Are you ready to stand out in your next interview? Understanding and preparing for Experience with Embroidering on Different Fabrics and Materials interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Experience with Embroidering on Different Fabrics and Materials Interview

Q 1. What types of embroidery machines are you familiar with?

My experience encompasses a wide range of embroidery machines, from single-needle domestic machines to multi-needle industrial machines. I’m proficient with both computerized and free-motion embroidery machines. Specifically, I’ve worked extensively with brands like Brother, Singer, and Tajima. Each machine has its strengths – for example, domestic machines are great for smaller projects and ease of use, while industrial machines offer speed and precision for large-scale production. Understanding the capabilities and limitations of each type is crucial for selecting the right tool for the job.

- Domestic Machines: Ideal for hobbyists and smaller projects. They are user-friendly and relatively inexpensive.

- Industrial Machines: Designed for high-volume production. They offer greater speed, precision, and multiple needle capabilities. Examples include multi-head machines for high-speed embroidery.

- Computerized Machines: These allow for intricate designs through digital control and offer a wider variety of stitch options.

Q 2. Describe your experience with different embroidery stitches.

My repertoire of embroidery stitches is extensive, ranging from basic running stitches and satin stitches to complex fill stitches, chain stitches, and free-motion embroidery. Each stitch type has its own aesthetic and functional properties. For example, a satin stitch is perfect for creating solid blocks of color, while a running stitch is ideal for outlines and delicate details. Understanding stitch properties helps choose appropriate techniques for various projects and fabric types.

- Satin Stitch: Creates a smooth, dense surface. Excellent for lettering and filling areas.

- Running Stitch: Simple and versatile. Ideal for outlining and creating textured effects.

- Chain Stitch: Creates a textured loop effect. Often used for decorative outlines or free-motion embroidery.

- Fill Stitches: Numerous variations, designed for filling shapes and adding texture. Examples include a dense pattern fill, or open designs that show some fabric between the stitches.

Q 3. How do you select the appropriate thread type for various fabrics?

Thread selection is paramount for successful embroidery. The right thread will not only look good but also help prevent fabric damage and ensure the longevity of the embroidery. Factors to consider include the fabric type (lightweight fabrics need finer threads, heavier fabrics can handle thicker ones), thread material (polyester is a popular choice due to its durability and vibrancy, while rayon offers a softer sheen), and the desired effect.

- Lightweight Fabrics (silk, chiffon): Use finer threads like 40 wt or 60 wt rayon or polyester.

- Medium-weight Fabrics (cotton, linen): 40 wt polyester or cotton thread works well.

- Heavyweight Fabrics (denim, canvas): Use heavier threads, such as 30 wt polyester or even heavier specialty embroidery threads.

Experimentation is key. I always test a small area before embroidering the whole piece. For example, I might stitch a swatch to check if the thread tension is correct and if the thread color is true on the chosen fabric.

Q 4. Explain the process of digitizing an embroidery design.

Digitizing an embroidery design is the process of converting a graphic image or artwork into a stitch file that an embroidery machine can read and execute. This involves using specialized software to trace the design’s outlines and fill areas with appropriate stitch types. Careful consideration of stitch density, underlay, and jump stitches is crucial for a successful result. In short, digitizing is an art form in itself that requires skill, practice, and specialized software.

The process typically involves:

- Scanning or Importing Artwork: Converting your design into a digital format suitable for embroidery software.

- Tracing and Outlining: Using the software to create accurate stitch paths along the outline of the design.

- Fill Creation: Defining the stitching pattern for filling the interior of the design.

- Stitch Density Adjustment: Balancing stitch density for different areas to ensure a balanced and even stitch out.

- Jump Stitch Optimization: Minimizing visible jump stitches to maintain the integrity of the embroidery.

- Testing and Refinement: Stitching out a test version to identify any necessary adjustments before final production.

Software like Wilcom, Embird, and Stitch Era are commonly used for this purpose.

Q 5. What are the common challenges you encounter when embroidering on delicate fabrics?

Embroidering on delicate fabrics presents unique challenges. The biggest concern is fabric damage due to needle punctures and thread tension. Other issues include puckering, stretching, and thread breakage.

- Puckering: Can be caused by excessive thread tension or using too heavy a thread for the fabric. Using a stabilizer, such as tear-away or water-soluble stabilizer, can help prevent this.

- Stretching: Delicate fabrics can easily stretch under the needle. Using a stabilizer, selecting the correct needle and thread type and slowing down the embroidery speed can help minimize this.

- Thread Breakage: Can occur from using low-quality thread or having the wrong tension settings.

To mitigate these issues, I always use a stabilizer appropriate for the fabric. For example, water-soluble stabilizer works well for lace and other delicate materials as it disappears easily after washing. I also reduce the stitch density on delicate fabrics and use a smaller needle size and finer threads.

Q 6. How do you troubleshoot common embroidery machine problems?

Troubleshooting embroidery machine problems requires a systematic approach. I start by identifying the issue – is it a thread-related problem, a mechanical issue, or a software issue?

Common problems and solutions include:

- Thread Breakage: Check thread tension, replace the thread, check for knots or damage in the thread path.

- Needle Breakage: Use the correct needle for the fabric type, check needle alignment, ensure the needle is inserted correctly.

- Skipping Stitches: Check the thread tension, clean the bobbin area, examine the needle for any damage, and ensure the bobbin is correctly wound.

- Inconsistent Stitching: Check the tension settings and adjust if needed. Check the bobbin casing for any lint or debris. Consider re-threading your machine.

If the problem persists, consulting the machine’s manual or contacting a service technician is always advisable.

Q 7. How do you ensure accurate color matching in embroidery?

Accurate color matching is critical for achieving the desired aesthetic in embroidery. It’s a multi-step process involving selecting the right threads, testing color on the fabric, and understanding how lighting and fabric influence color perception. I use a combination of techniques to ensure color accuracy.

- Thread Selection: Use color charts provided by thread manufacturers or refer to Pantone or other color matching systems.

- Fabric Testing: Always test the thread color on a scrap piece of the same fabric under the same lighting conditions as the final product will be displayed.

- Lighting Considerations: Different types of light (natural vs. artificial) can affect how colors appear. Maintaining consistent lighting throughout the process is crucial for accurate matching.

- Digital Color Matching (if applicable): When digitizing, color profiles and color matching tools in the software can be helpful, but should always be tested physically.

It’s important to remember that thread colors can sometimes appear slightly different on different fabric types or under different lighting conditions. Always allow for slight variations, and test, test, test!

Q 8. What is your experience with different embroidery hooping techniques?

Hooping is crucial for even fabric tension during embroidery. My experience encompasses various techniques, tailored to the fabric type and design complexity. For delicate fabrics like silk or lace, I prefer the slow and gentle method, using a hoop slightly larger than the design area to avoid stretching. This prevents damage and ensures a smooth, even surface. For heavier fabrics like denim or canvas, a more forceful approach is acceptable, ensuring the fabric is taut and securely fastened within the hoop. I also utilize different hoop types – from the standard wooden hoops to magnetic hoops for quick changes and hoops with adjustable tension for maximum control. For very large projects, I’ll section the work, hooping only the area currently being embroidered, to maintain manageable tension.

Example: When embroidering a delicate floral design on silk, I’ll use a larger, gentler hooping technique, carefully easing the fabric into the hoop to avoid creases. However, for a large geometric design on canvas, I might opt for a tighter, more aggressive hooping style to prevent shifting and maintain crisp lines.

Q 9. Explain your process for preparing fabrics before embroidery.

Prepping the fabric is a critical step for achieving high-quality embroidery. My process starts with pre-washing the fabric to remove any sizing or finishes that may interfere with the stitching or cause the fabric to shrink after completion. Then I press the fabric, ensuring it’s smooth and free of wrinkles, as these will transfer to the final embroidery. I pay close attention to the fabric type; for instance, linen might require a slightly damp pressing to remove stubborn creases. Next, if the fabric is prone to fraying, I’ll finish the edges either by using pinking shears or by applying a small seam allowance. Finally, I carefully position the fabric in the hoop, making sure it’s taut but not stretched, avoiding any distortion.

Example: For a delicate linen tablecloth, I’ll pre-wash it gently, press it with a steam iron while it’s still slightly damp, and then carefully finish the edges before hooping. This prevents fraying and preserves the fabric’s integrity during the embroidery process.

Q 10. How do you handle fabric wrinkles or puckering during embroidery?

Wrinkles and puckering are common challenges in embroidery. To minimize these, I start with careful hooping, ensuring even tension. If puckering occurs during stitching, I’ll carefully loosen the hoop in that specific area, re-adjust the fabric, and then gently retighten. For stubborn wrinkles, I use a needle or small tool to gently coax the fabric flat while the machine is stopped. Using the appropriate stabilizer is also crucial – a cutaway stabilizer can help prevent puckering in looser fabrics. In cases of severe puckering, I might need to unhoop the fabric, completely re-press it, and re-hoop before continuing.

Example: While embroidering on a loosely woven cotton, I noticed puckering around a curved section of the design. I stopped the machine, loosened the hoop slightly in that area, smoothed the fabric, and retightened before resuming, which solved the issue.

Q 11. What are your experience with different embroidery stabilizers and their applications?

Stabilizers are essential for achieving professional embroidery results. My experience includes using various types, each with its unique application. Tear-away stabilizers are excellent for most fabrics, easily removed after stitching. Cut-away stabilizers offer greater support for intricate designs and delicate fabrics, requiring careful trimming after embroidery. Wash-away stabilizers are ideal for projects where the stabilizer needs to be completely removed, often used with water-soluble threads. I also use adhesive stabilizers for fabrics that are difficult to hoop, such as knits or velvet. The choice of stabilizer depends heavily on the fabric type, design complexity, and desired finish.

Example: For a delicate lace design, I’d use a cut-away stabilizer to provide extra support during stitching, then carefully trim away the excess. For a t-shirt, I’d choose a tear-away or wash-away stabilizer, depending on whether I want to remove it completely or leave some minor backing.

Q 12. How do you calculate the appropriate stitch density for a given fabric?

Stitch density is crucial for achieving the desired outcome. It’s not a fixed number, but rather determined by the fabric type and the design. For example, a tightly woven fabric like linen can handle higher stitch density, resulting in a crisp, detailed embroidery. Loosely woven fabrics, such as cotton lawn, need a lower stitch density to avoid distortion or damage. I usually start with the default stitch density in my design software and then experiment on scrap fabric to find the optimal setting. I also consider the thread weight and type; heavier threads often need a slightly lower density to prevent breakage. Observing the fabric during stitching helps identify adjustments. Too high a density leads to puckering, while too low a density may result in an uneven or loose finish.

Example: For a detailed design on linen, I might start with a density of 1.5, while for a simpler design on loosely woven cotton, I might use a density of 1.0 or even lower. I always test on a fabric scrap before starting the final piece.

Q 13. Describe your experience with various embroidery design software.

My experience encompasses several embroidery design software packages, including Embrilliance, Wilcom, and Bernina DesignerPlus. Each software has its own strengths and weaknesses; some are better for digitizing, while others excel in editing existing designs. I’m proficient in importing, editing, and manipulating various design formats (e.g., .dst, .exp, .jef). I use software features such as color sorting, stitch density adjustments, and underlay creation. The selection of the right software depends heavily on the project complexity and personal preferences. I also use simpler programs for basic design creation and editing. The ability to manipulate and adapt designs within software is crucial for achieving desired results.

Example: For a complex logo design, I might use a program like Embrilliance to create a clean and detailed design, carefully adjusting the stitch density to minimize distortion. For a simple text design, however, a simpler program could suffice.

Q 14. How do you maintain and clean your embroidery equipment?

Maintaining embroidery equipment is crucial for its longevity and performance. After each use, I clean the machine thoroughly, removing any lint or thread clippings from the bobbin case, the needle plate, and the hook area. I use a specialized brush and compressed air to reach hard-to-access areas. The needles are changed regularly, and I keep a variety of needles on hand to suit different fabrics and threads. I lubricate the moving parts of the machine according to the manufacturer’s instructions. Regular maintenance, including cleaning and lubrication, prevents mechanical issues and extends the machine’s lifespan. I also regularly check for any loose screws or other issues. I store the machine in a clean, dry place.

Example: After a particularly intricate embroidery project, I take the time to meticulously clean the entire machine, paying close attention to the bobbin case and hook area. I replace the needle and check the machine’s tension before my next project.

Q 15. How do you determine the optimal needle size for different fabrics?

Choosing the right needle size is crucial for successful embroidery. A needle that’s too small will break, while one that’s too large will create holes that are too big and damage the fabric. The selection depends primarily on the fabric’s weight and type.

- Lightweight fabrics (silk, chiffon): Require very fine needles, like size 70/10 or smaller. Think of it like sewing with delicate lace – you need a tiny needle to avoid tearing.

- Medium-weight fabrics (cotton, linen): Usually work well with needles in the size 75/11 to 80/12 range. This is a versatile size for a wide array of fabrics.

- Heavyweight fabrics (denim, canvas): Demand larger needles, such as size 90/14 or even larger. These fabrics are strong, and you need a sturdy needle to penetrate them.

Additionally, the type of thread also influences needle choice. Heavier threads require larger needles. Always consult your thread and fabric manufacturer’s recommendations for best results. For example, if embroidering a delicate silk scarf, I’d select a size 70/10 needle and a lightweight rayon thread. Conversely, embroidering a heavy denim jacket might call for a size 90/14 needle and a polyester thread.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What safety precautions do you follow when operating embroidery machines?

Safety is paramount when operating embroidery machines. My routine always includes:

- Proper machine setup: Ensuring the machine is stable on a flat surface, the bobbin is correctly wound and inserted, and the needle is securely tightened.

- Hand protection: Never reach into the needle area while the machine is running. Always use a needle threader to prevent needle pricks.

- Eye protection: Embroidery machines can sometimes throw off small debris. Safety glasses prevent potential eye injuries.

- Clothing considerations: Loose clothing or jewelry should be avoided to prevent entanglement in moving parts.

- Regular maintenance: Keeping the machine clean and lubricated helps prevent malfunctions and potential hazards.

- Emergency stops: Knowing where the emergency stop button is located and how to use it is crucial.

I also always unplug the machine when cleaning, changing needles, or making major adjustments. It’s better to be safe than sorry!

Q 17. Describe your experience working with different thread counts.

Thread count significantly impacts the final embroidery’s look and feel. Higher thread counts result in denser, more detailed embroidery, but can be more challenging to work with and increase the risk of needle breakage. Lower thread counts create a more open, airy design, which can be a stylistic choice, especially for certain fabrics.

I’ve worked with thread counts ranging from 40 to 120. For intricate designs on fine fabrics like silk, I prefer a higher thread count (around 100-120) for crisp details. On heavier fabrics like denim, a medium thread count (60-80) often provides sufficient strength and coverage. Experimentation is key to finding the optimal balance between detail and durability based on your project’s specific requirements. If you’re working on a larger piece with complex designs, a slightly lower thread count might save time and thread but still give a good result.

Q 18. How do you manage large embroidery projects efficiently?

Managing large embroidery projects efficiently requires planning and organization. My approach involves:

- Detailed design breakdown: Dividing the design into smaller, manageable sections. This allows for easier hooping and minimizes potential errors.

- Strategic hooping: Careful planning of the hooping placement to reduce the number of hoop changes. Overlapping areas help maintain consistency.

- Efficient stitching sequence: Optimizing the stitch order in the design software to minimize movement and wasted time.

- Regular breaks: Avoiding fatigue by taking regular breaks to maintain focus and accuracy. Fatigue can lead to errors.

- Use of templates and guides: Utilizing templates to ensure consistent placement and dimensions of repeating elements.

For example, when embroidering a large tapestry, I’d divide the design into quarters, embroider each section individually, and then carefully stitch them together, ensuring consistent tension and alignment.

Q 19. How do you ensure consistent quality in mass production embroidery?

Maintaining consistent quality in mass production requires a multi-faceted approach. This begins with:

- Calibration and maintenance: Regular calibration of the embroidery machine is essential to ensure consistent stitch length and tension. Regular cleaning and maintenance minimize machine errors.

- Standardized materials: Using the same type and batch of thread, needles, and stabilizers across all production runs ensures uniformity.

- Quality control checks: Implementing regular quality control checks throughout the production process. This allows for the early identification and correction of inconsistencies.

- Trained personnel: Having well-trained operators who understand the machine’s capabilities and limitations and are attentive to detail.

- Process documentation: Having detailed documentation of every step of the embroidery process ensures consistency across production runs.

For instance, in a large-scale order for embroidered logos on shirts, a color calibration test is essential to guarantee all shirts receive the exact same shade. Any deviations are immediately addressed through adjustments in the design or production parameters.

Q 20. What are your experiences with different embroidery thread types (e.g., rayon, polyester)?

I have extensive experience with various embroidery thread types. Each possesses unique characteristics:

- Rayon: Offers a beautiful sheen and lustrous finish, ideal for delicate designs and luxurious fabrics. However, it can be less durable than polyester and prone to breakage if not handled carefully.

- Polyester: More durable and colorfast than rayon. It’s a versatile option for various projects and fabrics, offering excellent resistance to fading and wear. A great choice for items that will be frequently washed.

- Cotton: A natural fiber that’s soft and comfortable, ideal for items intended for direct skin contact. However, it’s less shiny than rayon or polyester and can be slightly more prone to fraying.

- Metallic threads: Add a touch of glamour and sparkle but require a specific needle type and should be handled with care to prevent breakage. They are best used for embellishments rather than large areas.

The choice depends heavily on the project’s requirements. A delicate bridal gown might call for rayon, while a durable work shirt would benefit from polyester. For a children’s quilt, I’d opt for soft, comfortable cotton threads.

Q 21. Explain your knowledge of various fabric types (e.g., cotton, silk, linen, polyester) and their suitability for embroidery.

Fabric choice directly impacts embroidery results. Different fabrics have varying textures, weights, and compositions, requiring different techniques and needle sizes:

- Cotton: A widely used fabric for embroidery, offering good stability and a wide range of weights (from lightweight voile to heavy canvas). It’s easy to work with and holds stitches well.

- Silk: A delicate fabric requiring fine needles and a gentle touch. Its smooth texture allows for intricate embroidery but demands careful handling to prevent damage.

- Linen: Has a slightly more textured surface compared to cotton. It can be challenging to work with due to its uneven weave but results in beautiful, textured embroidery.

- Polyester: A synthetic fiber known for durability and wrinkle resistance. It can be a bit slippery to embroider on, necessitating the use of a stabilizer to prevent puckering.

For example, embroidering a delicate floral pattern would be ideal on silk or a fine cotton, while a bold design on a durable tote bag might be best suited for a heavier canvas cotton or polyester. Understanding the properties of each fabric is essential for success.

Q 22. Describe your experience with both hand and machine embroidery techniques.

My embroidery journey encompasses both hand and machine techniques, each offering unique creative avenues. Hand embroidery, with its meticulous detail and personalized touch, allows for intricate designs and a deep connection with the craft. I’m proficient in various stitches, from basic running stitch to complex ones like French knots and satin stitch, adapting them to different fabric types and project requirements. For example, I recently hand-embroidered a delicate floral pattern onto a linen tablecloth, requiring precise control and patience. Machine embroidery, on the other hand, offers efficiency and precision for larger projects or repetitive motifs. I’m skilled in operating various embroidery machines, utilizing different hoops and stabilizers to achieve professional results. I’ve used this technique extensively for personalizing clothing items, like monogramming towels or creating custom patches.

- Hand Embroidery Expertise: Cross-stitch, Satin stitch, French knots, Chain stitch, etc.

- Machine Embroidery Expertise: Programmed designs, free-motion embroidery, digitizing, various machine types (e.g., single-needle, multi-needle).

Q 23. What is your experience with creating and adapting embroidery patterns?

Creating and adapting embroidery patterns is a core part of my process. I’m adept at both designing original patterns from scratch and modifying existing ones to suit specific needs and client preferences. My process often begins with sketching ideas on paper, followed by digitizing the design for machine embroidery (using software like Wilcom or Embird) or translating it directly onto fabric for hand embroidery. I consider the fabric type, thread count, and overall design aesthetic during this phase. For instance, a simple geometric pattern might work well for a heavy cotton canvas, while a delicate floral design would be better suited for a finer fabric like silk. Adapting patterns often involves resizing, color changes, or adding/removing elements. Recently, a client requested a smaller version of an existing bird design to fit a child’s shirt. I skillfully adjusted the pattern size and simplified some details to maintain clarity without compromising its beauty.

Q 24. How do you handle customer requests or modifications to embroidery designs?

Handling customer requests and modifications is crucial for client satisfaction. I start by actively listening to their needs and visualizing their vision. Open communication is key—I ask clarifying questions to fully understand their preferences regarding design, placement, size, and color. I then present options based on their requirements, offering suggestions or alternative designs if necessary. For example, if a client asks for a change that might compromise the design’s integrity, I explain the potential issues and offer viable alternatives. Once we agree on the final design, I create a sample or mock-up before proceeding with the full embroidery to ensure they are entirely satisfied with the outcome. This iterative approach helps avoid errors and enhances the customer experience.

Q 25. How do you ensure the longevity and durability of your embroidery work?

Ensuring longevity and durability is paramount. I start by selecting high-quality threads known for their colorfastness and strength—brands like Madeira or DMC are favorites. Pre-washing the fabric removes any sizing that could hinder stitching and improves thread adhesion. I use appropriate stabilizers during machine embroidery to prevent fabric puckering and distortion. For hand embroidery, I choose a stabilizer suitable for the fabric type and design. After embroidery, I carefully trim excess threads and secure them well to prevent unraveling. Depending on the fabric, a gentle hand wash or dry clean might be recommended to maintain the vibrant colors and the integrity of the design. Finally, proper storage away from direct sunlight or moisture is crucial to preserve the embroidery’s life.

Q 26. Describe your experience with quality control procedures in embroidery production.

Quality control is integral to my process. For machine embroidery, I meticulously inspect the design digitization for potential errors like jump stitches or thread breaks before starting production. During production, I periodically check for consistency in stitching density, thread tension, and color accuracy. For hand embroidery, I continuously monitor stitch quality, ensuring evenness and accuracy. After completion, every piece undergoes a thorough final inspection, examining the stitching, colorfastness, and overall appearance for any imperfections. This thorough inspection ensures that every piece I produce meets my high standards of excellence, guaranteeing client satisfaction and brand reputation.

Q 27. What is your understanding of color separation in embroidery?

Color separation in embroidery is the process of dividing a design into its individual colors so each color can be embroidered separately, using a different thread spool. It’s crucial for both hand and machine embroidery. For machine embroidery, the digitizing software automatically handles this separation; however, I review and may adjust the separations to optimize thread usage and stitching efficiency. In hand embroidery, I need to carefully plan the thread colors and the sequence of stitching to minimize color changes and ensure clean transitions. Proper color separation prevents color muddling, achieves sharper images, and enables a professional look. For example, a detailed portrait might need a dozen color separations, while a simpler design can use just a few. Careful planning guarantees the final design is vibrant and true to the original image or design concept.

Q 28. How do you deal with thread breakage during embroidery?

Thread breakage is an occasional challenge in embroidery, but I have developed strategies to address it. First, I always use high-quality threads, which are less prone to breakage. Second, I ensure my machines are properly maintained and threaded, and needles are sharp and appropriate for the thread and fabric. During hand embroidery, using the correct needle size for the thread and fabric type is crucial to minimize breakage. If a thread does break, I carefully tie a knot (or use a thread splicing tool) to reconnect the ends ensuring minimal disruption to the design and maintaining stitch consistency. Preventing thread breakage involves preventative maintenance and a keen awareness of the whole process. It’s a matter of experience and patience – understanding why the thread broke (tension, knots, etc.) helps prevent future occurrences.

Key Topics to Learn for Experience with Embroidering on Different Fabrics and Materials Interview

- Fabric Selection & Suitability: Understanding the properties of various fabrics (cotton, linen, silk, synthetics) and their suitability for different embroidery techniques and thread types. This includes knowledge of fabric weight, weave, and drape.

- Thread Selection & Tension: Choosing appropriate embroidery threads (cotton, rayon, metallic) based on fabric type and desired effect. Mastering thread tension control to achieve professional results and avoid fabric damage.

- Embroidery Techniques: Proficiency in various embroidery techniques such as free-motion, appliqué, satin stitch, and shadow work, and understanding their application to different fabrics.

- Stabilizer Selection and Use: Knowing how to choose and apply different types of stabilizers (tear-away, cut-away, wash-away) to prevent puckering and achieve clean stitches on various fabric types.

- Machine vs. Hand Embroidery: Understanding the differences in techniques, thread types, and fabric suitability for machine and hand embroidery. Experience with both is highly valuable.

- Troubleshooting Common Issues: Identifying and resolving problems such as skipped stitches, broken threads, puckering, and uneven stitching on diverse fabrics.

- Design Adaptation: Adapting embroidery designs to suit different fabric types and weights. Understanding design limitations based on fabric properties.

- Finishing Techniques: Knowledge of various finishing techniques appropriate for different fabrics, such as trimming excess stabilizer, pressing, and preventing color bleeding.

Next Steps

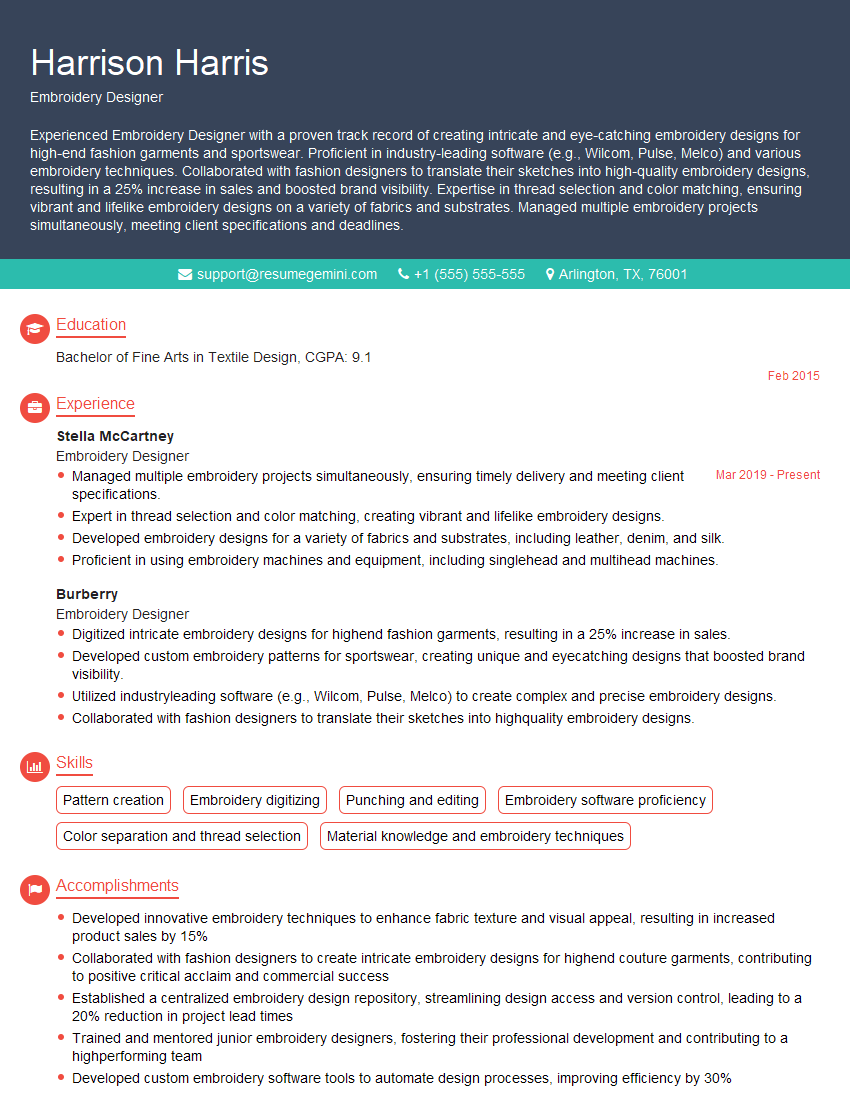

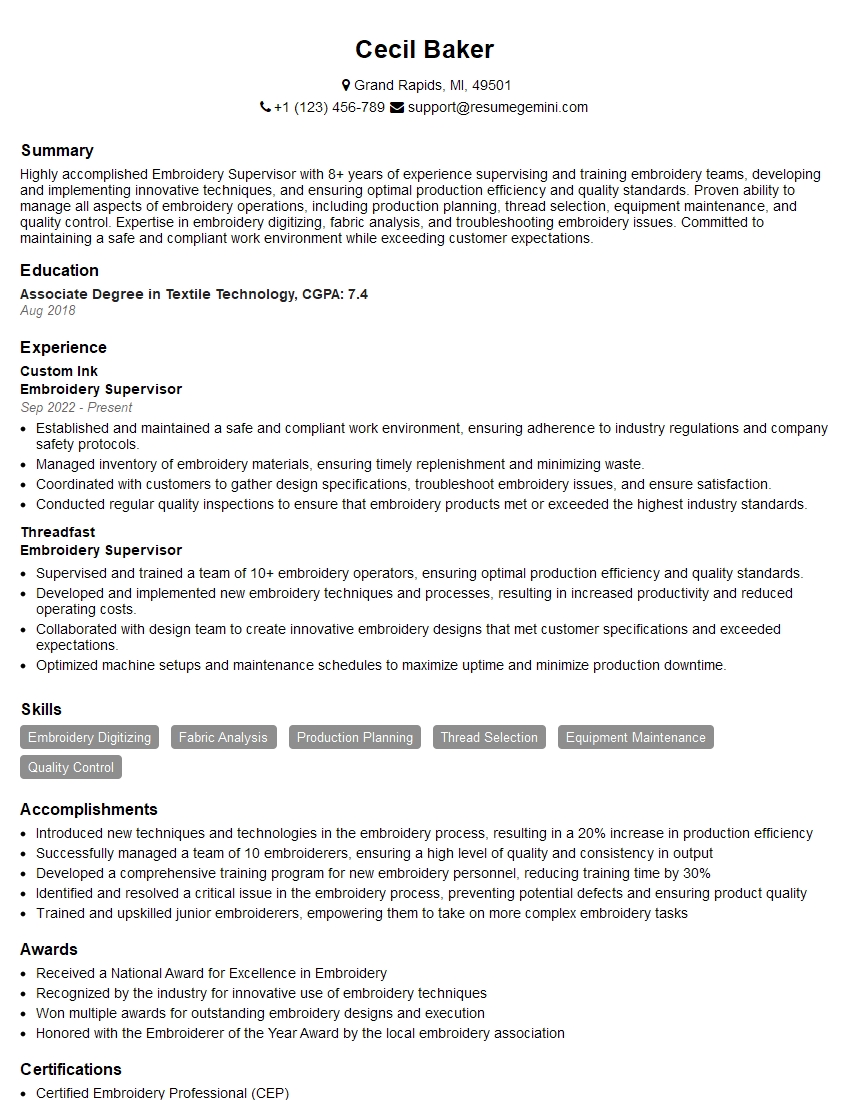

Mastering embroidery on various fabrics and materials significantly enhances your skillset and opens doors to diverse career opportunities in the textile, fashion, and craft industries. A strong resume showcasing your expertise is crucial for securing your ideal role. Creating an ATS-friendly resume is key to maximizing your job prospects. To build a compelling and effective resume, we recommend using ResumeGemini, a trusted resource designed to help you create professional resumes tailored to your specific skills and experience. Examples of resumes tailored to showcasing experience with embroidering on different fabrics and materials are available to further assist your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good