The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Fabrication Drawing interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Fabrication Drawing Interview

Q 1. Explain the difference between a fabrication drawing and a shop drawing.

While both fabrication drawings and shop drawings serve the purpose of guiding the fabrication process, there’s a key distinction. A fabrication drawing is a more general design document that details the overall assembly and components of a fabricated structure. It provides the necessary information for the fabrication team to understand the project’s scope, dimensions, and materials. Think of it as the blueprint for a building’s frame. On the other hand, a shop drawing is a highly detailed, often scaled-down, representation created by the fabricator *itself*. It clarifies the exact fabrication methods, dimensions, and sequences of operations, addressing specific challenges and ensuring constructability. Shop drawings are essentially a more detailed, customized version of the fabrication drawing. Imagine it as the construction manual for the individual parts of that building frame – precisely detailing how each beam and connection should be formed.

For example, a fabrication drawing for a steel staircase might show the overall design, dimensions, and material specification (e.g., A36 steel). The shop drawing would then further break down each step: welding details, bolt specifications, cut lengths, etc., specific to the fabricator’s processes and equipment.

Q 2. Describe your experience with various CAD software used in fabrication (AutoCAD, Revit, SolidWorks, etc.).

Throughout my career, I’ve extensively used various CAD software, each offering unique strengths in different aspects of fabrication drawing. My proficiency in AutoCAD is particularly strong, with experience in creating detailed 2D drawings, generating accurate dimensions, and managing layers for complex assemblies. I’ve used it for everything from simple steel connections to intricate piping systems. I’m also adept at using Revit for creating Building Information Modeling (BIM) data for larger-scale projects. Revit’s ability to manage components and generate schedules has proven invaluable for coordinating with other trades on complex projects. My experience with SolidWorks lies primarily in 3D modeling, which is particularly useful for visualizing complex geometries before fabrication and for creating detailed sections and exploded views for clarity. I find that choosing the right CAD software depends heavily on the project’s nature and requirements. Simple projects might only need AutoCAD, while large, collaborative projects benefit immensely from the integrated capabilities of Revit. SolidWorks provides an essential visual aid regardless of project size.

Q 3. How do you ensure accuracy and precision in fabrication drawings?

Ensuring accuracy and precision in fabrication drawings is paramount. My approach involves a multi-layered strategy. Firstly, I meticulously adhere to industry standards and best practices – including proper scaling, dimensioning techniques, and tolerance specifications. For example, I ensure all dimensions are clearly marked with tolerances (e.g., ±0.5mm) to account for manufacturing variations. I often employ dimensional checks and cross-references, verifying all dimensions against each other to prevent inconsistencies. Second, I utilize the capabilities of my CAD software to the fullest, using features like parametric modeling (in SolidWorks, for example), which dynamically updates dimensions if other related parts are modified. Finally, I regularly perform quality checks, often involving a peer review process to catch errors that might have been overlooked. This collaborative approach has proven highly effective in minimizing errors and preventing costly rework.

Q 4. What are the common types of fabrication drawings you have worked with?

My experience spans a wide range of fabrication drawing types, including:

- Structural Steel Drawings: Detailing beams, columns, connections, and bracing for buildings and other structures.

- Pipe Fabrication Drawings: Specifying pipe sizes, materials, fittings, and support systems for piping networks.

- Sheet Metal Drawings: Including details on bending, punching, and welding for components made from sheet metal.

- Welding Drawings: Featuring specific welding symbols and details, critical for ensuring structural integrity.

- Mechanical Assemblies: Detailing the assembly of components like machinery and equipment.

The complexity of these drawings varies widely depending on the specific project, but each requires meticulous attention to detail to ensure the success of the fabrication process.

Q 5. Explain your process for creating a detailed fabrication drawing from a design concept.

My process for creating a detailed fabrication drawing from a design concept typically follows these steps:

- Concept Review and Design Clarification: This involves careful review of the initial design concept, meeting with stakeholders to fully understand project requirements.

- 3D Modeling (optional): Often I start with 3D modeling in SolidWorks to visualize the design and check for potential clashes or interferences.

- 2D Detailing and Dimensioning: I create detailed 2D drawings in AutoCAD, accurately detailing components, dimensions, and tolerances.

- Material Selection and Specification: This crucial step involves selecting appropriate materials based on the design requirements, environmental conditions, and cost considerations. Material specifications are clearly indicated on the drawings.

- Fabrication Notes and Assembly Instructions: I include clear notes to guide the fabrication process, specifying procedures, tools, and sequences of operations. This is especially crucial for complex projects.

- Quality Assurance and Review: Final checks for dimensional accuracy and completeness, peer review for error detection.

Throughout this process, communication and collaboration with other members of the team are maintained to address any questions or challenges.

Q 6. How do you handle revisions and changes to fabrication drawings?

Handling revisions and changes is a normal part of any project. My approach focuses on maintaining version control and ensuring that everyone remains informed. I typically use the revision cloud feature in CAD software to track changes and revisions. Each revision is clearly documented with a revision number, date, and description of the change. This ensures a clear audit trail and allows everyone to access the most up-to-date version of the drawing. For major changes, I often issue a revised drawing with a new revision number. Clear communication with all stakeholders is key – I make sure everyone receives notification of any changes and understands their implications. For example, if a change impacts a critical dimension or tolerance, I will explicitly communicate those changes to the fabricator to prevent potential errors.

Q 7. Describe your experience with material selection and its impact on fabrication drawings.

Material selection is critical, as it directly impacts several aspects of the fabrication drawing. The choice of material (steel, aluminum, wood, etc.) affects the drawing’s dimensions, tolerances, and fabrication techniques. For instance, the welding procedures for steel are vastly different from those for aluminum. The material’s physical properties (strength, weight, corrosion resistance) are essential considerations that influence the design and fabrication process. Therefore, material specifications – including grade, composition, and relevant standards – must be clearly detailed in the fabrication drawing. Any special surface treatments or coatings are also included. For example, if a part requires a specific type of coating for corrosion protection, this must be clearly stated to ensure it is appropriately applied during fabrication. This detail is crucial for preventing costly errors and ensuring the final product meets the required specifications.

Q 8. How do you ensure your drawings comply with relevant building codes and standards?

Ensuring fabrication drawings comply with building codes and standards is paramount for safety and legal compliance. This involves a multi-step process starting with thorough research. I begin by identifying all applicable codes and standards relevant to the project’s location, material type, and intended use. This might include codes like IBC (International Building Code), ASCE (American Society of Civil Engineers) standards, and any local ordinances.

Next, I meticulously review the specifications within these codes. This includes checking requirements for material properties, dimensions, tolerances, weld types, and safety factors. For instance, if I’m designing a steel structure, I’ll cross-reference the design with AISC (American Institute of Steel Construction) specifications to confirm it meets the requirements for load bearing capacity and stability.

Finally, I incorporate these requirements directly into the drawings. This is done through clear annotations, dimensions with tolerances, specified material grades, and detailed weld symbols adhering to AWS (American Welding Society) standards. Regular internal reviews and potentially external audits help to ensure the drawings remain compliant throughout the project lifecycle. Imagine it like baking a cake – the recipe (codes) dictates the ingredients (materials) and process (fabrication methods) to ensure a safe and structurally sound outcome.

Q 9. Explain your experience with creating bill of materials (BOM) from fabrication drawings.

Creating a Bill of Materials (BOM) from fabrication drawings is a crucial step that bridges the design and manufacturing phases. My experience involves a systematic approach. First, I carefully review the finalized fabrication drawings, noting every component and its properties. This includes dimensions, material type (e.g., steel grade, aluminum alloy), quantity, and any special surface treatments or finishes.

Next, I organize this data into a structured format. I typically use a spreadsheet software like Microsoft Excel or a dedicated CAD software’s BOM generation feature. Columns might include part number, description, material, quantity, unit of measure, and weight. I also include any necessary annotations, such as notes on specific manufacturing requirements or surface treatments.

Finally, I cross-reference the BOM with the drawings to ensure accuracy and completeness. A well-structured BOM minimizes material waste, speeds up purchasing, and reduces manufacturing errors. In one project involving a complex piping system, a detailed BOM saved the client significant time and money by identifying and correcting a potential material mismatch early on, preventing costly rework.

Q 10. How do you manage tolerances and dimensions in fabrication drawings?

Managing tolerances and dimensions is crucial for ensuring the final fabricated product fits its intended purpose. I address this through careful planning and precise documentation. First, I establish appropriate tolerances based on the application and manufacturing process. For instance, tighter tolerances are needed for precision parts compared to less critical components.

I then incorporate these tolerances directly into the drawings. This is done by specifying dimensions with plus/minus values (e.g., 100 ± 0.5 mm). Geometric Dimensioning and Tolerancing (GD&T) symbols, as defined in ASME Y14.5, are used to clearly communicate complex tolerance requirements. GD&T uses symbols like straightness, flatness, and circularity to specify the acceptable variation in geometric features.

Finally, regular checks and verification help ensure the drawings are both accurate and feasible for manufacturing. During one project, using GD&T symbols to specify the permissible runout on a shaft avoided ambiguity and ensured the final component fit smoothly within its assembly.

Q 11. Describe your experience with creating weld symbols and specifications.

Creating weld symbols and specifications requires a deep understanding of welding processes and their impact on material properties. I start by referring to the AWS D1.1 Structural Welding Code – Steel, which provides a standardized system for depicting weld details.

Each weld symbol contains crucial information: the reference line, arrow indicating weld location, weld symbol itself (specifying type, size, and length), and supplementary symbols specifying additional requirements such as backing, weld finishing, or specific welding process. For example, a symbol might depict a fillet weld (represented by a triangle), its size (e.g., 6 mm leg size), and the required welding process (e.g., GMAW or Gas Metal Arc Welding).

I ensure complete weld specifications are provided, including details on pre-weld preparation, welding procedure qualifications (WPQ), and post-weld inspections. This is crucial for ensuring the weld meets the necessary strength and quality standards. I find that detailed weld symbols and specifications help prevent misinterpretations and costly rework. In a recent project, precise weld specifications ensured the structural integrity of a complex steel frame, preventing potential safety hazards.

Q 12. Explain your understanding of different welding processes and their implications for drawings.

Understanding different welding processes and their implications on drawings is essential. Different processes offer varying weld characteristics, impacting the drawing requirements. For example, Gas Metal Arc Welding (GMAW) produces smooth welds suitable for automated processes, while Shielded Metal Arc Welding (SMAW) is versatile but may produce less consistent welds.

This knowledge dictates the choice of weld symbols and specifications in the drawings. GMAW, known for its smooth beads, may require less post-weld cleaning than SMAW. These considerations influence the drawing’s annotations, specifying the chosen process and any associated requirements such as preheating or post-weld heat treatment.

Furthermore, the choice of welding process impacts material selection, joint design, and inspection needs. Different welding processes have different penetration depths and heat input, requiring specific joint designs and materials to accommodate. This understanding ensures that the drawings accurately reflect the manufacturing process and produce a high-quality, safe product. For instance, selecting the appropriate welding process for a high-strength steel is crucial for ensuring the weld possesses the necessary load-bearing capacity, a detail that must be fully detailed within the fabrication drawing.

Q 13. How do you interpret and utilize fabrication drawing annotations and symbols?

Interpreting and utilizing fabrication drawing annotations and symbols is fundamental to accurate fabrication. I start by familiarizing myself with the relevant standards (like ISO, ANSI, or AWS) to understand the meanings of different symbols and abbreviations. This includes understanding weld symbols, dimensioning conventions, surface finish indicators, material specifications, and notes regarding manufacturing processes.

I then systematically review the drawings, paying close attention to all annotations and symbols. I use a combination of drawing templates and check lists to make sure I do not miss any critical information. For instance, a note specifying ‘surface finish: 63 µm Ra’ indicates the required roughness of a specific surface. Such annotations guide the manufacturing process directly.

Next, I transfer this information to the manufacturing specifications, ensuring that every aspect of the drawing, from dimensions to material specifications, is precisely followed. If any ambiguity exists, I resolve it through clarification with the design team. Clear and accurate interpretation helps avoid errors during fabrication and ensure the final product matches the design intent. In one project, correctly interpreting a detail about a specific type of chamfer on a steel part prevented interference issues during assembly.

Q 14. How do you manage multiple projects and deadlines for fabrication drawings?

Managing multiple projects and deadlines for fabrication drawings requires a structured and organized approach. I employ a project management system that incorporates task prioritization and resource allocation. This system typically involves a detailed project schedule, outlining key milestones and deadlines for each project.

I utilize project management software to track progress and ensure deadlines are met. These tools allow me to assign tasks to team members, monitor progress, and identify potential delays early on. I also maintain clear communication with clients and project stakeholders, providing regular updates and addressing any concerns promptly.

Prioritization is crucial for managing competing demands. I focus on tasks with the most urgent deadlines and the greatest impact on the overall project timeline. This might involve allocating more resources or extending the timeline for less critical projects to meet more important ones. Effective communication, consistent monitoring, and proactive problem-solving are key to successfully managing multiple fabrication drawing projects concurrently.

Q 15. Describe your experience working with clients or other engineers to refine fabrication drawings.

Refining fabrication drawings is a collaborative process. My experience involves working closely with clients and engineers throughout the design lifecycle. This often starts with initial design concepts, where I help translate client needs into detailed, feasible fabrication drawings. I actively participate in design reviews, presenting my work and soliciting feedback. This might involve explaining technical details, discussing material choices, or proposing cost-effective alternatives. For example, I once worked with a client who wanted a complex curved steel structure. Through discussions, we revised the design to use pre-fabricated curved sections, which significantly reduced fabrication time and costs. I also use iterative design methods; incorporating feedback into updated drawings and presenting them for approval before fabrication begins. This ensures everyone is on the same page and avoids costly errors further down the line.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you use 3D modeling software to create and verify fabrication drawings?

3D modeling software is crucial for creating and verifying fabrication drawings. I primarily use SolidWorks and Autodesk Inventor. These tools allow me to create a virtual representation of the structure, ensuring all components fit together correctly before fabrication. The process typically involves:

- 3D Modeling: Building the model from scratch, or importing existing CAD data. I meticulously model every detail, including dimensions, tolerances, and material properties.

- Assembly Verification: Performing virtual assembly to check for interferences and clearances between components. This prevents costly errors during physical assembly.

- Drawing Generation: Automatically generating detailed 2D fabrication drawings directly from the 3D model. This ensures consistency between the 3D model and the drawings.

- Section Views & Detail Views: Generating various views to highlight critical aspects of the design. For instance, creating section views to illustrate internal structures and detail views to clarify complex features.

- Bill of Materials (BOM) generation: Using the software to generate an accurate list of all materials required for fabrication.

For instance, on a recent project involving a complex pipe network, 3D modeling allowed us to identify a potential clash between two pipe runs early on, saving significant time and resources.

Q 17. What are the common challenges you face when creating fabrication drawings, and how do you overcome them?

Creating fabrication drawings presents several common challenges. One is managing complex geometries, especially in intricate assemblies. I overcome this by breaking down the design into smaller, manageable modules, modeling and detailing each individually before assembling them in the 3D environment. Another is maintaining consistency across multiple drawings. To address this, I use standardized templates and drawing conventions, ensuring consistent annotation and labeling throughout. Managing revisions and changes is another key challenge; I use version control software to track every revision, keeping a detailed history of changes for easy reference. Finally, ensuring dimensional accuracy and meeting tight tolerances is always a focus, demanding meticulous attention to detail throughout the modeling and drawing generation process. Utilizing GD&T (Geometric Dimensioning and Tolerancing) is essential in this process.

Q 18. Explain your experience with creating drawings for different fabrication materials (steel, aluminum, etc.).

My experience encompasses a range of fabrication materials, including steel, aluminum, and stainless steel. The approach to drawing creation varies depending on the material. Steel drawings, for instance, often require more detailed weld specifications, including weld symbols, types, and sizes. Aluminum drawings might focus on detailing specific anodizing or finishing processes. Stainless steel requires attention to corrosion resistance and the appropriate welding procedures. I consider factors such as material properties, fabrication methods (welding, machining, casting etc.), and surface finishes when generating drawings. For example, when detailing a stainless steel component for a food processing application, I would specify the surface finish to ensure it meets hygiene requirements. Each material has specific considerations, and my drawings reflect those nuances for accurate fabrication.

Q 19. How do you ensure that your drawings are clear, concise, and easy to understand for fabricators?

Clear, concise, and easily understandable drawings are crucial for efficient fabrication. I achieve this by following established drafting standards (like ASME Y14.5), using clear and consistent annotations, and employing a logical layout. I use clear line weights to distinguish different components and features. Dimensions are explicitly labeled and clearly presented. I avoid unnecessary clutter and maintain a balance between detail and simplicity. Leader lines and notes are used sparingly, only where absolutely necessary. Furthermore, I always include a revision table to track changes and ensure fabricators are working with the latest version. A simple analogy is like providing a well-written recipe – it must be easy to follow, using clear instructions and measurements to achieve the desired outcome.

Q 20. Describe your experience with checking and reviewing fabrication drawings for errors and inconsistencies.

Checking and reviewing fabrication drawings is a critical stage to prevent errors and ensure quality. My process involves a thorough review of every drawing to check for dimensional inconsistencies, missing information, clashes between components, and adherence to company and industry standards. I use checklists to systematically review every aspect of the drawings. This includes verifying dimensions, tolerances, material specifications, and annotations. I also perform a visual inspection, looking for any ambiguities or potential problems. In addition to self-checking, I often conduct peer reviews with other engineers, further enhancing the accuracy and completeness of the drawings. A common example is checking for correct weld symbols and their proper placement, ensuring consistent and clear communication to the fabricator. This multi-layered approach minimizes errors before fabrication commences.

Q 21. Explain your understanding of geometric dimensioning and tolerancing (GD&T).

Geometric Dimensioning and Tolerancing (GD&T) is a language used on engineering drawings to define the size, shape, orientation, and location of features. It uses symbols and standardized notation to clearly communicate tolerances and specifications to fabricators. A basic understanding of GD&T symbols, such as position, perpendicularity, flatness, and runout, is crucial. My understanding involves using GD&T to define acceptable variations in a part’s features. For instance, I might specify the position tolerance of a hole to ensure it is within an acceptable range relative to other features. This minimizes ambiguity and avoids misinterpretations by fabricators. Proper application of GD&T leads to more precise fabrication, reduces rework, and ensures the final product meets the design intent. It’s critical for ensuring interchangeability and functionality, especially in complex assemblies.

Q 22. How do you handle conflicts between design intent and fabrication practicality?

Resolving conflicts between design intent and fabrication practicality is crucial for successful project delivery. It requires a collaborative approach, involving constant communication between designers and fabricators. My strategy begins with a thorough review of the design, identifying potential challenges early on. This often involves considering material properties, manufacturing limitations of chosen processes, and assembly complexities.

For example, a design might call for a complex, intricately curved component. While aesthetically pleasing, this could be incredibly expensive and time-consuming to manufacture using standard machining techniques. The solution might involve suggesting a simpler, more modular design, perhaps using welded sheet metal instead of a single machined piece, or exploring alternative manufacturing processes like casting. The key is to maintain the design’s core functionality and aesthetic appeal while making it feasible and cost-effective to fabricate.

I often use 3D modeling software to visualize potential issues and explore alternative solutions. This allows for early detection and correction of discrepancies before they become major problems during production. Through detailed analysis and open communication, I aim to find solutions that satisfy both design vision and fabrication constraints.

Q 23. Describe your experience using various drawing standards (e.g., ANSI, ISO).

I’m proficient in both ANSI and ISO drawing standards, having utilized them extensively throughout my career. My experience spans projects employing ANSI Y14.5M (Dimensioning and Tolerancing) and various ISO standards, including ISO 128. Understanding these standards is essential for clear communication and unambiguous interpretation of fabrication drawings. ANSI standards tend to be prevalent in North America, while ISO standards are more widely adopted globally. I’ve found that the core principles of both standards – clear dimensioning, tolerance specification, and material identification – remain consistent, although the specific notations and symbol conventions might vary.

For example, in a project utilizing ANSI standards, I’d ensure consistent use of geometric dimensioning and tolerancing (GD&T) symbols to specify dimensional requirements accurately. If the project necessitates ISO standards, I’d adapt my approach to comply with the specific requirements for drawing layouts and annotations, such as different conventions for surface finish notations or the preferred style for tolerance indication.

My familiarity extends to other relevant standards and specifications as well, depending on the material and manufacturing processes involved (e.g., AWS for welding). This ensures that the fabrication drawings are compliant, leaving no room for ambiguity during manufacturing.

Q 24. How familiar are you with different types of fabrication processes (e.g., machining, welding, casting)?

I have extensive experience with a wide array of fabrication processes including machining, welding, casting, sheet metal forming, and additive manufacturing (3D printing). Understanding these processes is vital to creating realistic and manufacturable drawings. For instance, when designing parts for machining, I consider factors like material machinability, tool access, and surface finish capabilities. In the case of welding, my drawings would incorporate considerations for weld joint design, weld symbols, and required weld quality specifications according to relevant codes (like AWS D1.1).

My experience with casting involves understanding casting processes such as sand casting, investment casting, and die casting, which influence design decisions like draft angles and parting line considerations. Sheet metal forming requires knowledge of bending radii, bend allowances, and potential for springback, influencing part geometries. I’m also aware of the capabilities and limitations of additive manufacturing, such as build orientation and support structures.

I frequently collaborate with manufacturing engineers and shop floor personnel to ensure drawings accurately reflect the practical aspects of the chosen fabrication method. This collaborative approach helps to avoid design flaws and reduces the risk of costly rework.

Q 25. How do you incorporate safety considerations into your fabrication drawings?

Safety is paramount in fabrication drawings. I incorporate safety considerations throughout the drawing creation process. This begins with clear indication of potential hazards, such as sharp edges, pinch points, or areas requiring specific safety precautions during handling or assembly. My drawings will include warnings, notes, or symbols to highlight these hazardous areas. For example, I might specify the use of safety guards or protective equipment.

I also ensure that the drawings contain information about materials that might pose specific risks, such as specifying the material’s toxicity or flammability properties. If special handling or disposal instructions are necessary, these are clearly detailed in the drawings. Further, when designing parts for assembly, I pay particular attention to ergonomics, minimizing the risk of repetitive strain injuries during the manufacturing and assembly process. By thoughtfully incorporating safety details directly into the drawings, I significantly reduce the likelihood of accidents during fabrication and assembly.

Q 26. What is your experience with creating fabrication drawings for large-scale projects?

I possess significant experience in creating fabrication drawings for large-scale projects. These projects often require a highly organized and systematic approach. My experience includes working on projects involving multiple disciplines, large assemblies, and extensive coordination amongst different fabrication teams. A key element in handling such projects is effective breakdown of the design into manageable sub-assemblies, each with its own dedicated set of detailed drawings.

For instance, working on a large-scale steel structure, I would divide the structure into manageable sections (beams, columns, bracing, etc.) with separate drawings for each. Each drawing would include detailed dimensions, material specifications, and fabrication instructions. Then, I would develop assembly drawings showing the relationships between these sub-assemblies. This modular approach simplifies fabrication, assembly, and quality control by allowing different teams to work concurrently.

In addition to the detailed drawings, I ensure comprehensive documentation including bills of materials, welding procedures, and any necessary special instructions. This ensures that all stakeholders have the necessary information to complete the project safely and accurately.

Q 27. How do you utilize version control systems for managing fabrication drawings?

I utilize version control systems, primarily through platforms like Autodesk Vault or similar systems, to manage fabrication drawings effectively. This is crucial for tracking revisions, preventing accidental overwrites, and maintaining a clear history of changes. It also allows for easy collaboration among team members.

My typical workflow involves checking out drawings to make modifications, then checking them back in with detailed descriptions of the changes. This makes it straightforward to identify what was modified, who made the changes, and when. The version control system also helps in reverting to previous versions if necessary, minimizing the risk of losing important design data. Furthermore, it provides a centralized repository for all drawings, simplifying access and distribution to different stakeholders.

Access controls can be implemented to ensure only authorized personnel can modify drawings, which is critical for maintaining design integrity and preventing unauthorized changes to final approved designs.

Q 28. Explain your process for preparing and presenting fabrication drawings for client review.

Preparing and presenting fabrication drawings for client review involves several key steps. Firstly, I ensure all drawings are complete, accurate, and compliant with the relevant standards. This involves a thorough internal review before presenting them to the client. This review also helps identify and resolve any potential issues or ambiguities in advance. Secondly, I create a clear and concise presentation package which not only includes the drawings but also associated documentation such as material lists, fabrication specifications, and any other relevant information.

The presentation itself is tailored to the client’s level of technical understanding. I use clear and concise language, avoiding jargon whenever possible. I may employ 3D models or animations to help illustrate complex aspects of the design. During the presentation, I aim to actively engage the client, answering any questions and addressing any concerns promptly. Client feedback is crucial; I use it to refine the drawings and make sure they fully meet the client’s needs and expectations. Finally, I provide mechanisms for easy feedback and revision tracking following the review.

This collaborative approach ensures the client understands the design and the fabrication process, leading to a smoother project implementation.

Key Topics to Learn for Fabrication Drawing Interview

- Reading and Interpreting Fabrication Drawings: Understanding symbols, dimensions, tolerances, and specifications. Practical application includes accurately identifying materials, processes, and assembly sequences.

- Geometric Dimensioning and Tolerancing (GD&T): Interpreting GD&T symbols and their impact on part manufacturing and assembly. Practical application includes ensuring parts meet required specifications and fit within assemblies correctly.

- Material Selection and Properties: Understanding the properties of different materials (metals, plastics, composites) and their suitability for specific applications. Practical application involves choosing the optimal material for a given design based on strength, cost, and manufacturability.

- Manufacturing Processes: Familiarity with common fabrication techniques like machining, welding, casting, and forming. Practical application includes identifying feasible manufacturing methods based on the drawing specifications and material properties.

- Bill of Materials (BOM) and Component Identification: Understanding how to extract a complete BOM from fabrication drawings. Practical application includes accurately estimating material costs and ensuring all necessary components are available for production.

- Drawing Revisions and Change Management: Understanding how to interpret revision marks and manage changes to fabrication drawings. Practical application involves ensuring that all team members work from the most up-to-date documentation.

- Blueprint Reading and Technical Drawings: A foundational understanding of how to interpret different types of engineering drawings, including orthographic projections and isometric views. Practical application includes visualizing the final product from 2D representations.

- Problem-Solving and Critical Thinking: Applying knowledge to identify potential design flaws, manufacturing challenges, and propose solutions. This includes evaluating tolerances, identifying potential conflicts in assembly, and suggesting design improvements.

Next Steps

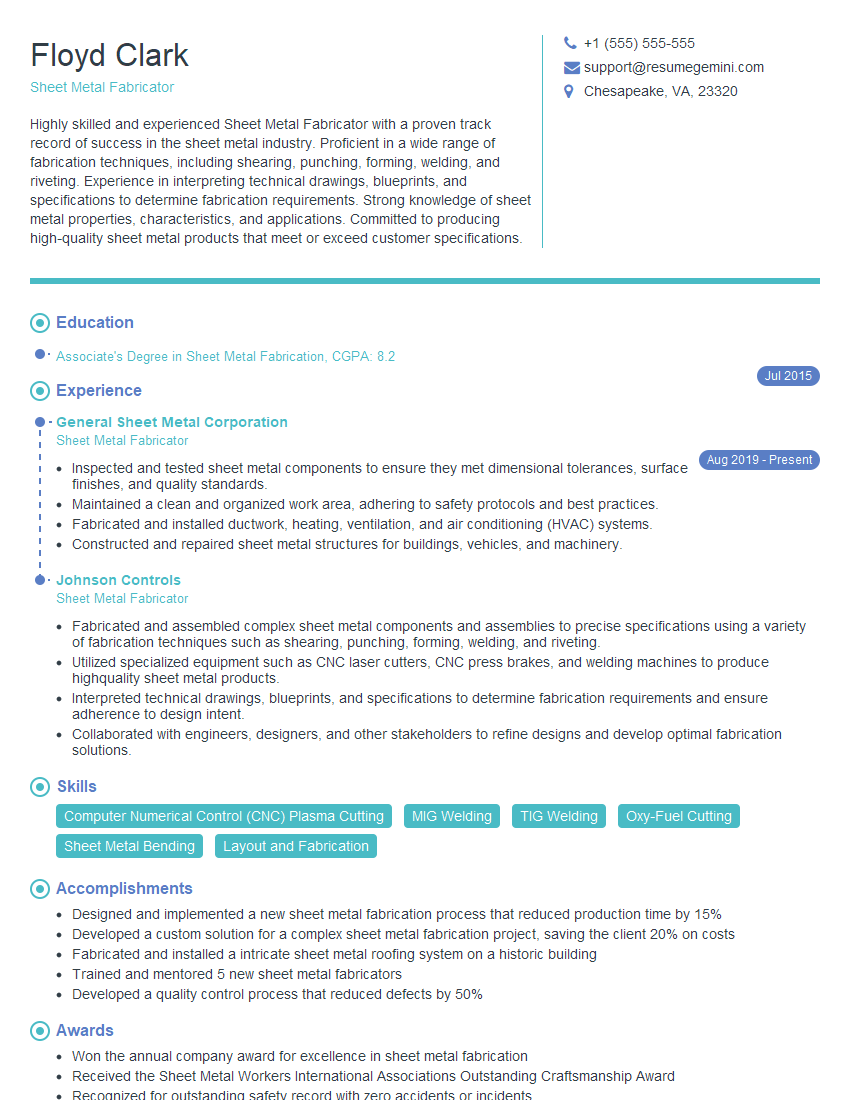

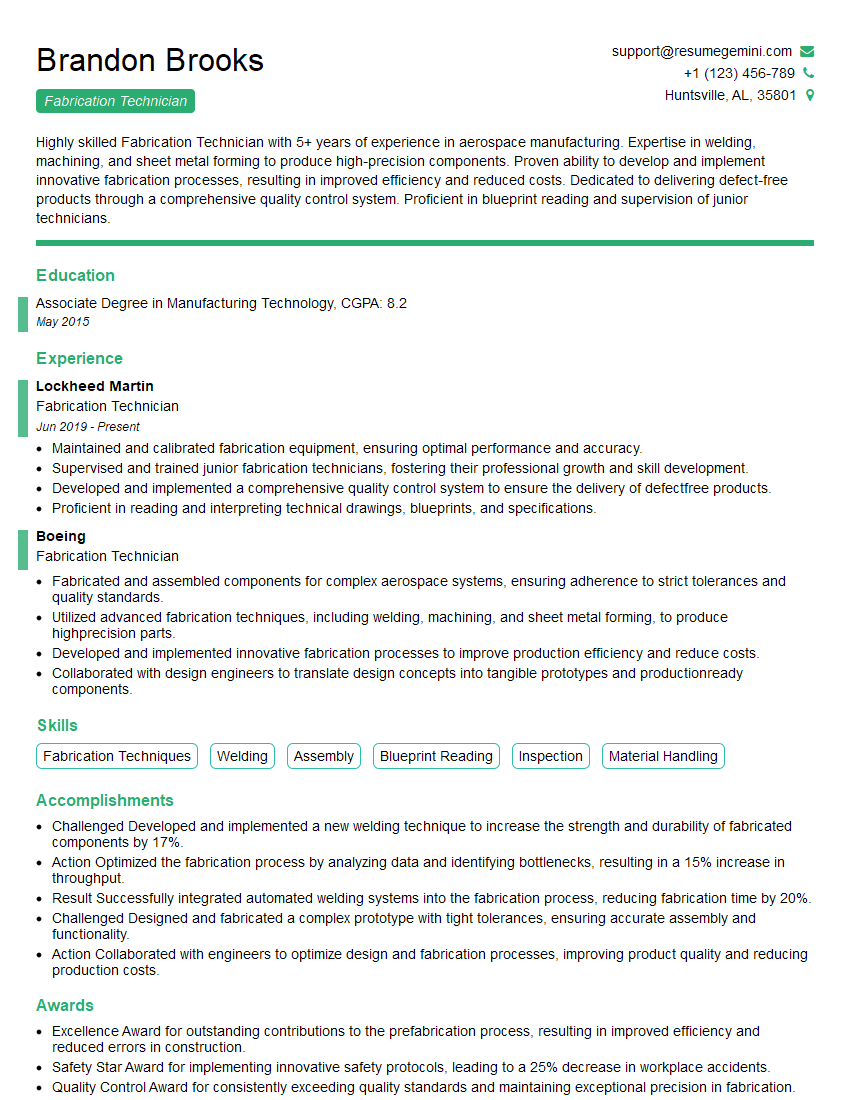

Mastering fabrication drawing is crucial for career advancement in manufacturing, engineering, and related fields. A strong understanding of these concepts directly translates to efficiency, accuracy, and problem-solving capabilities in your role. To showcase your expertise, a well-crafted, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Fabrication Drawing professionals are available to help guide you. Invest time in perfecting your resume to maximize your job prospects and land your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good