Preparation is the key to success in any interview. In this post, we’ll explore crucial Fabric Selection and Material Knowledge interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Fabric Selection and Material Knowledge Interview

Q 1. What are the key differences between natural and synthetic fabrics?

Natural and synthetic fabrics differ fundamentally in their origin and properties. Natural fabrics, like cotton, silk, wool, and linen, are derived from natural sources—plants or animals. Synthetic fabrics, such as polyester, nylon, rayon, and acrylic, are manufactured from chemical compounds. This difference leads to significant variations in their characteristics.

- Origin: Natural fabrics originate from plants or animals; synthetic fabrics are created through chemical processes.

- Durability: Natural fabrics often have varying durability depending on the fiber and processing. Synthetics can be very durable or less durable depending on the type and construction.

- Breathability: Natural fibers generally offer better breathability than synthetics, allowing air circulation and moisture wicking. However, advancements in synthetic technology have improved breathability in certain synthetics.

- Drape: Natural fibers often exhibit unique drape properties depending on their structure, while synthetics can vary widely.

- Cost: Natural fabrics usually command higher prices due to their origin and processing compared to the often mass-produced synthetics.

- Care: Care instructions vary widely, with some natural fabrics requiring more delicate handling than synthetics.

For example, cotton is a breathable natural fiber ideal for summer clothing, while polyester is a durable synthetic often used in sportswear for its moisture-wicking properties. Choosing between natural and synthetic fabrics often depends on the desired performance characteristics and the end-use of the garment.

Q 2. Explain the drape characteristics of various fabrics (e.g., silk, cotton, linen).

Drape refers to the way a fabric hangs or falls when it is not supported. Different fabrics possess unique drape characteristics influenced by fiber type, weave structure, and finishing processes.

- Silk: Known for its luxurious, smooth drape that falls in graceful folds. Its inherent luster and softness contribute to its elegant drape.

- Cotton: Cotton’s drape varies widely depending on its weave and weight. Lightweight cotton fabrics have a softer drape, while heavier weights can be stiffer.

- Linen: Linen possesses a crisp, slightly stiff drape with a characteristic texture. Its fibers’ strength result in a more structured drape than some softer fabrics.

Imagine silk flowing like a waterfall, cotton exhibiting a softer, gentler fall, and linen hanging in crisper, more defined lines. These differences are critical for garment design; silk’s drape suits flowing dresses, cotton’s versatility allows for various styles, and linen’s structured drape works well in tailored pieces.

Q 3. How does fabric weight influence garment construction and fit?

Fabric weight significantly impacts garment construction and fit. Heavier fabrics require more robust construction techniques and affect the overall silhouette.

- Construction: Heavier fabrics necessitate stronger seams and more durable stitching to withstand stress. Lighter fabrics, conversely, allow for more delicate construction methods.

- Fit: Heavy fabrics tend to create a more structured and formal fit, often clinging less to the body than lighter fabrics. Lighter fabrics can drape more loosely, creating a softer or more flowing silhouette.

- Design Considerations: Heavier fabrics may not be suitable for garments requiring intricate detail work or delicate draping. Similarly, lighter weight fabrics might lack the structure needed for more formal or tailored items.

For instance, a heavy wool coat needs strong seams and interfacing for structural support, unlike a lightweight chiffon blouse that can be easily constructed with simpler seams.

Q 4. Describe the various weave structures and their impact on fabric properties.

Weave structures describe how yarns are interlaced to create fabric. Different weave structures significantly influence a fabric’s properties:

- Plain Weave: The simplest weave, where warp and weft yarns interlace in an over-under pattern. It results in fabrics with moderate strength, durability, and breathability (e.g., calico, muslin).

- Twill Weave: Characterized by diagonal lines created by yarns floating over multiple yarns before interlacing. This creates durable, strong, and wrinkle-resistant fabrics (e.g., denim, gabardine).

- Satin Weave: Creates a smooth, lustrous surface with long floats on the surface. It yields luxurious but less durable fabrics prone to snagging (e.g., satin, charmeuse).

The weave structure directly impacts the fabric’s texture, drape, durability, and overall appearance. A twill weave’s diagonal lines create a more structured drape than a plain weave’s simple pattern. The smoothness of satin contrasts sharply with the texture of twill, impacting its use in garments.

Q 5. What are the common fabric finishes and their effects on performance?

Fabric finishes modify a fabric’s properties to enhance its performance and appearance.

- Mercerization: Treatment of cotton to increase its luster, strength, and dye affinity.

- Calendering: Pressing the fabric to create a smooth or embossed finish.

- Water-Repellent Finishes: Applied to make the fabric resistant to water, useful in outerwear.

- Flame-Resistant Finishes: Used for safety in specific applications.

- Shrink-Proofing: Prevents shrinkage during washing.

For example, mercerized cotton is stronger and more lustrous than untreated cotton, while a water-repellent finish is essential for raincoats. These finishes tailor the fabric to meet specific needs of the garment and its intended use.

Q 6. Explain the concept of fabric hand and its importance in selection.

Fabric hand refers to the tactile quality of a fabric—how it feels to the touch. It encompasses aspects like softness, smoothness, stiffness, and texture.

- Importance: Fabric hand significantly impacts the consumer’s perception of quality and comfort. A garment’s success often depends on its pleasing hand.

- Factors Influencing Hand: Fiber type, yarn structure, weave structure, and finishes all contribute to a fabric’s hand.

Think about the difference between stroking a soft cashmere sweater and a coarse burlap sack. The significant difference in their hand influences their suitability for different garments and applications. A luxurious hand is typically associated with higher quality and commands a higher price.

Q 7. How do you determine the appropriate fabric for a specific garment?

Selecting the appropriate fabric for a specific garment involves considering several interconnected factors.

- Garment Style: A flowing dress would need a drapey fabric like silk or rayon, while a tailored suit requires a structured fabric like wool or linen.

- Season: Breathable fabrics like cotton and linen are suitable for warm weather, while heavier fabrics like wool or cashmere are ideal for colder climates.

- Intended Use: Sportwear needs fabrics that wick moisture and are durable, while formal wear often requires luxurious fabrics with elegant drape.

- Care Instructions: The ease of care impacts fabric selection. A busy professional might favor wrinkle-resistant fabrics that require less maintenance.

- Budget: Fabric costs can vary significantly. It’s important to balance fabric qualities with budgetary constraints.

Determining the right fabric is a holistic process involving considering the style, season, intended use, care, and budget. This ensures the final garment meets both aesthetic and practical requirements.

Q 8. Discuss the importance of colorfastness and its testing methods.

Colorfastness is crucial in fabric selection; it refers to a fabric’s ability to retain its color despite exposure to various factors like light, washing, and rubbing. Poor colorfastness leads to fading, bleeding, or discoloration, rendering the garment or product unattractive and potentially damaging other items. Testing methods are vital to ensure acceptable colorfastness levels.

- Lightfastness Testing: Samples are exposed to controlled light sources (xenon arc lamps) simulating sunlight to measure color change. The results are graded according to standardized scales (e.g., Blue Wool Scale).

- Washfastness Testing: Samples are laundered under specific conditions (temperature, detergent, agitation) to evaluate color bleeding and fading. The change in color is assessed using a gray scale.

- Rubbing Fastness Testing: This tests color transfer when rubbed with a specified material (e.g., white cotton cloth) under controlled pressure. Again, a gray scale is used to determine the degree of color transfer.

- Perspiration Fastness Testing: This measures color change upon contact with artificial sweat solutions, simulating human perspiration.

These tests provide objective data for assessing colorfastness, helping manufacturers and buyers make informed decisions about fabric suitability for specific applications. For example, a fabric intended for swimwear needs superior lightfastness and chlorine resistance compared to a piece of indoor upholstery.

Q 9. What are the key factors to consider when sourcing fabrics?

Sourcing fabrics involves a multifaceted decision-making process. Key factors include:

- Fiber Content and Properties: Understanding the fiber’s characteristics (strength, drape, durability, wrinkle resistance) is paramount. Cotton is breathable but wrinkles easily, while polyester is durable but less breathable.

- Fabric Construction: The weave (plain, twill, satin), knit structure, and finishing treatments impact the final fabric’s properties (e.g., weight, texture, hand feel). A tightly woven fabric will be more durable than a loosely woven one.

- Quality and Consistency: Sourcing from reputable suppliers ensures consistent quality throughout the production run. This involves examining fabric samples for defects and conducting rigorous testing.

- Cost and Availability: Balancing cost-effectiveness with quality is crucial. The fabric’s price should reflect its properties and intended application.

- Lead Times and Minimum Order Quantities (MOQs): Understanding production timelines and MOQs is essential for planning and managing inventory.

- Sustainability and Ethical Considerations: Increasingly, businesses prioritize eco-friendly and ethically sourced fabrics, considering factors like water usage, chemical treatments, and fair labor practices.

Consider the example of a high-end clothing manufacturer. They would prioritize premium quality fibers like organic cotton or sustainably sourced silk, focusing on unique weave structures and finishes. The cost is higher, but aligns with the brand’s image and target market.

Q 10. How do you assess the quality of a fabric sample?

Assessing a fabric sample requires a thorough examination focusing on several key aspects:

- Visual Inspection: Checking for uniformity in color, texture, and weave. Any inconsistencies, such as slubs, holes, or discoloration, point to quality issues.

- Hand Feel: Evaluating the fabric’s texture, drape, and softness. This gives a sense of its overall quality and suitability for a specific application.

- Fiber Content Analysis: Determining the fiber composition through burning tests or microscopy ensures accuracy in labeling and helps predict fabric performance.

- Strength and Durability Testing: Simple tests, such as pulling threads or applying pressure, can reveal strength and resistance to tearing.

- Shrinkage Test: Measuring shrinkage after washing provides an estimate of the fabric’s dimensional stability.

- Colorfastness Assessment: Preliminary checks for colorfastness to light and rubbing can indicate potential issues.

For example, when assessing a wool sample for a suit, one would look for a consistent, even texture, a smooth drape, and a high degree of strength and resilience. A noticeable variation in color or the presence of knots would be cause for concern.

Q 11. Explain different fiber types (cotton, wool, silk, polyester, nylon etc.) and their properties.

Different fiber types exhibit unique properties:

- Cotton: A natural cellulosic fiber known for its softness, breathability, and absorbency. It’s versatile but wrinkles easily and can shrink.

- Wool: A natural protein fiber providing warmth, elasticity, and moisture-wicking properties. It’s durable but can be sensitive to moths and harsh cleaning.

- Silk: A luxurious natural protein fiber offering smoothness, luster, and excellent drape. It’s delicate and requires careful handling.

- Polyester: A synthetic fiber known for its durability, wrinkle resistance, and low cost. It’s less breathable and prone to static cling.

- Nylon: A strong, resilient synthetic fiber commonly used in hosiery and outerwear. It offers good elasticity and is resistant to stretching.

- Linen: A natural cellulosic fiber known for its strength, durability and breathability. Its texture is often rough.

- Rayon: A semi-synthetic fiber made from cellulose; it has a soft, smooth feel with good drape but poor durability.

The choice of fiber type dictates the final product’s properties. A sportswear brand might prioritize nylon’s strength and moisture-wicking, while a luxury fashion house might choose silk for its elegant drape and luxurious feel.

Q 12. Describe the process of fabric testing and quality control.

Fabric testing and quality control is a systematic process ensuring consistent quality. It involves:

- Incoming Inspection: Checking the raw materials (fibers, yarns) for defects and compliance with specifications.

- In-Process Testing: Monitoring fabric production for consistent quality, including checks on yarn count, fabric weight, and other parameters.

- Finished Goods Testing: Evaluating the final fabric for defects, colorfastness, strength, and other relevant properties. This often involves physical tests and laboratory analyses.

- Statistical Process Control (SPC): Utilizing statistical methods to monitor production processes and identify potential problems before they escalate.

- Quality Assurance (QA) Procedures: Implementing standardized procedures and documentation to maintain consistency and traceability.

A dedicated quality control department might employ sophisticated equipment like tensile testers, colorimeters, and microscopes. The data generated helps identify deviations from standards and enables corrective actions, ultimately reducing waste and ensuring customer satisfaction.

Q 13. How do you choose a fabric considering sustainability and ethical sourcing?

Choosing sustainable and ethically sourced fabrics involves prioritizing materials and suppliers with minimal environmental and social impact.

- Organic Fibers: Opting for organic cotton, wool, or silk produced without harmful pesticides or fertilizers.

- Recycled Fibers: Using recycled polyester, nylon, or other fibers reduces reliance on virgin materials.

- Sustainable Production Practices: Choosing suppliers committed to reducing water and energy consumption and minimizing waste.

- Fair Labor Practices: Prioritizing suppliers that ensure fair wages, safe working conditions, and no child labor.

- Certifications: Looking for certifications like GOTS (Global Organic Textile Standard), OEKO-TEX Standard 100, or Fair Trade labels provides assurance of ethical and sustainable production.

For instance, a company focused on sustainability might opt for organic cotton sourced from a Fair Trade certified supplier, ensuring environmental responsibility and worker welfare. While the upfront cost may be higher, it aligns with their brand values and attracts environmentally conscious customers.

Q 14. What are the common fabric defects and their causes?

Several common fabric defects can occur during production or handling. Understanding their causes is critical for prevention:

- Slubs: Thickened areas in the yarn resulting from uneven spinning. They compromise the fabric’s appearance and evenness.

- Holes: Breaks or missing yarns caused by machine malfunction, rough handling, or inherent weakness in the yarn.

- Broken Ends: Individual yarns breaking during weaving or knitting, leading to visible gaps in the fabric.

- Pilling: Small balls of fiber forming on the fabric surface due to friction; it affects appearance and reduces durability.

- Wrinkles: Permanent creases or folds in the fabric due to improper finishing or handling.

- Uneven Dyeing: Inconsistent color distribution caused by improper dyeing processes or variations in fiber absorbency.

Understanding defect causes allows for improved manufacturing processes and better quality control. For instance, adjusting spinning parameters can reduce slubs, while proper handling can minimize holes and broken ends. Regular maintenance of dyeing equipment can address uneven dyeing.

Q 15. How do different fabric constructions impact durability and comfort?

Fabric construction significantly impacts both durability and comfort. Think of it like building a house: the type of bricks (fibers), how they’re arranged (yarn structure), and how they’re connected (fabric construction) all determine its strength and livability.

- Durability: Tightly woven fabrics, like those used in denim, are inherently more durable because the yarns are closely interlocked, resisting wear and tear. Conversely, loosely knit fabrics, such as jersey, are more prone to snags and stretching. The type of yarn also plays a key role; stronger yarns (like nylon) create more durable fabrics than weaker ones (like silk).

- Comfort: Loosely constructed fabrics, like knits, often drape better and feel softer against the skin, enhancing comfort. However, these fabrics may not offer the same level of protection from the elements or provide the same structure as tightly woven fabrics. Factors like breathability (determined by fiber type and weave structure) and moisture-wicking properties also impact comfort. A tightly woven, waterproof fabric might be durable but less breathable than a loosely woven linen.

For example, a tightly woven canvas is incredibly durable but less comfortable for clothing than a loosely knit cotton jersey. Understanding this interplay is crucial for selecting the right fabric for a specific application.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Discuss the relationship between fabric selection and garment manufacturing processes.

Fabric selection is intrinsically linked to garment manufacturing processes. The choice of fabric dictates the machinery, techniques, and even the overall workflow of production. Imagine trying to sew a delicate silk chiffon on a heavy-duty industrial sewing machine – it would be a disaster!

- Weaving vs. Knitting: Woven fabrics require looms, while knitted fabrics use knitting machines. The fabric’s structure dictates the appropriate machinery and skills required. A highly complex jacquard weave requires specialized looms and skilled operators.

- Fabric Weight and Drape: Heavy fabrics like wool require sturdier sewing machines and needles than lightweight fabrics like voile. Drape heavily influences pattern cutting and construction techniques.

- Fiber Properties: Synthetic fibers might require different cutting and sewing techniques than natural fibers due to their elasticity and heat-sensitivity. For example, certain synthetics are prone to melting under high heat, which necessitates using different press settings.

- Finishing Processes: The choice of fabric influences finishing techniques such as dyeing, printing, and washing. Delicate fabrics need gentler processing than more robust ones. A delicate silk requires a specialized dyeing process to prevent damage.

In short, fabric selection isn’t just an aesthetic choice; it’s a critical decision that impacts the entire manufacturing process, affecting efficiency, cost, and the final garment’s quality.

Q 17. What are the challenges in selecting fabrics for performance apparel?

Selecting fabrics for performance apparel presents unique challenges. The fabric must not only look good but also perform optimally under specific conditions, often involving extreme temperatures, moisture, or physical activity.

- Moisture Management: The fabric needs to wick away sweat efficiently to prevent discomfort and overheating, requiring the use of specialized fibers like polyester or nylon blends. Finding the balance between wicking and breathability is key.

- Breathability: The fabric must allow air circulation to keep the wearer cool and prevent overheating. Open weaves or specialized membrane technologies are commonly employed.

- Durability and Abrasion Resistance: Performance apparel faces considerable stress and friction, demanding durable fabrics that withstand repeated wear and tear.

- Stretch and Recovery: For activewear, the fabric should offer sufficient stretch for freedom of movement, yet retain its shape after stretching (recovery).

- UV Protection: Often, performance apparel needs to shield the wearer from harmful UV rays, requiring fabrics with a high UPF rating.

For instance, choosing the right fabric for running tights involves considering moisture-wicking properties, stretch, breathability, and durability to ensure comfort and performance during strenuous activity. The wrong choice can lead to overheating, chafing, or premature wear.

Q 18. Explain how fabric flammability is tested and regulated.

Fabric flammability is rigorously tested and regulated to ensure safety. Several standardized tests determine a fabric’s flammability, and regulations vary depending on the intended use and geographical location.

- Testing Methods: Common tests include the vertical burn test (ASTM D6413), which measures the speed of flame spread, and the horizontal burn test (ASTM D4036) for assessing ignition resistance. Specific standards exist for children’s sleepwear, which mandates stricter flammability standards.

- Regulations: Regulatory bodies, such as the Consumer Product Safety Commission (CPSC) in the US and similar organizations worldwide, establish flammability standards and enforce compliance. These regulations often specify maximum allowable flame spread rates and ignition times for different fabric types and end-uses.

- Certification and Labeling: Manufacturers may obtain certifications to demonstrate their fabrics meet flammability requirements. Labels often indicate the fabric’s flammability characteristics or compliance with relevant standards. For example, certain clothing items intended for specific uses, such as firefighter uniforms, must meet stringent flammability standards and carry appropriate certifications.

Failure to meet flammability standards can lead to product recalls, legal action, and significant reputational damage. Rigorous testing and compliance are essential aspects of responsible fabric manufacturing.

Q 19. How do you handle discrepancies between fabric specifications and actual fabric properties?

Discrepancies between fabric specifications and actual properties are a serious issue. A robust quality control process is essential to identify and address such problems.

- Thorough Testing: Upon receiving the fabric, a comprehensive evaluation is performed, including tests for strength, colorfastness, shrinkage, and other relevant properties. These tests compare the received fabric’s properties against the original specifications.

- Root Cause Analysis: If discrepancies are found, a thorough investigation is initiated to determine the root cause. This could involve reviewing production records, inspecting the manufacturing process, or analyzing the raw materials.

- Communication and Collaboration: Open communication with the fabric supplier is vital. Any discrepancies are discussed to find solutions, which may involve negotiating replacements or adjusting production processes.

- Documentation and Record Keeping: Meticulous record-keeping is crucial, documenting all testing results, communications with suppliers, and any corrective actions taken. This ensures accountability and helps prevent similar issues from recurring.

For example, if the fabric’s shrinkage rate is higher than specified, we’d investigate the dyeing process, pre-treatment, or even the fiber itself. Depending on the severity, we might request a replacement or adjust the garment’s pattern to compensate for the additional shrinkage.

Q 20. What is your experience with different knitting and weaving techniques?

My experience encompasses a wide range of knitting and weaving techniques. I’ve worked with various constructions, understanding their strengths and limitations.

- Knitting: I’m proficient in jersey, rib, interlock, and double-knit constructions. I understand how stitch structures affect drape, elasticity, and stability. My experience extends to different knitting machine types, from flat bed to circular knitting machines. I know how to assess the quality and structure of a knitted fabric by evaluating its stitch definition and hand-feel.

- Weaving: My expertise includes plain weave, twill weave, satin weave, and jacquard weaves. I understand how warp and weft yarns interact to create different textures and appearances. I am familiar with various weaving patterns and their impact on durability, drape, and visual appeal. I can distinguish between different weave structures by visually inspecting the fabric and understanding its construction.

This knowledge allows me to effectively select appropriate knitting or weaving techniques for specific garment requirements, considering factors like desired drape, durability, and cost-effectiveness. For instance, I know that a tightly woven twill is appropriate for a durable work pant, whereas a loosely knit jersey is ideal for a comfortable T-shirt.

Q 21. Describe your experience with CAD software for textile design and selection.

I’m proficient in several CAD software packages for textile design and selection, including [List specific software, e.g., Adobe Illustrator, CLO 3D, Optitex]. These tools are invaluable for visualizing fabric properties, creating designs, and simulating the drape and behavior of different fabrics in a garment.

- Fabric Libraries: I utilize built-in fabric libraries or create custom ones to easily access and manage fabric information, including physical properties, drape characteristics, and color options. This streamlines the fabric selection process.

- Virtual Prototyping: I use CAD software to create virtual prototypes, allowing me to experiment with different fabrics and designs without needing physical samples. This saves time and reduces material waste.

- Pattern Making and Grading: I leverage CAD software for creating patterns and grading them for different sizes, optimizing the use of fabric and minimizing waste. This is particularly important for complex designs and high-volume production.

- Color and Texture Simulation: I use CAD capabilities to simulate the appearance of different fabrics and colors in a design, ensuring accuracy and consistency between the design concept and the finished product.

For example, using CLO 3D, I can simulate how a particular silk fabric drapes on a 3D avatar, enabling me to make informed decisions about fabric suitability and design adjustments before production begins. This advanced simulation capability reduces the risk of errors and allows for more precise fabric selection.

Q 22. How do you stay up-to-date with the latest trends in fabric technology?

Staying current in the dynamic world of fabric technology requires a multi-pronged approach. I leverage several key resources to ensure I’m always informed about the latest innovations and trends.

- Industry Publications and Journals: I regularly read publications like Textile World, Textile Today, and others specific to niche areas like performance fabrics or sustainable textiles. These provide in-depth analysis of new materials, processes, and market trends.

- Trade Shows and Conferences: Attending events like Premiere Vision, Texworld, and industry-specific conferences allows me to network with leading manufacturers, researchers, and designers. It’s a great opportunity for hands-on experience with new fabrics and to learn directly from experts.

- Online Resources and Databases: I utilize online databases like those offered by textile research institutions and material science organizations. These often contain detailed technical specifications and research papers on emerging fabric technologies.

- Supplier Relationships: Maintaining strong relationships with key fabric suppliers provides early access to information on new developments and allows me to discuss specific application needs and explore customized solutions.

- Continuing Education: I actively participate in workshops and online courses focused on advancements in textile engineering, material science, and sustainable textile practices. This ensures my knowledge remains sharp and aligned with industry best practices.

For example, recently I discovered a new bio-based nylon developed using castor beans at a trade show. This immediately sparked ideas for sustainable apparel applications.

Q 23. What is your approach to problem-solving when faced with fabric-related challenges?

My approach to problem-solving with fabric-related challenges is systematic and data-driven. It involves these key steps:

- Problem Definition: Clearly defining the issue, identifying the specific fabric-related shortcoming, and understanding the desired outcome are crucial. Is it durability, drape, cost, or a regulatory compliance issue?

- Data Gathering: I gather all relevant information about the fabric, its composition, manufacturing process, and performance characteristics. This often involves laboratory testing or consulting technical data sheets.

- Root Cause Analysis: Using the gathered data, I systematically analyze the root cause of the problem. Is it a flaw in the material itself, an issue with the manufacturing process, or an incorrect application of the fabric?

- Solution Generation: Based on the root cause analysis, I brainstorm potential solutions, considering factors like cost-effectiveness, sustainability, and the feasibility of implementation.

- Solution Testing and Evaluation: Selected solutions are thoroughly tested and evaluated to ensure effectiveness and to identify any potential drawbacks. This may involve physical testing, simulations, or pilot projects.

- Implementation and Monitoring: Once a suitable solution is found, I oversee its implementation and closely monitor its performance to ensure it addresses the initial problem and meets the project objectives.

For instance, I once encountered a problem with a fabric’s excessive shrinkage after washing. Through testing, I identified the cause as an improper pre-treatment process. The solution was to implement a new pre-shrinking method, resolving the issue.

Q 24. Explain the importance of understanding the end-use application when selecting a fabric.

Understanding the end-use application is paramount in fabric selection. The fabric’s performance must align perfectly with how it will be used. Neglecting this can lead to product failure, customer dissatisfaction, and financial losses.

Consider these factors influenced by the end-use:

- Durability and Abrasion Resistance: A fabric for outdoor furniture needs significantly higher abrasion resistance than one for a blouse.

- Water Resistance and Breathability: A rain jacket demands waterproofness, while athletic wear prioritizes breathability and moisture-wicking.

- Drape and Hand Feel: A flowing evening gown requires a different drape than a sturdy work uniform.

- Care Instructions: A delicate silk scarf needs different care than a machine-washable cotton t-shirt. This impacts the selection of fibers and finishes.

- Regulatory Compliance: A child’s toy fabric must adhere to strict safety standards concerning flammability and toxicity, while apparel might have specific regulations on dyes.

For example, selecting a lightweight, breathable fabric for a summer dress wouldn’t be suitable for a winter coat, which requires warmth and insulation.

Q 25. How do you communicate technical fabric information to non-technical stakeholders?

Communicating technical fabric information to non-technical stakeholders requires clear, concise, and relatable language, avoiding jargon. I use several techniques:

- Visual Aids: Using charts, graphs, and images simplifies complex data. Showing fabric swatches and samples enhances understanding.

- Analogies and Metaphors: Relating fabric properties to familiar experiences makes technical concepts more accessible (e.g., comparing a fabric’s drape to silk or cotton).

- Focus on Key Performance Indicators (KPIs): Instead of overwhelming them with technical details, I highlight the most relevant KPIs for the application, such as water resistance, durability, or comfort.

- Storytelling: Narrating the fabric’s journey from fiber to finished product helps connect with the audience on a more personal level.

- Simplified Language and Terminology: Using layman’s terms eliminates confusion. If technical terms are necessary, I ensure to define them clearly.

For example, instead of saying ‘the fabric exhibits high tensile strength,’ I might say, ‘This fabric is very strong and resistant to tearing.’ This makes the information easily understandable for all.

Q 26. Describe your experience with different fabric costing and pricing models.

My experience encompasses several fabric costing and pricing models. The most common include:

- Cost-Plus Pricing: This model calculates the total cost of production (raw materials, labor, overhead) and adds a predetermined markup to determine the selling price. This is transparent but might not account for market fluctuations.

- Value-Based Pricing: This sets prices based on perceived value to the customer. It considers factors like brand reputation, unique properties, and market demand. This might involve a premium price for high-performance or sustainable fabrics.

- Competitive Pricing: This aligns prices with competitors while considering the unique value proposition of the product. It’s reactive rather than proactive.

- Market-Based Pricing: This adjusts prices according to market trends and demand. This is suitable for commodities, where prices fluctuate greatly.

- Target Costing: This sets a target price and works backward to determine the maximum cost of production. This is beneficial for meeting budgetary constraints.

Selecting the appropriate model depends on factors such as production scale, market competition, and target customer segments. I have experience adapting these models for different projects and clients.

Q 27. What are the legal and regulatory considerations related to fabric selection?

Legal and regulatory considerations regarding fabric selection are crucial and vary considerably depending on the end-use and geographic location. Key areas include:

- Flammability Standards: Many countries have stringent regulations regarding flammability, especially for fabrics used in apparel, bedding, and upholstery. Examples include the California Technical Bulletin 116 (CBTB 116) and international standards like ISO 3795.

- Chemical Safety: Regulations exist regarding the use of harmful chemicals in dyes and finishes. Restrictions on azo dyes, formaldehyde, and heavy metals are common. REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the EU is a prime example.

- Labeling Requirements: Accurate labeling of fiber content and care instructions is mandatory in most markets, to avoid misleading consumers. This often requires compliance with national standards.

- Textile Waste Management: Growing environmental concerns necessitate compliance with regulations on waste disposal and recycling of textile materials. This includes the management of dyehouse effluent and textile waste streams.

- Intellectual Property: Protecting designs and technologies through patents and trademarks is important for manufacturers. This requires understanding intellectual property rights related to fabric patterns and manufacturing processes.

Understanding and adhering to these regulations is critical to avoiding legal issues and ensuring product safety and ethical sourcing.

Q 28. Discuss your experience with global fabric suppliers and their sourcing capabilities.

My experience includes collaborations with global fabric suppliers across Asia, Europe, and North America. This has given me a broad understanding of their sourcing capabilities and diverse strengths.

- Geographic Specialization: Certain regions specialize in specific fabric types. For example, Italy is known for high-quality silk and wool, while China excels in large-scale production of synthetic fabrics. I understand these regional specializations and leverage them to source optimal materials.

- Production Capacity and Technology: Different suppliers possess varying production capabilities and technological advancements. I consider these factors to select suppliers that meet project scale, quality, and delivery demands.

- Sustainability and Ethical Sourcing: I actively seek suppliers committed to sustainable practices, including responsible water and energy use, ethical labor conditions, and waste reduction. I perform due diligence to ensure compliance with ethical sourcing standards.

- Quality Control and Certification: Working with suppliers possessing robust quality control measures and certifications (e.g., OEKO-TEX, GOTS) ensures consistency and compliance with industry standards.

- Communication and Collaboration: Effective communication and collaborative relationships with suppliers are paramount to ensure timely delivery and problem resolution. Cultural differences are considered to foster a productive partnership.

For example, for a project requiring high-performance outdoor fabric, I sourced from a specialized supplier in Germany known for its advanced fabric technologies and rigorous quality control.

Key Topics to Learn for Fabric Selection and Material Knowledge Interview

- Fiber Properties: Understanding natural (cotton, wool, silk, linen) and synthetic (polyester, nylon, rayon) fibers; their characteristics (strength, drape, absorbency, durability), and suitability for different applications.

- Fabric Construction: Knowledge of weaving, knitting, and non-woven techniques; their impact on fabric properties (texture, weight, breathability); identifying different weave structures (plain, twill, satin).

- Fabric Finishes: Understanding various finishes (mercerization, dyeing, printing, water-repellent treatments); their effects on fabric aesthetics and performance; and their relevance to end-use.

- Fabric Testing and Quality Control: Familiarity with common fabric testing methods (strength, abrasion resistance, colorfastness); understanding quality standards and their importance in ensuring product consistency.

- Sustainability and Ethical Sourcing: Awareness of eco-friendly materials, sustainable manufacturing practices, and ethical sourcing of fabrics; understanding the importance of responsible material selection.

- Application and Problem-solving: Analyzing fabric requirements for specific garments or products based on factors like end-use, target market, and budget; troubleshooting issues related to fabric selection and performance.

- Industry Trends and Innovation: Staying updated on emerging materials, technologies, and trends in fabric development; demonstrating an understanding of innovative sustainable and functional fabrics.

Next Steps

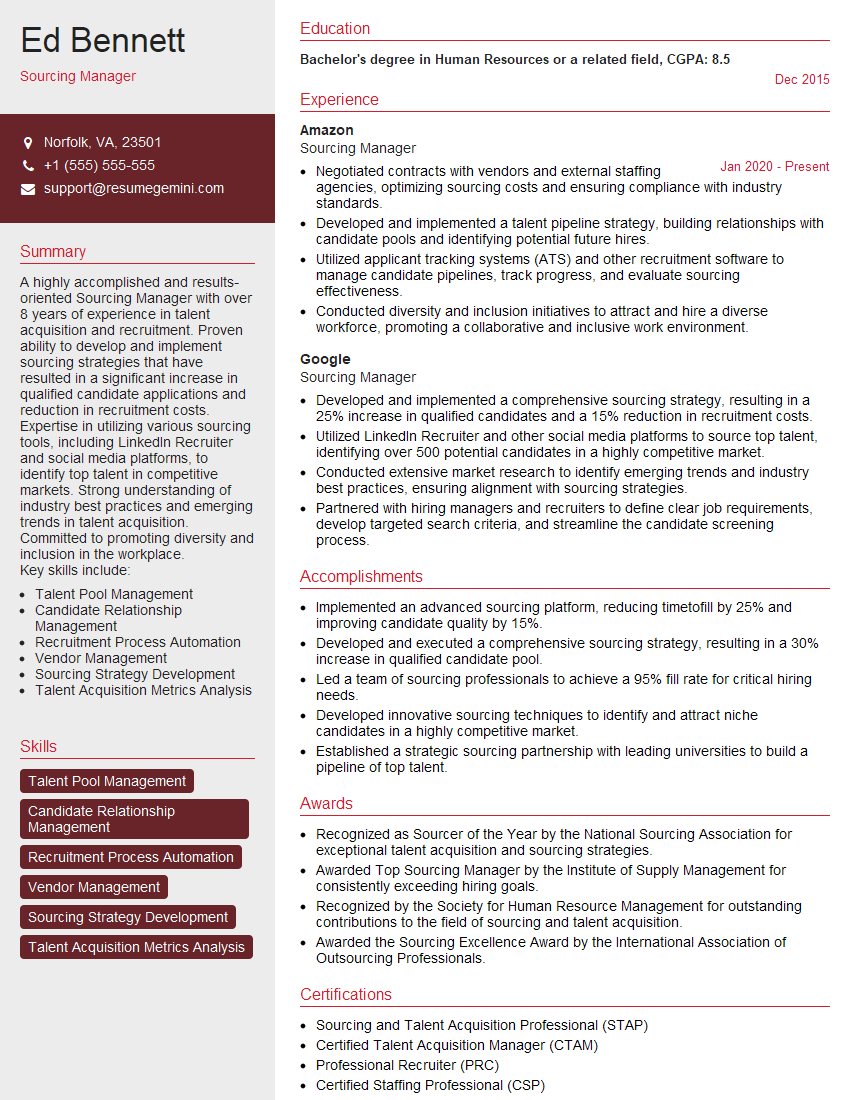

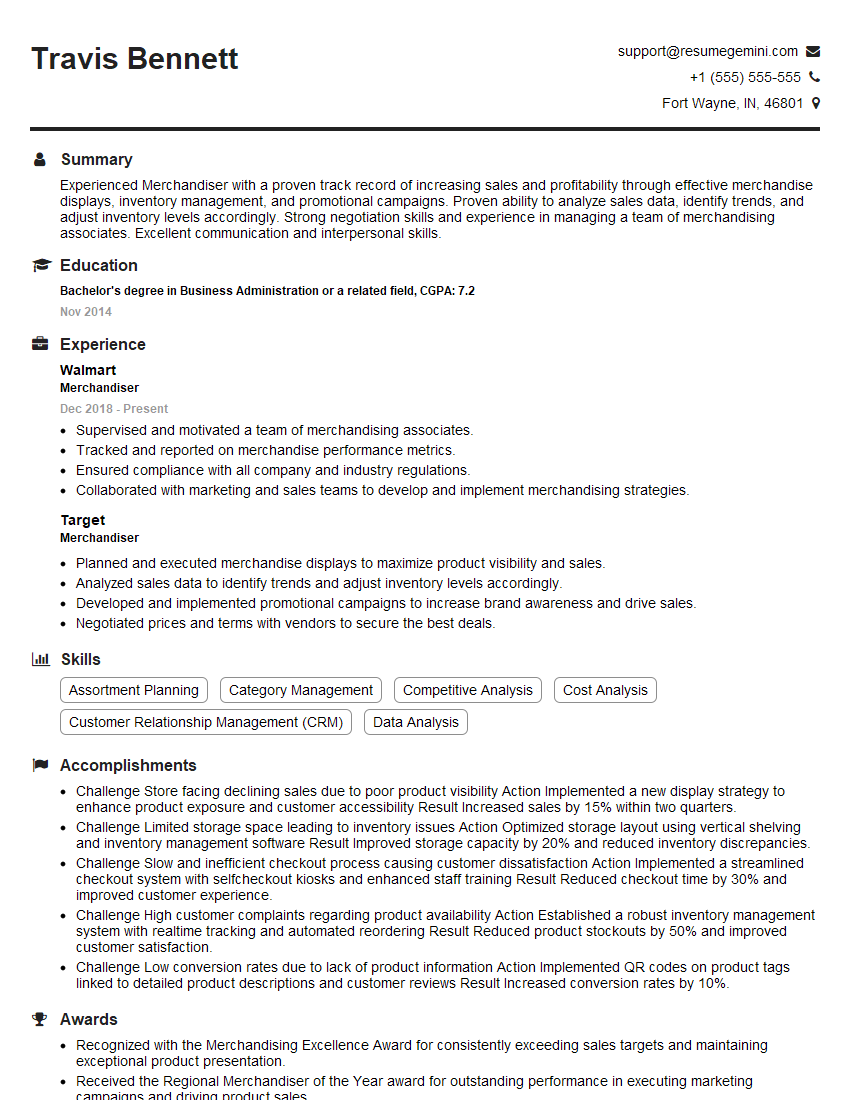

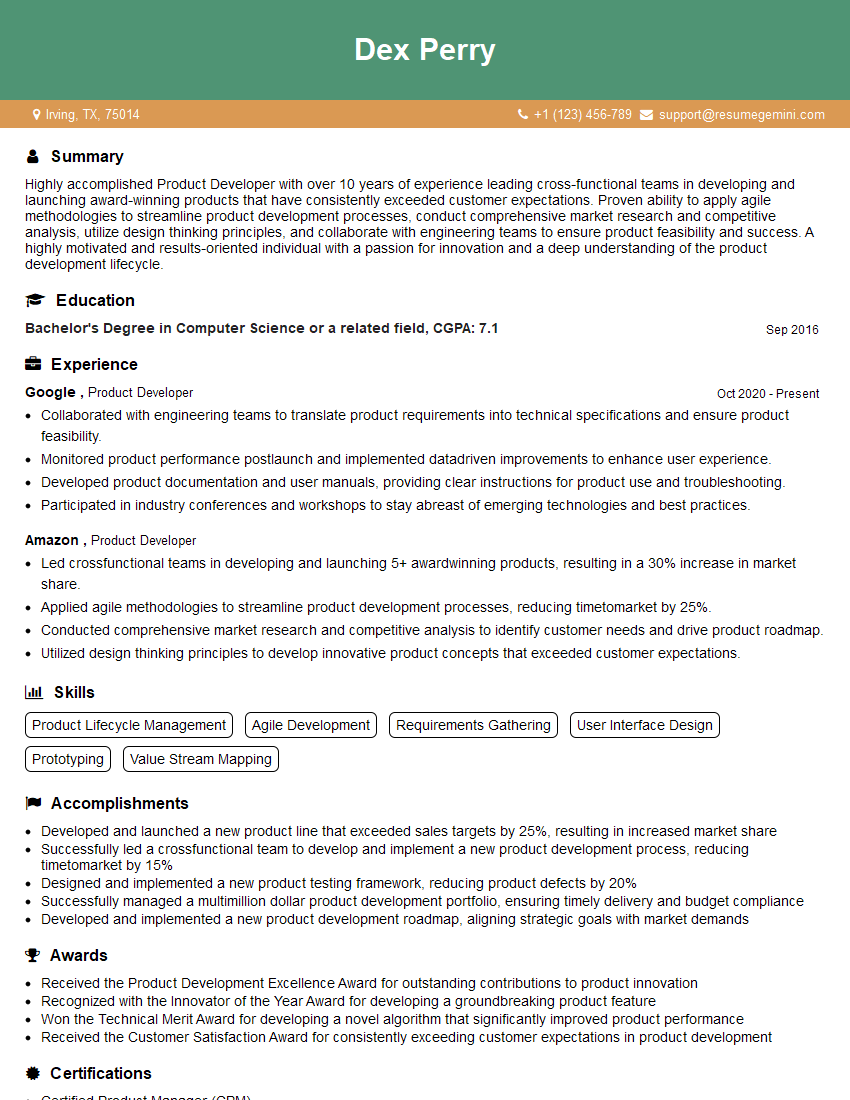

Mastering Fabric Selection and Material Knowledge is crucial for career advancement in the textile and fashion industries. A strong understanding of these concepts will significantly enhance your problem-solving skills and allow you to make informed decisions throughout the design and production process. To maximize your job prospects, create an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your skills effectively. Examples of resumes tailored to Fabric Selection and Material Knowledge are available to help guide you. Invest the time to craft a compelling resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good