance of choosing appropriately sized grounding conductors and ensuring that connections are properly made and maintained. For instance, in a recent project, I had to ensure proper grounding for a large industrial motor to prevent damage in the event of a short circuit.

Proper grounding and bonding are critical for ensuring the safety of personnel and equipment and preventing potential electrical hazards.

Q 14. How do you handle emergency situations involving electrical hazards?

Handling electrical emergencies requires quick thinking and a methodical approach. My first priority is always safety – both mine and others’.

- Assess the situation: Quickly and safely assess the nature of the emergency (e.g., electrical shock, fire, equipment malfunction). Do not approach the situation without proper safety precautions.

- Isolate the power source: If possible and safe to do so, immediately isolate the power source using a lockout/tagout procedure or by switching off the main breaker. If it’s not safe to approach the equipment, call for emergency assistance.

- Administer First Aid: If someone has suffered an electrical shock, immediately administer first aid, including CPR if necessary. Call emergency medical services.

- Call for help: Depending on the nature and severity of the emergency, contact appropriate emergency services (fire department, paramedics, etc.)

- Investigate the cause: Once the situation is under control, investigate the cause of the emergency to prevent similar incidents in the future. This could include checking the equipment, reviewing procedures, or performing tests.

In a past incident, a short circuit caused a small fire. Following established procedures, I immediately isolated the power, used a fire extinguisher to extinguish the fire, and then called the fire department to ensure the area was safe. Following this, I conducted a thorough investigation to determine the cause of the short circuit, making necessary repairs and improving safety procedures to prevent future incidents.

Q 15. Describe your experience with different types of electrical panels.

My experience encompasses a wide range of electrical panels, from simple residential load centers to complex industrial switchboards. I’m familiar with various panelboard manufacturers and their specific designs. For instance, I’ve worked extensively with Square D QO panels in residential settings, noting their ease of use and common configurations. In industrial environments, I’ve encountered larger, more intricate switchboards from manufacturers like Siemens and Eaton, requiring a deeper understanding of busbar configurations, metering systems, and safety interlocks. My experience also includes working with older, sometimes obsolete panels, requiring careful assessment and potentially challenging troubleshooting. I understand the importance of proper grounding, bonding, and the National Electrical Code (NEC) standards for panel installation and maintenance.

For example, I once worked on a renovation project where the existing panel was overloaded and outdated. I had to carefully plan the upgrade, ensuring the new panel had sufficient capacity to meet the increased load demands of the remodeled space while adhering to all safety regulations and local codes.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of circuit breakers and their functions?

Circuit breakers are safety devices designed to protect electrical circuits from overcurrent. There are several types, each with a specific function:

- Thermal-Magnetic Circuit Breakers: These are the most common type found in homes and small businesses. They use a bimetallic strip (thermal) to respond to sustained overloads and an electromagnetic coil (magnetic) to trip quickly in response to short circuits. Think of them as a two-pronged defense against electrical issues.

- Ground Fault Circuit Interrupters (GFCIs): These protect against ground faults, which can be deadly. They monitor the balance of current flowing in the hot and neutral wires. If an imbalance is detected (indicating current is flowing to ground), the GFCI instantly trips. These are vital in areas near water sources like bathrooms and kitchens.

- Arc Fault Circuit Interrupters (AFCIs): These are designed to detect and interrupt arcing faults, which can be a common cause of electrical fires. They are increasingly required in bedrooms and other areas of residential construction.

- Molded-Case Circuit Breakers: These are more robust and are typically used in industrial and commercial settings. They handle larger currents and offer advanced features such as overload protection, short-circuit protection and other advanced capabilities.

Understanding the specific function of each type of breaker is crucial for proper circuit protection and fault diagnosis. For example, a tripped GFCI might indicate a faulty appliance or wiring near water, while a tripped thermal-magnetic breaker might indicate an overloaded circuit.

Q 17. How do you diagnose and repair faulty electrical appliances?

Diagnosing and repairing faulty electrical appliances begins with a thorough safety assessment. Always disconnect power to the appliance before beginning any work. Then I typically follow these steps:

- Visual Inspection: Examine the appliance for any obvious signs of damage, such as frayed cords, loose connections, or burn marks.

- Testing: Use a multimeter to check voltage, current, and resistance at various points in the appliance’s circuitry. This helps isolate the faulty component.

- Component Identification: Once the faulty component is identified (e.g., a capacitor, motor, switch), I’ll carefully remove and replace it. Sometimes simple repairs like cleaning a corroded connection are sufficient.

- Troubleshooting: If the fault is not readily apparent, I’ll follow the appliance’s wiring diagram and systematically check for continuity, resistance, and voltage drops.

- Reassembly and Testing: After repairs are complete, I reassemble the appliance and perform thorough testing to ensure it’s functioning correctly and safely.

For example, I recently repaired a malfunctioning washing machine by replacing a faulty motor capacitor. A multimeter confirmed the capacitor was shorted, indicating the need for replacement. Following the repair, the machine operated normally.

Safety is paramount. If I’m unsure about any aspect of the repair, I’ll consult the appliance’s manual or seek assistance from a qualified technician.

Q 18. What is your experience with using hand tools specific to electrical work (e.g., wire strippers, crimpers)?

I have extensive experience using hand tools vital for electrical work. My tool kit includes a variety of wire strippers (both automatic and manual, for different wire gauges), crimpers (for various connector types), wire cutters, and lineman’s pliers. I’m proficient in using these tools to safely and efficiently strip, terminate, and crimp wires according to the specific requirements of the job. I am also adept at using specialized tools like fish tapes, to snake wires through walls, and various types of testing tools. Selecting the right tool for the job is essential to efficient and safe work. For example, using an incorrect wire stripper can damage the wire, leading to poor connections or electrical hazards.

I always prioritize using the correct tools to avoid damage or injury. Using a sharp, well-maintained toolset increases efficiency and reduces the likelihood of errors.

Q 19. Describe your experience with power tools used in electrical work (e.g., drills, saws).

Power tools are essential for many electrical projects. I’m experienced with using drills (both corded and cordless) for tasks such as creating holes for conduit, mounting electrical boxes, and installing equipment. I also use saws, including reciprocating saws (for cutting conduit and other materials), to prepare for electrical installations. Other tools I regularly employ include hole saws for precise cutouts, and specialized tools like a cable stapler for neatly securing wires. Safety is critical when operating power tools; I always wear appropriate personal protective equipment (PPE) such as safety glasses and hearing protection.

For example, when installing a new circuit in a home, I might use a drill to create holes for the conduit, a reciprocating saw to cut the conduit to length, and a hole saw to cut the hole for an electrical box in the drywall.

Q 20. What are the proper methods for installing and terminating wires?

Proper wire installation and termination are crucial for electrical safety and system integrity. The process depends on the wire type, gauge, and the termination method. Generally, it involves these steps:

- Stripping Insulation: Using the appropriate wire stripper, carefully remove the insulation from the wire ends, exposing the required length of bare conductor. Over-stripping can damage the wire; under-stripping can lead to poor connections.

- Preparing the Wire: For stranded wires, twisting the strands together neatly prevents fraying and ensures a good connection. For solid core, clean any oxidation.

- Connecting to a Terminal: Screw-type terminals require careful tightening to ensure a secure connection. Push-in terminals require correct insertion and positive clicking to ensure contact.

- Crimping: For crimp connectors, I use a crimper to create a strong, mechanically sound joint. Proper crimping ensures consistent, reliable electrical contact.

- Protecting the Connection: Once connected, the connection often needs protection. This might be achieved with wire nuts, heat shrink tubing, or other specialized coverings.

- Inspection: After completing the termination, I always visually inspect the connection for signs of damage or loose strands. Ensuring proper grounding and bonding, and adherence to NEC guidelines, is critical for safety.

Consistent and meticulous attention to detail is key. Poor wire terminations can lead to overheating, fire hazards, and system malfunctions. Adhering to best practices and using the correct tools is essential for safe and reliable electrical installations.

Q 21. Explain your experience with different types of transformers.

My experience with transformers includes both step-up and step-down types, as well as various applications. I’ve worked with:

- Step-Down Transformers: These are commonly used to reduce high-voltage electricity from the power grid to safer, lower voltages for residential and commercial use. For example, a typical household transformer reduces 240V to 120V.

- Step-Up Transformers: Used in power transmission systems to increase voltage for efficient long-distance power transfer. Higher voltage reduces power loss over distance.

- Isolation Transformers: These provide electrical isolation between the input and output circuits, enhancing safety by preventing ground faults and electrical shock. These are often used in sensitive electronic equipment and medical devices.

- Autotransformers: These have only one winding, providing a variable voltage output. They’re commonly used for voltage regulation or testing.

I understand the principles of transformer operation, including the relationship between voltage, current, and turns ratio. I’m also aware of the safety precautions necessary when working with transformers, such as ensuring proper grounding and insulation to prevent electrical shock. Working with transformers demands knowledge of their specifications to ensure safe and proper integration in circuits.

For example, I assisted in the installation of a new transformer for a larger industrial facility to support additional machinery. I needed to carefully assess the power requirements of the machinery and the existing system to ensure the selected transformer met the demands without overloading the system.

Q 22. How do you calculate voltage, current, and resistance in a circuit?

Ohm’s Law is the foundation for calculating voltage, current, and resistance in a circuit. It states that voltage (V), current (I), and resistance (R) are related by the equation: V = I * R. This means voltage is directly proportional to current and resistance. We can rearrange this equation to solve for any of the three variables.

- Calculating Voltage (V): If you know the current (I) and resistance (R), you can calculate the voltage using the formula:

V = I * R. For example, if a circuit has a current of 2 amps (I = 2A) and a resistance of 10 ohms (R = 10Ω), the voltage would beV = 2A * 10Ω = 20V. - Calculating Current (I): If you know the voltage (V) and resistance (R), you can calculate the current using the formula:

I = V / R. For example, if a circuit has a voltage of 12V and a resistance of 4Ω, the current would beI = 12V / 4Ω = 3A. - Calculating Resistance (R): If you know the voltage (V) and current (I), you can calculate the resistance using the formula:

R = V / I. For example, if a circuit has a voltage of 24V and a current of 6A, the resistance would beR = 24V / 6A = 4Ω.

Understanding Ohm’s Law is crucial for troubleshooting circuits and designing electrical systems. Imagine working on a lighting system where a bulb isn’t working. By measuring the voltage at the bulb’s socket and the current flowing through the circuit, you can calculate the resistance and determine if the problem lies in the bulb itself (high resistance) or elsewhere in the wiring (unexpectedly high resistance indicating a fault).

Q 23. Describe your experience with PLC programming (if applicable).

I have extensive experience with PLC programming, primarily using Siemens TIA Portal and Allen-Bradley Studio 5000. My experience spans various industrial applications, including automated assembly lines, process control systems, and robotic integration. I’m proficient in ladder logic, function block diagrams (FBD), structured text, and sequential function charts (SFC).

In a recent project, I developed a PLC program to control a complex automated packaging machine. This involved coordinating multiple conveyor belts, robotic arms, and sensors to ensure precise and efficient product handling. The program included intricate timing sequences, error handling routines, and communication protocols (e.g., Ethernet/IP, Profibus) for data acquisition and remote monitoring. I utilized structured text for complex calculations and decision-making, while ladder logic was used for simpler on/off control functions. This project required meticulous attention to detail and a deep understanding of both hardware and software integration.

I’m also comfortable working with HMI (Human Machine Interface) software to design user-friendly interfaces for operators to monitor and control the PLC-based systems. I am familiar with troubleshooting PLC programs using various diagnostic tools, including online monitoring and simulation software.

Q 24. What are your experiences with various types of relays?

My experience encompasses a wide range of relays, including electromechanical, solid-state, and time-delay relays. Each type has its specific applications and advantages.

- Electromechanical Relays: These are the most common type, using an electromagnetic coil to actuate mechanical contacts. They’re robust and reliable, suitable for high-current switching, but have limited switching speed and a finite lifespan due to mechanical wear. I’ve used them extensively in motor control circuits and overload protection systems.

- Solid-State Relays (SSRs): These relays use semiconductor devices instead of mechanical contacts, offering faster switching speeds, longer life, and increased noise immunity. SSRs are ideal for applications requiring precise timing and high switching frequencies. I’ve incorporated them in high-speed control systems and temperature regulation circuits.

- Time-Delay Relays: These introduce a time delay before the relay switches, allowing for sequential operations or preventing unwanted activations. I’ve used them in motor starting sequences and safety interlocks to ensure correct operational timing.

Choosing the right relay for a specific application depends on factors like the load characteristics, switching speed requirements, environmental conditions, and budget considerations. For instance, I once had to replace electromechanical relays in a high-vibration environment with solid-state relays to prevent premature failures.

Q 25. What is your understanding of different types of grounding systems?

Grounding systems are essential for safety and proper circuit operation. They provide a low-resistance path for fault currents to flow to the earth, preventing dangerous voltage buildup and protecting personnel and equipment. There are several types of grounding systems:

- Grounding Electrode System: This involves driving a conductive rod or using a buried conductor as a ground electrode, connecting it to the main electrical panel. It’s crucial for dissipating fault currents.

- Equipment Grounding: This involves connecting the metallic enclosures of electrical equipment to the grounding electrode system, ensuring that if a fault occurs, the enclosure doesn’t become energized.

- System Grounding: This relates to how the electrical system (e.g., power transformer neutral) is grounded. Common methods include grounding the neutral point (wye connection) or a grounding transformer for isolation.

The choice of grounding system depends on factors such as the voltage level, the type of installation (e.g., residential, industrial), and local regulations. For example, a high-voltage industrial facility will require a more complex and robust grounding system compared to a standard residential setting. Understanding the different types and their respective applications is paramount for ensuring electrical safety.

Q 26. Describe your proficiency in using various electrical measuring instruments.

I’m proficient in using a variety of electrical measuring instruments, including multimeters, oscilloscopes, clamp meters, and power analyzers.

- Multimeters: I routinely use multimeters for measuring voltage, current, resistance, and continuity. I’m adept at selecting the appropriate range and function to avoid damage to the meter or the circuit under test.

- Oscilloscopes: Oscilloscopes are indispensable for analyzing waveforms and identifying transient events. I use them to troubleshoot electronic circuits, examine signal integrity, and investigate issues with timing and frequency.

- Clamp Meters: These meters allow me to measure current without breaking the circuit, which is essential for safety and efficient troubleshooting in live systems. I’ve used them to diagnose motor faults, investigate power imbalances, and verify circuit loading.

- Power Analyzers: These sophisticated instruments measure various electrical parameters, including power factor, harmonic distortion, and energy consumption. I utilize these for energy efficiency analysis and diagnosing power quality problems.

Accurate measurements are critical for safe and effective electrical work. A recent instance involved using an oscilloscope to identify a spurious noise signal affecting the performance of a control system. By pinpointing the source of the interference, I was able to implement a solution to restore the system’s stability and reliability.

Q 27. How do you ensure compliance with electrical safety standards in your work?

Ensuring compliance with electrical safety standards is paramount in my work. I adhere to relevant codes and regulations, including NFPA 70 (National Electrical Code) and OSHA guidelines. My safety practices include:

- Lockout/Tagout Procedures: I rigorously follow lockout/tagout procedures before working on any energized equipment, ensuring that the power is isolated and the equipment is made safe for maintenance.

- Proper Personal Protective Equipment (PPE): I always use appropriate PPE, including safety glasses, insulated gloves, and safety shoes, to minimize the risk of electrical shock or injury.

- Regular Inspections: I regularly inspect electrical equipment and wiring for signs of damage or wear, promptly addressing any identified issues.

- Grounding and Bonding: I ensure proper grounding and bonding of all equipment to prevent hazardous voltage buildup.

- Risk Assessments: I conduct thorough risk assessments before undertaking any electrical work to identify potential hazards and develop mitigation strategies.

Compliance isn’t just a checklist; it’s a mindset. I treat every electrical job with the utmost respect, prioritizing safety above all else. My experience has reinforced the critical need for disciplined safety procedures – a single lapse can have devastating consequences.

Q 28. What are your strategies for staying updated on the latest advancements in electrical technology?

Staying current with advancements in electrical technology is crucial for maintaining my expertise. My strategies include:

- Professional Organizations: I’m an active member of professional organizations such as IEEE (Institute of Electrical and Electronics Engineers), which provides access to publications, conferences, and networking opportunities.

- Industry Publications and Journals: I regularly read industry publications and journals such as IEEE Spectrum and Electrical Contractor to stay informed about new technologies and best practices.

- Online Courses and Webinars: I frequently participate in online courses and webinars offered by reputable organizations to enhance my knowledge and skills in specific areas.

- Manufacturer Training: I actively seek out training opportunities offered by equipment manufacturers to gain hands-on experience with the latest products and technologies.

- Conferences and Trade Shows: Attending conferences and trade shows allows me to learn about the latest advancements and network with other professionals in the field.

Continuous learning is not just a professional imperative; it’s a personal passion. The rapid pace of technological change demands ongoing self-improvement to remain at the forefront of the field. This commitment ensures I can deliver optimal solutions and anticipate future challenges.

Key Topics to Learn for Experience with Electrical Tools and Equipment Interview

- Safety Procedures and Regulations: Understanding and adhering to OSHA and NEC safety standards, lockout/tagout procedures, and proper personal protective equipment (PPE) usage.

- Tool Operation and Maintenance: Demonstrate proficiency in operating various electrical tools (e.g., multimeters, wire strippers, crimpers, power drills) and performing routine maintenance to ensure optimal functionality. This includes understanding the limitations and potential hazards associated with each tool.

- Electrical Theory Fundamentals: A solid grasp of basic electrical principles such as Ohm’s Law, voltage, current, resistance, and power calculations. Be prepared to explain how these concepts apply to practical situations.

- Wiring and Circuit Diagrams: Ability to interpret and understand electrical schematics and wiring diagrams, including single-line diagrams and panel layouts. Practice reading and explaining different types of diagrams.

- Troubleshooting and Diagnostics: Experience with identifying and resolving electrical faults, using appropriate testing equipment to diagnose problems in circuits and appliances. Be prepared to discuss your problem-solving approach.

- Specific Equipment Knowledge: Depending on the role, you may need to demonstrate expertise with specific types of electrical equipment (e.g., motors, transformers, control systems). Research the requirements of the specific job you’re applying for.

- Code Compliance: Familiarity with relevant electrical codes and regulations (e.g., NEC) and how to ensure installations meet these standards. Highlight any experience with code inspections.

Next Steps

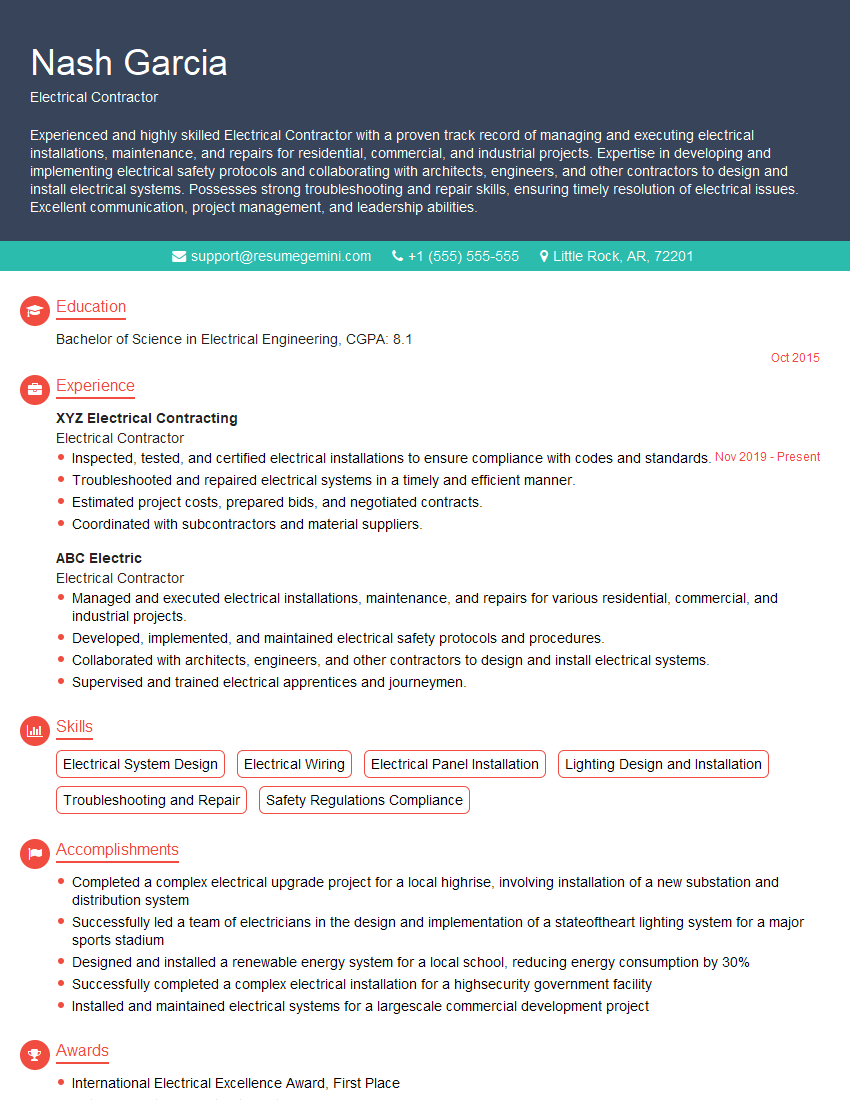

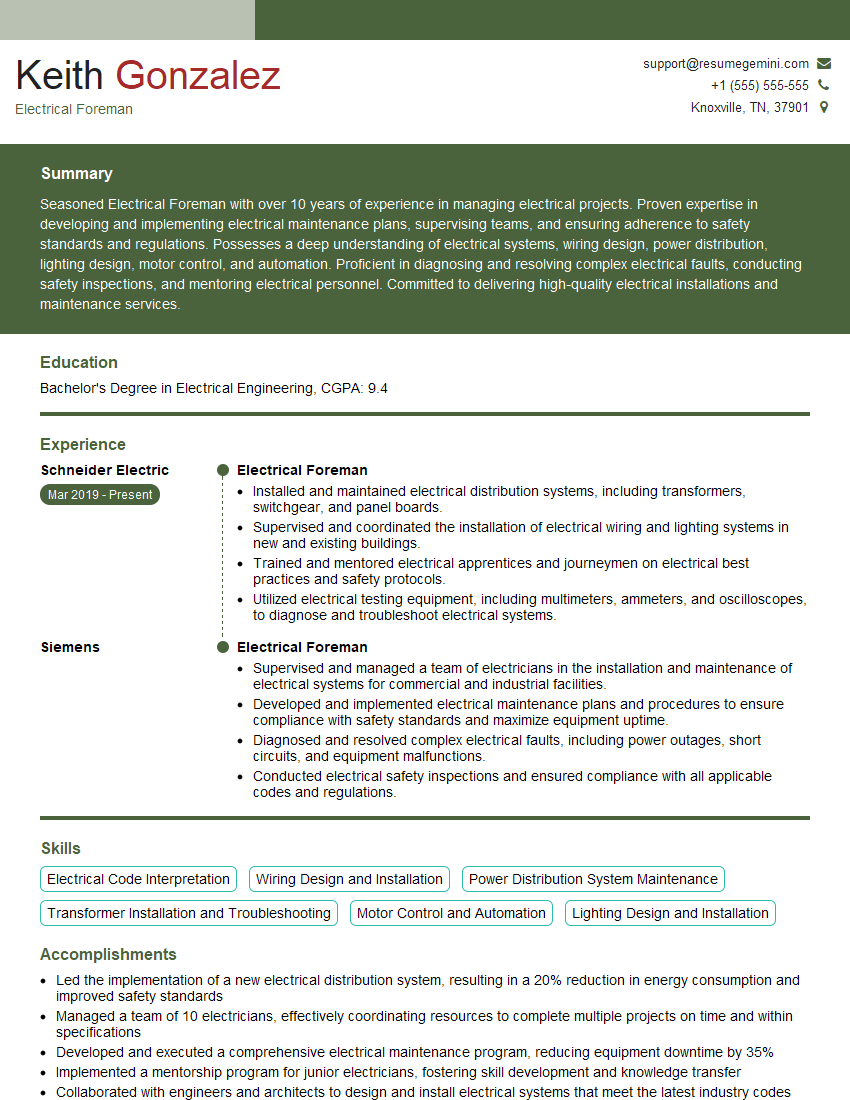

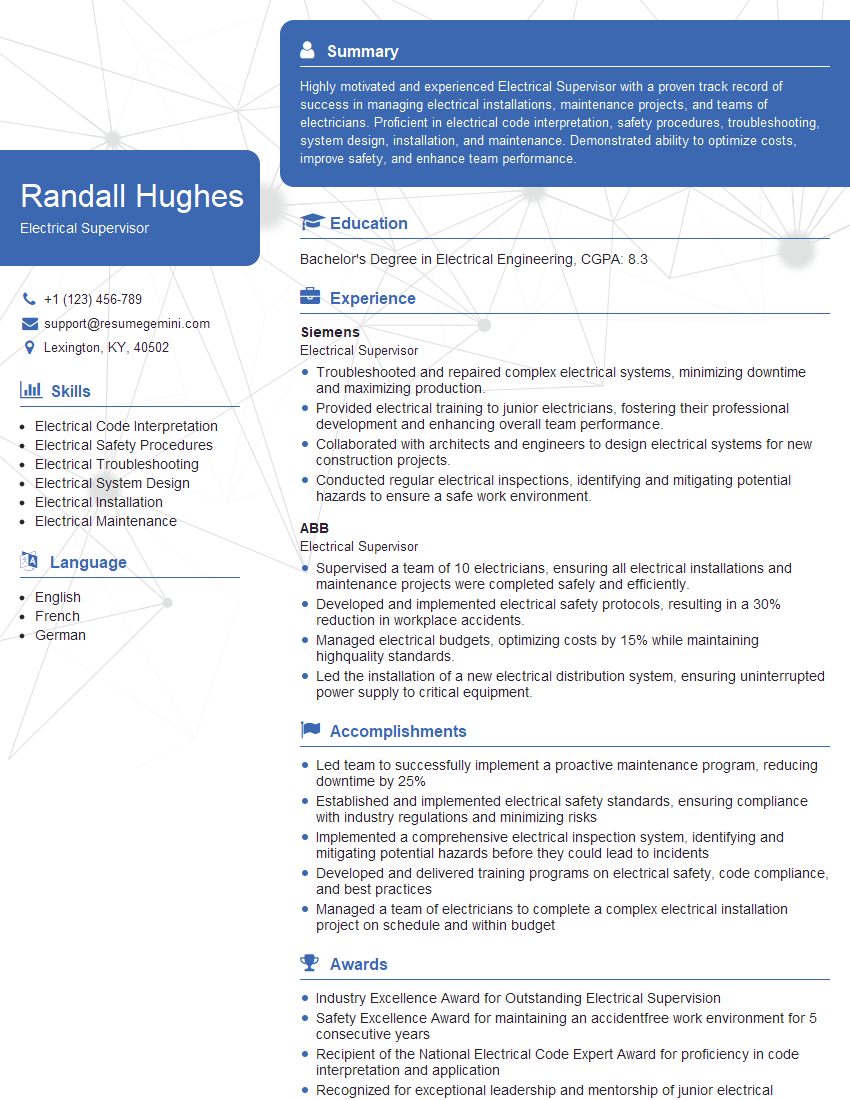

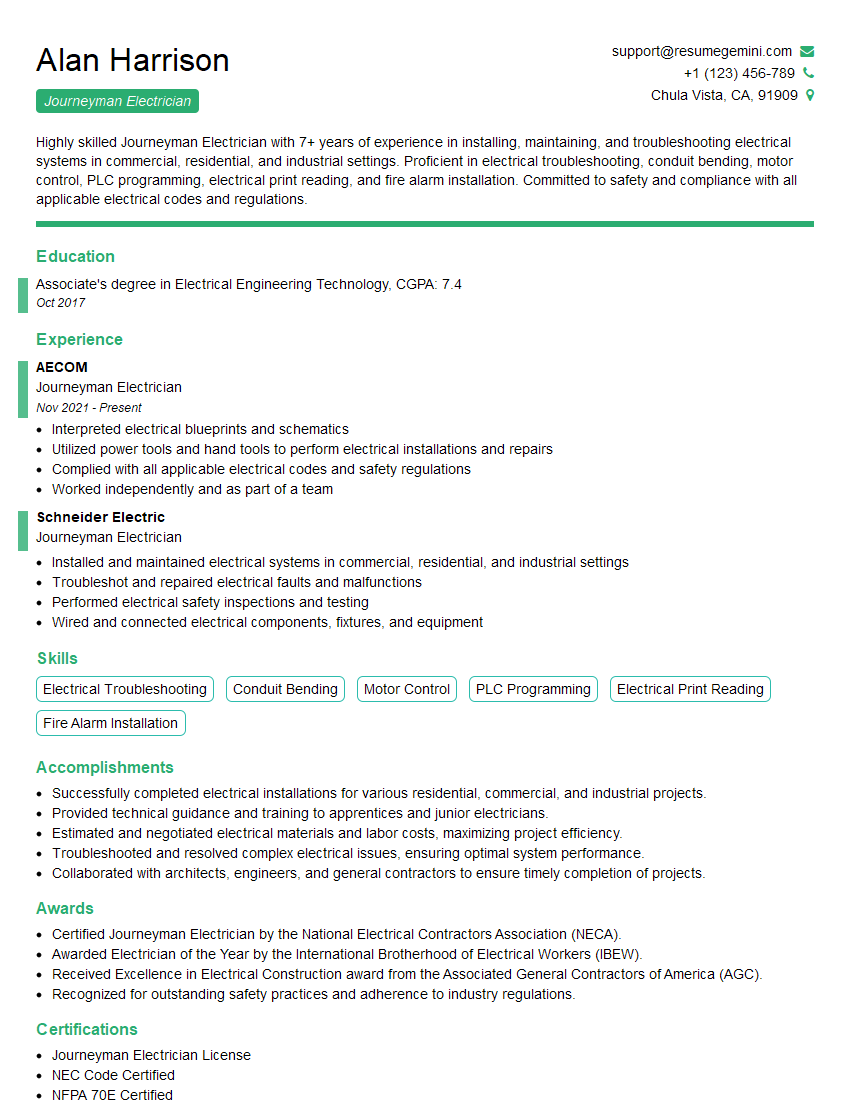

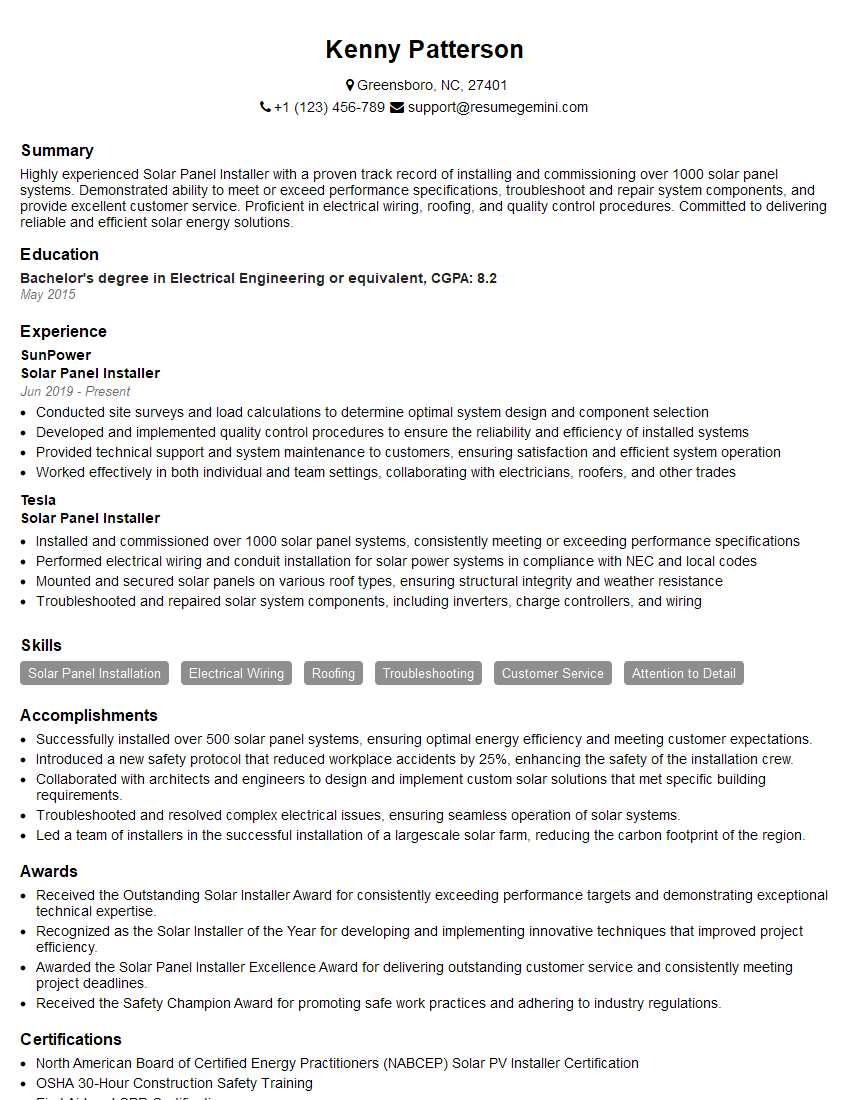

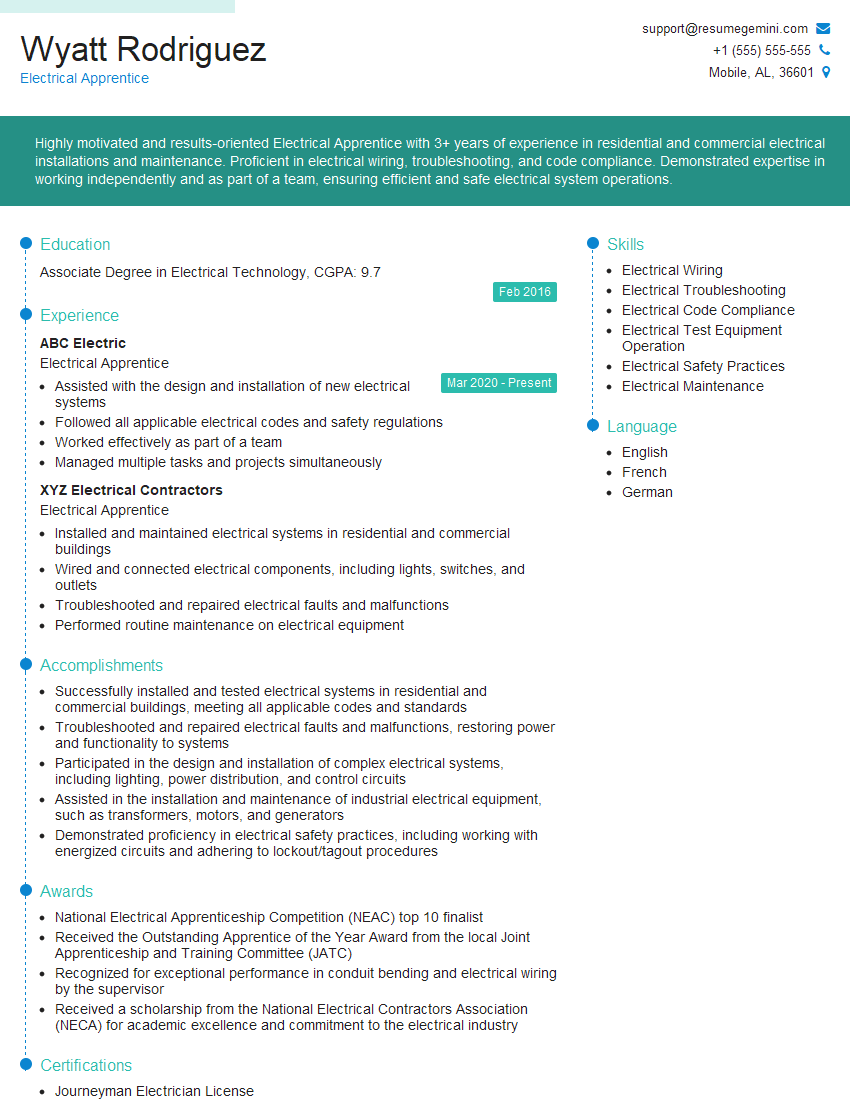

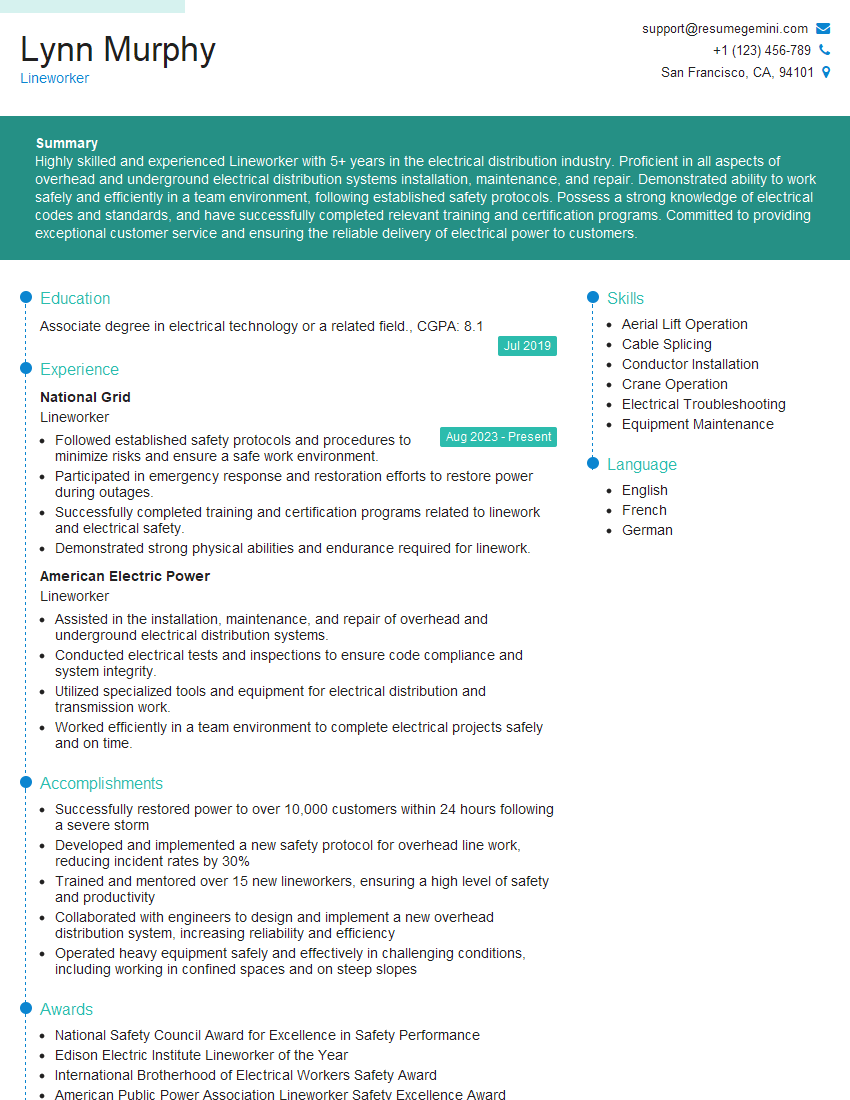

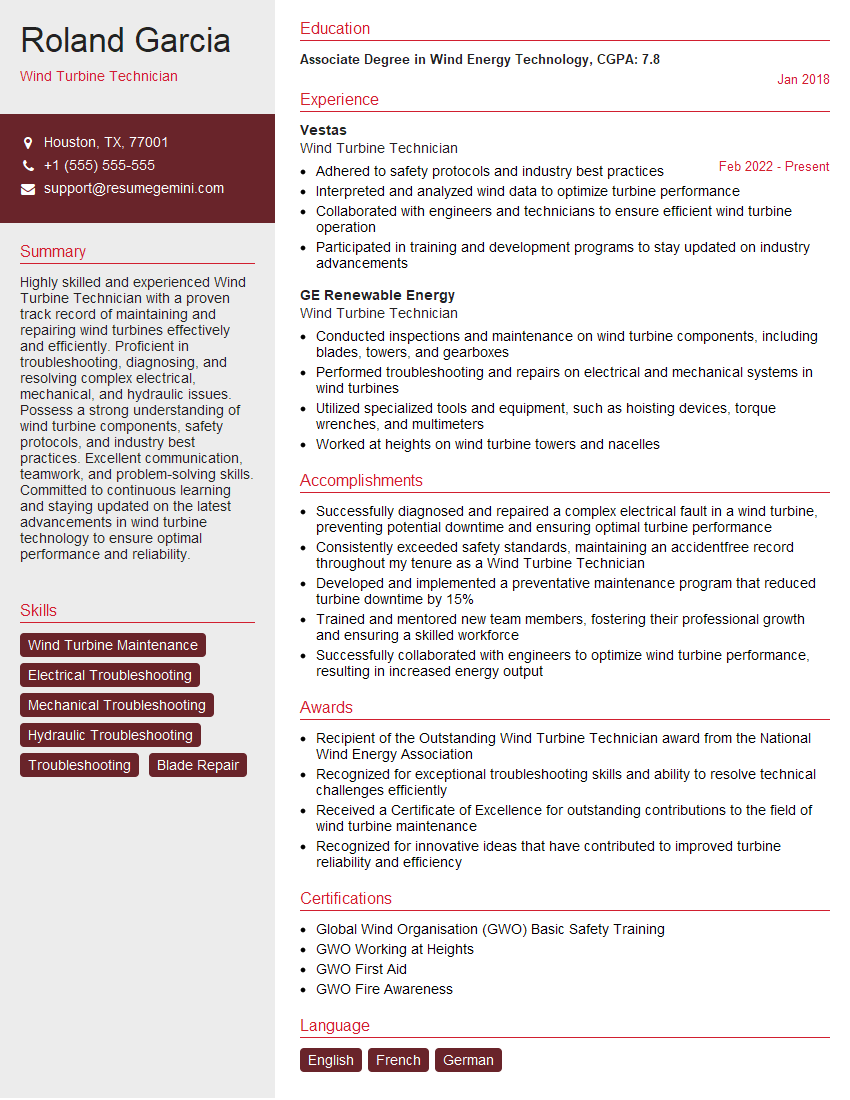

Mastering your experience with electrical tools and equipment is crucial for career advancement in this field. A strong understanding of safety, practical application, and theoretical knowledge will significantly improve your interview performance and open doors to exciting opportunities. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience. Examples of resumes specifically tailored to showcase experience with electrical tools and equipment are available on ResumeGemini, to help you craft a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good