Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Experience with Explosive Materials interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Experience with Explosive Materials Interview

Q 1. Describe the different types of explosives and their applications.

Explosives are broadly classified into several categories based on their properties and applications. Understanding these differences is crucial for safe and effective use.

- High Explosives: These detonate rapidly, producing a supersonic shockwave. Examples include TNT (trinitrotoluene), RDX (cyclotrimethylenetrinitramine), and PETN (pentaerythritol tetranitrate). They are commonly used in military applications, demolition, and mining due to their powerful brisance (shattering effect).

- Low Explosives: These burn rapidly, producing a subsonic deflagration (explosion). Black powder and smokeless powder are prime examples. These are used in propellants for firearms and fireworks, and some specialized demolition applications where a pushing or heaving effect is desired.

- Primary Explosives: These are extremely sensitive to shock, friction, or heat and are used to initiate the detonation of other, less sensitive explosives. Lead azide and mercury fulminate are common examples. They are inherently dangerous and require careful handling.

- Secondary Explosives: These are relatively insensitive to shock and require a primary explosive to initiate detonation. TNT, RDX, and PETN fall into this category. Their insensitivity makes them safer to handle and transport than primary explosives.

The choice of explosive depends heavily on the specific application. For instance, a controlled demolition of a building might use a combination of high explosives strategically placed to achieve a precise collapse, while mining operations could utilize a different explosive formulation optimized for rock fragmentation based on the rock type.

Q 2. Explain the process of calculating the required charge for a demolition project.

Calculating the required charge for a demolition project is a complex process that involves several factors. It’s not a simple formula, but rather a combination of engineering principles and experience.

The process typically begins with a thorough site assessment, including geological surveys to determine the rock type and its strength, the desired fragmentation size, and the geometry of the structure. Experienced blasters use various methods and software, often employing empirical equations that relate the explosive charge weight to factors such as the borehole diameter, spacing, burden (distance from the hole to the free face), and stemming (material placed in the borehole above the explosive to confine it).

Several factors influencing charge calculations include:

- Rock strength: Harder rock requires more explosive.

- Rock mass characteristics: Fractures and discontinuities influence the fragmentation.

- Desired fragmentation size: Finer fragmentation requires a higher charge density.

- Borehole geometry: Diameter, depth, and spacing significantly influence blast effectiveness.

- Type of explosive: Different explosives have different energy densities.

Experienced blasters will often use specialized software or established formulas based on their experience and the specific conditions of the site. Often, multiple calculations and simulations are performed to refine the charge design.

Q 3. What safety precautions must be taken when handling explosives?

Handling explosives demands the utmost caution and adherence to strict safety protocols. A single mistake can have catastrophic consequences. Key safety measures include:

- Proper Training and Certification: Only individuals with adequate training and certification should handle explosives.

- Personal Protective Equipment (PPE): This includes safety glasses, gloves, hearing protection, and appropriate clothing to minimize the risk of injury from flying debris and noise.

- Safe Storage: Explosives should be stored in secure, climate-controlled magazines designed to prevent unauthorized access and protect them from environmental factors.

- Careful Handling: Avoid dropping, striking, or subjecting explosives to heat or friction. Use specialized tools designed for explosive handling.

- Emergency Preparedness: Having a well-defined emergency plan and the necessary equipment to handle any incident is critical.

- Environmental Considerations: Minimize environmental impact by following regulations regarding air and ground pollution.

- Strict adherence to regulations: All relevant local, state, and federal laws concerning explosive materials must be strictly followed.

Remember, complacency is the enemy of safety when working with explosives. Every action should be deliberate and carefully considered.

Q 4. What are the legal requirements for storing and transporting explosives?

Legal requirements for storing and transporting explosives are stringent and vary by jurisdiction but generally involve:

- Licensing and Permits: Businesses and individuals handling explosives must obtain the necessary licenses and permits.

- Storage Facilities: Storage must meet strict safety standards, including construction, ventilation, and security measures to prevent theft or unauthorized access. Magazines are often required, depending on the quantity and type of explosives.

- Transportation Regulations: Explosives must be transported in accordance with Department of Transportation (DOT) regulations, including proper packaging, labeling, and vehicle requirements. Special permits and escorts might be necessary for large quantities.

- Record Keeping: Detailed records of the purchase, storage, use, and disposal of explosives must be maintained.

- Regular Inspections: Storage facilities and transportation vehicles are frequently subject to inspections to ensure compliance.

Non-compliance can lead to severe penalties, including hefty fines and imprisonment. It is essential to familiarize oneself with all applicable laws and regulations before handling or transporting explosives.

Q 5. How do you determine the blast radius of an explosive charge?

Determining the blast radius of an explosive charge isn’t a simple calculation; it’s an estimate based on several factors.

There is no single formula for calculating blast radius accurately, as it’s highly dependent on factors like the type and amount of explosive, the confinement of the blast, the surrounding environment (geology, obstacles), and the definition of ‘blast radius’ (e.g., maximum ground displacement, lethal radius, damage radius).

Empirical equations and blast simulation software are commonly used to estimate blast effects. These tools often incorporate data from previous blasts and other relevant information. The accuracy of these predictions depends heavily on the input data and the model used. It is important to remember that these are estimations and actual results may vary.

Safety factors are always built into calculations to ensure sufficient standoff distance to protect people and structures. In practice, the blast radius is often determined through a combination of calculation, simulation, and experience.

Q 6. Explain the concept of fragmentation and its relevance in blasting.

Fragmentation refers to the breaking up of a material into smaller pieces due to the energy released by an explosion. In blasting, effective fragmentation is crucial for achieving the desired outcome, whether it’s breaking rock in mining or demolishing a structure.

The size and distribution of fragments are affected by various factors, including the type and amount of explosive used, the confinement of the blast, the rock properties (strength, hardness, fractures), and the borehole pattern. A poorly designed blast can lead to large, oversized fragments, making subsequent handling or processing difficult and potentially dangerous.

Optimizing fragmentation involves careful selection of the explosive charge, borehole design, and initiation sequence to create a network of cracks and fractures throughout the material. This is often achieved through a combination of techniques, including the use of different explosive types, stemming and initiation systems to control the direction and intensity of the blast.

Fragmentation analysis is often conducted post-blast to evaluate the effectiveness of the blasting operation and to inform future operations.

Q 7. What are the different types of blasting initiation systems?

Blasting initiation systems are crucial for controlling the detonation sequence of explosives in a blast. The choice of system depends on factors such as the scale of the operation, safety considerations, and the desired blast pattern.

- Non-electric systems: These systems use shock tubes or detonating cords to transmit the detonation impulse to the individual explosives. They are preferred in environments with a risk of electrical hazards.

- Electric systems: These use electrical detonators which are initiated by a low voltage electrical current. They offer greater flexibility in timing and sequencing blasts, particularly for large-scale projects.

- Electronic detonators: These advanced systems offer precise timing and sequencing control, allowing for complex blasting patterns and increased safety. They often incorporate data logging capabilities for post-blast analysis.

Regardless of the system chosen, proper testing and verification of the initiation system before the blast is essential to ensure reliable detonation and to prevent misfires or premature detonations.

Q 8. Describe the various methods used for seismic monitoring during blasting operations.

Seismic monitoring during blasting operations is crucial for assessing the effectiveness of the blast and mitigating potential environmental impacts. We employ various methods to accurately measure ground vibrations. This data is then used to optimize blasting parameters and ensure compliance with regulations.

Geophones: These are sensors placed at various distances from the blast site. They detect ground vibrations and transmit the data to a recording device. Think of them as highly sensitive microphones for the ground.

Accelerometers: These measure the acceleration of ground motion, providing more precise data on the intensity and frequency of vibrations. They are particularly useful for measuring high-frequency vibrations.

Seismic arrays: These are networks of geophones or accelerometers strategically positioned to capture a three-dimensional picture of the seismic waves generated by the blast. This is similar to how a network of weather stations provides a comprehensive weather picture.

Velocity sensors: These measure the particle velocity of the ground vibrations, which is directly related to the energy released by the blast. This can help determine the amount of vibration reaching nearby structures.

The data collected from these sensors is analyzed to create a seismic profile of the blast, allowing us to assess its impact on the surrounding environment and fine-tune future operations for better control and minimization of vibrations.

Q 9. How do you mitigate the risk of premature detonation?

Preventing premature detonation is paramount in explosive handling. A premature detonation can cause serious injury or death and significant property damage. Our mitigation strategies focus on meticulous attention to detail and robust safety protocols.

Careful handling and transportation: Explosives are transported and handled according to strict safety regulations. This involves specialized vehicles and trained personnel. We never compromise on safety procedures.

Thorough pre-blast inspections: We meticulously inspect all electrical connections, blasting caps, and initiation systems to rule out any potential flaws before initiating the blast. Imagine a surgeon meticulously checking their instruments before an operation – the same level of scrutiny is applied here.

Use of safety devices: We use safety devices like short-period delay detonators that provide a buffer between initiation signals, reducing the chances of a chain reaction if there’s an issue with one detonator.

Ground conditions assessment: Understanding the ground’s composition and potential for electrical interference is vital in preventing mishaps. This is because moisture and certain mineral compositions can affect the initiation process.

Controlled blasting techniques: Employing techniques like millisecond delay blasting allows for a controlled release of energy, reducing the risk of premature detonations.

Q 10. What are the common causes of misfires and how are they addressed?

Misfires, where a charge fails to detonate, are a serious concern. Common causes include faulty detonators, poor electrical connections, and insufficient initiation energy. Addressing misfires demands a systematic approach that prioritizes safety.

Faulty detonators: Manufacturing defects or damage during handling can lead to detonator malfunction. Using high-quality, certified detonators is essential. Our rigorous quality control procedures and careful handling processes minimize this risk.

Poor electrical connections: Poor connections in the initiation circuit result in insufficient energy reaching the detonator. We use proper crimping tools and ensure all connections are sound. Similar to ensuring a good power supply for other equipment.

Insufficient initiation energy: This can occur due to problems with the power supply or the electrical circuit design. Regular maintenance of equipment and adherence to established procedures ensure sufficient power.

Addressing Misfires: A misfire is never approached without thorough planning and safety precautions. This usually requires a controlled waiting period followed by careful investigation and disposal by trained professionals. In many cases, this involves a controlled detonation or removal of the misfired charge using specialized tools.

Q 11. Explain the process of disposing of unexploded ordnance.

Unexploded ordnance (UXO) disposal is a specialized and highly regulated process. It requires extensive training, specialized equipment, and strict adherence to safety protocols. The process varies depending on the type and condition of the UXO.

Assessment and Identification: A thorough assessment of the UXO is the first step. This involves identifying the type of explosive, its condition, and the surrounding environment. This often employs advanced detection tools like ground-penetrating radar and metal detectors.

On-site Neutralization: In-situ neutralization methods include controlled detonation using specialized techniques to minimize hazards, often performed in controlled environments. This might involve careful excavation and the use of water jets to remove ordnance.

Controlled Transportation and Disposal: If on-site neutralization isn’t feasible, the UXO is carefully transported to a licensed disposal facility. Specialized containers and transportation procedures are employed to mitigate risks. The exact method of destruction at the facility would depend on the type of UXO, it may involve incineration, controlled detonation, or other approved methods.

UXO disposal is not something to be taken lightly. It’s a complex process governed by numerous laws and regulations to ensure public safety and environmental protection.

Q 12. How do you ensure compliance with environmental regulations during blasting operations?

Ensuring environmental compliance during blasting operations is critical. We adhere to strict regulations regarding air and water quality, noise levels, and ground vibrations. We develop comprehensive environmental management plans for each project.

Pre-blast environmental surveys: Baseline data collection on air and water quality, noise levels, and ground vibrations before the blast establishes a benchmark for post-blast comparison. This data is critical for demonstrating compliance.

Minimizing dust and air pollution: We employ dust suppression techniques like water sprays and utilize blasting methods that minimize particulate matter. We regularly monitor air quality during and after the blast.

Noise monitoring and mitigation: Noise levels are monitored with sound level meters, and mitigation strategies, such as using directional blasting techniques and providing warning signals, are implemented to control noise impacts on the surrounding environment.

Water quality monitoring: We monitor water quality in nearby bodies of water before, during, and after blasting to ensure that there is no contamination. This often involves regular water sampling and testing.

Ground vibration monitoring and control: Using appropriate vibration monitoring equipment ensures that ground vibration limits set by the regulators are respected. Careful blast design and controlled charges help in this.

Our commitment to environmental responsibility guides all our blasting operations, ensuring minimal disruption to the environment.

Q 13. What are the effects of different explosive compositions on the surrounding environment?

Different explosive compositions have varying effects on the surrounding environment. Factors like the explosive’s energy output, chemical composition, and the detonation method influence these effects. Understanding these differences is vital for selecting appropriate explosives for specific applications.

High explosives: These generate a large amount of energy, causing significant ground vibrations and potentially leading to more substantial air pollution. The chemical composition can also influence the level and type of gaseous emissions.

Low explosives: These produce a relatively lower energy output, resulting in less ground vibration and less air pollution. However, they still have to be carefully used.

Water gels: These are relatively low-sensitivity explosives that are popular for their reduced impact on the environment compared to traditional dynamite. They often result in reduced ground vibration, dust, and gaseous emissions.

Proper explosive selection, combined with appropriate blasting techniques and environmental monitoring, is crucial for minimizing environmental impact.

Q 14. Describe your experience with different types of detonators.

My experience encompasses a wide range of detonators, each with unique characteristics and applications. The choice of detonator depends on factors like the type of explosive, the desired initiation timing, and safety considerations.

Electric detonators: These are initiated by an electrical current, offering precise timing control and are widely used in various applications. They are very versatile but require careful handling to avoid accidental initiation.

Non-electric detonators: These use shock tubes or other non-electrical methods for initiation, providing enhanced safety in environments susceptible to electrical interference. They are typically preferred in applications where there is a risk of stray electrical currents.

Delay detonators: These incorporate a delay element, allowing for precise sequencing of blasts for enhanced control and reduced vibrations. They are crucial in controlled blasting to improve efficiency and mitigate environmental impacts.

Blasting caps: These are small detonators used to initiate primary explosives. They are often part of a larger initiation system and are crucial for safety and reliability.

My experience includes selecting and deploying various detonator types based on site-specific requirements and safety protocols to ensure controlled and reliable blasts.

Q 15. What is your experience with different types of blasting caps?

My experience with blasting caps encompasses a wide range of types, each designed for specific applications and explosive materials. I’ve worked extensively with electric blasting caps, which are initiated by a precisely timed electrical signal, offering excellent control and synchronization in large-scale blasts. Non-electric, or detonator, caps, initiated by a shockwave from a detonator cord, are another common type I’ve used, particularly where electrical interference is a concern. I am also familiar with delay blasting caps, which incorporate a delay element allowing for sequenced detonation. This is crucial for controlled rock fragmentation and minimizing vibrations. Finally, I have experience with specialized blasting caps, such as those designed for underwater blasting, which require robust construction and specialized initiation systems. The selection of the appropriate cap type is paramount to ensuring safety and efficiency in blasting operations. For instance, in a quarry operation needing precise fragmentation, electric delay caps are preferred for their timing accuracy. In an underwater demolition where electrical interference is a possibility, non-electric caps would be the safer choice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you assess the stability of an explosive material?

Assessing the stability of an explosive material is critical for safety and effective operations. This involves a multi-faceted approach. First, we consider the material’s chemical composition and its susceptibility to decomposition or degradation due to factors like temperature, humidity, or exposure to contaminants. Then, we analyze its physical properties such as sensitivity to friction, impact, or static electricity. This is often done through standardized tests, like the impact sensitivity test or friction sensitivity test. Furthermore, we examine its long-term storage properties to evaluate any potential changes in its performance or stability over time. We also rely on the manufacturer’s data sheets for stability parameters and recommended storage conditions. Any signs of degradation, such as discoloration, exudation of oils, or changes in crystal structure, demand immediate attention and potentially disposal of the affected material. Think of it like checking the expiration date on food; an unstable explosive poses a significant safety risk and can lead to premature detonation.

Q 17. Explain the concept of critical diameter and its importance in explosives handling.

The critical diameter is the minimum diameter of an explosive charge that will allow for a complete and stable detonation. Imagine a thin rope of dynamite; if it’s too thin, the detonation wave might extinguish before it fully traverses the charge, leading to an incomplete detonation. The critical diameter is crucial because using a charge smaller than this minimum diameter can result in misfires or partial detonations, rendering the blasting operation ineffective and potentially dangerous. Larger diameter charges are generally preferred to ensure complete and consistent detonation, though excessively large charges are also less efficient. In practical terms, choosing the appropriate charge diameter is fundamental for designing safe and effective blasting patterns, ensuring the energy released is fully utilized for the intended purpose, be it rock fragmentation in quarrying or controlled demolition of a building.

Q 18. How do you calculate the burden and spacing in a blasting pattern?

Calculating burden and spacing in a blasting pattern is crucial for optimizing fragmentation and minimizing vibration. Burden refers to the distance from the free face (the exposed rock surface) to the nearest borehole. Spacing is the distance between adjacent boreholes. The optimal burden and spacing values depend on several factors, including the rock’s physical properties (strength, fracturing), the type of explosive, and the desired fragmentation size. There isn’t a single formula; experienced blasters often use empirical relationships or specialized blasting design software that incorporates the various parameters. However, a key principle is to achieve a balance: too small a burden can lead to excessive vibration and incomplete fragmentation; too large a burden can result in poor fragmentation and inefficient explosive use. Similarly, incorrect spacing can affect the uniformity of the blast. Many practitioners use the burden:spacing ratio as a starting point to optimize the pattern. The calculations usually begin with an initial estimate based on past experience and then are refined through field testing and analysis of blast results.

Q 19. Describe the different methods for controlling the vibration from blasting.

Controlling vibration from blasting is vital for protecting nearby structures and ensuring public safety. Several methods are employed. One of the most effective is careful design of the blasting pattern, such as optimizing burden and spacing, using smaller charges in multiple delays, and pre-splitting. Pre-splitting involves drilling a series of closely spaced holes on the perimeter of the blast area and detonating them before the main blast, creating controlled fractures to guide the energy of the main blast. Another approach involves using stemming—inert material packed into the boreholes above the explosive charge—to dampen the blast vibrations. Moreover, choosing the appropriate explosive type with lower vibration characteristics is key. Finally, the timing and sequencing of blasts are also vital to reducing vibration. The use of vibration monitoring equipment provides valuable feedback for refining blasting strategies and minimizing vibrations.

Q 20. What are the potential hazards associated with underwater blasting?

Underwater blasting presents unique hazards. The most significant risk is the generation of shockwaves and pressure waves, which can damage marine life and nearby structures. Bubbles generated by the explosion can also cause damage. The potential for uncontrolled projection of debris and the risk of injury from flying fragments are also major concerns. Furthermore, the underwater environment introduces complications in terms of controlling the blast pattern and assessing the effectiveness of the detonation. Environmental concerns include the impact on fish populations, damage to coral reefs, and the release of harmful substances into the water. It’s critical to comply with stringent environmental regulations and safety protocols to mitigate these hazards. These often involve careful selection of explosives and initiation systems designed for underwater use, precise blast pattern design, and detailed environmental impact assessments.

Q 21. How do you ensure the safety of personnel during blasting operations?

Ensuring personnel safety during blasting operations is paramount and requires a comprehensive approach. This begins with thorough training, ensuring all personnel understand the risks and procedures. Strict adherence to safety regulations and company policies is essential, including the use of personal protective equipment (PPE) such as earplugs, eye protection, and hard hats. Clear communication and established emergency procedures are also critical. Before any blast, a thorough site survey is undertaken to identify potential hazards and establish safe zones. This includes informing all nearby residents and businesses. Careful planning and execution of the blasting sequence is critical, ensuring that all safety measures are in place before initiation. Post-blast inspections are necessary to ensure the complete and safe execution of the operation. Finally, comprehensive records of every blast are maintained for future analysis and continuous improvement of safety procedures. Safety isn’t just a checklist; it’s a culture fostered through continuous vigilance and commitment.

Q 22. What is your experience with various types of explosive initiation systems?

My experience encompasses a wide range of explosive initiation systems, from the simplest electric detonators to sophisticated non-electric and electronic systems. Electric detonators, using a simple electrical current to initiate the explosive, are common and cost-effective but susceptible to misfires in wet conditions. Non-electric systems, utilizing a shock tube or similar method, offer superior safety and reliability in adverse environments as they are immune to stray electrical currents. Electronic detonators provide even greater control and precision, allowing for precise timing and sequencing of blasts, crucial for complex demolition projects. I’ve worked extensively with all three types, and my expertise includes selecting the appropriate system based on project specifics like the environment, the type of explosive, and the desired outcome. For instance, in a deep underwater demolition, a non-electric system would be preferred over an electric system to avoid electrical shorts. In a large quarry blast, an electronic system would allow for precise control over hundreds or even thousands of detonators to optimize rock fragmentation.

- Electric Detonators: Simple, cost-effective, but vulnerable to moisture.

- Non-electric Detonators (Shock Tube): Reliable, safe, suitable for wet environments.

- Electronic Detonators: Precise timing, ideal for complex projects.

Q 23. How do you conduct a pre-blast survey?

A pre-blast survey is critical for ensuring safety and minimizing environmental impact. It’s a systematic process involving a thorough investigation of the blast site and its surroundings. The process begins with a detailed site map, identifying structures, utilities, and geological features. Next, we assess the proximity of sensitive structures to the blast area, measuring distances and calculating potential vibrations. We also consider the geology – the type of rock, its strength, and the presence of any fractures or weaknesses. The type of explosive used and the amount of explosive charge are carefully calculated based on these factors. Soil composition is also critical, as it affects vibration transmission. We document everything – taking photographs, obtaining samples, and creating detailed reports. This detailed information allows us to model the blast, predict its effects, and develop a safe and effective blasting plan that minimizes damage to surrounding infrastructure and the environment. For instance, in a recent project near a historic building, the pre-blast survey led us to implement vibration monitoring during blasting, ensuring the building remained undamaged.

Q 24. Describe your experience with different types of explosives used in mining.

In mining, the choice of explosive depends heavily on the type of rock, its hardness, and the desired fragmentation. I have experience with a variety of explosives, including ANFO (Ammonium Nitrate Fuel Oil), emulsions, and water gels. ANFO is a popular choice due to its cost-effectiveness and ease of handling, but its performance can be affected by moisture. Emulsions and water gels are more robust, offering improved water resistance and performance in challenging conditions. The selection process involves careful consideration of factors like sensitivity, detonation velocity, and the desired level of fragmentation. For example, harder rock formations may require a more powerful explosive like an emulsion, while softer rock might be effectively broken with ANFO. The optimization of explosive selection ensures efficiency in mining operations, minimizing costs and maximizing productivity.

- ANFO (Ammonium Nitrate Fuel Oil): Cost-effective, sensitive to moisture.

- Emulsions: Water-resistant, high performance.

- Water Gels: Versatile, good for various rock types.

Q 25. What is your experience with the transportation of explosives?

Safe and compliant transportation of explosives is paramount. My experience includes strict adherence to all relevant regulations, including DOT (Department of Transportation) guidelines in the United States, or equivalent regulations in other regions. This involves ensuring proper packaging, labeling, and vehicle placarding. The type of vehicle used must be approved for explosive transport. The route planning is equally crucial – avoiding populated areas and sensitive infrastructure. Drivers undergo specialized training and must be properly licensed. Detailed documentation, including manifests and shipping papers, is maintained throughout the transportation process. Regular vehicle inspections are also critical to ensure compliance. A significant part of my role was overseeing logistics, ensuring that explosives were transported safely and efficiently from the manufacturing plant to the job site, with utmost respect for the safety of the public and the environment.

Q 26. Describe the different types of explosives used in demolition.

Demolition projects often utilize a range of explosives tailored to the specific structure and desired outcome. Common explosives include military-grade C4 (cyclotrimethylenetrinitramine), which is potent and very reliable, but requires special handling and permits. Commercial explosives, often similar in composition to those used in mining, but packaged differently, are more readily available and used for more common demolition tasks. The selection of the explosive and its placement (charges) are crucial for a controlled and effective demolition. Factors considered include the type of structure (concrete, steel, wood), its size and condition, and the desired outcome (complete collapse or partial removal). For instance, in a controlled demolition of a large building, a combination of strategically placed charges might be used to achieve a specific collapse pattern, ensuring public safety.

- Military-grade explosives (e.g., C4): High-power, controlled environments.

- Commercial explosives: More readily available, various applications.

Q 27. What are your experience with the environmental impact assessment of blasting?

Environmental impact assessments (EIAs) for blasting operations are crucial for responsible and sustainable practices. The assessment covers potential impacts such as air and water pollution, noise pollution, ground vibrations, and habitat disturbance. We use specialized software and models to predict the extent of these impacts, and we implement mitigation measures to minimize them. For instance, we might use specialized blasting techniques to reduce air and noise pollution. Water quality monitoring before, during, and after blasting is crucial to ensure no contamination occurs. The EIA ensures compliance with environmental regulations and contributes to minimizing the project’s ecological footprint. A robust EIA is a vital component in obtaining necessary permits and demonstrating environmental responsibility.

Q 28. Explain your experience with post-blast assessments.

Post-blast assessments are vital for evaluating the effectiveness and safety of a blasting operation. This involves a thorough inspection of the blast site to assess the extent of fragmentation, confirming the successful achievement of the project objectives. We also check for any unexpected damage to surrounding structures or the environment. Debris removal and site cleanup are then planned and executed according to environmental standards. Data from vibration monitoring equipment is analyzed to confirm that vibration levels remained within acceptable limits, ensuring public safety and protecting nearby structures. Analysis of the post-blast data helps refine our blasting techniques and improve future operations.

Key Topics to Learn for Experience with Explosive Materials Interview

- Explosive Chemistry and Thermodynamics: Understanding the chemical reactions involved in explosive initiation, detonation, and energy release. This includes concepts like heat of explosion, detonation velocity, and sensitivity.

- Explosive Handling and Safety Procedures: Practical application of safety regulations, procedures for storage, transportation, and handling of explosive materials. This includes risk assessment and mitigation strategies.

- Blast Effects and Fragmentation: Analyzing the effects of explosions, including shockwave propagation, crater formation, and the behavior of fragments. This is crucial for understanding the destructive power and potential hazards.

- Initiation Systems and Detonation Mechanisms: Knowledge of different initiation systems (e.g., electric detonators, non-electric detonators) and the mechanisms by which explosives are initiated and detonated.

- Explosive Manufacturing and Processing: Understanding the processes involved in the production and formulation of various explosive materials. This might include mixing, pressing, and casting techniques.

- Demolition and Controlled Blasting Techniques: Practical application of explosive materials in controlled demolition projects, mining operations, and other applications. This includes designing and executing safe and effective blasting plans.

- Regulatory Compliance and Legal Aspects: Familiarity with relevant regulations, permits, and licensing requirements for handling and using explosive materials.

- Troubleshooting and Problem-Solving: Developing skills in diagnosing issues related to explosive performance, malfunctions, and safety concerns.

Next Steps

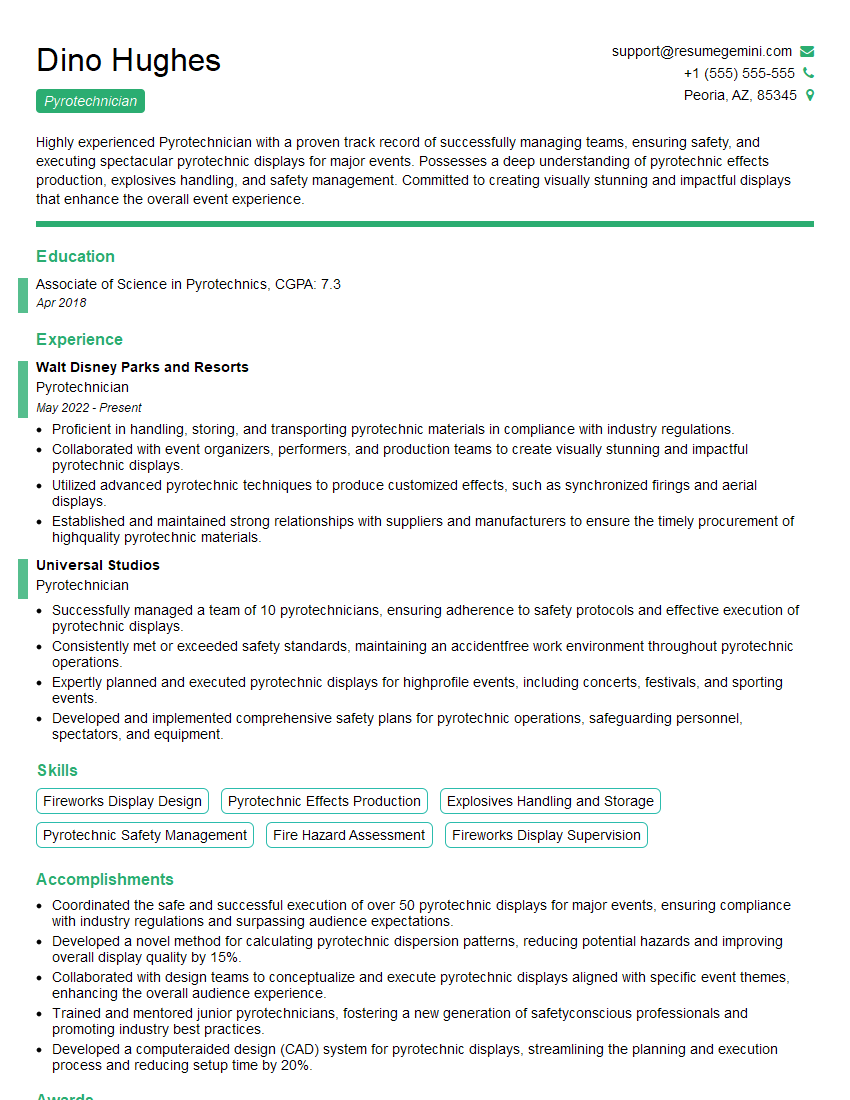

Mastering the intricacies of explosive materials handling and application is critical for career advancement in fields like mining, construction, demolition, and defense. A strong understanding of these principles showcases your expertise and commitment to safety. To significantly boost your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you craft a compelling and impactful resume. We offer examples of resumes tailored to Experience with Explosive Materials to guide you in showcasing your unique qualifications. Take the next step towards your dream career – build a resume that truly reflects your expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good