The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Experience with robotics interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Experience with robotics Interview

Q 1. Explain the difference between kinematics and dynamics in robotics.

In robotics, kinematics and dynamics are crucial concepts describing a robot’s movement. Kinematics deals solely with the geometry of motion – the relationship between joint angles and the robot’s end-effector position and orientation, without considering forces or torques. Think of it like studying the path of a ball thrown through the air, ignoring gravity and air resistance. Dynamics, on the other hand, incorporates forces, torques, and inertia into the motion equation. This means it accounts for how forces affect the robot’s movement. It’s like considering gravity and air resistance when analyzing the ball’s trajectory. Kinematics is simpler to solve but less realistic; dynamics provides a more accurate, albeit complex, model for robot control.

Example: In kinematics, we might calculate the angles required at each joint of a robotic arm to reach a specific point in space. In dynamics, we would also consider the forces and torques needed to move the arm at a desired speed and acceleration, accounting for the mass of each link and any external forces acting on the arm, such as gravity.

Q 2. Describe different robot manipulator architectures (e.g., articulated, SCARA, delta).

Robot manipulators come in various architectures, each best suited for different tasks. Here are some key examples:

- Articulated Robots: These are the most common type, resembling a human arm with several rotary joints. They offer a large workspace and flexibility, making them versatile for a wide range of applications. Think of industrial robots used in assembly lines.

- SCARA (Selective Compliance Assembly Robot Arm): These robots are characterized by two parallel rotary joints that provide compliance in the horizontal plane and rigidity in the vertical direction. This makes them ideal for assembly tasks requiring precise horizontal movements, like inserting components into a circuit board.

- Delta Robots: These robots have three arms connected to a common base, each with a rotary joint. They are known for their high speed and precision, typically found in fast-paced applications like pick-and-place operations in food packaging or electronics manufacturing.

- Cartesian Robots (Gantry Robots): These robots use three linear axes of movement (X, Y, Z) to position their end-effector. They’re often found in applications needing precise positioning along straight lines, such as CNC machining or 3D printing.

The choice of architecture depends on factors such as workspace requirements, payload capacity, speed, accuracy, and the specific application.

Q 3. What are the common types of robot sensors and their applications?

Robot sensors provide critical feedback for accurate and safe operation. Common types include:

- Proximity Sensors: Detect the presence of objects without physical contact. Examples include ultrasonic, infrared, and capacitive sensors. Applications include collision avoidance and object detection in automated guided vehicles (AGVs).

- Force/Torque Sensors: Measure the forces and torques applied to the robot’s end-effector. Used for tasks requiring delicate manipulation, such as assembly or surgery.

- Vision Systems (Cameras): Provide visual input to the robot, enabling it to perceive its environment and objects within it. Applications include object recognition, navigation, and quality inspection.

- Encoders (Joint Sensors): Measure the position and sometimes velocity of robot joints. Essential for precise control of robot movement.

- IMU (Inertial Measurement Unit): Measures orientation and acceleration. Used for robot localization and navigation, particularly in mobile robots.

- Laser Scanners (LIDAR): Create a 3D map of the robot’s surroundings. Used in autonomous navigation and mapping applications.

Sensor selection depends on the task; a surgical robot would need force/torque sensors, while an autonomous vehicle would rely heavily on LIDAR and cameras.

Q 4. Explain the concept of forward and inverse kinematics.

Forward and inverse kinematics are fundamental concepts in robot manipulation.

- Forward Kinematics: This involves calculating the end-effector’s position and orientation given the values of all the joint angles. It’s a straightforward process, typically involving matrix transformations. Think of it as knowing the joint angles and determining where the robot’s hand ends up.

- Inverse Kinematics: This is the inverse problem – determining the required joint angles to achieve a desired end-effector pose (position and orientation). This is significantly more challenging than forward kinematics and often requires iterative numerical solutions because it is a nonlinear problem. Think of it as knowing where you want the robot’s hand to be and finding out which joint angles will get it there.

Example: Imagine a robotic arm with three joints. Forward kinematics would take the three joint angles as input and calculate the coordinates of the hand. Inverse kinematics would take the desired hand coordinates and calculate the three joint angles needed to reach that position. Inverse kinematics solutions can be multiple, requiring further criteria to determine which is most desirable in a particular application (such as shortest path or avoiding joint limits).

Q 5. How do you calibrate a robotic arm?

Calibrating a robotic arm ensures accurate and repeatable movements. The process involves several steps:

- Geometric Calibration: This determines the precise physical parameters of the robot, such as link lengths, joint offsets, and the location of the end-effector relative to the joints. This often involves using a measurement device like a laser tracker to precisely determine the locations of markers fixed to the robot.

- Kinematic Calibration: This refines the kinematic model to match the actual robot’s behavior. This typically involves collecting data by moving the arm to various poses and comparing the measured end-effector position with the position predicted by the kinematic model. Adjustments are then made to the model parameters to reduce discrepancies.

- Sensor Calibration: Ensures that the sensors (e.g., encoders, force sensors) provide accurate measurements. This may involve comparing the sensor readings to known values, possibly using high-precision devices as a reference.

Advanced techniques such as optimization algorithms are commonly used to fine-tune the parameters based on the collected data. The goal is to minimize errors between the commanded and actual positions and orientations of the robot during operation. The calibration process often involves sophisticated software and tools, making it a task best performed by trained technicians.

Q 6. Describe different robot control architectures (e.g., joint-space, task-space).

Robot control architectures determine how a robot’s motion is planned and executed. Two common approaches are:

- Joint-Space Control: This approach focuses on controlling the individual joint angles of the robot. Each joint is treated independently and its position is controlled directly. It’s simpler to implement but might result in less optimal overall motion for complex tasks. Think of it as controlling each joint’s angle individually, even though this might result in more awkward movements than necessary.

- Task-Space Control: This approach involves controlling the end-effector’s position and orientation directly, with the joint angles calculated automatically by the inverse kinematics algorithm. This results in more intuitive and natural motion, especially for complex tasks involving interactions with the environment. Think of instructing the robot to “pick up that object”, and the control system figures out how to manipulate the joints to do so.

Often, a hybrid approach combining both methods is used to leverage the advantages of each.

Q 7. Explain the role of PID controllers in robotics.

PID (Proportional-Integral-Derivative) controllers are widely used in robotics for precise position and velocity control. They are feedback controllers that compare the desired value (setpoint) to the actual value (measured by sensors) and adjust the control signal accordingly. The controller has three terms:

- Proportional (P): The output is proportional to the error (difference between setpoint and actual value). A larger error leads to a larger control signal.

- Integral (I): The output is proportional to the integral of the error over time. This compensates for persistent errors, such as a constant external force acting on the robot.

- Derivative (D): The output is proportional to the rate of change of the error. This helps to dampen oscillations and improve stability.

By tuning the gains (proportional, integral, and derivative gains – Kp, Ki, Kd), the controller’s responsiveness and stability can be adjusted. The PID controller’s structure is fairly simple, yet incredibly effective in controlling robot joint angles and achieving desired motion.

Example: In controlling a robot arm’s joint angle, the PID controller would continuously monitor the actual angle, compare it to the desired angle, and adjust the motor’s torque to minimize the error. The I term ensures the robot ultimately reaches the target, while the D term prevents overshooting and oscillations.

Q 8. What are the challenges of implementing real-time control in robotics?

Real-time control in robotics demands immediate responses to sensor inputs and environmental changes. The challenge lies in the inherent limitations of computing power and the need for deterministic behavior. Imagine a robot arm needing to catch a falling object – delays, even fractions of a second, can mean failure. The major challenges include:

- Computational constraints: Real-time algorithms need to complete their calculations within strict time deadlines. Complex control systems often require significant processing power, making it challenging to achieve real-time performance on limited-resource robots.

- Sensor latency and noise: Sensors provide information with inherent delays and inaccuracies. This noisy data needs to be processed and filtered effectively to prevent erroneous control actions.

- Actuator dynamics: Robot actuators (motors, etc.) have their own response times and limitations. The control system must account for these to accurately follow desired trajectories.

- Unpredictable environments: Real-world environments are rarely perfectly known. Unexpected obstacles or disturbances can require quick adaptations in control strategy, posing significant challenges for real-time systems.

Overcoming these challenges often involves using efficient algorithms, optimized hardware, and robust control techniques such as model predictive control (MPC) or advanced Kalman filtering for state estimation.

Q 9. How do you handle sensor noise and uncertainty in robot control?

Sensor noise and uncertainty are pervasive issues in robotics. Think of it like trying to navigate a city with a slightly blurry map – you’ll still get to your destination, but with some uncertainty. We address this using several strategies:

- Filtering techniques: Kalman filters and their variants are commonly employed to estimate the true sensor values by considering the noise characteristics. They essentially predict the state and update it with noisy measurements, minimizing the impact of noise.

- Sensor fusion: Combining data from multiple sensors (e.g., cameras, lidar, IMUs) provides redundancy and improves overall accuracy. If one sensor is unreliable, data from others can compensate.

- Robust control design: Control algorithms are designed to be tolerant to sensor uncertainties. For example, using feedback control allows the robot to correct deviations from the desired path based on actual sensor measurements, even if they’re noisy.

- Probabilistic approaches: Representing uncertainty using probability distributions (e.g., Gaussian distributions) allows for a more realistic model of the robot’s state and environment. This is crucial in areas like simultaneous localization and mapping (SLAM).

For example, in a self-driving car, sensor fusion from lidar, radar, and cameras is vital for robust obstacle detection and path planning, even in adverse weather conditions.

Q 10. Describe different path planning algorithms used in robotics.

Path planning algorithms determine collision-free paths for robots to move from a starting point to a goal. Imagine planning a road trip – you wouldn’t just drive randomly; you’d use a map and plan your route. Several algorithms exist:

- A* search: A graph-search algorithm that finds the optimal path considering both distance and cost (heuristic). It’s widely used due to its efficiency and optimality guarantees.

- Dijkstra’s algorithm: Another graph-search algorithm, but it finds the shortest path without considering heuristics, making it suitable for situations where the cost is uniform.

- Rapidly-exploring Random Trees (RRT): A sampling-based algorithm particularly effective in high-dimensional spaces or environments with complex obstacles. It randomly samples configurations and connects them to form a tree, eventually reaching the goal.

- Potential field methods: These methods create a potential field where the robot is attracted to the goal and repelled by obstacles. The resulting gradient guides the robot along a path.

The choice of algorithm depends on the specific application and environmental constraints. For example, A* is suitable for static environments with known obstacles, while RRT is better suited for dynamic environments or complex robotic manipulators.

Q 11. Explain the concept of collision avoidance in robotics.

Collision avoidance ensures a robot safely navigates its environment without colliding with obstacles. It’s crucial for safety and task completion. Techniques range from simple geometric checks to sophisticated machine learning approaches.

- Geometric methods: These involve creating representations of the robot and obstacles (e.g., bounding boxes, polygons) and checking for overlaps. Simple, but can be computationally expensive for complex shapes and environments.

- Sensor-based methods: Using sensors (lidar, ultrasound, cameras) to detect obstacles in real-time. This allows for reactive collision avoidance, adjusting the robot’s path based on immediate sensory information.

- Artificial potential fields: As mentioned in path planning, repelling forces from obstacles help to steer the robot away from collisions.

- Reactive control: Simple rules or reflexes are used to react to imminent collisions. This is often combined with higher-level path planning.

- Machine learning-based methods: Training models (e.g., neural networks) on large datasets of obstacle avoidance scenarios can enable the robot to learn complex and robust avoidance behaviors.

In a warehouse setting, a robot navigating among shelves would use a combination of geometric planning (pre-planned paths) and sensor-based reactive control to avoid unexpected obstacles or humans.

Q 12. What are some common robot programming languages?

Several languages are used for robot programming, each with its strengths and weaknesses:

- ROS (Robot Operating System): Not strictly a language, but a framework that provides tools and libraries for robot software development. It uses C++, Python, and other languages.

- C++: Often used for low-level control and performance-critical applications due to its speed and efficiency.

- Python: Popular for its ease of use, extensive libraries (e.g., NumPy, SciPy), and suitability for higher-level tasks like planning and perception.

- MATLAB: Widely used in robotics research and prototyping for its strong mathematical capabilities and simulation tools.

- URScript: A specific language for Universal Robots (UR) collaborative robots.

The choice depends on the project requirements and the programmer’s expertise. For example, C++ might be preferred for real-time control, while Python might be better for developing algorithms and simulations.

Q 13. Explain the difference between supervised, unsupervised, and reinforcement learning in robotics.

These are different approaches to training robots using machine learning:

- Supervised learning: The robot is trained on a labeled dataset, where each input is paired with a desired output. For example, showing the robot many images of objects with their labels helps it learn object recognition. This is like teaching a child by showing them examples and telling them what each example is.

- Unsupervised learning: The robot learns patterns from unlabeled data. For example, clustering similar movements or exploring an environment without explicit instructions. This is analogous to letting a child explore and discover patterns on their own.

- Reinforcement learning: The robot learns through trial and error, receiving rewards for desirable actions and penalties for undesirable ones. The robot learns an optimal policy to maximize its reward. This is like teaching a dog using treats and corrections.

In practice, a combination of these methods is often used. For instance, a robot might use supervised learning to initially recognize objects and reinforcement learning to learn how to manipulate them effectively.

Q 14. Describe different methods for robot localization and mapping.

Robot localization and mapping are crucial for robots to understand their position and create a map of their surroundings. Think of it like knowing your location and creating a mental map of a new city.

- Simultaneous Localization and Mapping (SLAM): This is a fundamental problem in robotics, where a robot simultaneously builds a map of its environment and determines its location within that map. Common approaches use Kalman filtering, particle filters, and graph-based SLAM.

- GPS-based localization: Using GPS signals to determine the robot’s location. However, GPS is prone to inaccuracies and doesn’t work indoors.

- Inertial Measurement Units (IMUs): These sensors measure acceleration and rotation, allowing for dead-reckoning (estimating position based on movement). However, errors accumulate over time (drift).

- Lidar-based mapping: Using lidar sensors to create point cloud maps of the environment. This provides accurate 3D representations of the surrounding space.

A mobile robot cleaning a home might use SLAM to create a map of the house while simultaneously determining its location within that map, allowing it to effectively navigate and clean all areas.

Q 15. What are some common issues in robot vision systems and how to mitigate them?

Robot vision systems, while powerful, face several common challenges. One major issue is lighting variations. Changes in ambient light, shadows, or reflections can significantly impact image processing and object recognition. Mitigation strategies include using robust lighting systems with controlled illumination, incorporating algorithms that compensate for variations in brightness and contrast (like histogram equalization or adaptive thresholding), and employing multi-spectral imaging to capture information beyond the visible spectrum.

Another frequent problem is occlusion, where parts of the object are hidden from view. This can be addressed using multiple cameras with different viewpoints, employing 3D vision techniques (like structured light or time-of-flight), or developing algorithms that can intelligently predict the hidden portions based on known object geometry and previously observed information.

Noise in the image, due to sensor limitations or environmental factors, is another hurdle. Noise reduction techniques such as median filtering or wavelet denoising can improve image quality. Finally, the system’s accuracy can be affected by calibration errors. Regular calibration using precise tools and procedures is critical to maintain accuracy and reliability. For instance, in a manufacturing setting, inaccurate robot vision could lead to incorrect part placement or faulty assembly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of SLAM (Simultaneous Localization and Mapping).

SLAM, or Simultaneous Localization and Mapping, is a crucial capability for autonomous robots. Imagine a robot exploring an unknown environment – it needs to build a map of its surroundings while simultaneously figuring out its location within that map. This is precisely what SLAM achieves.

It works by iteratively combining sensor data (typically from lidar, cameras, or IMUs) to estimate its pose (position and orientation) and update a map concurrently. Popular approaches include Extended Kalman Filter (EKF) and particle filters, each offering different trade-offs in terms of computational cost and accuracy. EKF works well for relatively simple environments and low noise levels, while particle filters are better suited for handling more complex scenarios with significant uncertainty.

In practice, SLAM is fundamental for autonomous navigation in robotics. Self-driving cars use SLAM to create maps of their surroundings and track their location. Similarly, robots used in exploration, search and rescue, and warehouse automation heavily rely on SLAM for navigation and task execution. Think of a Roomba navigating your home – it’s essentially using a simpler form of SLAM to build an internal map and avoid obstacles.

Q 17. What are some ethical considerations in robotics?

Ethical considerations in robotics are paramount, as robots become increasingly integrated into society. One key concern is job displacement. As robots automate tasks previously performed by humans, there’s a risk of widespread unemployment, requiring careful planning for retraining and societal adaptation. We need to consider the social impact of widespread automation and develop strategies for mitigating its potential negative consequences.

Another critical issue is algorithmic bias. If the algorithms controlling robots are trained on biased data, they can perpetuate and amplify existing societal inequalities. This can manifest in areas like facial recognition, where biases in training data have led to disproportionate misidentification of certain demographics. Rigorous testing and validation of algorithms, as well as careful consideration of data sources, are crucial to avoid such biases.

Safety and accountability are also central ethical concerns. As robots become more sophisticated, accidents are inevitable, and we need clear frameworks for determining liability in case of robot-related harm. Furthermore, the development of autonomous weapons systems raises serious ethical questions about accountability, potential for misuse, and the impact on warfare.

Finally, privacy concerns arise when robots are equipped with sensors that collect personal data. Clear guidelines and regulations are needed to ensure responsible data handling and prevent misuse.

Q 18. Describe different types of robot end-effectors and their applications.

Robot end-effectors are the tools at the end of a robot arm, enabling it to interact with its environment. The choice of end-effector depends heavily on the specific application.

- Grippers: These are perhaps the most common type, designed to grasp and manipulate objects. They range from simple parallel-jaw grippers to more sophisticated designs like three-fingered or soft robotic grippers, each suitable for different object shapes and sizes. For example, a parallel-jaw gripper is ideal for picking up rectangular boxes, while a soft gripper is better suited for delicate or oddly shaped items.

- Vacuum cups: These are effective for handling flat, smooth surfaces like sheets of glass or metal. They create a suction force to securely hold the object.

- Magnetic grippers: These are useful for manipulating ferrous materials. They offer a simple and reliable solution for handling metallic objects.

- Tools: End-effectors can also be specialized tools such as welding torches, spray guns, or drills. These allow robots to perform specific tasks like welding, painting, or drilling holes.

- Specialized end-effectors: Some applications require highly customized end-effectors. For instance, a surgical robot may use specialized instruments for delicate operations, while a robot in a nuclear power plant may have manipulators designed for handling radioactive materials.

Q 19. How do you perform robot safety assessments?

Robot safety assessments are critical to prevent accidents and ensure human safety. A comprehensive assessment follows a structured approach:

- Hazard identification: This involves identifying all potential hazards associated with the robot and its operational environment. This includes physical hazards (e.g., crushing, impact, entanglement), electrical hazards, and environmental hazards (e.g., chemical spills). Techniques like HAZOP (Hazard and Operability study) are often used.

- Risk assessment: Once hazards are identified, a risk assessment is conducted to evaluate the likelihood and severity of each hazard. This often involves a qualitative or quantitative assessment, determining the probability of the hazard occurring and the potential consequences. Risk matrices are frequently used to visualize this information.

- Risk mitigation: Based on the risk assessment, appropriate safety measures are implemented to mitigate the identified hazards. These measures might include incorporating safety sensors (e.g., light curtains, pressure sensors), using interlocks, implementing emergency stop systems, reducing speeds, or modifying the robot’s workspace to limit access.

- Validation and verification: After implementing safety measures, the effectiveness of the mitigation strategies is validated and verified through testing and simulations. This might involve functional safety testing and risk reduction verification.

- Documentation: A comprehensive safety report detailing the entire assessment process, identified hazards, risk assessments, implemented safety measures, and verification results is crucial for ongoing safety management.

For instance, in a collaborative robot application (cobot), the safety assessment focuses on ensuring safe interaction between humans and robots, often employing collaborative safety standards like ISO/TS 15066.

Q 20. Explain the role of ROS (Robot Operating System) in robotics development.

ROS, or the Robot Operating System, is a flexible framework that simplifies the development of robotic systems. Think of it as a middleware layer that handles many low-level details, allowing developers to focus on higher-level functionalities like control algorithms, perception, and planning. It’s not an operating system in the traditional sense (like Windows or Linux), but rather a collection of tools and libraries that provide a standard communication infrastructure and a set of reusable components.

ROS facilitates communication between different parts of the robot system through a publish-subscribe mechanism. Modules (called nodes) can publish data to specific topics, while other nodes subscribe to those topics to receive the data. This modularity allows developers to easily integrate different sensors, actuators, and algorithms. For example, one node might handle camera input, another might perform image processing, and a third might control the robot’s movement, all communicating seamlessly through ROS.

ROS also provides tools for visualization (RViz), simulation (Gazebo), and debugging, significantly accelerating the development process. Its extensive community support and availability of pre-built packages further contribute to its popularity among robotics researchers and developers. In essence, ROS acts as a common language for diverse robot components, making it easier to create complex and integrated robotic systems.

Q 21. Describe your experience with robotic simulation software (e.g., Gazebo, V-REP).

I have extensive experience with both Gazebo and V-REP, two leading robotic simulation software packages. Gazebo excels in its physics engine, providing highly realistic simulations of robot dynamics and interactions with the environment. I’ve used Gazebo extensively for testing and validating robot control algorithms, particularly in scenarios involving complex terrain or object manipulation. For example, I simulated a mobile robot navigating a cluttered warehouse environment in Gazebo, allowing me to thoroughly test its navigation algorithm before deploying it on the physical robot.

V-REP, on the other hand, provides a more general-purpose simulation environment with a strong focus on virtual prototyping and remote control. I’ve employed V-REP for simulating robot arms performing complex assembly tasks and for testing the control algorithms in a virtual factory setting. Its ability to seamlessly integrate with various hardware interfaces is particularly valuable in virtual commissioning and testing.

In both cases, my experience has involved building detailed models of robots, environments, and sensors, writing custom plugins to add specific functionalities, and integrating the simulations with my control algorithms. The use of simulation greatly reduces the cost and risk associated with testing and development on physical robots, allowing for more rapid iteration and better system optimization.

Q 22. How do you troubleshoot robotic systems?

Troubleshooting robotic systems is a systematic process that requires a blend of technical expertise, problem-solving skills, and a methodical approach. It often involves a combination of hardware and software diagnostics. My approach typically starts with a careful observation of the system’s behavior, identifying the specific malfunction. Then I move to a structured investigation.

- Visual Inspection: I begin with a thorough visual inspection, checking for loose connections, damaged wires, physical obstructions, and any signs of overheating or wear and tear. Think of it like a detective looking for clues at a crime scene.

- Error Logs and Diagnostics: Next, I review the robot’s error logs and diagnostic reports for any clues. Many robotic systems provide detailed error codes that pinpoint the problem. For instance, a specific error code might indicate a motor fault or communication issue.

- Systematic Testing: I then proceed with systematic testing of individual components. This might involve checking sensor readings, verifying actuator functionality, and testing communication links. This stage is like checking each part of a machine one by one to find the broken link.

- Software Debugging: If the issue lies in the software controlling the robot, I utilize debugging tools to trace program execution, check for variables and conditional statements, and identify the source of bugs. Breakpoints and stepping through the code are valuable tools in this process.

- Sensor Calibration: Finally, recalibration of sensors is often essential, especially after any physical changes or impacts to the robot. I use calibration routines specific to the sensor technology, ensuring accuracy.

For example, on a recent project involving a robotic arm failing to grasp objects, I discovered a faulty proximity sensor causing inaccurate gripping. Replacing the sensor immediately resolved the issue.

Q 23. Explain your experience with different robot communication protocols (e.g., CAN, Ethernet/IP).

I’ve worked extensively with various robot communication protocols, each with its own strengths and weaknesses. My experience includes:

- CAN (Controller Area Network): CAN is a robust protocol well-suited for real-time control applications in harsh environments. I’ve used it extensively in industrial robotics for controlling actuators, sensors, and safety systems. Its deterministic nature ensures timely communication between devices, crucial for precise movement control. I’m familiar with CANopen, a higher-level protocol built on CAN, which provides standardized communication objects for industrial automation devices.

- Ethernet/IP: Ethernet/IP offers high bandwidth and flexibility for communication within a larger industrial automation network. It’s advantageous for handling large data streams, such as high-resolution sensor data or complex robot program instructions. I’ve used it to integrate robots into larger production systems, facilitating seamless communication with PLCs and other industrial components. Understanding the intricacies of Ethernet/IP’s addressing and communication mechanisms is critical to effective system integration.

One project involved integrating a robotic arm controlled by CAN with a vision system using Ethernet/IP. This required careful handling of data transfer between the two networks, often employing a gateway device to translate the communication protocols. Understanding the strengths of each and employing the appropriate gateway were key to successful implementation.

Q 24. Describe your experience with robotic vision systems and image processing techniques.

My experience with robotic vision systems and image processing techniques is extensive. I’ve worked with various types of cameras, from simple CCD cameras to advanced 3D vision systems. Image processing techniques are essential for extracting useful information from the images.

- Camera Selection: Choosing the right camera for the application is critical. Considerations include resolution, field of view, frame rate, and lighting conditions. For example, a high-resolution camera might be required for detailed object recognition, whereas a high-frame-rate camera may be necessary for fast-moving objects.

- Image Processing Algorithms: I’m proficient in using image processing algorithms such as edge detection, feature extraction, object recognition, and 3D reconstruction. Libraries like OpenCV provide a comprehensive suite of tools for these tasks. For instance, Canny edge detection can be used to identify object boundaries, while SIFT or SURF algorithms are valuable for feature matching in object recognition.

- Calibration: Accurate camera calibration is crucial to ensure precise measurements. Methods like camera matrix calibration (using checkerboard patterns) are vital for translating image coordinates to real-world coordinates.

In a recent project, I utilized a 3D vision system to guide a robotic arm in picking and placing irregularly shaped parts. This involved using stereo vision to reconstruct the 3D geometry of the parts, performing object recognition to identify individual parts, and then using the 3D information to plan the robot’s movements accurately.

Q 25. What are some common failures in robotic systems and how to prevent them?

Common failures in robotic systems can be broadly categorized into hardware and software issues. Prevention often involves a proactive approach.

- Hardware Failures:

- Actuator malfunctions (motors, pneumatic cylinders): Regular maintenance, lubrication, and timely replacements are crucial. Preventive maintenance schedules can help avoid catastrophic failures.

- Sensor failures: Calibration and testing can detect drift or malfunction. Redundant sensors can provide backup in case of failure.

- Mechanical wear and tear: Regular inspections and preventative maintenance are essential to address wear and tear before it becomes a major issue. Proper lubrication can reduce friction and prolong component lifespan.

- Software Failures:

- Software bugs: Thorough testing and code reviews are critical. Version control and robust error handling can mitigate unexpected behavior.

- Communication errors: Redundant communication pathways and error detection mechanisms can ensure robust communication.

- Integration issues: Careful planning and thorough testing of interfaces between different components are vital to prevent integration-related failures.

For example, to prevent actuator failure, we implemented a system that monitors motor current and temperature, automatically shutting down the system if abnormal levels are detected. This prevented potential damage to the motor and the surrounding equipment.

Q 26. Explain your experience with different types of actuators used in robotics.

My experience encompasses a range of actuator types commonly used in robotics:

- Electric Motors: These are prevalent in many robotic applications due to their precision, controllability, and ease of integration. I’ve worked with various types, including DC motors, servo motors, and stepper motors. Servo motors, with their built-in feedback mechanisms, are particularly useful for applications requiring precise positioning and control.

- Pneumatic Actuators: These are powerful and relatively inexpensive actuators, useful in applications requiring high force and speed. However, they lack the precision of electric motors and are typically less suitable for delicate tasks. Safety precautions are essential when dealing with high-pressure pneumatic systems.

- Hydraulic Actuators: Hydraulic actuators offer high force and power, ideal for heavy-duty applications. They’re commonly found in larger industrial robots and manufacturing systems. Leakage and maintenance are key concerns with hydraulic systems.

In one project involving a large robotic arm for material handling, the high-force requirements led us to use hydraulic actuators. This required careful consideration of safety procedures, pressure regulation, and maintenance routines to ensure the reliability and safety of the system.

Q 27. Describe your experience with robotic system integration and deployment.

Robotic system integration and deployment involve a multi-stage process requiring meticulous planning and execution:

- System Design: This stage involves defining the overall system architecture, selecting appropriate components (hardware and software), and creating detailed design specifications. It’s crucial to consider factors such as workspace, payload capacity, accuracy requirements, and safety considerations.

- Hardware Integration: This phase involves physically assembling the robotic system, connecting all components, and ensuring proper communication between the various parts. Careful attention to wiring, grounding, and safety interlocks is crucial.

- Software Integration: This stage focuses on developing and integrating the control software, incorporating algorithms for motion planning, sensor processing, and task execution. Rigorous testing is essential to ensure proper functionality and stability.

- Testing and Commissioning: Thorough testing is critical to identify and rectify any errors before deployment. This includes functional testing, safety testing, and performance evaluation.

- Deployment and Support: Deployment involves installing the system in its intended environment, providing operator training, and establishing a maintenance plan. Ongoing support and maintenance are crucial to ensure the long-term reliability of the system.

For example, during the deployment of a palletizing robot in a warehouse, we had to account for environmental factors like dust and temperature fluctuations, and ensure the system could withstand them reliably.

Q 28. How do you ensure the reliability and maintainability of robotic systems?

Ensuring the reliability and maintainability of robotic systems is crucial for their successful long-term operation. This involves a multi-faceted approach:

- Redundancy: Implementing redundant components (e.g., sensors, actuators, communication pathways) can enhance system reliability and resilience to failures. If one component fails, the redundant component can take over, preventing system downtime.

- Modular Design: A modular design allows for easier maintenance and repair. Individual components can be replaced or repaired without requiring a complete system shutdown.

- Preventive Maintenance: Establishing a regular preventive maintenance schedule (including lubrication, inspections, and calibration) can significantly extend the lifespan of the system and reduce the likelihood of unexpected failures.

- Diagnostics and Monitoring: Implementing robust diagnostic systems and monitoring tools allows for early detection of potential issues, enabling timely intervention and preventing major failures.

- Documentation: Comprehensive documentation (including schematics, software code, maintenance manuals) is vital for efficient troubleshooting and repairs.

For instance, in one project, we implemented a system that monitored the health of critical components and alerted maintenance personnel before potential failures occurred, significantly reducing downtime and maintenance costs.

Key Topics to Learn for Robotics Interviews

- Robotics Fundamentals: Understanding kinematic chains, degrees of freedom, forward and inverse kinematics, and robot workspace analysis.

- Control Systems: PID control, trajectory planning, motion control algorithms, and the implementation of control strategies in robotic systems.

- Sensors and Perception: Familiarity with various sensors (e.g., lidar, cameras, IMUs), sensor fusion techniques, and object recognition algorithms used in robot perception.

- Programming and Software: Proficiency in relevant programming languages (e.g., Python, C++), experience with ROS (Robot Operating System), and familiarity with robotic simulation software.

- Mechanical Design and Hardware: Understanding of robotic mechanisms, actuators, and end-effectors. Knowledge of different robot architectures (e.g., articulated, parallel, mobile).

- AI and Machine Learning in Robotics: Experience with applying machine learning algorithms for tasks such as path planning, object recognition, and reinforcement learning for robot control.

- Practical Applications: Discuss real-world applications of robotics in areas like manufacturing, healthcare, logistics, or exploration, highlighting your contributions and problem-solving skills.

- Troubleshooting and Debugging: Be prepared to discuss your experience with identifying and resolving technical issues in robotic systems. Showcase your problem-solving methodology.

- Ethical Considerations: Demonstrate awareness of the ethical implications of robotics and AI, particularly concerning safety, bias, and societal impact.

Next Steps

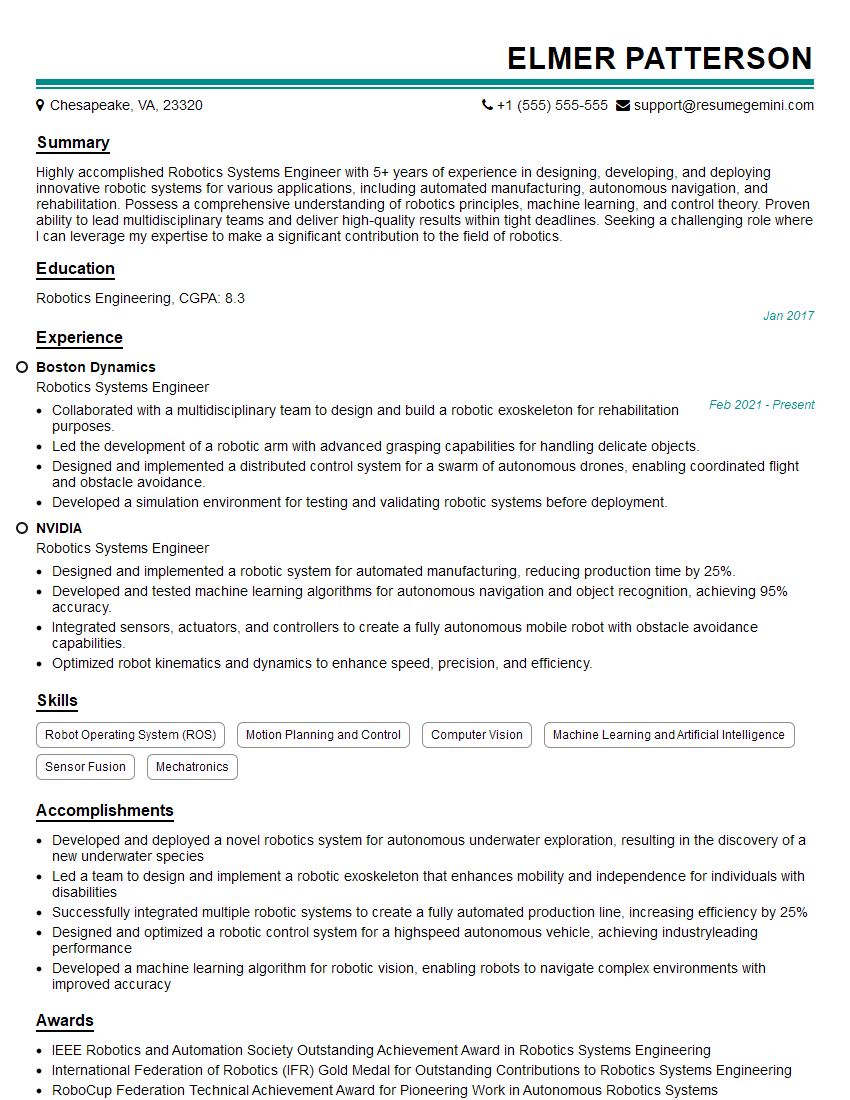

Mastering robotics principles and showcasing your practical experience is crucial for career advancement in this rapidly evolving field. A well-crafted resume is your first step towards securing your dream role. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. To help you build a standout resume that highlights your robotics expertise, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to robotics professionals, ensuring your qualifications are presented effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good