Cracking a skill-specific interview, like one for Fabric Knowledge and Analysis, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Fabric Knowledge and Analysis Interview

Q 1. Explain the difference between woven and knitted fabrics.

Woven and knitted fabrics are fundamentally different in their construction, leading to distinct properties. Think of weaving as creating a fabric by interlacing two sets of yarns at right angles – the warp (lengthwise) and weft (crosswise). Knitting, on the other hand, involves interlocking loops of a single yarn, creating a more flexible and often stretchy structure.

- Woven Fabrics: Stronger, less stretchy, often crisper drape. Examples include denim, twill, satin. Think of the tightly-woven structure of a sturdy denim jeans.

- Knitted Fabrics: More flexible, often stretchy, softer drape. Examples include jersey, rib knit, purl knit. Imagine the comfortable stretch of a cotton t-shirt.

The differences are apparent in their use: woven fabrics are suitable for structured garments like trousers and jackets, while knitted fabrics are ideal for comfortable apparel like sweaters and t-shirts. The choice depends heavily on the desired garment properties.

Q 2. Describe the properties of cotton, polyester, and nylon fabrics.

Cotton, polyester, and nylon are common fibers, each with unique properties:

- Cotton: A natural fiber known for its softness, breathability, and absorbency. It’s comfortable against the skin but wrinkles easily and can shrink when washed improperly. Think of the classic feel of a cotton t-shirt.

- Polyester: A synthetic fiber that’s durable, wrinkle-resistant, and relatively inexpensive. It’s less absorbent than cotton and can feel less comfortable against the skin in hot weather. It’s commonly used in sportswear for its quick-drying properties.

- Nylon: Another synthetic fiber, nylon is incredibly strong, lightweight, and elastic. It’s water-resistant and quick-drying, often used in outerwear and hosiery. Think of the strength and durability of nylon climbing rope.

Understanding these fiber properties allows designers to select the best fabric for a particular application, considering factors such as comfort, durability, and cost.

Q 3. What are the common fabric testing methods used in quality control?

Fabric testing is crucial for quality control, ensuring consistent quality and meeting industry standards. Several methods are commonly used:

- Tensile Strength: Measures the fabric’s resistance to pulling forces, indicating its durability.

- Abrasion Resistance: Assesses the fabric’s ability to withstand rubbing and wear, crucial for garments subjected to friction.

- Colorfastness: Determines the fabric’s resistance to color fading due to washing, light exposure, or rubbing. This is essential to maintain garment appearance over time.

- Shrinkage: Measures the percentage of fabric shrinkage after washing, important to prevent garment distortion.

- Bursting Strength: Determines the fabric’s resistance to tearing from internal pressure, relevant for applications like airbags.

These tests are performed using standardized equipment, and the results are compared to predetermined acceptance criteria to ensure the fabric meets the required quality standards.

Q 4. How do you identify different types of fibers?

Fiber identification is critical for accurate fabric analysis and quality control. Several techniques are employed:

- Microscopic Examination: Observing the fiber’s shape, size, and surface characteristics under a microscope allows identification of different fiber types. Cotton, for example, will show its characteristic twisted ribbon shape.

- Burning Test: Carefully burning a small fiber sample and observing its odor, ash residue, and burning behavior can provide clues. Wool, for instance, will smell like burning hair.

- Solubility Tests: Using specific solvents to dissolve certain fibers helps in their identification. Polyester, for example, is not soluble in most solvents.

- Chemical Tests: Specific chemical reagents can react with certain fibers to confirm their identity.

A combination of these methods is often used to ensure accurate fiber identification, particularly when dealing with blends.

Q 5. Explain the concept of fabric drape and its importance in garment design.

Fabric drape refers to the way a fabric falls and hangs under the influence of gravity. It’s a crucial factor in garment design as it directly impacts the garment’s appearance and the overall silhouette. Imagine the dramatic, flowing drape of silk versus the crisp drape of linen.

Importance in Garment Design: Drape influences the garment’s shape and style, shaping the body and creating a specific look. A fabric with excellent drape will flow nicely and create desirable folds and curves, while a stiff fabric will create a structured shape. Consider the elegant drape required for a flowing evening gown versus the tailored drape needed for a structured blazer.

Understanding fabric drape helps designers choose the right fabric to achieve the desired garment silhouette, avoiding issues such as poor fit or undesirable wrinkles.

Q 6. What are the different types of fabric finishes and their effects?

Fabric finishes modify the properties of a fabric to enhance its performance or aesthetic qualities. Several finishes exist, each impacting the fabric differently:

- Calendering: Pressing the fabric to create a smooth, glossy surface. This improves the fabric’s luster and hand-feel.

- Mercerization: Treating cotton fabric with sodium hydroxide to improve its luster, strength, and dye affinity.

- Water Repellent Finish: Coating the fabric to make it resistant to water absorption, preventing wetting and staining.

- Flame Retardant Finish: Treating the fabric to make it less flammable, improving safety.

- Softening Finish: Applying chemicals to give the fabric a softer, more comfortable feel.

These finishes enhance the fabric’s functionality and appeal for different garment types. For example, a water-repellent finish is crucial for outdoor jackets, while a softening finish is desirable for comfortable pajamas.

Q 7. Describe the process of fabric dyeing and printing.

Fabric dyeing and printing are processes that add color to fabric. While both achieve color, they differ in their approach:

- Dyeing: This involves immersing the fabric in a dye bath to uniformly color the entire fabric. The dye penetrates the fibers, resulting in a solid color throughout. Various dyeing methods exist, such as vat dyeing, reactive dyeing, and direct dyeing, each suitable for different fibers and colors.

- Printing: This is a more localized approach, applying color to specific areas of the fabric using printing methods like screen printing, digital printing, or roller printing. This allows for intricate patterns and designs on the fabric.

The choice between dyeing and printing depends on the design requirements. A simple solid color requires dyeing, while complex patterns necessitate printing. Both processes require careful control of temperature, time, and chemicals to achieve consistent and high-quality results.

Q 8. What are the key factors to consider when selecting fabrics for specific garments?

Selecting the right fabric is crucial for garment success. It’s like choosing the right ingredients for a recipe – the wrong choice can ruin the final product. Key factors depend heavily on the garment’s intended use, target market, and desired aesthetic.

- End-use: A lightweight cotton is perfect for a summer dress, while a heavy wool is ideal for a winter coat. Consider factors like breathability, durability, and drape.

- Target market and price point: Luxury garments might use high-quality silk or cashmere, demanding a higher price point, whereas budget-friendly options might employ blends of polyester and cotton.

- Aesthetic: The desired look and feel influences fabric choice. A crisp, structured look calls for linen or cotton poplin; a flowing, elegant look might suit silk charmeuse or chiffon.

- Maintenance: Consider the ease of care. Some fabrics, like linen, require special washing instructions, while others, such as polyester blends, are more durable and easily cared for.

- Seasonality: Fabrics must be appropriate for the season. Summer fabrics should be breathable and lightweight, while winter fabrics need to offer warmth and insulation.

For example, designing a performance athletic wear line requires fabrics with moisture-wicking properties, excellent elasticity, and durability to withstand repeated washing and strenuous activity. In contrast, a formal evening gown might prioritize luxurious drape and rich color, selecting fabrics like silk or velvet.

Q 9. How do you assess the quality of a fabric sample?

Assessing fabric quality is a multi-sensory process. It goes beyond just looking at the fabric; it involves careful examination and testing.

- Visual Inspection: Check for evenness of weave, consistent color, absence of flaws like holes, knots, or slubs. Look closely at the fabric’s drape and handle.

- Texture and Hand: Feel the fabric. Is it soft, rough, smooth, crisp? The hand (how it feels) is an indicator of quality and fiber type.

- Weight and Thickness: Weigh a standard sample size to assess its density. Thicker fabrics are often more durable but may feel heavier.

- Fiber Content: Identify the fibers (cotton, wool, silk, etc.) using a burn test or microscopic analysis (for a definitive answer). The fiber content significantly impacts the fabric’s properties.

- Strength and Durability: Simple tests, like pulling the fabric gently, can reveal its strength. More rigorous tests, like tensile strength testing, quantify durability.

- Shrinkage: Test for shrinkage by washing a sample according to care instructions. Significant shrinkage indicates poor quality.

Imagine you’re assessing a cashmere sweater. You’d look for a consistent, soft hand, a fine gauge (the fineness of the knit), minimal pilling (the formation of small balls of fiber), and a luxurious drape. Any noticeable irregularities would indicate lower quality.

Q 10. Explain the importance of colorfastness in fabric selection.

Colorfastness is critical. It refers to a fabric’s ability to retain its color when exposed to washing, sunlight, or rubbing. Poor colorfastness leads to fading, discoloration, and bleeding, ruining the garment’s appearance and potentially causing dye transfer to other garments.

Consider a white shirt stained with dye from a poorly colorfast red sweater after washing – a clear example of the problems caused by lacking colorfastness. For instance, a children’s clothing line requires exceptionally high colorfastness to withstand frequent washing and rough play.

Therefore, colorfastness testing, using standard methods like the AATCC tests, is essential during fabric selection. These tests simulate various conditions, evaluating the fabric’s resistance to color loss.

Q 11. What are the common fabric defects and how are they identified?

Fabric defects can significantly impact garment quality. Early detection is crucial to prevent costly mistakes.

- Weaving defects: These include broken ends (missing yarns), slubs (thickened areas of yarn), holes, and mispicks (incorrect interlacing of yarns).

- Knitting defects: Dropped stitches, laddering (runs in the fabric), and holes are common knitting defects.

- Dyeing defects: Uneven dyeing, color bleeding, and shading (variations in color) are dyeing issues.

- Finishing defects: These can involve problems with shrinkage control, creasing, and surface imperfections.

Identifying defects requires careful visual inspection and often specialized testing. For instance, using a magnifying glass can help detect small weaving faults. Fabric testing equipment can quantify defects like uneven dyeing.

For example, a fabric with numerous broken ends might be unsuitable for a tailored suit, as these weak points can easily lead to tears. Similarly, uneven dyeing on a garment designed for a high-end market could be unacceptable.

Q 12. Describe your experience with fabric testing equipment.

My experience with fabric testing equipment is extensive. I’m proficient in using a wide range of instruments, including:

- Tensile strength testers: These measure the fabric’s resistance to pulling forces, indicating its strength and durability.

- Bursting strength testers: These assess the fabric’s resistance to pressure, essential for evaluating its ability to withstand pressure during wear.

- Abrasion testers: These machines simulate wear and tear, measuring the fabric’s resistance to rubbing and friction.

- Colorfastness testers: These test color retention under various conditions (washing, light exposure, rubbing).

- Microscope: Useful for fiber identification and defect analysis.

I have used these instruments extensively to assess the quality of numerous fabrics for various projects, ranging from high-end fashion apparel to industrial textiles. The data obtained from these instruments are critical for informed decision-making during fabric selection and quality control.

Q 13. How do you interpret fabric test reports?

Interpreting fabric test reports requires understanding the specific tests conducted and their relevant standards (e.g., AATCC, ISO). The report should clearly state the test methods used and provide numerical data for various parameters.

For example, a tensile strength test might provide values for warp and weft strength. High values indicate strong and durable fabric. Abrasion resistance values indicate the fabric’s resilience to wear. Colorfastness scores show the fabric’s ability to retain its color. Shrinkage percentages show the potential for fabric dimensions to change after washing.

I analyze these values in the context of the garment’s intended use. Acceptable values depend on the specific application and target quality level. A high-performance athletic wear fabric would require superior strength and abrasion resistance compared to a decorative fabric. Any values outside acceptable ranges would flag potential problems and need further investigation.

Q 14. What are the different types of fabric structures?

Fabric structures are broadly categorized into woven, knitted, and non-woven fabrics. Each type has unique properties affecting drape, durability, and breathability.

- Woven fabrics: Created by interlacing warp (lengthwise) and weft (crosswise) yarns. Examples include plain weave (simple over-under pattern), twill weave (diagonal pattern), satin weave (smooth, lustrous surface).

- Knitted fabrics: Made by interlooping yarns. They are generally more stretchy and drapey than woven fabrics. Examples include jersey (single knit), rib knit (vertical ribs), double knit (more stable and less prone to stretching).

- Non-woven fabrics: Made from fibers bonded together mechanically, chemically, or thermally. They are often less durable than woven or knitted fabrics but offer unique characteristics like high absorbency (e.g., felt, fleece).

Understanding these structures is crucial. For example, a woven fabric with a tight weave is more likely to be durable and less permeable to water, while a loosely knit fabric is more breathable but less durable. The choice depends on the garment’s design and intended function.

Q 15. Explain the concept of fabric shrinkage and how it is controlled.

Fabric shrinkage is the reduction in fabric dimensions after washing or wetting. It occurs due to the relaxation of fibers, yarns, and the fabric structure itself. Several factors contribute to shrinkage, including the type of fiber (wool and cotton are prone to shrinkage), the yarn construction (tightly twisted yarns shrink less), the fabric weave (loose weaves shrink more), and the finishing processes applied.

Controlling shrinkage involves several methods:

- Pre-shrinking: This is a crucial process where the fabric is subjected to controlled washing and drying before it’s made into garments. This process significantly reduces or eliminates further shrinkage after the final product is made. Think of it as ‘training’ the fabric to its final size.

- Fiber Selection: Choosing inherently less shrinkable fibers like polyester or treated cotton can reduce shrinkage issues. Synthetics are generally more dimensionally stable than natural fibers.

- Yarn Construction: Using tightly spun yarns reduces the potential for fiber movement and subsequent shrinkage. It’s like holding a tightly bound rope – it’s less likely to loosen and shrink than one that’s loosely twisted.

- Fabric Construction: Choosing a tightly woven fabric structure minimizes shrinkage. This is directly related to the yarn density and weave patterns.

- Finishing Treatments: Specific chemical treatments can help to minimize shrinkage. These treatments may involve resin finishes or other processes to stabilize the fiber structure.

For example, a high-quality cotton shirt will undergo pre-shrinking to ensure it doesn’t shrink significantly after washing. Conversely, a garment made from untreated wool might shrink considerably unless properly pre-treated.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate fabric for a given application?

Selecting the right fabric for a given application requires careful consideration of several factors. It’s not just about aesthetics, but also about functionality, durability, and cost-effectiveness.

- End Use: What will the fabric be used for? A garment for outdoor activities needs different properties than a delicate evening gown (e.g., durability, water resistance versus drape and softness).

- Fiber Properties: Natural fibers like cotton offer breathability and comfort, while synthetics like polyester provide durability and wrinkle resistance. Consider the fiber’s properties, including its strength, elasticity, moisture absorption, and drape.

- Fabric Construction: The weave, knit, or non-woven structure significantly impacts the fabric’s properties. A tightly woven fabric is more durable than a loosely woven one. Different constructions offer different levels of breathability, drape, and stretch.

- Finishing Processes: Finishes such as water-repellency, wrinkle resistance, or anti-microbial treatments can greatly enhance the fabric’s functionality and suitability for a specific application.

- Cost: Budget considerations are paramount. Some fibers and finishing processes are more expensive than others.

For instance, designing a windbreaker requires a fabric with water resistance and wind protection. Nylon or polyester with a waterproof finish would be ideal, whereas a summer dress would benefit from a lightweight and breathable cotton fabric.

Q 17. What is your experience with different types of textile machinery?

My experience encompasses a broad range of textile machinery, from fiber preparation and spinning to weaving, knitting, and finishing. I’m familiar with:

- Spinning machinery: Ring spinning, open-end spinning, air-jet spinning, and compact spinning machines, understanding their impact on yarn quality and characteristics.

- Weaving machinery: Various types of looms, including projectile, rapier, and air-jet looms, with experience in setting up, troubleshooting, and optimizing production parameters. I understand the impact of loom speed and settings on fabric quality.

- Knitting machinery: Circular and flat knitting machines, with practical knowledge of different knitting structures and their resulting fabric properties. This includes understanding stitch density, needle gauges, and yarn selection.

- Finishing machinery: This includes knowledge of dyeing, printing, bleaching, calendaring, and other finishing processes that impact the final fabric appearance, feel, and performance. I’m familiar with the intricacies of dyeing equipment, such as jet dyeing machines.

This experience helps me understand the entire textile production process, from raw material to finished fabric, enabling me to assess fabric quality, identify potential issues, and optimize production parameters.

Q 18. Explain the importance of sustainability in fabric selection.

Sustainability is increasingly critical in fabric selection, impacting both environmental and social responsibility. It’s not just a trend, but a necessity for ethical and environmentally conscious manufacturing. Consider these factors:

- Fiber Source: Choosing organically grown cotton or recycled fibers reduces the environmental impact compared to conventionally grown cotton, which requires significant amounts of water, pesticides, and fertilizers.

- Production Processes: Assessing the energy consumption and waste generation of the manufacturing process is crucial. Processes that minimize water usage, energy consumption, and waste are preferred.

- Chemical Usage: Minimizing the use of harmful chemicals in dyeing and finishing processes is essential to protect both the environment and the workers’ health. Eco-friendly dyes and finishes are increasingly important.

- End-of-Life Considerations: The recyclability and biodegradability of the fabric are crucial factors to consider. Choosing fabrics that can be recycled or compostable at the end of their life minimizes waste.

- Fair Labor Practices: Ensuring that the fabric is sourced ethically and that fair labor practices are employed throughout the supply chain is essential for social sustainability.

For instance, selecting Tencel (Lyocell) as a fiber shows a commitment to sustainability as it involves a closed-loop production system with low environmental impact. Similarly, utilizing recycled polyester reduces reliance on virgin materials.

Q 19. How do you handle fabric complaints and quality issues?

Handling fabric complaints and quality issues requires a systematic and thorough approach.

- Gather Information: Collect detailed information regarding the complaint, including visual evidence (photos), the circumstances of the issue, and the specific fabric used. If possible, obtain a sample of the faulty material.

- Analyze the Issue: Carefully examine the fabric to determine the root cause of the complaint. Is it a manufacturing defect, a finishing problem, or a result of improper handling or use? Use laboratory testing if necessary.

- Identify the Source: Trace the fabric back through the supply chain to identify the point of origin of the defect. This helps to prevent similar issues in the future.

- Implement Corrective Actions: Depending on the nature of the issue, corrective actions could involve replacing the faulty fabric, adjusting production parameters, or revising quality control procedures. Document all corrective measures taken.

- Communicate with Stakeholders: Keep all relevant stakeholders, including suppliers, customers, and internal teams, informed about the progress of the investigation and the corrective actions taken.

- Preventative Measures: Implement preventative measures to avoid similar issues in the future. This may involve changes in quality control procedures, improved supplier selection, or better training of personnel.

For example, if a customer complains about color fading, we investigate the dye type, the dyeing process, and the post-dyeing treatments to find the cause and prevent it in future production runs. Documentation of the entire process ensures transparency and accountability.

Q 20. Describe your experience working with different types of textile suppliers.

My experience working with textile suppliers is extensive and covers a diverse range of suppliers, from small, local businesses to large, multinational corporations. This includes:

- Domestic Suppliers: I’ve collaborated with numerous domestic suppliers providing various fabrics and materials. This includes building strong relationships based on trust and regular communication.

- International Suppliers: I’ve worked with international suppliers, navigating the complexities of international trade, including logistics, customs, and international quality standards.

- Specialized Suppliers: I’ve sourced specialized fabrics from suppliers specializing in specific fiber types, constructions, or finishing treatments (e.g., technical textiles, performance fabrics).

- Supplier Evaluation: My experience includes evaluating potential suppliers based on their quality control systems, production capacity, sustainability practices, and financial stability. This includes conducting thorough audits to ensure compliance with ethical and environmental standards.

Building strong, collaborative relationships with reliable suppliers is crucial for ensuring consistent fabric quality and timely delivery. Regular communication and feedback are essential to maintain these relationships.

Q 21. Explain the difference between greige goods and finished fabrics.

Greige goods and finished fabrics represent distinct stages in the textile manufacturing process.

- Greige Goods: These are fabrics in their raw, unfinished state, directly off the loom or knitting machine. They haven’t undergone any bleaching, dyeing, or finishing processes. They usually appear dull and lack the desired aesthetic qualities. Think of them as the ‘blank canvas’ before the artistic process begins.

- Finished Fabrics: These are greige goods that have undergone various finishing processes, such as bleaching, dyeing, printing, and various treatments to enhance their appearance, feel, and performance. This is where the fabric gets its final color, texture, and other functional properties, like wrinkle resistance or water repellency.

The difference is akin to the difference between plain, unpainted wood and a finished piece of furniture. The greige good is the raw material, while the finished fabric is the polished, functional, and aesthetically pleasing end product. The transformation from greige goods to finished fabrics often involves significant value addition.

Q 22. What are the various methods for measuring fabric strength?

Measuring fabric strength involves assessing its resistance to various forces. Several methods exist, each targeting different aspects of strength. The most common include:

- Tensile Strength: This measures the fabric’s resistance to pulling forces. A sample is clamped at both ends and stretched until it breaks. The force at breakage and the elongation are recorded. This is crucial for determining a fabric’s suitability for applications requiring high tensile strength like ropes or parachute material.

- Bursting Strength: This tests the fabric’s resistance to a sudden pressure applied across its surface, simulating impact or pressure. A pressure is applied to a small area of the fabric until it ruptures, providing a measure of the fabric’s resistance to pressure. This is important for bags or containers that need to withstand pressure.

- Tear Strength: This evaluates the fabric’s resistance to tearing. A small cut is made in the fabric, and force is then applied to propagate the tear. The force required to extend the tear provides an indication of tear resistance. This is key for applications where snags or tears are a concern, such as clothing.

- Abrasion Resistance: This assesses the fabric’s ability to withstand rubbing or friction. A standardized abrasion test is performed, and the weight loss or changes in fabric appearance are measured to determine its durability under friction. This is critical for assessing the longevity of fabrics subjected to wear and tear.

The choice of method depends on the intended application of the fabric. For example, a fabric designed for upholstery needs high abrasion resistance, while a fabric for a shirt may prioritize tensile strength and drape.

Q 23. How do you assess the durability of a fabric?

Assessing fabric durability is a multifaceted process involving multiple tests and considerations. It’s not just about strength; it encompasses several factors:

- Strength Tests (as detailed above): Tensile, bursting, tear, and abrasion resistance tests are fundamental. They provide quantitative data on the fabric’s ability to withstand stress and wear.

- Colorfastness: This measures the fabric’s resistance to fading from washing, sunlight, or perspiration. We assess color change using standardized scales.

- Dimensional Stability: This evaluates shrinkage or stretching after washing or dry cleaning. We measure dimensional changes to ensure consistent size and shape after laundering.

- Pilling Resistance: This assesses the fabric’s tendency to form pills (small balls of fiber). We subject the fabric to abrasion and evaluate the severity of pilling.

- Wrinkle Resistance: This measures the fabric’s tendency to wrinkle. We assess wrinkle recovery after crumpling or stretching.

By combining the results from these tests, we gain a comprehensive understanding of the fabric’s long-term performance and its suitability for different end uses. For example, a durable outdoor fabric will require high abrasion and colorfastness, while a delicate blouse fabric might prioritize wrinkle resistance and pilling resistance.

Q 24. What is your experience with CAD software used in textile design?

I have extensive experience with various CAD software used in textile design, including industry-standard packages like Lectra Modaris, Gerber Accumark, and Optitex. My expertise extends to using these tools for pattern design, grading, marker making, and 3D visualization.

For example, I’ve used Lectra Modaris to develop complex patterns for garments with intricate details, ensuring precise fit and efficient fabric utilization. Gerber Accumark has been crucial in streamlining marker making processes, reducing fabric waste, and improving production efficiency. Optitex’s 3D simulation capabilities have been invaluable in visualizing fabric drape and fit before actual production, reducing costly errors. I’m proficient in importing and exporting design data between different CAD systems and integrating them with other software for production management.

Q 25. Explain your understanding of different yarn counts and their implications.

Yarn count refers to the number of strands of yarn per unit length or unit weight. Different systems exist, creating potential confusion. The most common include:

- English System (Count): Expresses the number of hanks (840 yards) per pound of yarn. A higher count indicates finer yarn.

- Metric System (Tex): Expresses the weight in grams of 1000 meters of yarn. A higher tex value indicates thicker yarn.

- Denier: Expresses the weight in grams of 9000 meters of yarn. Similar to Tex, a higher denier means thicker yarn.

The implication of yarn count is significant. Finer yarn counts (higher English count, lower Tex/Denier) produce smoother, more delicate fabrics, while coarser yarn counts (lower English count, higher Tex/Denier) result in stronger, more textured fabrics. The choice of yarn count depends on the desired fabric properties like drape, strength, and texture. A fine cotton yarn count will be appropriate for a delicate shirt, whereas a thicker yarn count might be necessary for a durable canvas.

Q 26. How do you handle fabric inconsistencies during production?

Fabric inconsistencies during production are addressed through a multi-pronged approach:

- Preventive Measures: Implementing strict quality control checks at every stage of production, from raw material inspection to weaving or knitting, is crucial. This includes monitoring yarn quality, machine settings, and environmental conditions.

- In-Process Monitoring: Regular checks during production help identify inconsistencies early. This involves examining fabric samples at regular intervals for defects like slubs, uneven dyeing, or weaving flaws.

- Sorting and Grading: Once detected, inconsistencies may be sorted into different grades based on the severity of the defect. First-quality fabric is used for high-end products while lower-grade fabric might be used for less demanding applications.

- Statistical Process Control (SPC): Using SPC methods helps identify patterns in defects and systematically improve processes. It enables the identification of root causes and timely corrective actions.

- Rework or Reclaim: Depending on the nature and extent of the inconsistency, it may be possible to rework the fabric or use it for other purposes, minimizing waste.

A proactive approach to quality control is essential. Identifying and addressing inconsistencies early helps reduce waste and maintains product quality. For instance, if uneven dyeing is observed, we trace the root cause, potentially to the dye bath temperature or mixing, and implement corrective measures.

Q 27. Describe your approach to troubleshooting fabric-related problems.

My approach to troubleshooting fabric-related problems is systematic and data-driven:

- Define the Problem: Clearly identify the nature and extent of the problem. This involves detailed observation of the defect, including its location, frequency, and severity.

- Gather Data: Collect relevant information, such as fabric construction details, processing parameters, and test results. Analyze these data to pinpoint potential causes.

- Formulate Hypotheses: Based on the data, develop plausible hypotheses for the root cause of the problem. This could involve issues with raw materials, processing conditions, or equipment malfunction.

- Test Hypotheses: Design and conduct experiments to test the hypotheses. This may involve repeatability experiments or targeted material testing.

- Implement Corrective Actions: Based on the experimental results, implement appropriate corrective actions to resolve the issue. This might involve adjustments to processing parameters, equipment repair, or supplier changes.

- Verify Solution: Verify the effectiveness of the implemented solutions by repeating testing and monitoring for recurrence of the problem.

For example, if fabric shrinkage is excessive, I would investigate factors such as fiber type, yarn construction, and finishing processes to identify the root cause and recommend adjustments to achieve acceptable shrinkage levels.

Q 28. What are your preferred methods for documenting fabric properties?

Documenting fabric properties is crucial for traceability, quality control, and future reference. My preferred methods combine digital and physical documentation:

- Digital Database: I utilize a comprehensive database system to store fabric information. This system includes details on fiber composition, yarn count, fabric construction (weave, knit, etc.), weight, width, strength test results (tensile, tear, abrasion), colorfastness data, and other relevant properties. Digital images and microscopic images are also stored.

- Physical Samples: Maintaining a physical archive of fabric samples is essential. Samples are properly labeled and stored under controlled conditions to prevent degradation. This ensures that original fabric samples are available for comparison and further testing if needed.

- Test Reports: Standardized test reports documenting all testing procedures and results are maintained. These reports include details of the testing methods used, ensuring that the data is traceable and reliable.

- Specifications Sheets: Detailed specification sheets are created for each fabric, summarizing its key properties and intended end-use applications. These documents serve as a reference for manufacturers and designers.

This combined approach ensures thorough and readily accessible documentation of fabric characteristics. It is an efficient and effective way to manage information and facilitate decision-making throughout the entire product lifecycle.

Key Topics to Learn for Fabric Knowledge and Analysis Interview

- Fiber Properties: Understanding the characteristics of natural (cotton, wool, silk, linen) and synthetic (polyester, nylon, acrylic) fibers; their strengths, weaknesses, and suitability for different applications.

- Yarn Structures: Knowledge of different yarn constructions (e.g., single, ply, core-spun) and their impact on fabric properties like strength, drape, and texture. Practical application: analyzing yarn composition to predict fabric performance.

- Fabric Construction: Mastering various weave structures (plain, twill, satin), knit structures (weft, warp), and non-woven techniques. Problem-solving: identifying fabric construction from a sample to determine its properties and limitations.

- Fabric Testing Methods: Familiarity with standard tests for evaluating fabric properties such as tensile strength, abrasion resistance, colorfastness, and shrinkage. Practical application: interpreting test results to assess fabric quality and suitability.

- Fabric Finishes: Understanding different finishing processes (e.g., mercerization, dyeing, printing) and their effects on fabric hand, appearance, and performance. Problem-solving: troubleshooting fabric defects related to finishing processes.

- Fabric Defects: Identifying common fabric defects (e.g., slubs, holes, mispicks) and understanding their causes and potential solutions. Practical application: quality control and inspection of fabrics.

- Fabric Selection and Application: Matching fabric properties to end-use applications (e.g., apparel, upholstery, industrial textiles). Problem-solving: recommending appropriate fabrics based on specific performance requirements.

Next Steps

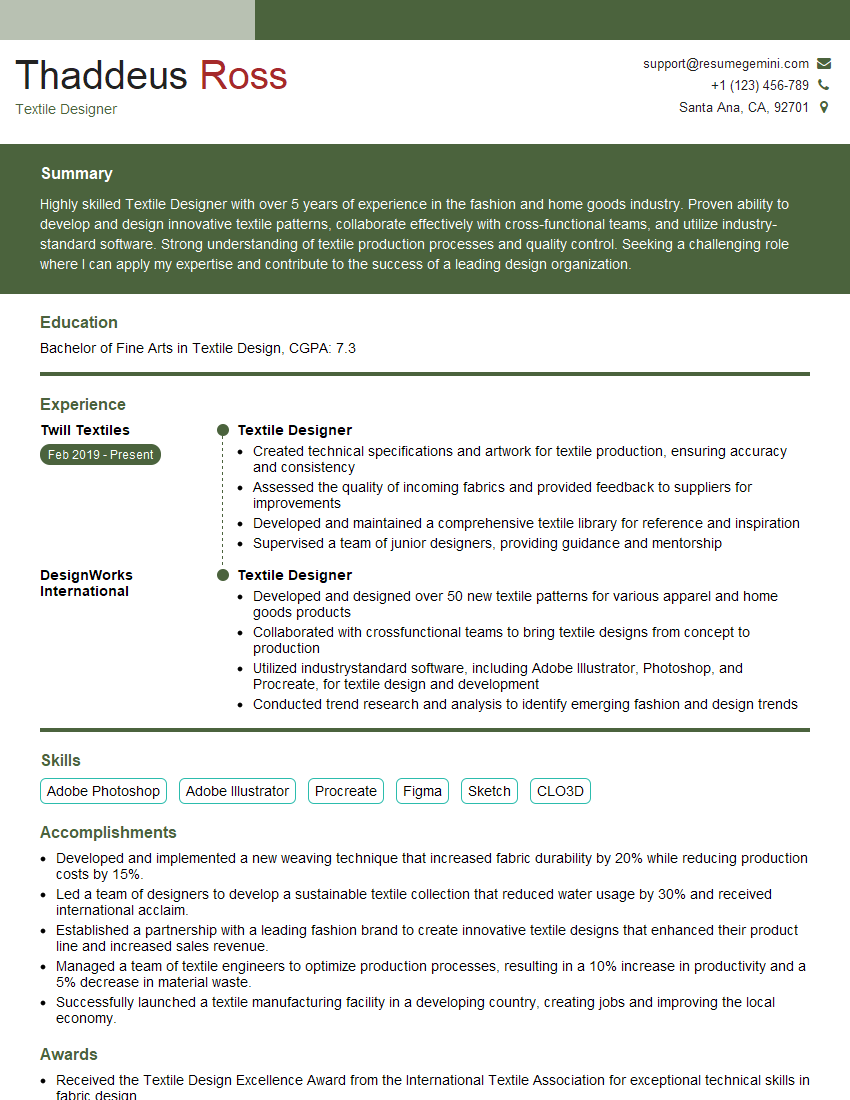

Mastering Fabric Knowledge and Analysis is crucial for career advancement in the textile and apparel industries, opening doors to roles with increased responsibility and higher earning potential. To significantly boost your job prospects, crafting a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to highlight your skills and experience. Examples of resumes tailored to Fabric Knowledge and Analysis are available to help guide your resume creation process. Invest time in crafting a compelling resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good