Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Experience with Irrigation Equipment Manufacturers interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Experience with Irrigation Equipment Manufacturers Interview

Q 1. Describe your experience with different types of irrigation systems (drip, sprinkler, etc.).

My experience encompasses a wide range of irrigation systems, from the highly efficient drip irrigation to the more traditional sprinkler systems. Drip irrigation, using emitters or drippers to deliver water directly to plant roots, excels in water conservation and minimizes evaporation. I’ve worked extensively with subsurface drip systems, which offer even greater efficiency by placing the tubing below the soil surface. Sprinkler systems, while less water-efficient, are suitable for larger areas and offer flexibility in coverage patterns. I’ve designed and implemented various sprinkler configurations, including rotary, impact, and pop-up sprinklers, each tailored to specific landscape needs. I’ve also worked with micro-sprinklers, offering a compromise between the precision of drip and the wider coverage of sprinklers.

- Drip Irrigation Example: A recent project involved designing a drip irrigation system for a vineyard, optimizing emitter spacing and pressure to ensure consistent water delivery to each vine.

- Sprinkler Irrigation Example: I oversaw the installation of a large-scale sprinkler system for a sports field, ensuring even water distribution across the playing area using a combination of rotary and impact sprinklers.

Q 2. Explain your understanding of water pressure regulation in irrigation systems.

Water pressure regulation is crucial for efficient and effective irrigation. Inconsistent pressure leads to uneven watering, reduced efficiency, and potential damage to components. Regulation is achieved through various methods. Pressure-regulating valves are essential for maintaining a consistent pressure at different points in the system, preventing overwatering in low-lying areas and ensuring adequate flow in elevated regions. Pressure-reducing valves are used to lower the water pressure from a high-pressure source to a level suitable for the irrigation system’s components. These valves often incorporate pressure gauges, providing visual confirmation of the regulated pressure. Think of it like controlling water flow from a hose—a pressure regulator is like a valve that ensures a steady stream, preventing it from being too weak or too strong.

Proper pressure regulation is particularly critical in drip irrigation, where excessive pressure can damage delicate emitters. In sprinkler systems, consistent pressure ensures even water distribution and prevents some sprinklers from outperforming others.

Q 3. How do you troubleshoot common irrigation system malfunctions?

Troubleshooting irrigation malfunctions involves a systematic approach. I start by visually inspecting the entire system, looking for obvious issues like leaks, clogged emitters, or broken pipes. Then I check the water source, ensuring adequate water pressure and flow. I utilize pressure gauges at various points to pinpoint pressure drops. If a problem persists, I systematically isolate sections of the system, using shut-off valves to identify the affected area.

- Clogged Emitters: Frequently, clogged emitters are the cause of poor water distribution in drip systems. These can be easily cleaned with a small wire or by replacing the emitter.

- Broken Sprinkler Heads: In sprinkler systems, broken or misaligned sprinkler heads can lead to uneven coverage. These can often be repaired or replaced.

- Pump Issues: If the entire system is affected, the problem often lies with the pump. This might involve checking for sufficient power, checking for leaks in the pump itself, or performing pump maintenance.

I always document my findings and the steps taken to resolve the issue, helping with future maintenance and troubleshooting.

Q 4. What experience do you have with irrigation control systems (e.g., timers, sensors)?

I have extensive experience with a variety of irrigation control systems. This includes simple timer-based systems, more advanced weather-based controllers, and sophisticated smart irrigation systems. Timer-based systems provide basic scheduling functionality, allowing for automated irrigation cycles. Weather-based controllers incorporate sensors that measure rainfall, temperature, and soil moisture, adjusting watering schedules accordingly. These are particularly useful in conserving water. Smart irrigation systems offer remote control and monitoring capabilities, providing real-time data on system performance and allowing adjustments based on real-time conditions.

I’ve worked with various brands and models, gaining proficiency in their programming and maintenance. For example, I’ve programmed systems to run different zones at different times based on plant type and water requirements, optimizing water usage and plant health.

Q 5. Describe your experience with irrigation system design software.

My experience with irrigation design software includes using programs such as AutoCad, Irrigation Designer and other specialized CAD software for creating detailed irrigation system layouts. This includes mapping out the location of pipes, valves, emitters, and sprinklers, and calculating water requirements based on landscape characteristics and plant needs. The software allows for accurate sizing of pipes and selection of appropriate components, ensuring optimal system performance. It also helps in generating detailed cost estimates for materials and labor. For example, I used specialized software to simulate water flow patterns for a large golf course, ensuring uniform coverage across the greens and fairways and minimizing water waste.

Q 6. How familiar are you with different types of irrigation pumps?

I am familiar with various irrigation pump types, including centrifugal pumps, submersible pumps, and booster pumps. Centrifugal pumps are commonly used in larger irrigation systems, offering high flow rates at moderate pressures. Submersible pumps are ideal for deep wells and offer reliable operation. Booster pumps are often used to increase water pressure in sections of the system where it is insufficient. The choice of pump depends on factors such as water source depth, required flow rate, pressure requirements, and budget. For instance, in a recent project, we chose submersible pumps for accessing water from a deep well to supply a large agricultural area, providing the necessary water pressure and flow efficiently and cost-effectively.

Q 7. What are your troubleshooting techniques for low water pressure issues?

Low water pressure problems require a systematic approach. I first check the water source, ensuring adequate pressure and flow are available. This might involve contacting the water utility company if the issue seems broader than the irrigation system. Next, I inspect the pump, checking for any blockages, leaks, or operational issues. A faulty pump is a common cause of low water pressure. I then carefully examine the piping system for leaks, blockages, or areas of significant friction which could be reducing water flow. Clogged filters are another common culprit, so I inspect and clean them regularly. Lastly, I verify the proper functioning of pressure-regulating valves, ensuring they are not restricting water flow unnecessarily. By methodically checking each component, I can typically identify the root cause of the low pressure and take appropriate corrective action.

Q 8. How do you calculate water requirements for different plant types?

Calculating water requirements for different plant types involves understanding their evapotranspiration (ET) rates – the combined loss of water from evaporation and plant transpiration. This isn’t a simple calculation and depends on several factors.

- Plant Type: Different plants have different water needs. A thirsty lawn requires significantly more water than drought-tolerant succulents.

- Climate: Temperature, humidity, wind speed, and sunlight intensity all affect ET rates. Hot, windy, sunny days lead to higher water loss.

- Soil Type: Sandy soils drain quickly, requiring more frequent but less intense watering than clay soils, which retain water longer.

- Plant Stage: Young plants generally need less water than mature plants, especially during establishment.

We typically use tools like evapotranspiration models (often based on Penman-Monteith equations) or reference ET data from weather stations combined with crop coefficients specific to the plant type. For example, a reference ET of 0.4 inches per day and a crop coefficient of 0.8 for a particular type of grass would indicate a daily irrigation need of 0.32 inches (0.4 * 0.8). Irrigation scheduling software and online calculators can significantly simplify this process, but a good understanding of the underlying principles remains crucial for accurate results and adjustments for local conditions. On-site soil moisture monitoring can also help refine irrigation schedules.

Q 9. What safety procedures do you follow when working with irrigation equipment?

Safety is paramount when working with irrigation equipment. Our procedures include:

- Personal Protective Equipment (PPE): Always wearing appropriate safety glasses, gloves, and sturdy footwear is non-negotiable. Depending on the task, this may also include hearing protection and high-visibility clothing.

- Lockout/Tagout Procedures: Before performing any maintenance or repairs on motorized equipment (pumps, controllers), we strictly follow lockout/tagout procedures to prevent accidental energization.

- Hazard Awareness: We are trained to identify and mitigate hazards, such as working near power lines, operating heavy machinery safely, and handling chemicals responsibly. We always follow the manufacturer’s instructions and safety data sheets for all materials.

- Emergency Preparedness: We have established emergency response protocols and understand how to handle potential incidents, such as leaks, equipment malfunctions, or injuries. First aid training is a requirement.

- Regular Inspections: Regular visual inspection of all equipment and components to prevent and early identification of potential issues.

We conduct thorough site safety assessments before commencing any work. Our team is always briefed on the specific hazards present on each job site.

Q 10. Describe your experience with installation and maintenance of irrigation systems.

My experience encompasses the entire lifecycle of irrigation systems, from initial design and site surveys to installation, commissioning, and ongoing maintenance. I’ve worked on diverse projects, including residential lawns, agricultural fields, and commercial landscapes. Installation involves careful planning, precise pipe laying (considering slopes for proper drainage), and meticulous connection of all components. We use a variety of techniques such as trenching, directional drilling, and surface installations depending on the site conditions and desired aesthetics.

Maintenance tasks are regular and vary from simple tasks such as checking for leaks and clearing debris to more complex repairs involving pump replacements or controller programming. I’m proficient in troubleshooting various system malfunctions, identifying the root cause, and implementing effective solutions. I’ve worked with various brands and types of irrigation equipment, developing a comprehensive understanding of their unique features and maintenance requirements. Preventative maintenance is crucial to prolong system life and minimize costly repairs down the road.

Q 11. What is your understanding of water conservation techniques in irrigation?

Water conservation is critical in irrigation. My understanding covers several key techniques:

- Efficient Irrigation Technologies: This includes using drip irrigation or micro-sprinklers instead of inefficient spray systems, which minimizes water loss through evaporation and runoff. Properly designed and maintained sprinkler systems using low-pressure spray heads are also essential.

- Smart Irrigation Controllers: These controllers use weather data and soil moisture sensors to optimize irrigation schedules, preventing overwatering. They adapt to changing weather conditions, ensuring efficient water usage.

- Soil Moisture Monitoring: Using soil moisture sensors provides real-time data on soil water content, guiding irrigation decisions and preventing unnecessary watering.

- Water Audits: Regular water audits can identify leaks or inefficiencies in the system, allowing for prompt repairs and improvements.

- Proper Irrigation Scheduling: Watering deeply and less frequently encourages deeper root growth, leading to drought tolerance.

Implementing these techniques not only conserves water but also reduces energy consumption and maintenance costs. It’s about using technology and best practices to maximize the efficiency of every drop of water.

Q 12. How do you handle challenging terrain during irrigation system installation?

Challenging terrain requires adapting our installation methods. Steep slopes, rocky areas, and uneven surfaces pose unique problems. We overcome these challenges by:

- Site-Specific Design: Careful site surveys are crucial to create an irrigation plan that accommodates the terrain. This might involve using different piping materials or installation techniques.

- Terracing and Contouring: On steep slopes, terracing may be required to create level areas for efficient irrigation. Contouring helps to follow the natural slope of the land, reducing water runoff.

- Specialized Equipment: For rocky areas, we utilize specialized equipment like rock drills and trenchers designed for difficult terrain. Directional drilling minimizes surface disruption.

- Manual Labor: In some cases, manual installation may be necessary in areas inaccessible to machinery. Experienced crews are skilled in adapting to difficult conditions.

- Erosion Control: We take precautions to prevent soil erosion during and after installation, using measures like mulching and sediment control barriers.

Safety is paramount when working in challenging terrain. Our crews are trained to work safely in these conditions, using appropriate safety equipment and procedures.

Q 13. What is your experience with irrigation system automation?

My experience with irrigation system automation is extensive. I’ve worked with a variety of automation systems, from simple timers to sophisticated weather-based controllers integrated with soil moisture sensors and remote monitoring capabilities. This includes programming, installation, troubleshooting, and maintenance of these systems.

Automated systems offer significant advantages, including:

- Water Conservation: Precise scheduling based on real-time data minimizes water waste.

- Labor Savings: Automated systems eliminate the need for manual adjustments, freeing up time and resources.

- Improved Efficiency: Optimized watering schedules ensure plants receive the right amount of water at the right time.

- Remote Monitoring and Control: Some systems allow for remote monitoring and control, providing flexibility and convenience.

I am proficient in programming various controller types, integrating them with different sensors, and troubleshooting malfunctions. My expertise extends to networking multiple controllers for larger, more complex systems. I understand the benefits and limitations of various automation technologies and can recommend the most suitable solution based on project requirements and budget.

Q 14. Explain your knowledge of different irrigation pipe materials and their applications.

Irrigation pipe materials vary greatly in their properties and applications. The choice depends on factors like pressure, soil conditions, cost, and durability.

- Polyvinyl Chloride (PVC): A common and cost-effective choice for low-pressure systems. Relatively rigid, it’s suitable for many applications but can be susceptible to damage from freezing temperatures.

- High-Density Polyethylene (HDPE): More flexible and durable than PVC, making it ideal for challenging terrains and high-pressure systems. Resists freezing better than PVC and is commonly used for larger diameter mains.

- Chlorinated Polyvinyl Chloride (CPVC): Offers improved resistance to higher temperatures and pressures than PVC, making it suitable for hot water applications.

- Aluminum: Relatively lightweight, strong, and durable, often used in above-ground systems, but prone to corrosion.

- Galvanized Steel: Very strong and durable, but heavier than other materials and susceptible to corrosion if not properly coated.

In my experience, selecting the right pipe material is crucial for the long-term performance and reliability of the irrigation system. I carefully assess the site conditions and project requirements to specify the most appropriate material, considering factors such as pressure ratings, lifespan, and potential environmental impacts. I also ensure proper pipe fitting and joining techniques to prevent leaks and maintain system integrity.

Q 15. How familiar are you with the latest irrigation technologies and advancements?

I’m intimately familiar with the latest advancements in irrigation technology. This includes significant progress in areas like precision irrigation, smart controllers, and water-saving technologies. For example, I’ve worked extensively with variable rate irrigation (VRI) systems, which use GPS and sensors to precisely control water application based on real-time soil moisture and crop needs, resulting in significant water savings and increased yields. Another key area is the integration of smart sensors and IoT (Internet of Things) devices. These enable real-time monitoring of soil moisture, water pressure, and other critical parameters, allowing for proactive maintenance and optimized water management. My experience also covers advancements in water-efficient drip and micro-sprinkler irrigation systems, which are far more targeted than traditional methods, minimizing water waste. Finally, I am familiar with the development of drought-resistant and water-efficient crops, which are crucial elements in overall water conservation strategies.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with budgeting and cost estimation for irrigation projects.

Budgeting and cost estimation for irrigation projects is a crucial aspect of my expertise. I approach this systematically, starting with a detailed assessment of project requirements, including the area to be irrigated, the type of irrigation system, the water source, and any special site conditions. This assessment informs the selection of appropriate equipment and materials. I then develop a comprehensive cost breakdown, including labor, equipment, materials, permits, and contingency costs. For example, in a recent project for a large vineyard, I factored in the cost of GPS-guided VRI equipment, alongside labor costs for installation and future maintenance. I also incorporate cost-saving strategies while maintaining quality and functionality. This could involve leveraging economies of scale by negotiating bulk discounts or employing efficient installation techniques. The final budget is presented with clear justifications for each expense, making it transparent and easily understood by clients.

Q 17. What is your experience with managing irrigation system projects?

My experience in managing irrigation system projects spans various scales and complexities. This includes project planning and scheduling, resource allocation, coordination with contractors and suppliers, and ensuring adherence to deadlines and budgets. I utilize project management tools and techniques such as Gantt charts and critical path analysis to effectively track progress and manage resources. For instance, during a large-scale agricultural irrigation project, I managed a team of engineers, contractors, and technicians, overseeing every phase from design to completion. This included regular site visits, progress reports, and addressing any challenges or delays proactively. Effective communication and collaboration are key to successful project management. I ensure transparent communication between the client, the project team, and stakeholders throughout the project lifecycle.

Q 18. How do you ensure the quality and efficiency of irrigation systems?

Ensuring the quality and efficiency of irrigation systems involves a multi-faceted approach. It starts with a thorough design phase, accounting for factors such as soil type, topography, crop requirements, and water availability. Quality control measures are implemented throughout the construction and installation phases, including regular inspections and testing of equipment. We use high-quality components from reputable manufacturers to ensure system longevity and reliability. Following installation, thorough testing is crucial. This might involve pressure testing the pipes, checking the functionality of valves and controllers, and calibrating sensors for optimal performance. Finally, regular maintenance and monitoring of the system are crucial for long-term efficiency and problem prevention. This includes periodic inspections, cleaning of filters and emitters, and timely repairs or replacements of faulty components. I often use data-driven approaches, analyzing system performance data to identify areas for improvement and optimize water usage.

Q 19. Explain your knowledge of irrigation system schematics and blueprints.

I have extensive experience interpreting and working with irrigation system schematics and blueprints. These documents are essential for planning, designing, and installing irrigation systems accurately. I can interpret symbols, understand pipe sizing calculations, and identify critical components such as valves, pumps, and controllers. My ability to read and understand these documents ensures the precise implementation of the design. For example, I can identify potential conflicts or design flaws early on, ensuring a smooth and efficient installation process. Understanding blueprints is critical for accurate cost estimation and ensuring the project aligns with the client’s needs and budget. I am proficient in using CAD software to create and modify schematics, ensuring accuracy and collaboration with project teams.

Q 20. Describe your experience with working with different types of valves and fittings.

I’m experienced in working with various types of valves and fittings, including ball valves, gate valves, check valves, pressure regulating valves, and various types of pipe fittings like couplings, unions, and elbows. My experience extends to understanding their functions and applications. For instance, I know when to select a pressure-regulating valve to maintain consistent water pressure across different zones, or a check valve to prevent backflow. Choosing the right valves and fittings is crucial for ensuring system efficiency, preventing leaks, and maintaining water pressure. I also understand the importance of selecting materials suitable for specific water qualities and environmental conditions. For example, choosing corrosion-resistant materials in areas with highly mineralized water is essential for system longevity.

Q 21. How do you handle customer complaints and resolve irrigation system issues?

Handling customer complaints and resolving irrigation system issues requires a methodical and customer-focused approach. I begin by actively listening to the customer’s concerns, gathering detailed information about the problem, and asking clarifying questions. I then systematically troubleshoot the issue, checking components like sensors, valves, pumps, and controllers. This may involve inspecting the system physically or reviewing operational data. I communicate my findings transparently to the customer, explaining the problem and outlining the proposed solutions. In some cases, this might involve minor repairs or adjustments, while in other instances, it could necessitate more extensive repairs or part replacements. I strive to provide timely and effective solutions, ensuring customer satisfaction. A key aspect of this is clear communication, keeping the customer informed throughout the entire process. I always aim for a positive resolution, leaving the customer feeling valued and confident in the services provided.

Q 22. What is your understanding of water rights and regulations related to irrigation?

Water rights and regulations are crucial for responsible irrigation. They dictate how much water a user can withdraw from a water source (river, aquifer, etc.) and when. These rights vary greatly by location, depending on factors like historical use, water availability, and environmental considerations. For example, some regions operate under a prior appropriation doctrine, where the first to use the water holds the senior right, while others use riparian rights, granting water rights to landowners bordering a water source. Regulations often involve obtaining permits, adhering to usage limits (e.g., acre-feet per year), and following water conservation measures. Non-compliance can lead to penalties such as fines or even water allocation reductions. Understanding these legal frameworks is vital for any irrigation project to ensure its legality and sustainability.

In my experience, working on projects spanning different states requires thorough research into each area’s specific regulations. I’ve collaborated with legal counsel and water resource management agencies to navigate this complex landscape and ensure each project adheres to local rules. This has ranged from applying for permits to designing systems that minimize water usage while maintaining crop yields.

Q 23. How do you maintain accurate records and documentation for irrigation projects?

Maintaining accurate records is paramount for efficient irrigation management and compliance. This involves meticulous documentation at every stage of a project. I use a combination of digital and physical record-keeping. For example, digital tools such as Geographic Information Systems (GIS) are invaluable for mapping irrigation infrastructure, scheduling, and monitoring water usage. I use GIS software to store and visualize data related to soil types, irrigation system layout, and sensor readings. We also maintain detailed spreadsheets tracking pump run times, water usage, weather data, and maintenance schedules. Physical records include as-built drawings, equipment manuals, and maintenance logs. These records are crucial for troubleshooting, planning maintenance, and demonstrating compliance with regulations. They also serve as a valuable reference for future projects and renovations.

For instance, during a recent project, detailed records of soil tests allowed us to tailor the irrigation schedule to optimize water delivery based on specific soil characteristics. These precise data helped avoid overwatering and minimized water waste. This systematic approach not only ensures operational efficiency but also simplifies reporting to stakeholders and regulatory bodies.

Q 24. Describe your experience with troubleshooting issues related to irrigation controllers.

Troubleshooting irrigation controllers requires a systematic approach. I start by examining the controller’s programming, checking for issues such as incorrect scheduling, faulty sensor readings, or communication errors. I use a multimeter to test electrical connections and identify voltage problems. If a controller isn’t responding, I’ll check the power supply and any fuse boxes. Many controllers have diagnostic features, which can display error codes helping isolate the problem. Software updates, especially for older controllers, can resolve bugs or compatibility issues. If the controller is faulty, replacing it may be necessary. However, before replacing components, I always check the wiring and connections to the sensors and valves. Replacing faulty components is done only after careful inspection. I also consult the controller’s manual for specific troubleshooting steps.

For example, I once encountered a situation where an irrigation system was failing to operate during scheduled times. After systematic checks, I discovered a wiring issue caused by a rodent chewing through a power cable. Repairing the cable solved the problem and highlighted the importance of protecting wiring from rodents and other environmental factors.

Q 25. What is your experience with hydraulic calculations for irrigation systems?

Hydraulic calculations are essential for designing efficient and effective irrigation systems. These calculations determine the optimal pipe sizes, pump capacity, and pressure requirements for delivering the correct amount of water to each zone at the desired pressure. I utilize specialized software and engineering principles (e.g., Hazen-Williams equation, Darcy-Weisbach equation) to estimate head loss due to friction, elevation changes and minor losses. This process includes calculating the flow rate, pressure drop along the pipe network, and the required pump horsepower to meet the system’s demand. Accurate calculations minimize energy consumption, prevent over- or under-watering, and avoid costly equipment malfunctions. I also account for factors like water pressure variations, pipe roughness and altitude differences.

In a recent project, precise hydraulic calculations enabled us to optimize pipe sizing, resulting in a significant reduction in material costs and energy usage. This demonstrates the importance of applying robust engineering principles to irrigation design.

Q 26. Describe your experience with different types of soil and their impact on irrigation.

Different soil types dramatically impact irrigation needs. Sandy soils drain quickly, requiring more frequent but smaller applications of water. Clay soils, conversely, retain water, necessitating less frequent but potentially larger waterings to prevent waterlogging. Soil texture (the proportion of sand, silt, and clay) significantly affects infiltration rates, water holding capacity, and drainage characteristics. I take soil samples for laboratory analysis to determine the soil type and its inherent characteristics. Using this data, I use soil moisture sensors to monitor moisture content and adjust irrigation schedules accordingly. Other factors like soil organic matter content, structure, and depth also play crucial roles in determining irrigation needs. Understanding these soil properties is critical for optimizing water use and achieving plant health.

For example, in a project involving a mix of sandy and clay soils, we implemented a zone-based irrigation strategy to tailor water application based on each soil type’s unique water requirements. This ensured efficient water use, preventing both overwatering in clay areas and underwatering in sandy areas.

Q 27. How do you select the appropriate irrigation system for a given site and plant needs?

Selecting the appropriate irrigation system requires careful consideration of various factors. Site-specific parameters such as topography, soil type, climate, water availability, and budget influence the choice. Plant needs, including water requirements and spacing, are equally important. Several common systems exist: drip irrigation (highly efficient, ideal for row crops and orchards), sprinkler irrigation (suitable for larger areas, flexible but prone to evaporation), subsurface drip irrigation (minimizes evaporation, good for water scarcity regions), and flood irrigation (less efficient, but cost-effective for certain flat terrains). After evaluating the site and plant needs, a cost-benefit analysis is performed to determine the most appropriate and sustainable option.

For instance, on a sloping vineyard, a drip irrigation system would be much more efficient than a sprinkler system because it minimizes water runoff and evaporation. On a large field of uniform crops with ample water, sprinkler irrigation might be the most economical choice. The decision involves balancing efficiency, cost-effectiveness, and environmental impact.

Q 28. What is your experience with the maintenance and repair of various irrigation components?

Maintenance and repair of irrigation components are crucial for system longevity and efficiency. Regular inspections are essential to detect potential problems early. This includes checking for leaks in pipes and fittings, verifying the proper functioning of valves, examining pump operation and pressure, and inspecting controllers and sensors. Tasks involve cleaning filters, replacing worn-out components (e.g., nozzles, emitters), lubricating moving parts, and flushing pipelines. Troubleshooting and repairing problems promptly avoids larger, more expensive repairs down the line. I keep a detailed log of all maintenance activities, including dates, work performed, and parts replaced, facilitating efficient tracking and future planning.

For example, timely detection and repair of a leaking pipe not only saved water but also prevented soil erosion and damage to the surrounding vegetation. Regular maintenance ensures that the irrigation system operates at peak efficiency, resulting in reduced operational costs and improved crop yields.

Key Topics to Learn for Experience with Irrigation Equipment Manufacturers Interview

- Irrigation System Design & Layout: Understanding different irrigation methods (drip, sprinkler, center pivot), water source considerations, and designing efficient systems based on land topography and crop needs.

- Equipment Operation & Maintenance: Practical experience with various irrigation equipment, including pumps, valves, controllers, and sensors. Troubleshooting common malfunctions and performing preventative maintenance.

- Water Management & Conservation: Strategies for optimizing water use, including soil moisture monitoring, scheduling irrigation based on evapotranspiration, and implementing water-saving technologies.

- Hydraulics & Fluid Mechanics: Fundamental understanding of pressure, flow rate, and pipe sizing calculations relevant to irrigation systems. Ability to analyze system performance and identify areas for improvement.

- Control Systems & Automation: Experience with automated irrigation systems, including programming controllers, integrating sensors, and utilizing data analytics for optimized irrigation management.

- Irrigation Equipment Selection & Procurement: Knowledge of various manufacturers, models, and specifications. Ability to evaluate equipment based on performance, cost, and suitability for specific applications.

- Safety Procedures & Regulations: Understanding and adhering to safety protocols related to operating and maintaining irrigation equipment. Familiarity with relevant industry regulations and standards.

- Problem-Solving & Troubleshooting: Demonstrated ability to diagnose and resolve issues in irrigation systems, from minor repairs to major system failures, efficiently and effectively.

Next Steps

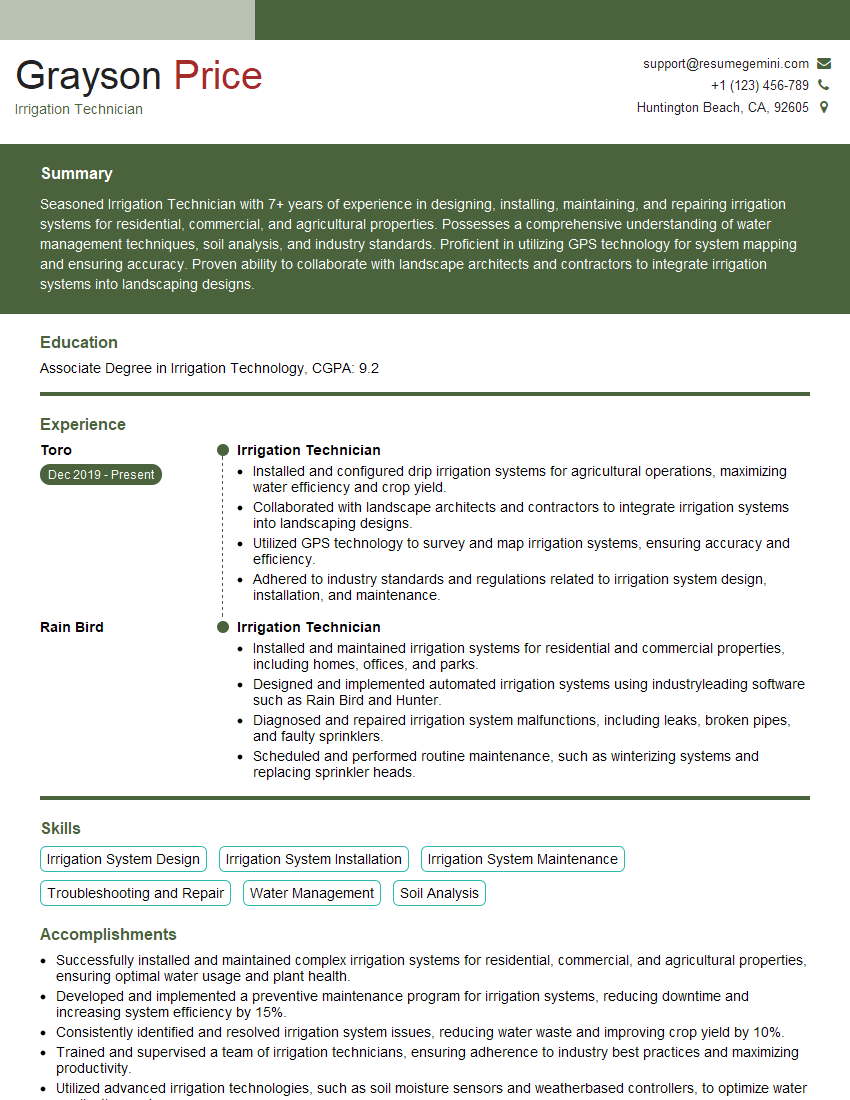

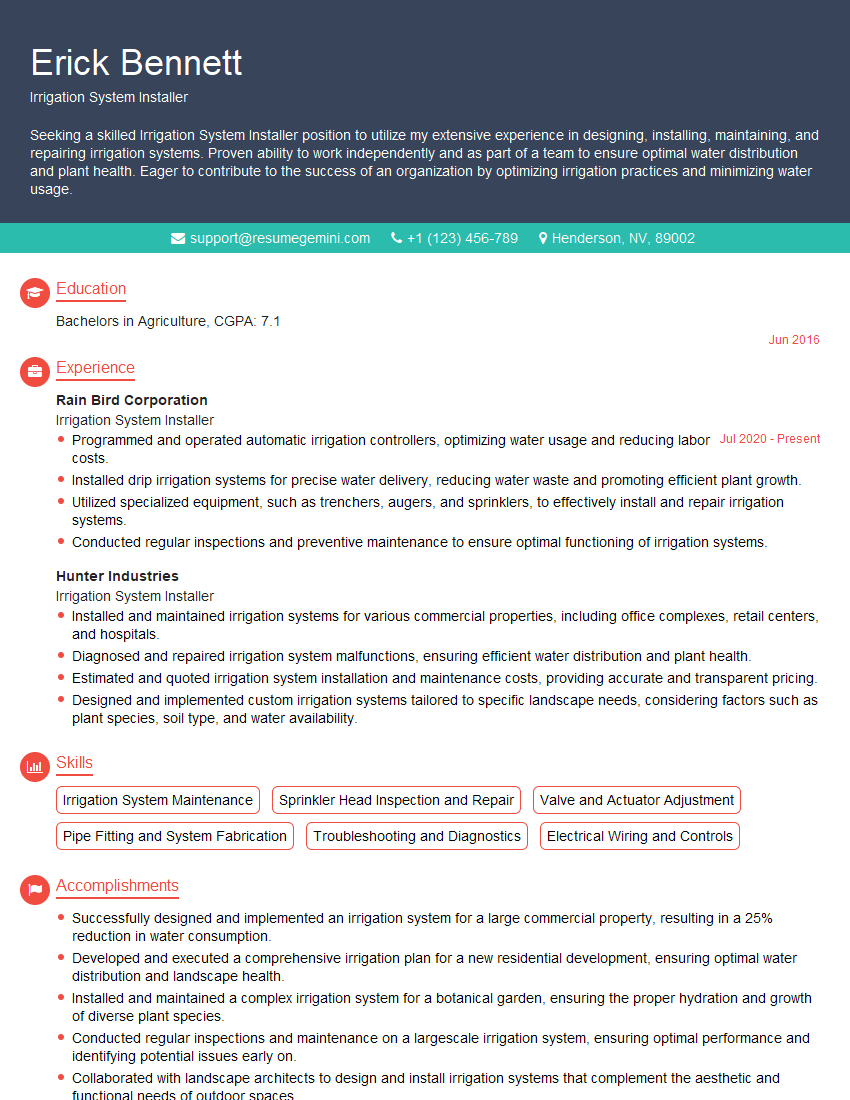

Mastering knowledge of irrigation equipment and systems is crucial for career advancement in this growing field. A strong understanding of these topics demonstrates valuable expertise to potential employers. To maximize your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini can significantly assist you in building a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to the Experience with Irrigation Equipment Manufacturers sector to help you create a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).