Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Fabrication and Construction Techniques interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Fabrication and Construction Techniques Interview

Q 1. Describe your experience with different welding techniques (MIG, TIG, stick).

My experience encompasses a wide range of welding techniques, primarily MIG, TIG, and stick welding. MIG (Metal Inert Gas) welding is my go-to for high-speed, production-oriented work, especially on sheet metal and larger structures. I’ve used it extensively in automotive repair and light fabrication projects, appreciating its ease of use and relatively fast deposition rate. For example, I successfully utilized MIG welding in a recent project constructing a custom metal enclosure where speed and consistency were critical.

TIG (Tungsten Inert Gas) welding, on the other hand, is my preferred choice for precision work requiring high-quality welds with minimal imperfections. Its versatility allows for welding a variety of materials, including aluminum and stainless steel. A prime example is the intricate welding required for repairing a damaged stainless steel component in a food processing plant – a job demanding the precision TIG offers.

Stick welding (Shielded Metal Arc Welding or SMAW) remains a valuable skill, especially in situations with limited access to power or when working outdoors in challenging conditions. Its portability and robustness make it ideal for field repairs and projects where other methods are impractical. I used stick welding during a site repair on a remote pipeline where a generator powered the welder.

Q 2. Explain the process of blueprint reading and its importance in fabrication.

Blueprint reading is the cornerstone of fabrication. It involves interpreting technical drawings that specify the dimensions, materials, and assembly details of a structure or component. Proficiency requires understanding various symbols, notations, and projections (orthographic, isometric). Think of a blueprint as a recipe for a physical object – without a clear understanding of the instructions, the final product will be flawed.

The process typically involves a systematic review: starting with the title block (identifying project details), then examining dimensions, material specifications (e.g., steel grade, wood type), and finally, studying assembly details, including weld symbols or joining methods. I always cross-reference different views to ensure dimensional accuracy and alignment. Any ambiguity is clarified with the design engineer before proceeding to fabrication.

Its importance lies in ensuring accuracy in material ordering, cutting, and assembly. A misinterpretation can lead to significant rework, material waste, and project delays. It’s crucial for accurate cost estimation, and ensures the finished product meets design specifications and quality standards.

Q 3. What are your experience with different types of construction materials (steel, concrete, wood)?

My experience includes extensive work with steel, concrete, and wood. Steel is the most common material in my fabrication work, encompassing various grades and forms (sheet metal, structural steel, etc.). I’m skilled in selecting the appropriate steel grade based on project requirements, understanding its properties and limitations regarding strength, weldability, and corrosion resistance.

Concrete work has involved various applications like foundation pouring, formwork construction, and concrete finishing. I understand the importance of proper mix design, curing processes, and reinforcement placement to achieve the desired strength and durability. I have experience working with various concrete additives to achieve specific properties, such as increased workability or improved strength.

My wood working experience, although less extensive than steel and concrete, includes framing, structural components, and finish carpentry. I am familiar with various wood types, their characteristics, and proper joining techniques. Safety is paramount when working with wood, particularly regarding dust and sharp tools.

Q 4. How do you ensure quality control during the fabrication process?

Quality control is a continuous process, starting from material selection and verification through to the final inspection. It involves a multi-pronged approach:

- Material Inspection: Verifying material certifications to ensure they meet specified standards.

- Process Monitoring: Regularly checking welding parameters (voltage, amperage, travel speed) during welding operations, ensuring consistent weld quality. This includes visual inspections and sometimes destructive or non-destructive testing.

- Dimensional Checks: Utilizing measuring tools (calipers, tape measures, levels) to verify dimensions against blueprints throughout the fabrication process.

- Regular Audits: Conducting internal quality audits to assess adherence to procedures and identify areas for improvement.

- Documentation: Meticulous record-keeping of all aspects of the fabrication process, including material certifications, welding parameters, inspection results, and non-conformances.

For example, in a recent project, a routine inspection revealed minor dimensional discrepancies. Immediate corrective action ensured the final product met the required specifications. The emphasis is always on preventing defects rather than correcting them.

Q 5. Describe your experience with different types of construction equipment.

My experience with construction equipment is extensive and includes:

- Welding Equipment: MIG welders, TIG welders, stick welders, along with associated equipment such as plasma cutters and grinders.

- Material Handling: Forklifts, cranes, and overhead hoists for moving and positioning heavy materials.

- Earthmoving: Experience operating excavators and backhoes for site preparation.

- Power Tools: A comprehensive range including saws, drills, and other power tools common in construction and fabrication.

Safety is always paramount when operating this equipment. I always adhere to the manufacturer’s safety guidelines and ensure regular maintenance schedules are followed. Proper training and certification are essential aspects of my approach to equipment use.

Q 6. How do you manage project timelines and budgets in construction?

Managing project timelines and budgets requires meticulous planning and proactive monitoring. It starts with a detailed project schedule, breaking down tasks into manageable segments and establishing clear dependencies. This schedule is then integrated into a budget, allocating resources (labor, materials, equipment) to each task. Think of it like a carefully choreographed dance; each step needs to be precisely timed and properly resourced.

Regular monitoring and progress reporting are crucial for identifying potential delays and cost overruns. This includes tracking actual hours against planned hours, material consumption, and equipment usage. Any deviations necessitate immediate corrective actions, which may include adjusting resource allocation, refining the schedule, or renegotiating contracts. This process requires strong communication with stakeholders to keep everyone informed and aligned.

Software tools, such as project management software, are invaluable for managing complex projects, assisting in scheduling, resource allocation, and budget tracking. Proactive risk management strategies are essential, anticipating potential issues and planning for mitigation strategies.

Q 7. What safety measures do you implement on a construction site?

Safety is my top priority on any construction site. My approach involves a multi-layered system:

- Pre-planning: Conducting thorough risk assessments to identify potential hazards, such as fall hazards, electrical hazards, and material handling risks, before commencing work.

- Site Safety Management: Implementing safety protocols, including regular tool inspections, appropriate Personal Protective Equipment (PPE) usage (helmets, safety glasses, gloves, etc.), and clear signage for hazards.

- Training and Communication: Providing regular safety training to all team members, including refresher courses and discussions on safe work practices. Ensuring open communication channels for reporting hazards and near misses.

- Emergency Procedures: Having clearly defined emergency procedures in place, including procedures for first aid, fire safety, and evacuation.

- Compliance: Adhering strictly to all relevant safety regulations and industry best practices.

A culture of safety is fundamental. Every team member is responsible for their own safety and the safety of their colleagues. This isn’t just a set of rules; it’s a mindset that permeates every aspect of the project.

Q 8. Explain your experience with CAD software in the context of construction or fabrication.

My experience with CAD software in construction and fabrication is extensive. I’m proficient in AutoCAD, Revit, and SolidWorks, using them daily for design, detailing, and documentation. For example, in a recent project involving a custom steel staircase, I used AutoCAD to create detailed 2D drawings, including dimensions, material specifications, and fabrication notes. Then, I leveraged SolidWorks to create a 3D model, allowing for better visualization and clash detection with other building components. This ensured a precise fabrication process and seamless on-site installation. Revit, on the other hand, is invaluable for larger-scale projects, allowing for Building Information Modeling (BIM) – a collaborative design process that improves coordination and reduces errors. I’ve used Revit to model entire building structures, integrating structural, architectural, and MEP (Mechanical, Electrical, and Plumbing) systems to avoid conflicts and optimize design efficiency. The ability to generate accurate quantities and schedules directly from the 3D model is a game changer for project planning and cost control.

Q 9. How do you handle unexpected challenges or delays during a project?

Handling unexpected challenges is a crucial aspect of construction and fabrication. My approach involves a systematic problem-solving method. First, I thoroughly assess the situation, identifying the root cause of the delay or challenge. This might involve reviewing the design specifications, material availability, or unforeseen site conditions. Once the problem is identified, I brainstorm potential solutions with my team, considering factors like cost, time, and safety. For instance, during a recent project, a supplier delayed a critical component. To mitigate the delay, I immediately contacted alternative suppliers, securing a substitute part within a shorter lead time while negotiating a revised timeline with the client. I also leverage my knowledge of construction techniques to find alternative solutions. For example, if a particular material isn’t available, I might explore a suitable substitute that maintains the project’s structural integrity and aesthetics. Open communication with the client, subcontractors, and my team is key. Regular updates and transparency help to maintain confidence and manage expectations effectively.

Q 10. Describe your experience with different types of construction drawings.

I have extensive experience working with various construction drawings, including architectural drawings, structural drawings, MEP drawings, and shop drawings. Architectural drawings provide the overall design and layout of the building, defining spaces and aesthetics. Structural drawings illustrate the load-bearing elements, such as columns, beams, and foundations, ensuring the building’s stability. MEP drawings showcase the locations of mechanical, electrical, and plumbing systems. Finally, shop drawings are crucial for fabrication, detailing the precise dimensions, specifications, and assembly instructions for each component. I understand the importance of each drawing type and how they interrelate to create a successful project. For example, in a recent project, I used architectural drawings to understand the overall building design, structural drawings to determine the load requirements for fabricated steel components, and shop drawings to ensure accurate fabrication and installation.

Q 11. How do you ensure the structural integrity of a fabricated component?

Ensuring structural integrity of fabricated components is paramount. My approach involves a multi-step process. Firstly, I rigorously review the design specifications, ensuring they comply with relevant building codes and industry standards. I meticulously check calculations for stress, strain, and deflection under anticipated loads. Secondly, I carefully select appropriate materials, considering their strength, durability, and corrosion resistance. Thirdly, I oversee the fabrication process, ensuring strict adherence to the shop drawings and quality control procedures. This includes regular inspections and testing, often involving non-destructive testing methods like ultrasonic inspection or radiographic testing to identify internal flaws. Documentation at every stage is key. For example, I meticulously record material test results, welding procedures, and inspection reports. This detailed documentation creates a comprehensive audit trail, ensuring compliance and accountability. Furthermore, Finite Element Analysis (FEA) software can be utilized to simulate real-world conditions and predict the component’s behaviour under various loads, providing additional confidence in the design’s integrity.

Q 12. What are your troubleshooting skills in fabrication and construction?

My troubleshooting skills involve a structured approach. I begin by systematically analyzing the problem, carefully examining the symptoms and gathering all relevant information. This might include reviewing drawings, inspecting the component, and interviewing involved personnel. Next, I develop a hypothesis, identifying potential causes based on my experience and knowledge. I then test this hypothesis through targeted investigations, using both theoretical knowledge and practical experimentation. For instance, if a fabricated steel beam is experiencing unexpected deflection, I would investigate factors such as material properties, load calculations, welding quality, and support conditions. If the problem is linked to a design error, I’d work with the design team to correct it. If a fabrication flaw is identified, I would collaborate with the fabrication team to rectify it. My experience also enables me to identify the root cause quickly, avoiding costly rework and project delays. Documentation of the troubleshooting process is crucial, enabling future reference and learning from past experiences.

Q 13. Explain your experience with different types of construction contracts.

I’m familiar with various construction contract types, including lump-sum contracts, cost-plus contracts, and unit-price contracts. A lump-sum contract involves a fixed price for the entire project, offering certainty but potentially limiting flexibility. Cost-plus contracts involve reimbursing the contractor for their actual costs plus a predetermined fee or percentage, offering flexibility but potentially increasing uncertainty regarding final costs. Unit-price contracts specify the cost for individual units of work, providing transparency and facilitating change orders. The choice of contract type depends on several factors, including the project’s complexity, the degree of risk involved, and the relationship between the client and the contractor. My experience spans all three types, allowing me to effectively manage the expectations and responsibilities involved in each.

Q 14. How do you communicate effectively with contractors, clients, and your team?

Effective communication is central to my work. I use various methods to communicate clearly and concisely with contractors, clients, and my team. With contractors, I use precise specifications and drawings to ensure alignment on project requirements. Regular on-site meetings and progress reports maintain transparency and facilitate issue resolution. With clients, I focus on clear and accessible explanations of technical details, coupled with regular updates on progress and potential challenges. I prioritize responsiveness and proactive communication to manage expectations. Within my team, I foster open dialogue, encouraging feedback and collaboration. Tools like project management software and regular team meetings facilitate efficient communication and coordination. Active listening and empathetic communication styles build strong relationships and foster trust, ultimately leading to successful project outcomes.

Q 15. Describe your experience with different types of construction inspections.

My experience encompasses a wide range of construction inspections, from initial site surveys to final walkthroughs. I’m proficient in various inspection types, including:

- Pre-construction inspections: Verifying site conditions, utility locations, and ensuring the foundation is prepared according to the plans.

- During-construction inspections: Regularly monitoring progress, checking for compliance with blueprints and building codes, and ensuring quality of materials and workmanship. This includes verifying proper installation of structural elements, MEP systems (Mechanical, Electrical, Plumbing), and fire protection systems.

- Final inspections: A thorough check of the completed project to ensure it meets all requirements before project handover, including compliance with building codes, safety regulations and client specifications.

For example, during a recent high-rise construction project, a pre-construction inspection revealed an underground utility line conflict not shown on the initial survey. This allowed for immediate corrective action, preventing costly delays and potential safety hazards later in the project. My detailed inspection reports and photographic documentation are key to avoiding such issues and ensuring projects remain on schedule.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage waste materials and maintain a clean worksite?

Waste management and maintaining a clean worksite are crucial for safety, efficiency, and environmental responsibility. My approach involves a multi-pronged strategy:

- Waste segregation at source: Clearly designated areas for different waste types (e.g., recyclable materials, construction debris, hazardous waste) are established from the project outset. This streamlines the disposal process and improves recycling rates.

- Regular waste removal: Frequent removal of waste prevents accumulation, which reduces the risk of accidents and improves site aesthetics. We schedule waste removal strategically to avoid disrupting ongoing work.

- Proper disposal methods: All waste is disposed of according to local regulations and environmental guidelines. Hazardous waste is handled by licensed professionals, ensuring compliance and environmental protection.

- Worker education and accountability: Clear instructions on waste management practices are communicated to all workers. Regular audits and inspections ensure consistent adherence to protocols.

On a recent project, we implemented a color-coded waste management system that significantly increased our recycling rate and minimized landfill waste. This also demonstrated our commitment to sustainability, which is increasingly important to clients.

Q 17. Explain your familiarity with building codes and regulations.

My familiarity with building codes and regulations is extensive. I understand and actively apply codes like the International Building Code (IBC), local amendments, and any specific regulations pertinent to the project’s location and type. This includes understanding requirements for structural integrity, fire safety, accessibility, energy efficiency, and environmental protection.

I regularly consult updated code books and attend relevant training sessions to maintain my knowledge. I’m adept at interpreting complex code provisions and translating them into practical construction procedures. For example, during a recent renovation project, I identified a discrepancy between the existing building’s features and the current accessibility code. This early identification prevented costly rework and ensured compliance with all regulations.

Q 18. How do you prioritize tasks and manage multiple projects simultaneously?

Managing multiple projects simultaneously requires a structured approach. I use a combination of tools and techniques, including:

- Project prioritization matrix: This helps me rank projects based on factors such as urgency, importance, and resource availability.

- Detailed project schedules: Creating well-defined timelines with milestones and deadlines ensures tasks are completed efficiently.

- Regular progress tracking: Using project management software and regular meetings, I track progress against schedules and identify potential bottlenecks early.

- Effective delegation: Assigning tasks to appropriate team members based on their expertise and availability optimizes efficiency.

- Risk management: Proactive identification and mitigation of potential risks prevents delays and cost overruns.

A key to success is effective communication and collaboration with all stakeholders. Transparent reporting and proactive problem-solving maintain momentum across all projects.

Q 19. What is your experience with different types of joining methods (welding, bolting, riveting)?

I possess extensive experience with various joining methods, each with its own strengths and applications:

- Welding: Proficient in various welding techniques (SMAW, GMAW, GTAW) for joining steel and other metals. I understand the importance of proper weld preparation, procedure qualification, and non-destructive testing (NDT) to ensure structural integrity.

- Bolting: Experienced in selecting appropriate bolt types and sizes, ensuring proper torque, and understanding the design considerations for bolted connections. This includes the use of high-strength bolts and the importance of proper washer selection and installation.

- Riveting: Familiar with different riveting methods, including solid and blind rivets, and understanding their application in various materials and construction scenarios.

Choosing the right joining method depends heavily on factors such as material type, load requirements, environmental conditions, and aesthetic considerations. For example, in a high-rise steel structure, welding might be preferred for its strength, whereas bolting might be more suitable for certain connections due to ease of assembly and disassembly.

Q 20. How do you ensure compliance with safety regulations on a construction site?

Ensuring compliance with safety regulations is paramount. My approach involves:

- Comprehensive safety plan: Developing a detailed safety plan outlining procedures, emergency protocols, and responsibilities for all personnel.

- Regular safety training: Providing comprehensive safety training to all workers, covering topics like hazard identification, fall protection, and the use of personal protective equipment (PPE).

- Site inspections and audits: Regularly inspecting the site to identify and mitigate potential hazards, ensuring compliance with safety regulations, and addressing any observed unsafe practices.

- Incident reporting and investigation: Establishing a clear procedure for reporting and investigating accidents or near misses to identify root causes and prevent future incidents.

- Maintaining accurate safety records: Keeping detailed records of safety training, inspections, and incidents to demonstrate compliance with regulations.

A proactive and vigilant approach to safety fosters a culture of responsibility and reduces the risk of accidents. Prioritizing safety directly translates to a more productive and efficient work environment.

Q 21. Describe your experience with different types of foundation construction.

My experience includes various foundation types, each suitable for different soil conditions and structural requirements:

- Shallow foundations: Including footings, strip footings, and raft foundations – suitable for stable soil conditions and lighter structures.

- Deep foundations: Such as piles (driven, bored, helical) and caissons – ideal for unstable soil conditions, heavy loads, or deep excavations.

- Mat foundations: Large reinforced concrete slabs providing uniform support for large structures.

The selection of the appropriate foundation type requires careful site investigation, geotechnical analysis, and structural engineering design. For example, on a project in an area with expansive clay soils, we opted for deep pile foundations to provide stability and prevent settlement issues. My understanding of soil mechanics and foundation design ensures the structural integrity and longevity of the buildings I work on.

Q 22. What is your experience with project management software?

My experience with project management software is extensive. I’m proficient in several leading platforms, including Procore, Autodesk BIM 360, and PlanGrid. These tools are essential for modern construction project management, and I leverage their capabilities across the entire project lifecycle. For instance, in a recent high-rise project, we utilized Procore to manage document control, track progress against the schedule, and facilitate communication among the diverse project teams. This allowed us to identify and mitigate potential issues early on, ultimately contributing to the project’s on-time and within-budget completion. Beyond task management, I’m skilled in using these platforms for resource allocation, cost tracking, and risk assessment, ensuring projects are executed efficiently and effectively.

Specifically, I utilize Procore’s features for daily reporting, RFI (Request for Information) management, and submittal tracking. Autodesk BIM 360 aids in the coordination of building information modeling (BIM) data among different disciplines. My experience extends to using these tools for both small-scale renovation projects and large-scale complex constructions, adapting my approach to the specific needs of each undertaking.

Q 23. How do you estimate materials needed for a construction project?

Accurately estimating materials is crucial for successful project execution. It’s a multi-step process starting with a thorough review of the project’s plans and specifications. This includes meticulous quantification of all materials, from concrete and steel to drywall and paint. I utilize a combination of take-off software and manual calculations to achieve precision. Take-off software helps to automatically calculate quantities from digital plans, providing a preliminary estimate. However, manual verification is essential to account for waste, unforeseen circumstances, and potential overages.

For example, when estimating concrete, I account for factors such as the required compressive strength, slump, and potential losses during transportation and placement. Similarly, with lumber, I consider the dimensional lumber requirements, waste factors associated with cutting and fitting, and potential defects. I also factor in a contingency percentage, typically 5-10%, to account for unforeseen issues or inaccuracies in the initial estimates. Regular on-site monitoring and communication with the material suppliers help refine these estimates throughout the project.

Q 24. Explain your experience with different types of finishing techniques.

My experience encompasses a wide range of finishing techniques. I’m familiar with various plastering methods, including Venetian plaster for high-end finishes and standard drywall finishing for more economical applications. I’m also experienced in tile installation, ranging from ceramic and porcelain tiles to natural stone. My expertise includes selecting and applying various paints and coatings, considering factors like durability, aesthetics, and environmental conditions. Furthermore, I’m skilled in installing various types of flooring, from hardwood and laminate to carpet and resilient flooring. Each technique requires a different skillset and attention to detail to achieve the desired result. For instance, Venetian plaster requires a highly skilled craftsman to achieve its distinctive and nuanced finish, while the installation of ceramic tiles demands precise measurement and execution to ensure a level, watertight surface.

In a recent project, we used a combination of techniques: high-end Venetian plaster in the foyer, durable epoxy flooring in the industrial kitchen, and standard paint in the office spaces. The selection was driven by the functionality and aesthetic requirements of each area. This illustrates my ability to adapt techniques to the specific needs of a project.

Q 25. How do you deal with conflicts among team members on a construction site?

Conflict resolution is a vital aspect of construction site management. My approach involves proactive communication and a focus on understanding the root cause of the disagreement. I encourage open dialogue among team members, creating a safe space for expressing concerns without fear of retribution. I facilitate discussions by actively listening to each perspective, identifying common ground, and exploring mutually agreeable solutions. When necessary, I intervene to mediate, ensuring that all parties feel heard and understood. If the conflict persists, I may employ conflict resolution techniques, such as compromise, collaboration, or even arbitration if necessary, always prioritizing the project’s success and the well-being of the team.

For example, a conflict between the electrician and plumber regarding conduit routing was resolved through a collaborative approach where I facilitated a meeting involving both trades, the project superintendent, and the design team. By reviewing the plans together and exploring alternative solutions, we found a compromise that accommodated both parties’ needs without compromising the project’s structural integrity or schedule.

Q 26. Describe your problem-solving approach in a high-pressure construction environment.

In high-pressure construction environments, my problem-solving approach is systematic and proactive. I employ a structured methodology that focuses on quickly identifying the issue, gathering relevant information, developing and evaluating solutions, and implementing the most effective one. This process includes analyzing the root cause of the problem rather than addressing only the symptoms. I emphasize clear communication throughout the process, ensuring that all relevant parties are informed and aligned on the chosen solution. Furthermore, I prioritize risk assessment, anticipating potential challenges and implementing preventative measures whenever possible. Flexibility and adaptability are crucial; I am prepared to adjust my approach based on the specific demands of each situation.

For instance, when faced with unexpected delays due to inclement weather, I immediately assessed the impact on the critical path, explored alternative solutions, such as accelerating some tasks or adjusting the sequence of operations, and coordinated with the relevant teams to implement the chosen strategy. This proactive approach mitigated the impact of the weather delays, keeping the project on track.

Q 27. What is your experience with sustainable construction practices?

Sustainable construction practices are central to my approach. I’m experienced in incorporating various strategies to minimize the environmental impact of construction projects. This includes utilizing sustainable materials, such as recycled steel, reclaimed wood, and low-VOC paints. I’m also skilled in implementing energy-efficient designs, incorporating renewable energy sources, and optimizing water management systems. Furthermore, I’m familiar with waste reduction strategies, emphasizing proper waste sorting and recycling to minimize landfill waste. Throughout the construction process, I strive to improve the project’s overall sustainability performance.

For example, on a recent project, we implemented a construction waste management plan that reduced waste sent to landfills by over 70% through material reuse and recycling. This not only decreased environmental impact but also resulted in cost savings for the project.

Q 28. Explain your understanding of different types of structural analysis.

My understanding of structural analysis encompasses several methods, each suitable for different scenarios. I’m proficient in static analysis, which examines the structure’s response to static loads, such as the weight of the building itself and permanent fixtures. I also utilize dynamic analysis to evaluate the structure’s behavior under dynamic loads, such as wind and seismic events. Finite Element Analysis (FEA) is a powerful computational technique I employ to model complex structures and analyze their performance under various loading conditions. Furthermore, I’m knowledgeable about linear and non-linear analysis techniques, choosing the most appropriate method based on the complexity of the structure and the anticipated loading.

The selection of the appropriate analysis method depends heavily on the project’s specific requirements and the nature of the structure. For instance, a simple residential building might only require static analysis, while a complex high-rise structure in a seismically active region would necessitate dynamic and potentially non-linear analysis using FEA software. My experience allows me to select and apply the most appropriate method for optimal design and structural integrity.

Key Topics to Learn for Fabrication and Construction Techniques Interview

- Material Science & Selection: Understanding material properties (strength, durability, cost-effectiveness) and their suitability for different construction applications. Practical application: Justifying the choice of steel vs. aluminum in a specific project.

- Fabrication Processes: Mastery of welding techniques (MIG, TIG, stick), cutting methods (plasma, laser), and other fabrication processes relevant to your specialization. Practical application: Describing your experience with a specific welding technique and troubleshooting a common problem.

- Construction Methods & Sequencing: Knowledge of different construction methodologies (prefabrication, modular construction, in-situ construction) and their impact on project timelines and budgets. Practical application: Explaining the advantages and disadvantages of a chosen construction method for a given project.

- Blueprint Reading & Interpretation: Ability to accurately interpret technical drawings, specifications, and construction documents. Practical application: Detailing your process for understanding and implementing information from blueprints.

- Safety Regulations & Compliance: Thorough understanding of relevant health and safety regulations and best practices in fabrication and construction. Practical application: Explaining how you ensure workplace safety in your daily tasks.

- Quality Control & Assurance: Implementing quality control measures throughout the fabrication and construction process. Practical application: Describing your experience in identifying and rectifying defects during construction.

- Project Management Fundamentals: Basic understanding of project scheduling, resource allocation, and risk management. Practical application: Explaining how you contribute to efficient project completion.

Next Steps

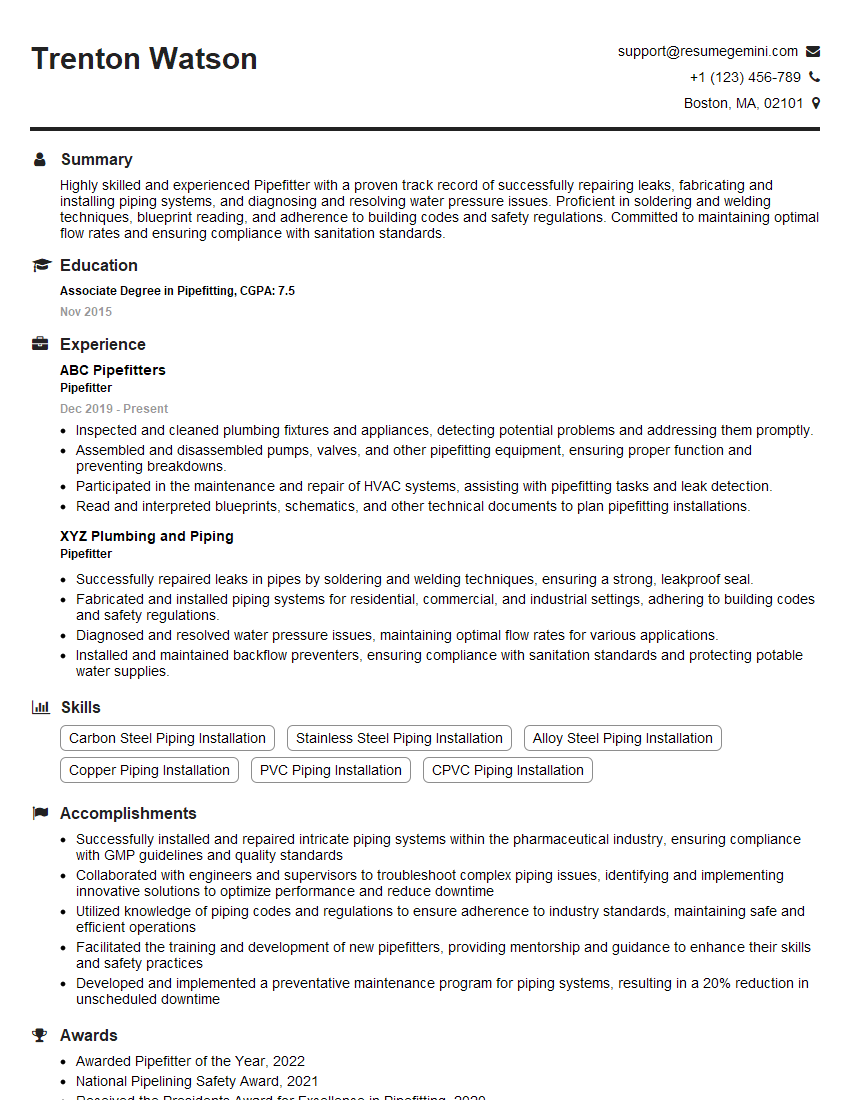

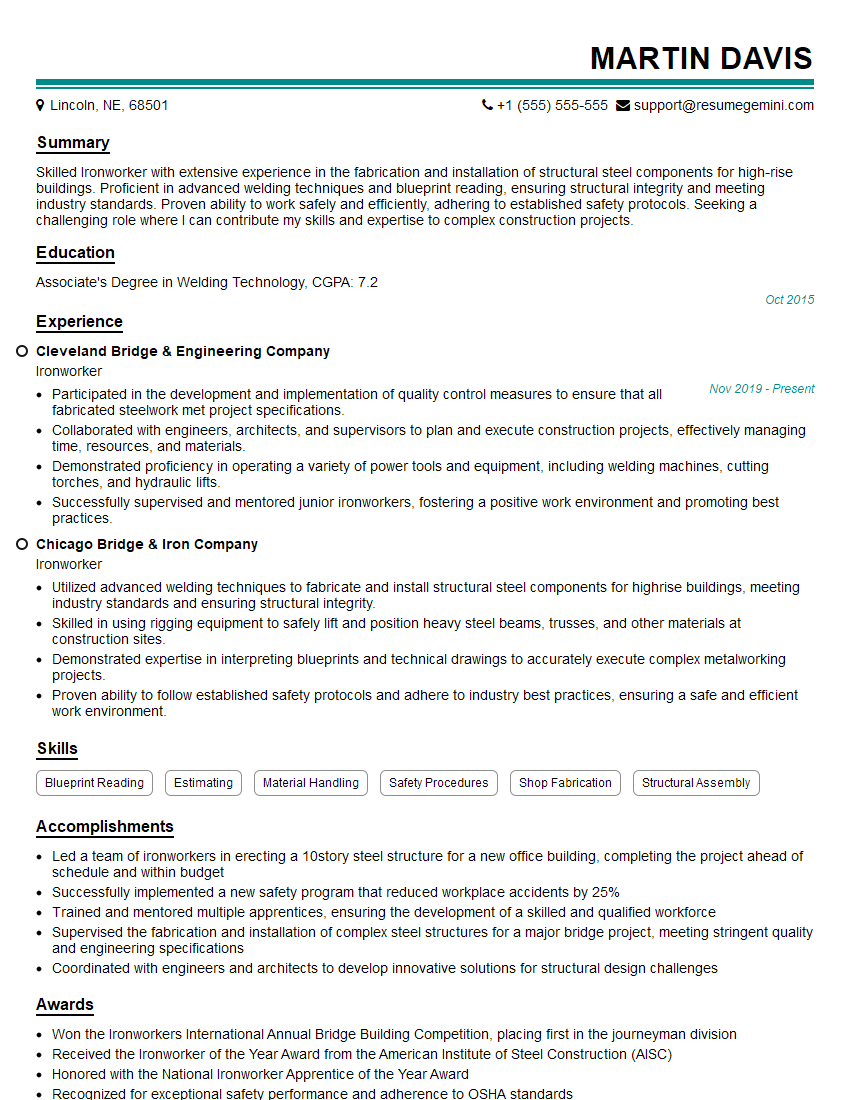

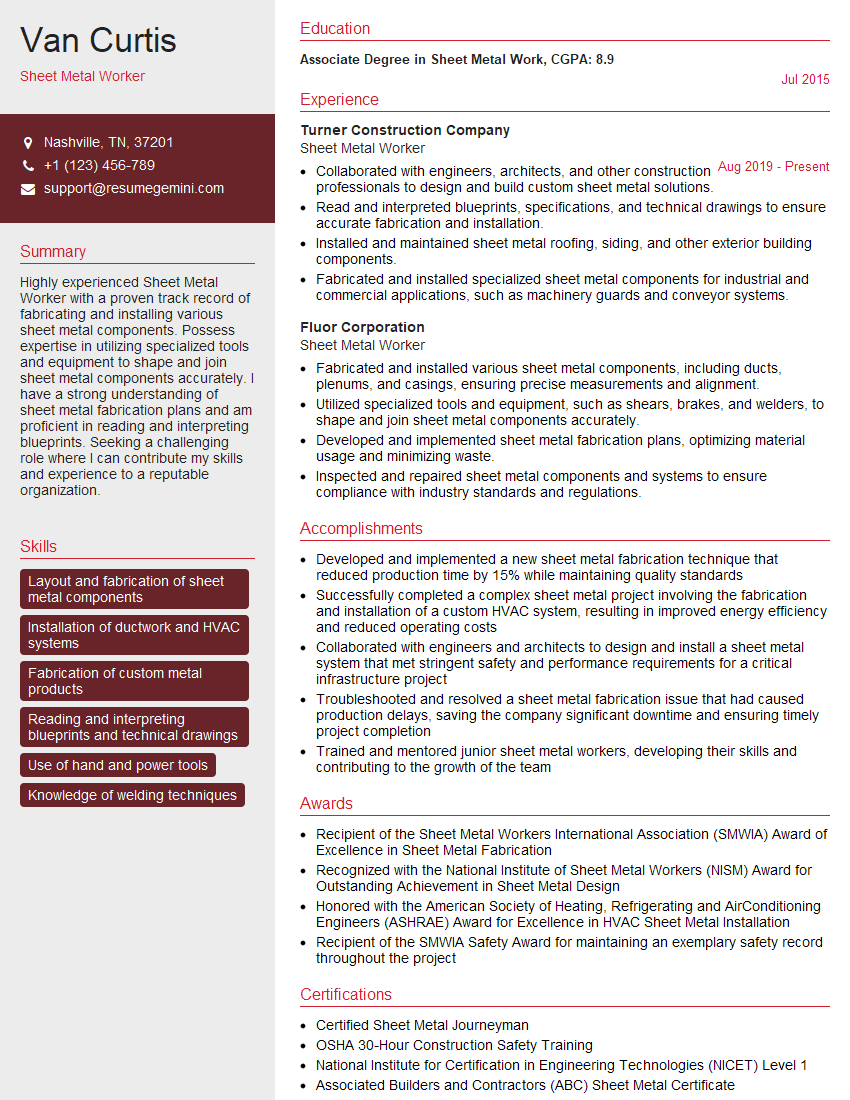

Mastering Fabrication and Construction Techniques is crucial for career advancement in this dynamic field. A strong understanding of these principles demonstrates your competence and opens doors to exciting opportunities and higher-level roles. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini can help you build a professional resume that showcases your skills effectively. ResumeGemini offers examples of resumes tailored to Fabrication and Construction Techniques to help you create a compelling document that highlights your qualifications for your target roles. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good