Cracking a skill-specific interview, like one for Experience with Oxidizing Materials, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Experience with Oxidizing Materials Interview

Q 1. Explain the different types of oxidation reactions.

Oxidation reactions are chemical processes where a substance loses electrons, resulting in an increase in its oxidation state. There are several types, broadly categorized by the oxidizing agent involved.

- Combustion: This is a rapid oxidation reaction involving oxygen (O2) as the oxidant, often producing heat and light, like the burning of wood (C6H10O5) + O2 → CO2 + H2O).

- Corrosion: This is a slower, electrochemical oxidation process, typically involving metals reacting with their environment, like rusting (Fe + O2 + H2O → Fe2O3·xH2O).

- Biological Oxidation: Enzymes in living organisms facilitate oxidation reactions, essential for metabolism, such as cellular respiration where glucose is oxidized to produce energy.

- Oxidation by other oxidizing agents: Many substances besides oxygen can act as oxidants. For example, potassium permanganate (KMnO4) is a strong oxidizing agent used in various chemical reactions. The oxidation of ethanol (CH3CH2OH) to acetic acid (CH3COOH) by KMnO4 is an example.

Understanding the type of oxidation reaction is crucial for predicting the reaction products and developing effective prevention strategies.

Q 2. Describe the factors that influence the rate of oxidation.

The rate of oxidation is influenced by several interacting factors:

- Temperature: Higher temperatures generally accelerate oxidation reactions because they increase the kinetic energy of the reacting molecules, leading to more frequent and energetic collisions.

- Concentration of reactants: A higher concentration of the oxidizing agent (e.g., oxygen) or the substance being oxidized will increase the rate of reaction, much like adding more fuel to a fire.

- Surface area: A larger surface area exposed to the oxidant increases the rate of oxidation. Think of a finely powdered metal oxidizing much faster than a solid block of the same metal.

- Presence of catalysts: Catalysts speed up chemical reactions without being consumed themselves. Rusting, for example, can be accelerated by the presence of certain impurities in the metal.

- Presence of inhibitors: Inhibitors are substances that slow down or prevent oxidation. These are often used to extend the shelf life of products.

- pH: The acidity or alkalinity of the environment can significantly influence the rate of oxidation. For example, many oxidation reactions proceed faster in acidic conditions.

These factors often interact in complex ways, making accurate prediction of oxidation rates challenging. For instance, a high temperature might offset the effect of a low oxygen concentration to some degree.

Q 3. What are the common methods used to prevent or control oxidation?

Preventing or controlling oxidation involves several strategies:

- Protective Coatings: Applying coatings like paint, varnish, or specialized oxidation-resistant materials creates a barrier that prevents the substance from interacting with the oxidant. This is common in protecting metals from corrosion.

- Inhibitors: Adding chemical inhibitors to the system slows down or stops the oxidation process. These are often used in food preservation and industrial applications.

- Reducing the exposure to oxidants: Storing materials in an inert atmosphere (e.g., nitrogen or argon) minimizes contact with oxygen, a common oxidant.

- Lowering the temperature: Reducing the temperature significantly slows down the rate of oxidation, as seen in refrigeration and freezing techniques for food preservation.

- Modifying the material composition: Alloying metals or using materials inherently resistant to oxidation can enhance their longevity. For example, stainless steel contains chromium which forms a protective oxide layer.

The best method depends on the specific material, application, and cost considerations. Often, a combination of techniques is employed for optimal protection.

Q 4. How do you determine the oxidation state of a metal?

The oxidation state of a metal represents the hypothetical charge it would have if all bonds to atoms of different elements were completely ionic. There are several ways to determine it:

- Using the rules of oxidation numbers: These rules assign oxidation numbers based on electronegativity differences. For example, in NaCl, sodium (Na) has an oxidation state of +1, and chlorine (Cl) has an oxidation state of -1.

- From the known oxidation states of other elements in the compound: If the oxidation states of all other elements in a compound are known, the oxidation state of the metal can be determined by ensuring the overall charge of the compound is zero.

- Using redox reactions: By analyzing the number of electrons gained or lost in a redox reaction involving a metal, its oxidation state can be inferred. For example, in the reaction Fe2+ → Fe3+ + e–, iron’s oxidation state increases from +2 to +3.

Determining the oxidation state is crucial in understanding the chemical behavior of metals and predicting their reactivity in various environments.

Q 5. Explain the difference between oxidation and reduction.

Oxidation and reduction are complementary processes that always occur together in a redox (reduction-oxidation) reaction. They involve the transfer of electrons.

- Oxidation: The loss of electrons by a species. The oxidation state of the species increases.

- Reduction: The gain of electrons by a species. The oxidation state of the species decreases.

Think of it like a seesaw: when one species is oxidized (loses electrons), another species must be reduced (gains those electrons) to balance the equation. For example, in the reaction 2Fe2+ + Cl2 → 2Fe3+ + 2Cl–, iron(II) is oxidized (loses electrons) and chlorine is reduced (gains electrons).

Q 6. What is Pourbaix diagram and its significance in oxidation?

A Pourbaix diagram (also known as a potential-pH diagram) is a graphical representation of the thermodynamically stable phases of an electrochemical system as a function of pH and electrode potential (voltage).

Significance in oxidation: Pourbaix diagrams are incredibly useful for understanding the conditions under which a metal will corrode (oxidize), passivate (form a protective oxide layer), or remain stable. By knowing the pH and electrode potential of a specific environment, one can predict whether a particular metal will be susceptible to oxidation. They are essential in material selection for applications involving corrosive environments.

For instance, a Pourbaix diagram for iron shows the regions of stability for different iron oxides and hydroxides, helping engineers design protective measures against rusting in different conditions (e.g., acidic soil versus alkaline water).

Q 7. Describe various oxidation-resistant coatings and their applications.

Many oxidation-resistant coatings are used to protect materials from degradation. The choice depends heavily on the application and the environment.

- Anodizing: This electrochemical process forms a thick, protective oxide layer on the surface of certain metals, especially aluminum. It’s widely used in aerospace and automotive industries.

- Chromizing: This diffusion process involves coating a metal with chromium, creating a layer resistant to high-temperature oxidation. It finds application in high-temperature components like gas turbine blades.

- Ceramic coatings: Ceramics such as alumina (Al2O3) and zirconia (ZrO2) offer excellent oxidation resistance at high temperatures and are used in thermal barrier coatings for aerospace and energy applications.

- Polymer coatings: Polymers like polyimides and fluoropolymers provide good protection in various environments but may have limitations at very high temperatures.

- Metallization: Coating with oxidation-resistant metals like nickel, chromium, or gold can also provide protection.

Choosing the right coating requires consideration of factors like temperature, exposure to chemicals, cost, and required lifespan.

Q 8. Explain the concept of passivation in oxidation.

Passivation in oxidation is a phenomenon where a thin, stable oxide layer forms on the surface of a metal, protecting the underlying material from further oxidation. Imagine it like a protective shield. This layer acts as a barrier, significantly slowing down or even stopping the oxidation process. The stability of this passive layer depends on several factors, including the metal’s nature, the environment (temperature, oxygen partial pressure), and the oxide’s properties. For instance, stainless steel owes its corrosion resistance to the formation of a chromium oxide passive layer. Without this passive layer, the steel would readily rust.

The formation of a passive layer is often a dynamic process. The oxide layer continually grows and dissolves, reaching a steady-state thickness where the rate of oxide formation equals the rate of dissolution. This self-regulating mechanism ensures continued protection.

Q 9. How do you measure the extent of oxidation in a material?

Measuring the extent of oxidation depends on the material and the level of detail required. Several techniques exist:

- Gravimetric Analysis: This is a straightforward method where the weight gain of the sample after oxidation is measured. The weight increase is directly proportional to the amount of oxygen incorporated into the material. This is a simple, yet powerful method, suitable for many applications.

- Electrochemical Techniques: Techniques like electrochemical impedance spectroscopy (EIS) can be used to assess the oxide layer’s properties and thickness indirectly, determining the extent of oxidation. EIS provides information about the electrical properties of the oxide layer, offering insights into its thickness and protective capabilities.

- X-ray Diffraction (XRD): XRD can identify the phases present in the oxide layer, helping determine the types and amount of oxides formed. This is particularly useful for complex oxidation scenarios where multiple oxide phases might exist.

The choice of method depends on the specific requirements. Gravimetric analysis is ideal for simple systems, whereas more sophisticated techniques like EIS and XRD provide in-depth information about the nature and extent of oxidation.

Q 10. Discuss different techniques for characterizing oxidized surfaces.

Characterizing oxidized surfaces involves a range of techniques providing different aspects of the oxidized layer:

- Scanning Electron Microscopy (SEM): Provides high-resolution images of the surface morphology, revealing the oxide layer’s microstructure, thickness, and any surface defects.

- Transmission Electron Microscopy (TEM): Offers even higher resolution imaging, enabling detailed analysis of the oxide layer’s crystal structure, defects, and interfaces.

- X-ray Photoelectron Spectroscopy (XPS): Determines the chemical composition and bonding states of elements in the oxide layer, providing valuable information about the oxidation states and the types of oxides present.

- Auger Electron Spectroscopy (AES): Similar to XPS, but with higher spatial resolution, ideal for analyzing compositional variations across the oxide layer’s thickness.

- Rutherford Backscattering Spectrometry (RBS): A non-destructive technique used to determine the depth profile of elements in the oxide layer, offering quantitative information about the oxide’s composition as a function of depth.

Often, a combination of techniques is used to gain a comprehensive understanding of the oxidized surface. For example, SEM can provide a general overview of the surface morphology, while XPS can reveal its chemical composition.

Q 11. What are the effects of high-temperature oxidation on material properties?

High-temperature oxidation significantly impacts material properties. The formation of oxide scales can lead to:

- Weight gain: As oxygen atoms integrate into the material’s structure, the overall weight increases.

- Dimensional changes: Oxide formation can cause dimensional changes (e.g., expansion or contraction), leading to warping or cracking of the material.

- Reduced ductility and toughness: Oxide scales can make the material brittle and less resistant to fracture.

- Decreased strength: The formation of brittle oxide layers can weaken the underlying material.

- Altered thermal properties: The oxide layer might change the material’s thermal conductivity and thermal expansion coefficients.

- Changes in electrical conductivity: Depending on the type of oxide formed, electrical conductivity can either increase or decrease.

Consider turbine blades in a jet engine: high-temperature oxidation can severely compromise their structural integrity and performance, leading to premature failure if not properly addressed through protective coatings.

Q 12. Describe the challenges associated with high-temperature oxidation.

High-temperature oxidation presents several challenges:

- Scale spallation: Oxide scales can crack and detach from the substrate, exposing fresh material to further oxidation. This can lead to catastrophic failure in high-stress environments.

- Pesting: This refers to a severe form of oxidation that causes a rapid deterioration of the material’s surface, characterized by extensive cracking and powder formation.

- Internal oxidation: Oxygen can diffuse into the material, causing internal oxidation and weakening of the bulk material, beyond the surface scale.

- Complex oxide formation: The formation of multiple oxide phases can make understanding and predicting oxidation behavior complex, making it difficult to control the process.

- Designing suitable protection strategies: Developing cost-effective and long-lasting protective coatings or alloys capable of withstanding high-temperature oxidation is a considerable challenge.

These challenges necessitate careful material selection, design optimization, and the implementation of protective measures to ensure material integrity and operational reliability at high temperatures.

Q 13. Explain the role of diffusion in oxidation processes.

Diffusion plays a crucial role in oxidation processes. It is the movement of atoms or ions through the material’s structure. In oxidation, oxygen atoms from the environment must diffuse through the oxide layer to reach the metal surface, and metal atoms from the substrate must diffuse outward to react with oxygen and form the oxide. This dual diffusion process governs the rate of oxidation.

Think of it like this: Imagine the oxide layer is a crowded street. Oxygen atoms are trying to reach the metal (a destination), while metal atoms are trying to move to the surface (another destination). The rate at which these atoms move through the ‘street’ (diffuse) dictates how quickly oxidation occurs. The diffusion rates are influenced by temperature, the oxide layer’s structure, and the presence of defects.

The rate-limiting step in oxidation is often the diffusion of the slowest-moving species. Understanding diffusion kinetics is critical for predicting and controlling oxidation behavior.

Q 14. How do you interpret oxidation kinetics data?

Oxidation kinetics data is often expressed using empirical relationships like the parabolic, linear, or logarithmic rate laws. These laws describe how the oxide layer’s thickness changes over time.

- Parabolic rate law: Indicates that the oxidation rate decreases with time, as the growing oxide layer acts as a diffusion barrier. This is common for protective oxide layers.

- Linear rate law: Suggests a constant oxidation rate over time, usually indicating a non-protective oxide layer.

- Logarithmic rate law: Represents a very slow oxidation rate, often associated with the formation of very thin, protective oxide films.

By plotting the oxide thickness or weight gain against time, you can determine the kinetics. The slope and shape of the curve reveal which rate law is applicable. The activation energy can be determined by performing experiments at different temperatures, using Arrhenius plots. This provides valuable insights into the oxidation mechanism and allows for predictions about the oxidation behavior at different temperatures and times.

The interpretation of kinetics data is critical for material selection and designing oxidation-resistant components for various applications such as gas turbines, aerospace components, and high-temperature reactors.

Q 15. What are the common analytical techniques used to study oxidation?

Studying oxidation requires a multifaceted approach, employing various analytical techniques to understand the process’s kinetics and mechanisms. These techniques can be broadly categorized into those that examine the surface and those that probe the bulk material.

Surface Analysis Techniques: These focus on characterizing the oxide layer formed on the material’s surface. Examples include:

- X-ray Photoelectron Spectroscopy (XPS): Provides information on the elemental composition and chemical states of the surface atoms. It’s invaluable for identifying the types of oxides formed and their thicknesses.

- Auger Electron Spectroscopy (AES): Similar to XPS, but often offers better spatial resolution, enabling the study of oxide layer variations across the surface.

- Scanning Electron Microscopy (SEM): Provides high-resolution images of the surface morphology, revealing details about the oxide layer’s structure, such as its thickness, porosity, and cracking.

- Ellipsometry: A non-destructive optical technique used to measure the thickness and refractive index of thin films, including oxide layers. This helps to quantify the oxidation process.

Bulk Analysis Techniques: These methods provide information on the changes in the material’s bulk composition and microstructure due to oxidation. Examples include:

- Thermogravimetric Analysis (TGA): Measures the weight change of a material as a function of temperature or time during oxidation. This directly reflects the amount of oxygen uptake.

- Differential Scanning Calorimetry (DSC): Detects heat flow associated with phase transitions and chemical reactions, including oxidation reactions. It provides information about the kinetics of the process.

- Transmission Electron Microscopy (TEM): Allows for high-resolution imaging of the microstructure, including the observation of oxide precipitates within the bulk material.

The choice of technique depends on the specific research question, the material being studied, and the resources available. Often, a combination of techniques is employed to obtain a complete understanding of the oxidation process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of oxidation resistance in alloys.

Oxidation resistance in alloys refers to their ability to withstand the effects of oxidation at high temperatures. This is crucial for applications involving high-temperature environments, such as gas turbines, jet engines, and furnace components. The resistance is determined by the alloy’s composition and microstructure.

Certain alloying elements significantly improve oxidation resistance. For example, chromium (Cr) forms a protective chromium oxide (Cr2O3) layer on the surface. This layer acts as a diffusion barrier, preventing further oxygen from reaching the underlying metal and slowing down the oxidation process. Other elements like aluminum (Al), silicon (Si), and titanium (Ti) also contribute to the formation of protective oxide layers.

The microstructure also plays a role. A fine-grained microstructure generally exhibits better oxidation resistance than a coarse-grained one because the finer grain boundaries provide more pathways for the diffusion of oxygen. Furthermore, the presence of precipitates can either enhance or hinder oxidation resistance, depending on their nature and distribution.

Imagine a stainless steel utensil in your kitchen. The chromium in the steel forms a passive layer that protects it from rusting (oxidation). This is a simple example of oxidation resistance in action.

Q 17. How do you select appropriate materials for oxidation-prone environments?

Selecting materials for oxidation-prone environments necessitates careful consideration of several factors. The most crucial step is identifying the specific operating conditions, including temperature, atmosphere (oxidizing agents present), and the desired service life.

1. Temperature: Higher temperatures generally accelerate oxidation. The choice of material must consider the maximum operating temperature and the acceptable rate of oxidation at that temperature.

2. Atmosphere: The nature of the oxidizing agent(s) present significantly impacts the choice of material. For example, materials resistant to oxidation in air may not be suitable for high-pressure oxygen environments. Understanding the partial pressures of oxygen, water vapor, and other reactive species is critical.

3. Service Life: The required service life dictates the allowable oxidation rate. For long-term applications, a material with exceptionally high oxidation resistance is needed.

4. Material Properties: Beyond oxidation resistance, other material properties such as strength, ductility, and cost need to be considered. The selected material must meet all the design requirements for the specific application.

Selection Strategy: A common approach is to consult material property databases and handbooks to identify candidate materials based on their known oxidation resistance under similar operating conditions. Laboratory testing may then be necessary to verify the performance under the actual service conditions.

Example: For a high-temperature gas turbine component operating at 1000°C in air, a nickel-based superalloy with high chromium content would likely be selected due to its exceptional high-temperature oxidation resistance. In contrast, a less demanding application might utilize a more cost-effective stainless steel.

Q 18. Describe different types of corrosion related to oxidation.

Oxidation-related corrosion encompasses several types, differing in their mechanisms and appearance:

Uniform Oxidation: This is the most common type, where a relatively uniform oxide layer forms on the metal surface. The rate of oxidation is typically controlled by the diffusion of either oxygen or metal ions through the oxide layer. This is what often happens with aluminum forming its protective aluminum oxide layer.

Selective Oxidation: This occurs when one component of an alloy oxidizes preferentially, leading to the formation of islands or precipitates of the oxide. For instance, in a stainless steel, chromium might oxidize preferentially, creating a protective chromium oxide layer.

Pesting: This is a form of accelerated oxidation that manifests as a rapid disintegration of the metal surface, forming a porous and flaky oxide layer. It’s typically associated with specific alloy compositions and environmental conditions.

Internal Oxidation: Unlike surface oxidation, internal oxidation occurs when oxygen diffuses into the metal’s bulk, leading to the formation of oxide precipitates within the grain structure. This weakens the material.

High-Temperature Corrosion: This involves oxidation reactions that are accelerated by the presence of aggressive gases, such as sulfur oxides or chlorides, in addition to oxygen. This type of corrosion can be severely damaging.

Understanding the specific type of corrosion is critical for implementing effective prevention and mitigation strategies. The chosen approach may involve selecting a more resistant material, modifying the environment, or applying protective coatings.

Q 19. What are the safety precautions when working with oxidizing materials?

Working with oxidizing materials requires strict adherence to safety protocols to prevent accidents and injuries. These precautions include:

Proper Ventilation: Many oxidation reactions release harmful gases. Adequate ventilation is essential to prevent their accumulation and inhalation.

Personal Protective Equipment (PPE): This should include safety glasses, gloves, lab coats, and respirators, depending on the specific materials and processes involved. The choice of PPE should be determined by a thorough risk assessment.

Fire Prevention: Oxidizing materials can often accelerate combustion. Flammable materials should be kept away, and appropriate fire extinguishers should be readily available. This is especially important when working with strong oxidizers.

Safe Handling Procedures: Materials should be handled carefully to prevent spills or accidents. Spills should be cleaned up immediately, using appropriate procedures. Always consult the Safety Data Sheets (SDS) for detailed handling instructions.

Emergency Response Plan: A comprehensive emergency response plan should be in place, outlining procedures for handling spills, fires, or other emergencies.

Remember, familiarity with the specific hazards associated with each oxidizing material is crucial for ensuring a safe working environment.

Q 20. Explain the concept of thermal oxidation.

Thermal oxidation refers to the oxidation of a material caused by exposure to high temperatures in an oxidizing atmosphere. It’s a significant concern in many high-temperature applications, as the rate of oxidation increases exponentially with temperature. The process involves the diffusion of oxygen atoms into the material’s surface and the subsequent reaction with the metal atoms to form an oxide layer.

Mechanism: The process can be explained in terms of the Wagner model, which considers the diffusion of metal cations and oxygen anions through the oxide layer. The rate of oxide growth is often dictated by the slower-moving species. The growth kinetics can often be described by parabolic, logarithmic, or linear laws depending on the conditions and materials involved.

Applications: Thermal oxidation is intentionally used in some processes, such as the formation of silicon dioxide (SiO2) layers on silicon wafers in semiconductor manufacturing. This SiO2 layer acts as an insulator and protects the underlying silicon. However, in many other applications, thermal oxidation is an undesirable phenomenon that leads to material degradation and component failure.

Mitigation: Several approaches can mitigate thermal oxidation. These include alloying the base material with elements that form protective oxide layers, applying protective coatings, or controlling the atmosphere to reduce the oxygen partial pressure.

Q 21. Discuss the environmental impact of oxidation processes.

Oxidation processes, while natural and essential in some contexts, can have significant environmental impacts, both positive and negative:

Greenhouse Gas Emissions: Combustion processes, which involve oxidation, release greenhouse gases like carbon dioxide (CO2) into the atmosphere, contributing to climate change. The burning of fossil fuels is a prime example.

Air Pollution: Incomplete combustion or oxidation of fuels can release various pollutants into the air, including particulate matter, nitrogen oxides (NOx), and sulfur oxides (SOx), harming air quality and human health.

Water Pollution: Oxidation processes can generate various byproducts that can contaminate water sources if not managed properly. Industrial wastewater often contains oxidized materials that necessitate treatment before disposal.

Waste Generation: Oxidation processes in many industrial applications create waste products, including spent catalysts, slag, and other residues, that require proper handling and disposal to minimize environmental impact.

Material Degradation: The oxidation of infrastructure materials such as steel bridges and pipelines can lead to structural weakening and premature failure, requiring costly repairs and replacement, which have their own environmental cost.

Sustainable practices are needed to mitigate the negative impacts of oxidation processes. This includes developing cleaner combustion technologies, improving waste management practices, utilizing more environmentally benign materials, and optimizing process parameters to minimize pollution.

Q 22. How do you mitigate oxidation-related failures in products?

Mitigating oxidation-related failures in products requires a multi-pronged approach focusing on material selection, design, and environmental control. Think of it like protecting a piece of iron from rust – you need to shield it from the elements.

Material Selection: Choosing inherently oxidation-resistant materials is the first line of defense. For instance, using stainless steel instead of mild steel in a corrosive environment significantly reduces oxidation. Similarly, applying protective coatings like anodizing on aluminum creates a barrier against oxygen and moisture.

Design Considerations: Proper design minimizes areas susceptible to oxidation. Sharp corners and crevices trap moisture and accelerate corrosion, so smooth surfaces and good drainage are crucial. Consider using sealed components to prevent oxygen ingress.

Environmental Control: Controlling the environment can dramatically reduce oxidation rates. This includes reducing temperature (oxidation is often temperature-dependent), controlling humidity levels, and eliminating aggressive chemicals or pollutants from the surrounding atmosphere. Think of museum-quality preservation techniques.

Protective Coatings: Applying various coatings like paints, polymers, or metallic coatings adds an extra layer of protection against oxygen and moisture. The choice depends heavily on the application and the material being protected.

Inhibitors: Adding oxidation inhibitors to the material or surrounding environment can significantly slow down the oxidation process. We’ll discuss this further in the next question.

Q 23. Explain the use of inhibitors to prevent oxidation.

Oxidation inhibitors are substances that, when added in small quantities, significantly slow down or prevent oxidation. They work through various mechanisms, often by forming a protective layer on the material’s surface or by chemically reacting with the oxidizing agent before it can attack the material.

Sacrificial Anodes: These are more reactive metals, such as zinc or magnesium, added to a system to preferentially oxidize. Think of it as a bodyguard – the zinc or magnesium corrodes instead of the protected metal. This is commonly used in cathodic protection systems for pipelines and ships.

Chemical Inhibitors: These are chemicals added directly to the environment or incorporated into the material to slow down oxidation. For example, certain organic compounds can form a protective film on metal surfaces, preventing oxygen access.

Passivating Agents: These substances create a passive layer on the metal surface that resists further oxidation. For instance, chromates were historically used as passivators in many industrial applications, but their toxicity necessitates more environmentally friendly alternatives.

Choosing the right inhibitor depends heavily on factors such as material composition, temperature, and the specific oxidizing environment. Incorrect selection might lead to unwanted side effects or ineffectiveness.

Q 24. Describe different types of oxidation testing methods.

Several methods exist to test a material’s oxidation resistance, each designed to simulate specific conditions. The choice depends heavily on the application and desired level of detail.

Thermogravimetric Analysis (TGA): This measures weight changes in a material as a function of temperature in a controlled atmosphere. It’s very useful for determining oxidation kinetics and activation energies.

Differential Scanning Calorimetry (DSC): This technique monitors the heat flow associated with oxidation. It can help identify oxidation onset temperatures and reaction enthalpies.

Accelerated Oxidation Testing: Methods like salt spray testing (ASTM B117) simulate harsh environments to accelerate corrosion and assess the material’s resistance more quickly. This is particularly relevant for coatings.

Cyclic Oxidation Testing: These tests expose materials to repeated cycles of high-temperature oxidation and cooling. This evaluates the material’s long-term resistance, especially crucial for high-temperature applications in power plants or aerospace industries.

Electrochemical Methods: Techniques like potentiodynamic polarization and electrochemical impedance spectroscopy are used to measure the corrosion rate and understand the electrochemical mechanisms driving oxidation. We’ll explore these further later.

Q 25. How can you improve the oxidation resistance of a material?

Improving oxidation resistance hinges on altering material properties to make them less susceptible to attack by oxygen. This can be achieved through various techniques:

Alloying: Adding alloying elements can significantly improve oxidation resistance. For example, adding chromium to iron forms stainless steel, vastly superior to plain carbon steel in oxidation resistance.

Surface Modification: Creating a protective surface layer can significantly enhance oxidation resistance. This can be achieved through methods like nitriding, carburizing, or applying coatings.

Thermal Treatment: Heat treating can alter the microstructure of a material, potentially enhancing its oxidation resistance. For example, controlled cooling rates can refine grain size, making it less susceptible to corrosion.

Controlled Atmosphere Processing: Performing processing steps in controlled atmospheres (e.g., inert gases like argon or nitrogen) can minimize oxidation during manufacturing.

Q 26. Explain the application of oxidation in various industrial processes.

Oxidation, while often viewed as a detrimental process, finds crucial applications in various industrial processes:

Metal Refining: Oxidation is used in processes like roasting to remove impurities from ores and convert them into usable forms.

Chemical Synthesis: Many chemical synthesis reactions rely on oxidation as a key step, for example, in producing chemicals used in pharmaceuticals and plastics.

Wastewater Treatment: Advanced oxidation processes are employed to degrade pollutants in wastewater through reactions with powerful oxidizing agents.

Catalysis: Oxidation reactions are essential in catalytic converters in vehicles, where they convert harmful pollutants into less harmful substances.

Combustion: Combustion engines rely on oxidation reactions to release energy from fuels.

Q 27. Describe the use of electrochemical methods to study oxidation.

Electrochemical methods provide powerful tools to study oxidation, giving insights into the processes at the atomic level. These methods usually involve immersing the material in an electrolyte and applying a potential difference.

Potentiodynamic Polarization: This technique measures the current as a function of applied potential. The resulting polarization curve provides valuable information on corrosion rates, passivation behavior, and breakdown potentials.

Electrochemical Impedance Spectroscopy (EIS): EIS measures the impedance of a system as a function of frequency. The resulting data can be analyzed to determine the various components contributing to the oxidation process, such as the oxide film resistance and capacitance.

Linear Polarization Resistance (LPR): A simpler technique than EIS, LPR measures the polarization resistance near the corrosion potential to estimate the corrosion rate.

These techniques allow scientists to quantify oxidation rates, understand the mechanisms involved, and develop effective corrosion protection strategies. They’re especially valuable for studying localized corrosion phenomena like pitting or crevice corrosion.

Q 28. What are the challenges in modeling oxidation processes?

Modeling oxidation processes presents significant challenges due to the complexity of the underlying mechanisms. Accurate modeling demands a deep understanding of various aspects:

Multiscale Phenomena: Oxidation processes occur across multiple length scales, from atomic diffusion to macroscopic material degradation. Bridging these scales in a single model is a major hurdle.

Complex Chemistry: Oxidation reactions often involve multiple species and intermediate products, requiring a detailed understanding of the chemistry involved. The reaction pathways can be extremely intricate.

Material Heterogeneity: Real-world materials are seldom homogenous; variations in composition and microstructure significantly influence oxidation behavior. Capturing these effects in the models can be challenging.

Environmental Factors: External factors like temperature, humidity, and the presence of aggressive chemicals significantly impact oxidation rates. These variables must be accurately incorporated into the model.

Despite these challenges, advancements in computational capabilities and improved understanding of oxidation mechanisms are continually improving the accuracy and predictive power of oxidation models.

Key Topics to Learn for Experience with Oxidizing Materials Interview

- Oxidation Mechanisms: Understanding various oxidation processes (e.g., high-temperature oxidation, electrochemical corrosion) and their underlying kinetics.

- Material Selection and Design: Choosing materials with appropriate oxidation resistance for specific applications (e.g., high-temperature alloys, coatings).

- Environmental Factors: Analyzing the influence of temperature, pressure, and atmosphere composition on oxidation behavior.

- Practical Applications: Discussing real-world examples where understanding oxidation is crucial (e.g., aerospace components, power generation, chemical processing).

- Oxidation Kinetics and Modeling: Familiarity with rate laws, diffusion processes, and the use of modeling techniques to predict oxidation behavior.

- Corrosion Prevention Strategies: Understanding and applying techniques like protective coatings, inhibitors, and alloying to mitigate oxidation.

- Characterization Techniques: Knowledge of analytical methods used to assess oxidation (e.g., microscopy, X-ray diffraction, weight gain measurements).

- Problem-Solving Approach: Demonstrating the ability to troubleshoot oxidation-related issues and propose effective solutions.

- Case Studies: Reviewing past oxidation failures and success stories to gain practical insights.

Next Steps

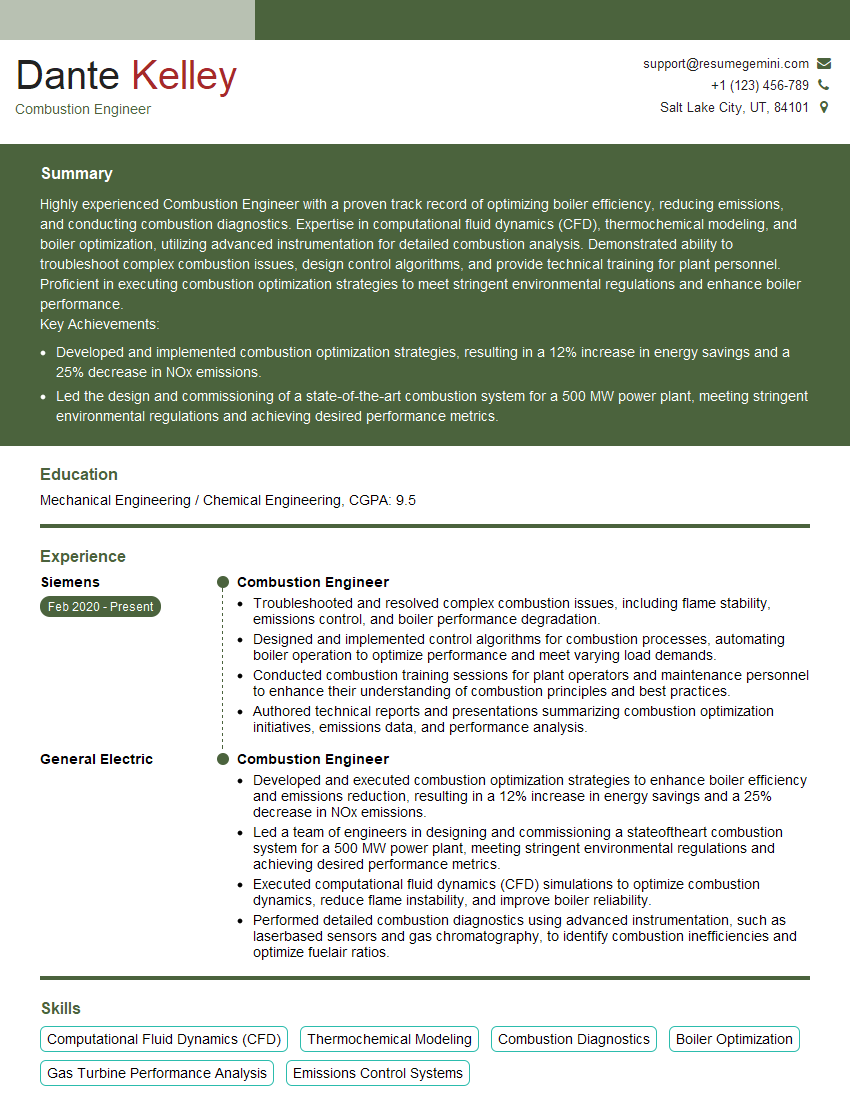

Mastering the complexities of oxidizing materials is vital for career advancement in numerous high-demand fields. A strong understanding of oxidation processes and mitigation strategies sets you apart as a highly skilled and sought-after candidate. To maximize your job prospects, focus on crafting an ATS-friendly resume that effectively showcases your expertise. ResumeGemini can be a valuable tool in this process, helping you build a professional and impactful resume that highlights your capabilities. We provide examples of resumes tailored to showcasing experience with oxidizing materials to help guide your efforts.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good