Cracking a skill-specific interview, like one for Expertise in Quality Control and Quality Assurance, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Expertise in Quality Control and Quality Assurance Interview

Q 1. Describe your experience with different quality control methodologies.

Throughout my career, I’ve implemented and managed various quality control methodologies, adapting them to different project contexts and industry standards. These include statistical process control (SPC), Six Sigma, total quality management (TQM), and lean manufacturing principles.

Statistical Process Control (SPC) involves using statistical methods to monitor and control processes, identifying variations and preventing defects. I’ve used control charts (like X-bar and R charts) to track key process parameters and identify trends indicating process instability. For example, in a manufacturing setting, we used SPC to monitor the weight of a product, setting upper and lower control limits to ensure consistency and prevent deviations that could lead to customer dissatisfaction.

Six Sigma is a data-driven methodology focused on minimizing defects and improving process efficiency. My experience with Six Sigma includes leading DMAIC (Define, Measure, Analyze, Improve, Control) projects to identify and eliminate root causes of variation in processes. In one project, we reduced the defect rate in a packaging process by 70% by applying DMAIC, leading to significant cost savings and improved customer satisfaction.

Total Quality Management (TQM) emphasizes a holistic approach to quality, involving every aspect of the organization. I’ve been part of implementing TQM initiatives, focusing on continuous improvement, employee empowerment, and customer focus. This involved training employees on quality principles and implementing feedback mechanisms to ensure customer needs are consistently met.

Lean Manufacturing focuses on eliminating waste and maximizing efficiency. My experience includes applying lean principles to streamline processes, reducing lead times and improving overall productivity. For instance, in a previous role, we implemented Kanban systems to optimize inventory management, reducing waste and improving production flow.

Q 2. Explain the difference between Quality Control and Quality Assurance.

While both Quality Control (QC) and Quality Assurance (QA) aim to ensure high-quality products or services, they approach it differently. Quality Control is a reactive process focused on detecting defects *after* they occur. It involves inspecting finished products or services to identify and rectify flaws. Think of it as a final check before something leaves the production line.

Quality Assurance, on the other hand, is a proactive process that aims to *prevent* defects from occurring in the first place. It focuses on processes, procedures, and systems. This involves setting quality standards, defining procedures, and ensuring these procedures are followed throughout the entire production process. It’s like designing a robust system to minimize the chances of errors.

Analogy: Imagine baking a cake. QC is like tasting the final cake to see if it’s good. QA is like ensuring you have the correct ingredients, follow the recipe meticulously, and use the right tools and equipment to minimize the chance of a poorly baked cake.

Q 3. How do you define and measure quality?

Defining and measuring quality is crucial. It depends heavily on the product or service and customer expectations. Quality is the totality of characteristics of a product or service that bear on its ability to satisfy stated or implied needs. This means quality isn’t just about functionality but also about meeting customer expectations regarding aesthetics, reliability, durability, and other factors.

Measuring quality involves using a variety of metrics, both quantitative and qualitative. Quantitative measures include defect rates, yield, cycle time, and customer satisfaction scores (CSAT). Qualitative measures might include customer feedback, surveys, and focus groups. The specific metrics used will depend on the context. For example, for software, we might measure quality using metrics such as code coverage, bug density, and user experience.

For a manufacturing plant producing widgets, quality might be measured by the number of defective widgets per batch, the consistency of widget dimensions, and customer feedback on durability and performance.

Q 4. What are some common quality control tools and techniques you’ve used?

I’ve extensively used various quality control tools and techniques, tailoring their application to specific needs. These include:

- Control Charts: As mentioned earlier, X-bar and R charts, p-charts (for proportions), c-charts (for counts) are essential for monitoring process stability.

- Check Sheets: Simple, yet powerful tools for collecting data on defects or process issues. I’ve used them in numerous audits and process improvement projects.

- Pareto Charts: These charts help visualize the most significant causes of defects, allowing us to prioritize improvement efforts. The 80/20 rule is often observed.

- Flowcharts: Essential for documenting processes, identifying bottlenecks, and improving efficiency. I use them for process mapping and analysis.

- Histograms: Show the distribution of data, helping to understand process variability and identify potential problems.

- Cause-and-Effect Diagrams (Fishbone Diagrams): Used for brainstorming potential causes of defects or problems. These are great for root cause analysis.

- Scatter Diagrams: Examine the relationship between two variables, identifying potential correlations.

The selection of tools depends on the specific challenge. A Pareto chart might be used to understand the major sources of customer complaints, while a flowchart might be used to optimize a complex manufacturing process.

Q 5. Describe your experience with ISO 9001 or other quality management systems.

I possess significant experience with ISO 9001:2015, a widely recognized international standard for quality management systems. I’ve been involved in ISO 9001 certification audits, internal audits, and the development and implementation of quality management systems aligned with ISO 9001 principles. This includes defining processes, establishing documentation controls, managing non-conformances, and conducting regular internal audits to ensure compliance.

My experience extends beyond ISO 9001. I’ve also worked with other quality management systems tailored to specific industries. Understanding these standards ensures consistent quality across various projects and aligns our processes with best practices, improving overall efficiency and reducing risks.

In one project, I led the team through the ISO 9001 certification process, resulting in successful certification and demonstrably improved quality and efficiency throughout the organization.

Q 6. How do you handle non-conforming materials or products?

Handling non-conforming materials or products requires a structured approach to prevent further defects and minimize impact. The first step is to identify and isolate the non-conforming items to prevent them from entering the production process or reaching customers.

Next, we investigate the root cause of the non-conformity. This often involves using tools like the 5 Whys or fishbone diagrams. Once the root cause is identified, corrective actions are implemented to prevent recurrence. This might involve adjusting process parameters, retraining personnel, or improving equipment.

Depending on the severity and nature of the non-conformity, we might decide to rework, repair, or scrap the affected materials or products. A thorough documentation of the non-conformity, investigation, corrective actions, and disposition is crucial for continuous improvement.

We also maintain a Non-Conformance Report (NCR) system for tracking and managing non-conformances effectively. This system allows us to monitor trends, identify recurring problems, and demonstrate our commitment to continuous improvement.

Q 7. How do you develop and implement quality control plans?

Developing and implementing quality control plans involves a systematic approach. It begins with a thorough understanding of the product or service, customer requirements, and potential risks. This involves gathering information through various methods such as customer feedback, process analysis, and risk assessments.

Next, we define specific quality metrics and acceptance criteria. This involves establishing clear standards and thresholds for key parameters. For example, we might define acceptable limits for the weight or dimensions of a product, or the number of defects allowed in a batch.

The plan outlines specific inspection methods, testing procedures, and sampling plans. We determine how often to inspect, what to inspect, and how to document the inspection results. This might include visual inspections, dimensional measurements, or functional tests.

The plan also specifies the responsibilities of different personnel and the required resources. We ensure that the necessary equipment, training, and personnel are available to execute the plan effectively. The plan should be reviewed and updated periodically to reflect changes in the process, customer requirements, or technology.

Finally, we implement the plan, monitor its effectiveness, and make necessary adjustments. This might involve regular performance reviews, analysis of inspection data, and implementation of corrective actions as needed. Using data and feedback loops is critical for continuous improvement of our processes.

Q 8. What is your experience with statistical process control (SPC)?

Statistical Process Control (SPC) is a powerful methodology used to monitor and control the variability in manufacturing and other processes. It involves using statistical techniques to analyze data from a process, identify trends, and determine whether the process is operating within acceptable limits. Think of it as a continuous health check for your production line.

My experience with SPC encompasses a wide range of applications, including control charts (like X-bar and R charts, p-charts, c-charts), process capability analysis (Cp, Cpk), and the use of software like Minitab to analyze data. For instance, in a previous role, I used X-bar and R charts to monitor the diameter of machined parts. By regularly plotting the data, we could quickly identify any shifts in the average diameter or increases in variability, allowing us to take corrective actions before producing a large batch of defective parts. This prevented significant scrap and rework costs.

Furthermore, I’ve utilized SPC to identify assignable causes of variation (special causes) versus common cause variation. Understanding this distinction is critical; addressing assignable causes requires specific corrective actions, while common cause variations often require process improvements or adjustments.

Q 9. Describe a time you identified a quality issue and how you resolved it.

During a project involving the assembly of circuit boards, we noticed a significant increase in the failure rate of the final product. Initially, the defect rate was within our acceptable limits. However, a sudden spike in returns indicated a problem. My first step was to systematically investigate the production process, focusing on each stage of assembly. We used a Pareto chart to identify the most frequent defects.

The Pareto chart revealed that approximately 70% of the failures stemmed from a faulty soldering process on a particular component. Further investigation, using a 5 Whys analysis, revealed that the problem was due to a recent change in the soldering iron’s tip, which was not properly maintained, leading to inconsistent solder joints. We addressed this issue immediately, implementing stricter maintenance protocols for the soldering irons and retraining operators. A control chart was then implemented to continuously monitor the soldering process, ensuring the problem didn’t recur.

Q 10. How do you ensure traceability in a manufacturing process?

Traceability in a manufacturing process is the ability to track a product or component from its origin to its final destination, and vice-versa. Think of it as a detailed ‘family tree’ for each item. It is crucial for quality control, recall management, and regulatory compliance.

To ensure traceability, we employ a combination of methods. This often involves unique identification numbers (serial numbers, barcodes, or RFID tags) assigned to each component and product at each stage of manufacturing. Detailed records, including production logs, supplier information, and testing data, are meticulously maintained. These records are usually integrated into a robust database or ERP system. For example, in a pharmaceutical manufacturing environment, batch numbers and lot tracking are crucial, ensuring the ability to trace the ingredients and manufacturing steps for each production run. In our company, we used a combination of barcodes scanned at each workstation and a centralized database to completely map each item’s path from raw materials to the finished goods.

Q 11. Explain your understanding of root cause analysis techniques.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of problems, rather than just addressing surface-level symptoms. Several techniques exist, each suited to different situations.

- 5 Whys: A simple, iterative questioning technique to uncover the root cause by repeatedly asking ‘why’ until the fundamental issue is identified. This is great for simple problems.

- Fishbone Diagram (Ishikawa Diagram): A visual tool that helps brainstorm potential causes categorized by factors like materials, methods, manpower, machinery, measurement, and environment. This is excellent for collaborative problem-solving.

- Fault Tree Analysis (FTA): A top-down, deductive approach used to systematically analyze potential failure modes and their contributing factors. This is valuable in complex systems.

The choice of technique depends on the complexity of the problem. For instance, a simple equipment malfunction might be effectively addressed using the 5 Whys, while a complex issue like recurring product defects might require a Fishbone Diagram combined with data analysis to pinpoint contributing factors.

Q 12. How do you prioritize quality issues?

Prioritizing quality issues requires a structured approach that considers several factors. I typically use a risk-based prioritization matrix, considering the severity of the issue, its frequency of occurrence, and its potential impact on the customer. For instance, a serious defect affecting safety, even if infrequent, would have high priority, whereas a minor cosmetic defect, even if frequent, would have lower priority.

This matrix helps us categorize issues into critical, high, medium, and low priority levels. We then allocate resources according to the priority level, addressing the most critical issues first. Regular review and updates of the priority matrix are important, especially in dynamic manufacturing environments where new issues may arise frequently.

Q 13. What is your experience with quality audits?

I have extensive experience in conducting and participating in quality audits, both internal and external. Internal audits focus on evaluating the effectiveness of our quality management system (QMS) against established standards, such as ISO 9001. External audits are conducted by third-party certification bodies to verify compliance with specific industry regulations or standards.

My approach involves meticulous planning, preparation of audit checklists, on-site inspections, record review, and follow-up on non-conformances. I am proficient in using various audit techniques, such as sampling, observation, and interviewing personnel. The goal is not simply to find problems, but to identify areas for improvement and ensure the QMS remains effective and efficient.

Q 14. How do you handle customer complaints related to quality?

Handling customer complaints related to quality requires a structured and empathetic approach. The key is to act quickly, investigate thoroughly, and communicate effectively. My first step is to acknowledge the complaint, empathize with the customer’s frustration, and assure them that their issue is being taken seriously.

A detailed investigation then follows to determine the root cause of the problem. This involves gathering data from various sources, including the customer’s report, internal records, and potentially testing the product. Once the root cause is identified, corrective actions are implemented to prevent similar issues from happening again. Finally, the customer is kept informed throughout the process, and a resolution, which may involve repair, replacement, or refund, is offered. For example, a detailed case study of the complaint and the resolution is created and stored for continuous improvement.

Q 15. Describe your experience with corrective and preventative actions (CAPA).

Corrective and Preventative Actions (CAPA) is a systematic process for identifying, investigating, and correcting quality problems, preventing their recurrence. It’s crucial for ensuring product quality and regulatory compliance. My experience encompasses the entire CAPA lifecycle, from initial defect identification to verification of implemented corrective actions.

For instance, in a previous role at a medical device manufacturer, we implemented a robust CAPA system using a dedicated software platform. When a non-conformance occurred – say, a batch of devices failing a critical functional test – we’d immediately initiate a CAPA investigation. This involved root cause analysis (using tools like Fishbone diagrams and 5 Whys), determining the impact of the non-conformance, and proposing corrective actions. Once approved, these actions were implemented, and effectiveness was verified through monitoring and data analysis. This ensured the issue wouldn’t repeat and strengthened our overall quality management system.

- Defect Identification: Thorough documentation and reporting of any deviation from quality standards.

- Root Cause Analysis: Using various tools to identify the underlying causes of defects, not just the symptoms.

- Corrective Actions: Implementing changes to eliminate the identified root cause.

- Preventative Actions: Implementing changes to prevent similar issues from arising in the future.

- Effectiveness Verification: Monitoring the results of implemented actions to confirm their effectiveness.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with process improvement methodologies (e.g., Lean, Six Sigma)?

I have extensive experience applying Lean and Six Sigma methodologies to improve processes and reduce variation. Lean focuses on eliminating waste, while Six Sigma aims to reduce defects to near zero. I’ve used both independently and in conjunction for optimal results.

In one project, we used Lean principles to streamline a manufacturing process. By mapping the value stream, we identified several areas of waste, such as unnecessary inventory, excessive motion, and waiting time. Applying tools like 5S (sort, set in order, shine, standardize, sustain) and Kaizen (continuous improvement), we significantly reduced lead times and improved overall efficiency. We then implemented DMAIC (Define, Measure, Analyze, Improve, Control) – the Six Sigma methodology – to further reduce defects in a specific area of the process. This involved meticulously analyzing process data, identifying key process variables, and implementing control charts to monitor and maintain improvements. The combined application of Lean and Six Sigma resulted in a substantial decrease in production costs and a noticeable increase in customer satisfaction.

Q 17. How do you measure the effectiveness of quality control initiatives?

Measuring the effectiveness of quality control initiatives requires a multi-faceted approach. We look at both quantitative and qualitative data. Key metrics include:

- Defect Rate: The number of defects per unit or per batch. A decrease indicates improvement.

- Yield Rate: The percentage of conforming units produced. An increase signifies higher quality.

- Customer Complaints: Tracking the number and types of customer complaints helps assess product quality in the field.

- Return Rate: High return rates indicate potential quality issues that need addressing.

- Process Capability Indices (Cpk, Ppk): These statistical measures quantify the process’s ability to consistently meet specifications.

Beyond numbers, qualitative feedback from audits, employee surveys, and customer feedback sessions provides valuable insight. A holistic view combining these metrics paints a comprehensive picture of the effectiveness of the implemented quality control measures.

Q 18. How familiar are you with various quality control charts (e.g., control charts, Pareto charts)?

I’m very familiar with various quality control charts. They are essential tools for visually monitoring process performance and identifying potential problems. My experience includes using:

- Control Charts (Shewhart Charts): These charts, such as X-bar and R charts, track process variables over time to identify patterns and detect shifts in the mean or variability.

Example: An X-bar chart shows the average weight of products over several batches, highlighting any significant deviations from the target weight. - Pareto Charts: These charts help prioritize quality problems by visualizing the frequency of different defects. The 80/20 rule is often applied here (80% of problems stemming from 20% of causes).

Example: A Pareto chart might show that 80% of customer complaints are related to a specific component of the product, highlighting the need to focus improvements there. - Histograms: These charts graphically represent the distribution of data, showing the frequency of different values. This helps understand process variability.

- Scatter Diagrams: Used to identify correlations between two variables. For instance, to see if there is a relationship between temperature and defect rate.

Q 19. How do you ensure data integrity in quality control processes?

Data integrity is paramount in quality control. Ensuring its accuracy and reliability is crucial for making informed decisions. My approach involves several key strategies:

- Data Validation: Implementing checks and balances at every stage of data collection and entry. This includes range checks, data type validation, and plausibility checks.

- Documented Procedures: Clearly defined procedures for data acquisition, handling, and storage. This reduces the risk of human error and ensures consistency.

- Auditing and Verification: Regular audits and verification procedures are performed to confirm data accuracy and completeness. This could include comparing data from different sources.

- Access Control: Restricting access to data to authorized personnel only, minimizing unauthorized alterations or deletions.

- Data Backup and Recovery: Having robust data backup and recovery mechanisms in place to protect against data loss due to system failures or other unforeseen events.

- Training: Providing thorough training to personnel on proper data handling practices.

For example, in a pharmaceutical setting, inaccurate data in a clinical trial could have devastating consequences. Therefore, a rigorous system of checks, balances, and documentation is essential.

Q 20. What is your experience with quality management software?

I have experience using several quality management software systems, including [mention specific software, e.g., TrackWise, MasterControl, SAP QM]. These systems streamline the entire quality management process, from non-conformance reporting to CAPA management and audit trails. I’m proficient in using these systems to manage data, generate reports, and analyze trends. The key benefits I’ve experienced include improved efficiency, reduced paperwork, enhanced data integrity, and better collaboration across teams.

For instance, using a system like MasterControl, we centralized our CAPA processes, significantly improving tracking, communication, and overall efficiency. The system’s reporting capabilities provided real-time insights into our quality performance, allowing us to identify trends and make data-driven decisions.

Q 21. Describe your experience with different types of testing (e.g., destructive, non-destructive).

My experience includes both destructive and non-destructive testing methods. The choice depends on the product, the criticality of the testing, and the information required.

- Destructive Testing: This involves testing a sample to failure to determine its strength, durability, or other properties. Examples include tensile testing, impact testing, and fatigue testing. This is often used to establish the safety and reliability of a product.

- Non-Destructive Testing (NDT): This involves testing a sample without causing damage. This is crucial for ensuring quality without compromising the product’s functionality. Examples include visual inspection, ultrasonic testing, radiographic testing, and magnetic particle inspection. NDT is frequently employed in applications such as aerospace and nuclear energy, where the integrity of components is critical.

In a previous role, we employed both types of testing. Destructive testing was used on a small sample of manufactured components to determine the material’s yield strength and ultimate tensile strength, ensuring they met specifications. Non-destructive testing, such as ultrasonic testing, was applied to the majority of components to detect internal flaws or defects without causing damage to the product. This ensured all produced components met quality standards while minimizing material wastage.

Q 22. How do you manage and track quality metrics?

Managing and tracking quality metrics is crucial for continuous improvement. It involves defining key performance indicators (KPIs), collecting data, analyzing trends, and taking corrective actions. This process typically starts with identifying the critical quality characteristics relevant to the product or service. Then, we select appropriate metrics to measure these characteristics.

- KPIs: Examples include defect rate, customer satisfaction scores (CSAT), process cycle time, and yield. These KPIs are tailored to the specific needs of the project or product.

- Data Collection: Data can be gathered from various sources, including automated testing tools, customer feedback surveys, internal inspections, and production records. The key here is to ensure data accuracy and reliability.

- Analysis and Reporting: Statistical process control (SPC) charts, dashboards, and reports are utilized to visualize trends and identify areas needing attention. This allows us to proactively address potential problems before they escalate.

- Corrective Actions: Based on the analysis, corrective and preventive actions (CAPA) are implemented. This might involve process improvements, employee training, or changes to materials or equipment. The effectiveness of these actions should be monitored over time.

For example, in a software development project, we might track the number of bugs found per 1000 lines of code, the time taken to resolve bugs, and the customer satisfaction rating after a software release. Regularly reviewing these metrics helps us pinpoint bottlenecks and improve the development process.

Q 23. How do you ensure compliance with industry regulations?

Ensuring compliance with industry regulations is paramount. This requires a thorough understanding of the applicable standards, establishing robust processes to meet these standards, and maintaining thorough documentation.

- Identify Applicable Regulations: The first step is to identify all relevant regulations, including ISO 9001, FDA guidelines (if applicable), industry-specific standards, and any legal requirements.

- Develop Compliance Processes: Based on the regulations, we design and implement processes to ensure compliance throughout the product lifecycle. This includes procedures for material sourcing, manufacturing, testing, and documentation.

- Documentation and Audits: Comprehensive documentation is crucial. This includes quality manuals, standard operating procedures (SOPs), and records of inspections and tests. Regular internal audits and external audits by regulatory bodies ensure that processes are consistently followed and effective.

- Training and Awareness: Employees involved in quality-related activities must be adequately trained on the relevant regulations and procedures.

For instance, in the pharmaceutical industry, maintaining Good Manufacturing Practices (GMP) is critical. This involves detailed documentation of every step in the drug manufacturing process, stringent testing procedures, and meticulous record-keeping to comply with FDA regulations. Failure to comply can result in severe consequences, including fines, product recalls, and reputational damage.

Q 24. Describe your experience with failure analysis.

Failure analysis is a systematic investigation to determine the root cause of a product or process failure. My approach involves a structured methodology to identify the problem, determine its cause, and implement corrective actions to prevent recurrence.

- Problem Definition: Clearly defining the failure is the first step. What exactly failed? When did it fail? What were the consequences?

- Data Collection: Gather all relevant data, including visual inspection, test results, process parameters, and historical data. This is often crucial.

- Root Cause Analysis: Employ tools like the 5 Whys, Fishbone diagrams (Ishikawa diagrams), and fault tree analysis to systematically investigate the cause of the failure. This often involves teamwork and brainstorming to discover underlying issues.

- Corrective Actions: Once the root cause is identified, effective corrective and preventive actions (CAPA) are implemented to prevent similar failures in the future.

- Documentation: Thorough documentation of the entire failure analysis process, including findings, conclusions, and implemented corrective actions, is essential for future reference and continuous improvement.

For example, if a batch of manufactured parts fails a strength test, a failure analysis might reveal that a faulty component or an incorrect process parameter was the root cause. Addressing this root cause might involve replacing the faulty component supplier or adjusting the manufacturing process.

Q 25. What is your experience with quality control in a specific industry (mention relevant industry)?

My experience in quality control within the automotive industry involved working on assembly line quality assurance for a major car manufacturer. My responsibilities included:

- Process Audits: Regularly auditing manufacturing processes to ensure adherence to quality standards and specifications.

- Inspection and Testing: Implementing and overseeing inspection and testing procedures to ensure that components and finished vehicles met quality requirements.

- Defect Tracking and Analysis: Tracking defects, conducting root cause analysis, and implementing corrective actions to prevent recurrence.

- Supplier Quality Management: Collaborating with suppliers to ensure that materials and components met the required quality standards.

- Continuous Improvement Initiatives: Participating in initiatives aimed at improving the quality of the manufacturing process and reducing defects.

One significant project involved implementing a new quality management system, which resulted in a 20% reduction in defects and a significant improvement in customer satisfaction.

Q 26. How do you communicate quality issues to different stakeholders?

Communicating quality issues effectively to different stakeholders is crucial for prompt resolution and continuous improvement. My approach involves tailoring the communication to the audience’s needs and level of understanding.

- Identify Stakeholders: First, identify all relevant stakeholders, including management, engineers, production staff, and customers.

- Tailor Communication: Adapt the communication style and level of detail to each stakeholder group. Technical details are relevant for engineers, while management needs a summary of the impact and proposed solutions. Customers need clear, concise information about the issue and its resolution.

- Choose Appropriate Channels: Select the appropriate communication channels, such as email, meetings, reports, or presentations.

- Provide Timely Information: Deliver information promptly and efficiently, keeping all stakeholders informed throughout the process. Proactive communication avoids surprises and builds trust.

- Document Everything: Maintain a record of all communications and actions taken.

For example, when a critical quality issue arises, I would communicate the problem to management immediately, provide a detailed report to the engineering team for root cause analysis, and inform customers about the steps being taken to resolve the issue.

Q 27. How do you stay up-to-date with industry best practices in quality control?

Staying up-to-date with industry best practices in quality control is essential for continuous improvement. I utilize several methods to maintain my knowledge and expertise.

- Professional Organizations: Active participation in professional organizations like ASQ (American Society for Quality) provides access to resources, conferences, and networking opportunities.

- Industry Publications and Journals: Regularly reading industry publications and journals keeps me abreast of the latest trends, technologies, and best practices.

- Conferences and Workshops: Attending industry conferences and workshops provides valuable insights and networking opportunities.

- Online Courses and Training: Utilizing online courses and training programs helps to maintain and expand my knowledge base.

- Mentorship and Networking: Engaging in mentorship and networking with other quality professionals provides opportunities to learn from their experiences.

By actively engaging in these methods, I ensure I remain proficient in the latest techniques and methodologies in quality control.

Q 28. How would you adapt your quality control approach to a new company or project?

Adapting my quality control approach to a new company or project requires a flexible and analytical approach. My strategy involves a structured process to understand the context, assess the existing systems, and integrate best practices.

- Understand the Context: Thoroughly understanding the industry, the company culture, the specific product or service, and the existing quality management system is crucial. This involves reviewing documentation, interviewing key personnel, and observing existing processes.

- Assess Current Systems: Assess the strengths and weaknesses of the existing quality systems and processes. Identifying gaps in processes, inadequate documentation, or missing key performance indicators (KPIs) is essential.

- Gap Analysis: Conduct a gap analysis comparing the current state to best practices and industry standards. This involves identifying areas for improvement and prioritizing them based on their impact.

- Develop an Implementation Plan: Create a detailed implementation plan outlining steps, timelines, resources, and responsibilities for implementing improvements and integrating best practices. This should consider training and communication needs.

- Continuous Monitoring and Improvement: Regular monitoring and review of the implemented changes are vital, using data analysis to track effectiveness and identify areas for further enhancement.

For instance, when joining a new company, I would first spend time understanding their existing processes, then identify any gaps in their quality management system compared to best practices. I’d propose improvements and work with the team to implement them smoothly, ensuring buy-in and collaboration at every step.

Key Topics to Learn for Expertise in Quality Control and Quality Assurance Interview

- Quality Management Systems (QMS): Understanding ISO 9001, other relevant standards, and their practical implementation within different industries. Consider the roles of documentation, process improvement, and internal audits.

- Statistical Process Control (SPC): Learn about control charts (e.g., Shewhart, CUSUM), process capability analysis (Cp, Cpk), and how to use these tools to monitor and improve processes. Be prepared to discuss real-world applications and interpret data.

- Root Cause Analysis (RCA): Master various RCA techniques like 5 Whys, Fishbone diagrams, and fault tree analysis. Practice applying these methods to identify and eliminate the underlying causes of quality defects.

- Quality Control Tools and Techniques: Familiarize yourself with various tools such as Pareto charts, histograms, scatter diagrams, and check sheets. Understand how to select the appropriate tool for a given situation and interpret the results effectively.

- Quality Assurance (QA) methodologies and processes: Explore different testing methodologies (e.g., black box, white box, integration testing), the software development lifecycle (SDLC) and its connection to quality, and the role of QA in ensuring product quality throughout the development process.

- Risk Management in Quality: Understand how to identify, assess, and mitigate risks that could impact product quality and customer satisfaction. Discuss the role of risk management in proactive quality improvement.

- Auditing and Compliance: Prepare to discuss your experience with conducting internal or external audits, understanding compliance requirements, and ensuring adherence to relevant regulations and standards.

- Continuous Improvement Methodologies (e.g., Lean, Six Sigma): Demonstrate your understanding of continuous improvement principles and how these methodologies are applied to enhance quality control and quality assurance processes.

Next Steps

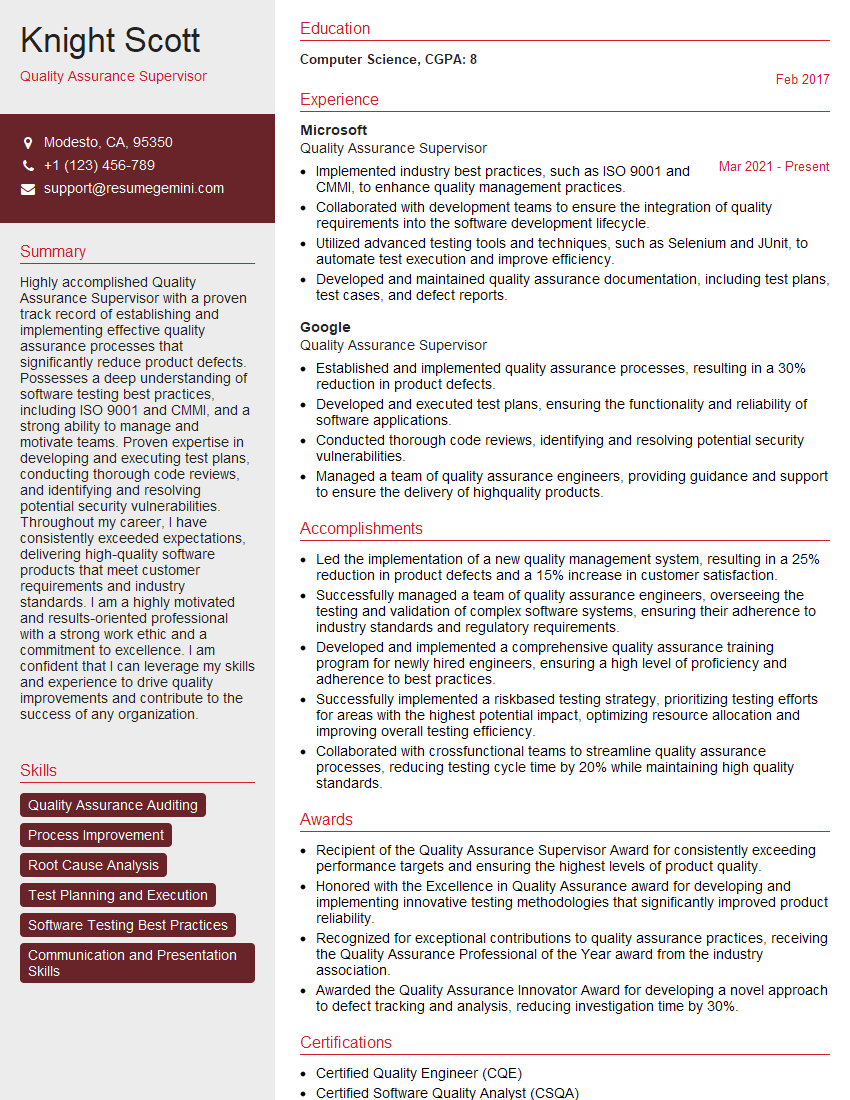

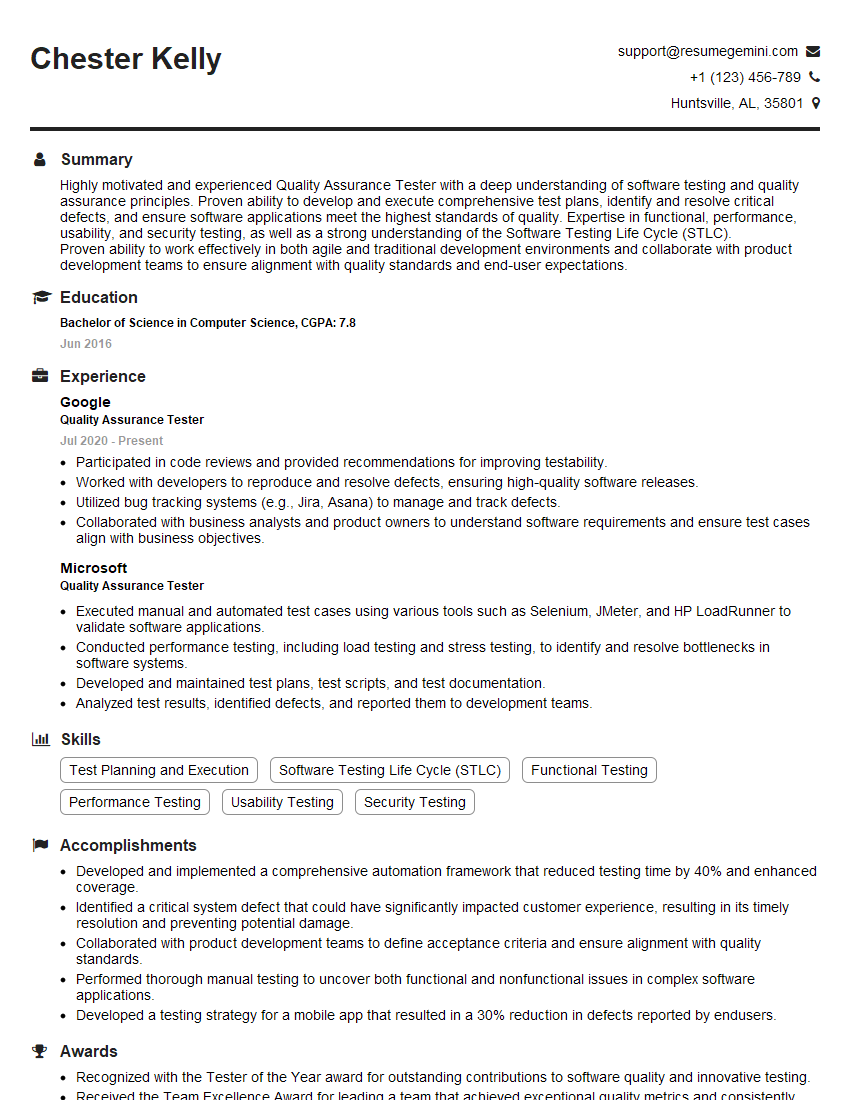

Mastering Expertise in Quality Control and Quality Assurance opens doors to rewarding and impactful careers across numerous industries. To significantly enhance your job prospects, it’s crucial to create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and compelling resume. We provide examples of resumes tailored specifically to Expertise in Quality Control and Quality Assurance to guide you in crafting your perfect application. Take advantage of these resources to make your application stand out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good