The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Familiarity with residential and commercial construction interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Familiarity with residential and commercial construction Interview

Q 1. Explain the difference between residential and commercial construction.

Residential and commercial construction differ significantly in their scope, scale, and regulations. Residential construction focuses on building individual homes, apartments, or small multi-family dwellings. It typically involves smaller budgets, simpler designs, and faster construction timelines. Commercial construction, on the other hand, encompasses larger projects like office buildings, shopping malls, hospitals, and industrial facilities. These projects often have larger budgets, more complex designs, stringent building codes, and longer construction periods. Think of it like this: building a single-family home is like baking a cake – relatively straightforward. Building a skyscraper is more akin to orchestrating a complex symphony – requiring precise coordination and planning.

- Scale: Residential projects are generally smaller than commercial ones.

- Complexity: Commercial projects tend to involve more intricate designs and systems.

- Regulations: Commercial projects face stricter building codes and safety regulations.

- Timeline: Residential projects usually have shorter construction timelines.

- Budget: Commercial projects typically involve larger budgets.

Q 2. Describe your experience with various construction materials.

My experience spans a wide range of construction materials, from traditional to cutting-edge. I’m proficient in working with various types of lumber, including engineered wood products like I-joists and laminated veneer lumber (LVL), which offer superior strength and stability compared to traditional lumber. I have extensive experience with concrete, both in its various mixes (e.g., high-strength concrete for high-rise buildings) and its application in foundations, walls, and slabs. I’m also familiar with various masonry materials like bricks, blocks, and stones, understanding their distinct properties and applications. Furthermore, my experience encompasses the use of steel in structural framing, roofing systems, and reinforcing bars (rebar) in concrete structures. Modern materials like composite materials and high-performance insulation are also part of my repertoire. For example, on a recent high-rise project, we employed a high-strength concrete mix to minimize the building’s footprint while maintaining structural integrity. In another project, we utilized cross-laminated timber (CLT) for its sustainable and efficient construction features.

Q 3. What are your preferred methods for managing construction schedules?

Effective construction schedule management is critical for on-time project completion. My preferred methods involve a combination of techniques. I begin with a thorough analysis of the project scope, breaking it down into smaller, manageable tasks. Then, I utilize project management software like Microsoft Project or Primavera P6 to create a detailed schedule, incorporating task dependencies, durations, and resource allocation. Critical Path Method (CPM) analysis helps identify tasks that are crucial to meeting the overall deadline. Regular progress meetings with the team and subcontractors are essential for monitoring progress, addressing potential delays, and making necessary adjustments. We use Gantt charts for visual representation of the schedule, and I encourage open communication to proactively address any challenges. For instance, on a recent project, we encountered an unexpected delay in material delivery. By promptly identifying the issue and communicating with all stakeholders, we were able to implement a revised schedule that minimized the overall impact on the project timeline.

Q 4. How do you handle budget overruns on a construction project?

Budget overruns are a significant concern in construction. My approach is proactive, focusing on prevention rather than cure. Detailed cost estimations at the outset, using various estimation techniques such as parametric estimating and bottom-up estimating, are crucial. Value engineering – identifying cost-saving alternatives without compromising quality – is an integral part of my process. Throughout the project, I implement rigorous cost tracking and reporting mechanisms to identify potential deviations early. If overruns occur, I convene meetings with the project team and the client to assess the cause of the overrun. This might involve analyzing change orders, unexpected site conditions, or unforeseen material price increases. Once the cause is identified, we explore various options to mitigate the impact. This could range from negotiating with subcontractors, adjusting the project scope, or securing additional funding from the client. Transparency and open communication are paramount in these situations. For example, on a recent project, an unexpected rock formation was discovered during excavation. By carefully assessing the situation, we devised a revised plan to address the challenge with minimal cost impact, ultimately minimizing the overrun.

Q 5. Describe your experience with different construction contracts (e.g., lump sum, cost-plus).

I have extensive experience with various construction contracts, including lump sum, cost-plus, and design-build contracts. A lump sum contract specifies a fixed price for the entire project. This is simple but requires accurate initial estimations. A cost-plus contract involves reimbursing the contractor for actual costs plus a predetermined fee or percentage. This is suitable for projects with uncertain scopes but can lead to cost overruns if not managed properly. Design-build contracts combine design and construction under a single contract, streamlining the process but requiring a highly coordinated team. My experience helps me select the most appropriate contract type for each project, considering the project’s complexity, risk factors, and client requirements. For instance, a lump sum contract is ideal for straightforward residential projects with well-defined scopes, while a cost-plus contract might be more suitable for complex commercial projects with evolving requirements.

Q 6. How do you ensure quality control on a construction site?

Quality control is a continuous process, starting from the initial design phase and extending through project completion. My approach involves a multi-layered system. First, I establish clear quality standards and specifications at the project’s outset. This includes regular inspections at key stages of construction. Detailed checklists are used to ensure compliance with these standards. Subcontractor performance is closely monitored, and their work is inspected regularly. We utilize quality control software to document inspections, track non-conformances, and ensure timely corrective actions. Finally, a comprehensive final inspection is conducted before project handover to ensure the project meets all quality requirements. For example, on a recent project, we implemented a rigorous concrete testing protocol to ensure the strength and durability of the concrete structures, avoiding potential long-term problems.

Q 7. What safety measures are crucial in construction projects?

Safety is paramount in construction. My approach integrates safety into every aspect of the project, starting with a thorough site safety plan. This includes identifying potential hazards, developing risk mitigation strategies, and providing comprehensive safety training to all workers. We adhere to all relevant OSHA regulations and implement procedures for the safe handling and use of equipment and materials. Personal Protective Equipment (PPE) is mandatory and regularly checked. Regular safety meetings and toolbox talks reinforce safety awareness. Incident reporting and investigation protocols are in place to learn from any accidents and prevent their recurrence. For example, we implement strict fall protection measures on elevated work areas and enforce the use of appropriate PPE, such as hard hats and safety harnesses. A proactive safety culture is essential to reduce risks and maintain a safe working environment.

Q 8. Explain your experience with building codes and regulations.

Building codes and regulations are the backbone of safe and compliant construction. My experience spans over 15 years, encompassing both residential and commercial projects, and I’m intimately familiar with the International Building Code (IBC), local ordinances, and specialized codes like those for fire safety and accessibility (ADA). I don’t just passively follow them; I actively engage with them throughout the project lifecycle.

- Early Planning: Before a single shovel hits the ground, I review plans meticulously to ensure complete compliance with all applicable codes. This often involves coordinating with engineers and architects to address potential conflicts or ambiguities early on, saving time and money later.

- Permitting: I’m adept at preparing comprehensive permit applications, addressing any queries from inspectors proactively, and ensuring timely approvals. A recent project involved navigating complex stormwater management regulations, requiring detailed calculations and site-specific analyses.

- On-Site Inspections: I regularly engage with inspectors during construction, maintaining open communication and addressing any code violations promptly. This proactive approach prevents costly delays and rework.

- Material Selection: I ensure all materials meet the required fire ratings, load-bearing capacities, and other code-specific requirements. We recently had to substitute a planned exterior cladding material due to a change in local fire code, showcasing my ability to adapt quickly and maintain compliance.

Understanding building codes isn’t just about avoiding penalties; it’s about ensuring the safety and longevity of the structure. My experience allows me to build projects that are not only compliant but also optimize design within the code parameters.

Q 9. How do you handle conflicts with subcontractors or suppliers?

Conflicts with subcontractors or suppliers are inevitable in construction, but effective communication and proactive conflict resolution are crucial. My approach focuses on clear communication, established contracts, and fair resolution.

- Clear Contracts: I ensure all contracts are comprehensive, outlining scope of work, payment schedules, and dispute resolution mechanisms. This acts as a framework for fair interactions.

- Open Communication: I foster open dialogue with all parties, addressing issues promptly. Regularly scheduled meetings, detailed progress reports, and transparent communication help to prevent misunderstandings.

- Mediation and Negotiation: If conflicts arise, I use my mediation skills to find mutually acceptable solutions. I recently mediated a dispute regarding a delayed material delivery by working with both the subcontractor and supplier to find an alternative solution without impacting the project timeline.

- Formal Dispute Resolution: In rare cases where negotiation fails, I’m well-versed in formal dispute resolution processes, such as arbitration, to ensure fair and legally sound outcomes.

The goal is not to win a battle but to complete the project successfully. My approach prioritizes maintaining positive working relationships even during disagreements.

Q 10. Describe your experience with project risk management.

Project risk management is an integral part of my approach. It’s about identifying potential problems before they occur and developing strategies to mitigate their impact.

- Risk Identification: This begins during the initial planning phase. We brainstorm potential issues such as weather delays, material shortages, regulatory changes, and labor disputes.

- Risk Assessment: Each identified risk is assessed based on its likelihood and potential impact. This helps prioritize which risks require the most attention.

- Risk Mitigation: We develop strategies to reduce the likelihood or impact of high-priority risks. For example, for weather delays, we might build in buffer time to the schedule or have alternative solutions ready. For material shortages, we work with multiple suppliers and build in contingency for potential lead-time increases.

- Contingency Planning: We always have a backup plan ready for unexpected events. This often includes budgeting for unforeseen costs and having alternative solutions available.

- Monitoring and Review: Throughout the project, we continually monitor for new risks and review the effectiveness of our mitigation strategies. This ensures we adapt to changing circumstances.

A recent project involved navigating unexpected soil conditions. By proactively assessing the risk, we developed a revised foundation plan that avoided significant delays and cost overruns.

Q 11. What software or tools do you use for project management?

I utilize a variety of software and tools for efficient project management. My go-to platforms include:

- Procore: For comprehensive project management, including document control, communication, and progress tracking.

- Microsoft Project: For detailed scheduling and resource allocation.

- BIM Software (Revit, ArchiCAD): For 3D modeling and coordination with architects and engineers.

- PlanGrid: For field documentation and real-time updates on the construction site.

- Other Tools: I also leverage tools like spreadsheets for budgeting and reporting, and communication platforms like Slack for quick updates.

The choice of tools depends on the specific project requirements, but my proficiency in these systems allows for seamless collaboration and efficient project delivery.

Q 12. How do you monitor progress and productivity on a construction site?

Monitoring progress and productivity is essential for timely and cost-effective project completion. I use a multi-faceted approach:

- Regular Site Visits: Daily or weekly site visits allow me to visually assess progress, identify potential issues, and ensure work is proceeding according to plan.

- Progress Reports: Subcontractors submit regular progress reports, detailing completed tasks, upcoming activities, and any challenges faced. These reports are analyzed to track progress against the schedule.

- Production Tracking: We monitor key metrics such as labor hours, material usage, and equipment uptime. This data is analyzed to identify areas for improvement and optimize productivity.

- Technology Integration: Software like PlanGrid enables real-time tracking of tasks, materials, and inspections, providing a comprehensive overview of progress.

- Performance Analysis: Regularly analyzing productivity data allows us to identify bottlenecks and implement corrective actions. For example, if we notice delays in a specific phase, we can investigate the cause and potentially reallocate resources.

This combination of on-site observation, regular reporting, and data analysis ensures we maintain project momentum and address challenges proactively.

Q 13. Explain your experience with change orders.

Change orders are an inevitable part of construction. They represent modifications to the original contract, often resulting from design changes, unforeseen site conditions, or client requests.

- Formal Process: I manage change orders using a formal process that includes written requests, detailed cost estimations, and client approval. This minimizes misunderstandings and protects both the client and the contractor.

- Impact Assessment: Before approving any change order, I assess its potential impact on the project schedule, budget, and overall design.

- Documentation: All change orders are meticulously documented, including the reason for the change, associated costs, revised timelines, and client approval signatures.

- Cost Control: I work closely with the client to ensure any additional costs associated with the change orders are clearly communicated and approved.

- Contract Modification: Formally amended contracts reflect all approved change orders, preventing future disputes.

I recently handled a change order involving an upgraded flooring material. We carefully documented the costs, obtained client approval, and adjusted the project schedule accordingly. This ensured a smooth transition and maintained transparency throughout the process.

Q 14. How do you communicate effectively with stakeholders (clients, architects, engineers)?

Effective communication is crucial for successful construction projects. My approach emphasizes clear, concise, and regular communication with all stakeholders.

- Regular Meetings: I hold regular meetings with the client, architect, and engineers to discuss progress, address concerns, and make informed decisions. These meetings are documented and distributed to all attendees.

- Progress Reports: I provide timely progress reports outlining completed work, upcoming tasks, and potential challenges. These reports use clear visuals and avoid technical jargon where possible.

- Open Communication Channels: I maintain open communication channels, promptly responding to emails and phone calls. I also leverage collaborative platforms to facilitate real-time communication and document sharing.

- Conflict Resolution: I actively work to resolve conflicts through clear communication, negotiation, and a focus on finding mutually beneficial solutions.

- Active Listening: I actively listen to stakeholder feedback and concerns, ensuring all parties feel heard and understood.

In a recent project, clear communication between the client, architect, and myself prevented significant delays caused by a design conflict. This emphasized the value of consistent and transparent communication throughout the project lifecycle.

Q 15. Describe your experience with different construction methods (e.g., prefabrication, traditional).

My experience spans both traditional and prefabrication construction methods. Traditional methods involve building on-site, piece by piece, which offers flexibility but can be time-consuming and susceptible to weather delays. I’ve managed numerous projects using this approach, from small residential renovations to larger commercial builds, focusing on meticulous planning and quality control at each stage. Prefabrication, on the other hand, involves constructing components off-site in a controlled environment and then assembling them on-site. I’ve worked on several projects incorporating prefabricated elements, like modular homes and pre-engineered steel structures. This method significantly reduces construction time, minimizes on-site waste, and improves quality consistency. For example, I oversaw a project where prefabricated bathroom pods were installed in a multi-family residential building, dramatically shortening the overall construction schedule and reducing labor costs.

The choice between methods depends on several factors, including project size, budget, schedule constraints, and the specific design requirements. For complex, bespoke designs, traditional methods might be more suitable. However, for larger-scale projects or when speed is paramount, prefabrication offers significant advantages.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with sustainable and green building practices?

Sustainable and green building practices are central to my approach. I’m experienced in incorporating various strategies to minimize environmental impact throughout the project lifecycle. This includes utilizing sustainable materials like recycled content lumber, reclaimed wood, and locally sourced stone. I’ve incorporated energy-efficient designs, focusing on proper insulation, high-performance windows, and renewable energy sources such as solar panels. Water conservation is also key; I’ve implemented rainwater harvesting systems and low-flow fixtures in several projects. For instance, on a recent commercial project, we used a low-embodied carbon concrete mix and achieved LEED certification (Leadership in Energy and Environmental Design). This involved meticulous documentation of material choices, energy usage during construction, and waste management practices.

Beyond material choices, I emphasize efficient construction techniques to minimize waste and energy consumption during the construction phase itself. Green building isn’t just about the materials used, it’s a holistic approach to construction.

Q 17. How do you manage construction waste and disposal?

Construction waste management is critical for both environmental responsibility and cost-effectiveness. My approach involves a multi-pronged strategy starting with careful planning. Before construction begins, I develop a detailed waste management plan that identifies potential waste streams, outlines recycling and disposal methods, and designates specific storage areas on-site. This plan includes selecting appropriate contractors for waste removal and recycling. During construction, we diligently sort materials, separating recyclable items like wood, metal, and plastics from non-recyclable waste. We utilize on-site composting for organic waste whenever possible. Accurate tracking and documentation are vital, ensuring compliance with local regulations and minimizing landfill contributions. For example, on a recent large-scale renovation, we achieved a 75% waste diversion rate through careful planning and effective material sorting.

Regular inspections and adjustments to the waste management plan are crucial to ensure efficiency and prevent issues. Minimizing waste is also beneficial financially, as less waste translates to lower disposal costs.

Q 18. Describe a challenging construction project you’ve worked on and how you overcame the obstacles.

One particularly challenging project involved the renovation of a historic building in a densely populated urban area. The project presented several obstacles: working within a tight timeframe, navigating complex city permits, dealing with unexpected structural issues during demolition, and managing the disruption to surrounding businesses and residents. Overcoming these challenges required a proactive approach. First, we established clear communication channels with the city, local businesses, and residents to keep everyone informed and address concerns promptly. We engaged specialized consultants to assess the structural integrity of the building and provide solutions for unexpected issues like weakened foundations. Secondly, we adopted a phased approach to construction, minimizing disruption and maintaining access to the surrounding areas. Finally, meticulous scheduling and diligent management of our subcontractors were essential to stay on track and within budget despite the unexpected setbacks.

The successful completion of this project highlighted the importance of effective communication, proactive problem-solving, and adaptability in overcoming unexpected challenges in construction.

Q 19. What is your experience with different types of foundations?

My experience encompasses various foundation types, including shallow foundations (slab-on-grade, footings, and strip footings), and deep foundations (piles, caissons, and piers). The choice of foundation depends on several factors: soil conditions, building weight, groundwater levels, and the overall project budget. Slab-on-grade foundations are cost-effective and suitable for stable soil conditions, often used in residential construction. Footings and strip footings provide support for walls and columns in areas with varying soil conditions. Deep foundations are necessary in areas with weak or unstable soils to transfer the building load to a more stable stratum. I’ve overseen projects utilizing each type, ensuring the correct foundation type is selected based on a thorough geotechnical investigation of the site.

For example, I oversaw the construction of a high-rise building where deep foundation piles were necessary due to the soft soil conditions. Careful geotechnical analysis and design were critical for the success of this project.

Q 20. Explain your understanding of building plans and specifications.

Building plans and specifications are the blueprints for a construction project. They provide detailed information on architectural designs, structural engineering, mechanical, electrical, and plumbing (MEP) systems, and construction materials. My understanding extends to interpreting these documents, identifying potential conflicts or ambiguities, and ensuring all aspects of the project align with the design intent. I’m proficient in reading and interpreting architectural drawings, structural plans, MEP drawings, and specifications. I’m able to identify key information such as dimensions, materials, and construction methods from these documents. I also understand how different sections of the plans interact and the importance of consistency across various disciplines.

Any discrepancies or ambiguities are addressed proactively through communication with architects, engineers, and other stakeholders. This ensures a clear understanding and avoids costly mistakes during construction.

Q 21. How do you ensure compliance with building permits and inspections?

Compliance with building permits and inspections is paramount. I ensure compliance through meticulous adherence to all applicable codes, regulations, and permit requirements. Before starting any project, I obtain all necessary permits from the relevant authorities and ensure that the construction process adheres to the conditions outlined in the permits. This includes submitting regular updates to the authorities as required. Thorough inspections are conducted at various stages of construction – foundations, framing, MEP rough-in, and final inspections – to verify that the work conforms to the approved plans and codes. Addressing any deficiencies promptly and efficiently is key to ensuring timely project completion.

Maintaining detailed records of all permits, inspections, and any corrective actions is crucial for ensuring accountability and avoiding potential legal issues. Non-compliance can lead to significant delays, fines, and even project shutdowns. Proactive compliance saves time and money in the long run.

Q 22. How familiar are you with different types of roofing systems?

My familiarity with roofing systems is extensive, encompassing both residential and commercial applications. I’m proficient in various roofing materials and their associated installation techniques. This includes asphalt shingles (3-tab, architectural), tile (clay, concrete), metal (standing seam, corrugated), flat roofing systems (built-up roofing (BUR), single-ply membranes like TPO and EPDM), and even more specialized systems like green roofs.

- Asphalt Shingles: I understand the nuances of underlayment selection, proper nailing techniques, and the importance of flashing around chimneys and vents to prevent leaks.

- Tile Roofing: My experience includes understanding the weight-bearing capacity of the roof structure, proper underlayment for tile, and the intricacies of creating a watertight seal between tiles and flashing.

- Metal Roofing: I’m familiar with the different types of metal roofing panels, their installation procedures, and the importance of proper seam sealing to ensure durability and weather resistance.

- Flat Roofing Systems: I have hands-on experience with the installation and maintenance of both BUR and single-ply membrane systems, understanding the critical role of proper slope and drainage in preventing ponding water.

Understanding the specific requirements of each roofing system based on climate, budget, and aesthetic considerations is crucial, and I’ve successfully managed projects involving each of these types.

Q 23. What is your experience with HVAC systems in construction?

My experience with HVAC systems in construction is broad, ranging from design review to installation oversight and troubleshooting. I’m knowledgeable about both residential and commercial systems, including various types of heating and cooling equipment. This includes understanding the load calculations, ductwork design, refrigerant handling, and the integration of smart home technology.

- Residential Systems: I’m familiar with common systems such as split systems (heat pumps, air conditioners), furnaces (gas, electric), and boilers. I understand the importance of proper sizing to ensure efficient and comfortable climate control.

- Commercial Systems: My experience extends to larger scale systems like chillers, air handling units (AHUs), and variable refrigerant flow (VRF) systems. I understand the intricacies of building automation systems (BAS) and their role in energy efficiency.

For example, on a recent commercial project, I worked with the HVAC engineer to optimize the ductwork layout to minimize pressure drops, resulting in improved energy efficiency and reduced operating costs. This required coordination with other trades, like electricians and plumbers, to ensure proper integration.

Q 24. What is your understanding of plumbing and electrical systems in construction?

My understanding of plumbing and electrical systems is comprehensive, incorporating both the practical aspects of installation and the essential safety regulations. I’m familiar with the design, installation, testing, and inspection of these systems in both residential and commercial settings.

- Plumbing: I understand various plumbing materials (copper, PEX, PVC), fixture installation, drainage systems, water heater selection and installation, and the importance of proper venting and pressure testing to ensure code compliance and prevent leaks.

- Electrical: My knowledge includes wiring methods (Romex, conduit), panel upgrades, lighting design, grounding techniques, and the safe installation of electrical fixtures and appliances. I am familiar with NEC (National Electrical Code) requirements and ensure all work is performed to these standards.

In a recent residential renovation, I coordinated with the plumbing and electrical subcontractors to ensure proper placement of fixtures and outlets, avoiding conflicts and minimizing rework. This involved careful review of blueprints and proactive communication to avoid potential issues before they arose.

Q 25. How do you use technology to improve efficiency in construction projects?

Technology plays a vital role in enhancing efficiency on construction projects. I utilize several technologies to streamline processes and improve outcomes. This includes Building Information Modeling (BIM), project management software, and drone technology.

- BIM: Using BIM software allows for better coordination between trades, early detection of clashes, and more accurate quantity takeoffs, leading to reduced material waste and cost overruns. For example, I’ve used Revit to model entire buildings, which facilitated coordination among various contractors, avoiding costly clashes during construction.

- Project Management Software: Software like Procore or PlanGrid allows for better communication, document control, and task management. This facilitates real-time tracking of progress and allows for proactive identification and mitigation of potential problems.

- Drone Technology: Drones provide a cost-effective and efficient method for site surveying, progress monitoring, and even safety inspections. This allows for quick identification of issues and facilitates rapid decision-making.

The integration of these technologies has consistently resulted in improved project timelines, reduced costs, and enhanced overall quality.

Q 26. Describe your experience with site surveying and layout.

My experience with site surveying and layout is extensive. I’m proficient in using various surveying instruments, interpreting plans, and establishing accurate site lines and elevations. This involves understanding and applying principles of geometry and trigonometry to ensure the accurate placement of buildings and other structures.

- Total Stations: I’m skilled in using total stations to perform accurate measurements, setting out building corners, and verifying elevations.

- GPS Surveying: I’m familiar with using GPS technology for larger-scale site surveys and boundary location.

- Plan Interpretation: I possess the ability to effectively read and interpret architectural and engineering plans, understanding the details required for accurate layout.

On one project, precise site surveying was critical to ensuring the foundation alignment of a complex multi-story building. Accurate layout minimized rework and ensured the structural integrity of the building. My experience in this area ensures that projects start on solid footing, literally and figuratively.

Q 27. How do you handle unexpected delays or unforeseen circumstances?

Handling unexpected delays or unforeseen circumstances is a crucial aspect of construction management. My approach involves proactive risk assessment, effective communication, and problem-solving skills. When challenges arise, I use a systematic approach:

- Assess the situation: Thoroughly identify the cause of the delay and its potential impact on the project timeline and budget.

- Develop mitigation strategies: Brainstorm solutions with the project team, exploring options to minimize the impact of the delay. This may involve adjusting the schedule, finding alternative materials or subcontractors, or negotiating with clients.

- Communicate effectively: Keep all stakeholders informed of the situation, explaining the cause of the delay, the planned mitigation strategies, and any potential adjustments to the project timeline or budget.

- Document everything: Maintain detailed records of the incident, the mitigation strategies, and the impact on the project. This documentation is crucial for future planning and dispute resolution.

For instance, on one project, unexpected soil conditions delayed foundation work. By promptly assessing the situation, engaging geotechnical engineers, and communicating transparently with the client, we developed a revised plan, minimizing the overall project delay.

Q 28. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and skills in the construction industry. Based on my research and understanding of the current market rates for a construction professional with my level of expertise and experience, my salary expectation is between $X and $Y per year. However, I am open to discussion and willing to consider a compensation package that reflects the specific responsibilities and benefits of this role.

Key Topics to Learn for Familiarity with Residential and Commercial Construction Interviews

- Building Codes and Regulations: Understanding local, state, and national building codes for both residential and commercial projects. This includes zoning regulations and permit acquisition processes.

- Construction Drawings and Specifications: Interpreting blueprints, specifications, and other construction documents to understand project scope, materials, and methods. Practical application: Being able to identify potential conflicts or ambiguities in the drawings.

- Project Management Fundamentals: Familiarity with project scheduling, budgeting, resource allocation, and risk management principles within the context of construction. Practical application: Describing experience managing timelines, budgets, or teams on past projects.

- Construction Materials and Methods: Knowledge of various building materials (concrete, wood, steel, etc.) and their appropriate applications in residential and commercial settings. Understanding different construction techniques and their relative strengths and weaknesses.

- Health and Safety Regulations (OSHA): Demonstrating awareness of OSHA regulations and safety procedures on construction sites. Practical application: Describing experiences implementing or enforcing safety protocols.

- Estimating and Cost Control: Understanding the process of estimating project costs, including material, labor, and equipment. Practical application: Explaining experience with cost tracking and variance analysis.

- Sustainability and Green Building Practices: Familiarity with environmentally friendly construction methods and materials, LEED certification, and sustainable building design principles.

- Residential vs. Commercial Differences: Articulating the key differences in project scale, complexity, and regulatory requirements between residential and commercial construction.

Next Steps

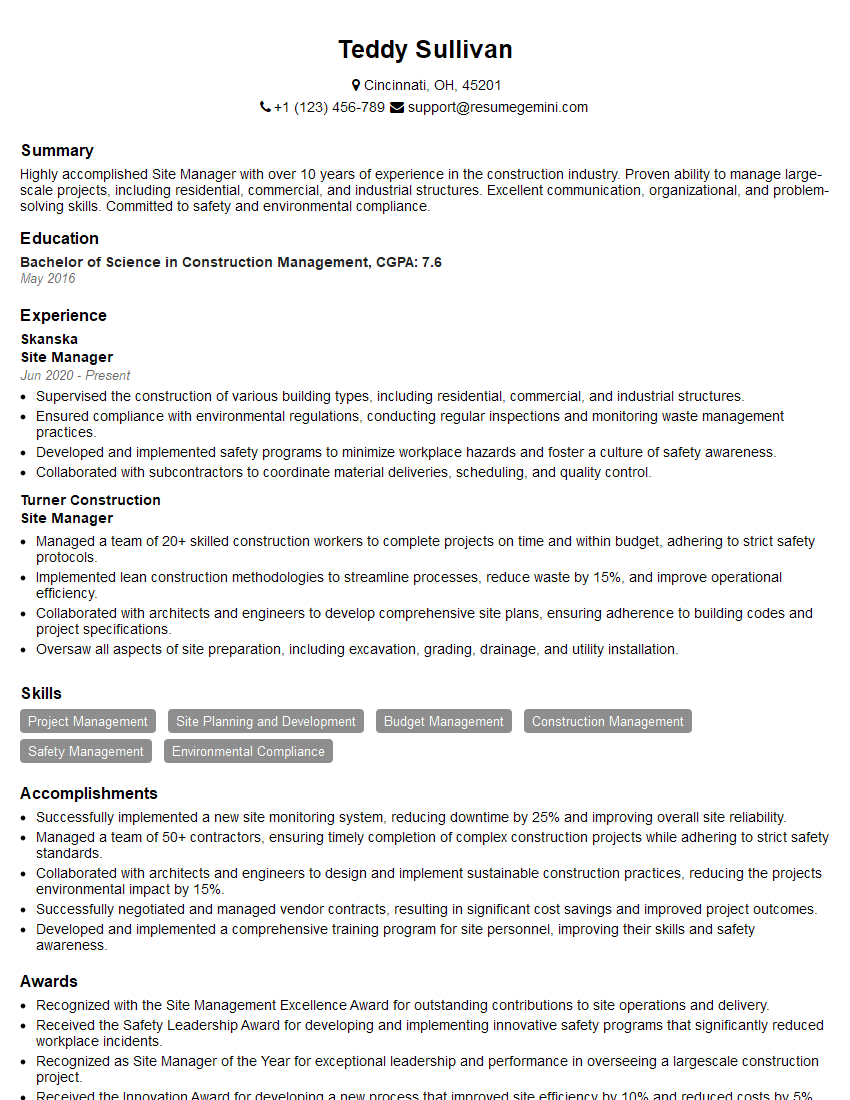

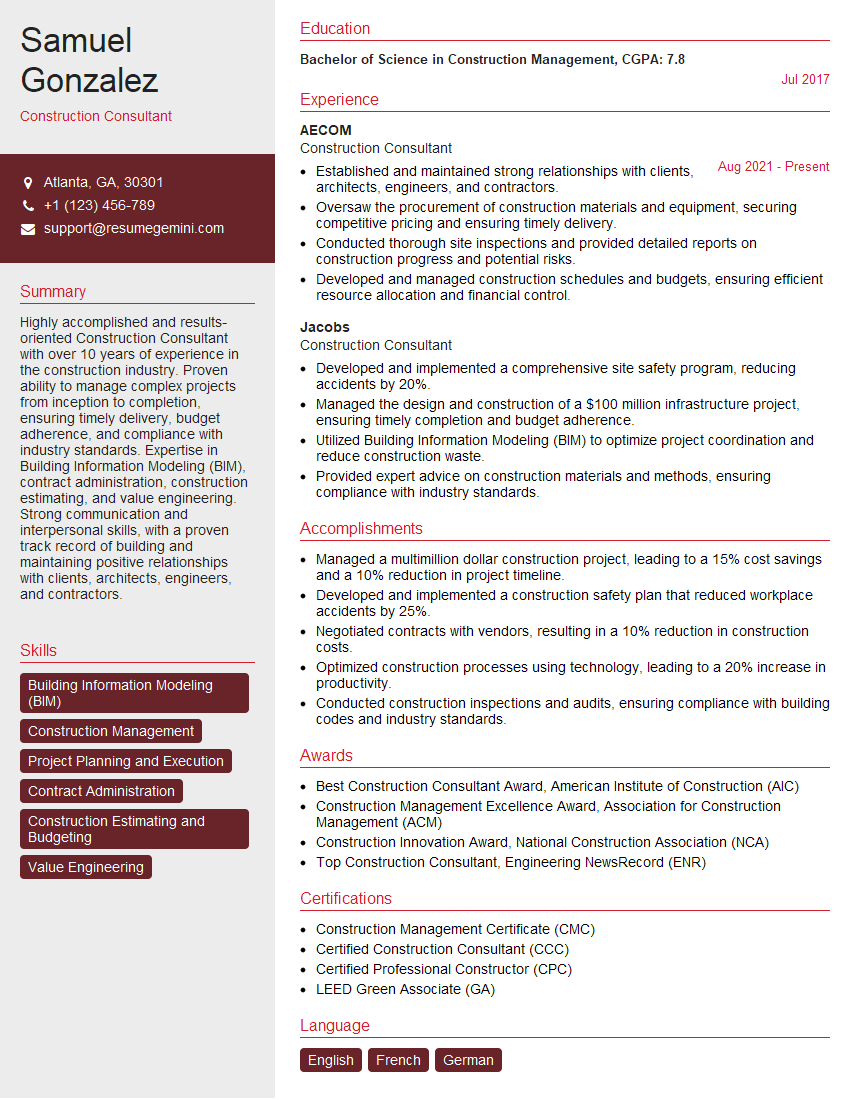

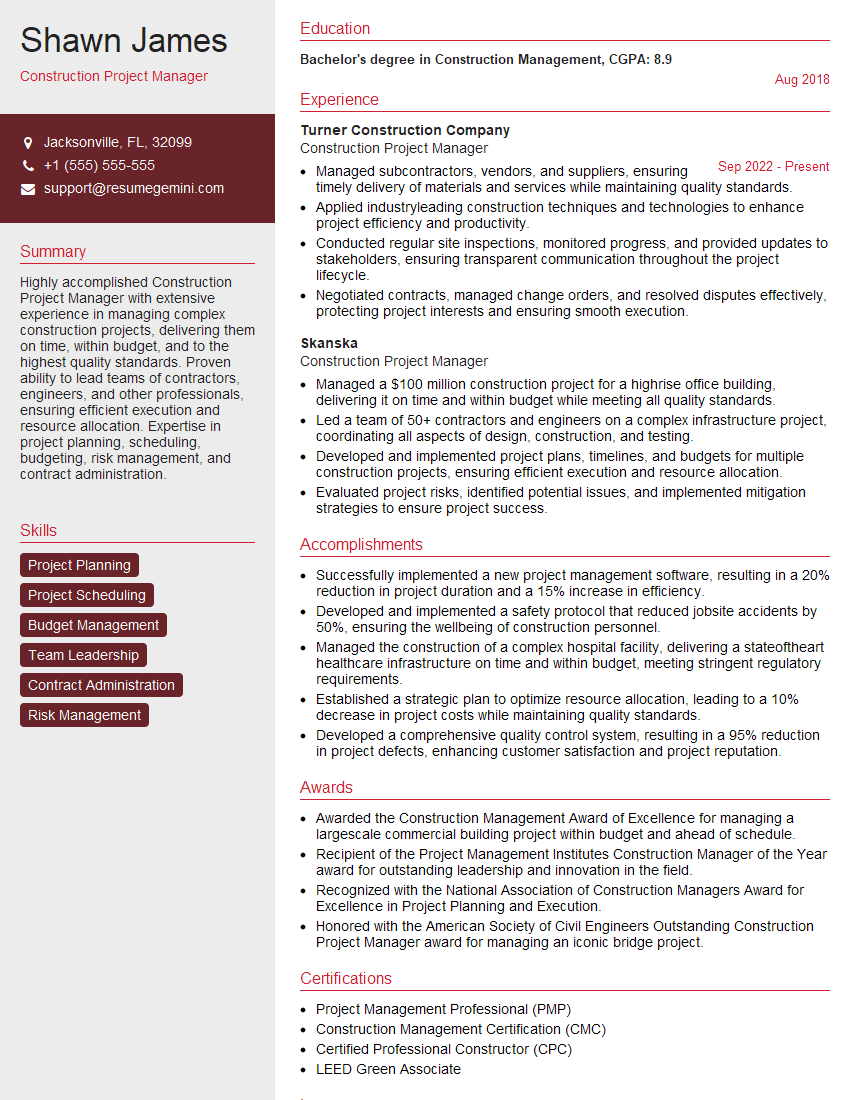

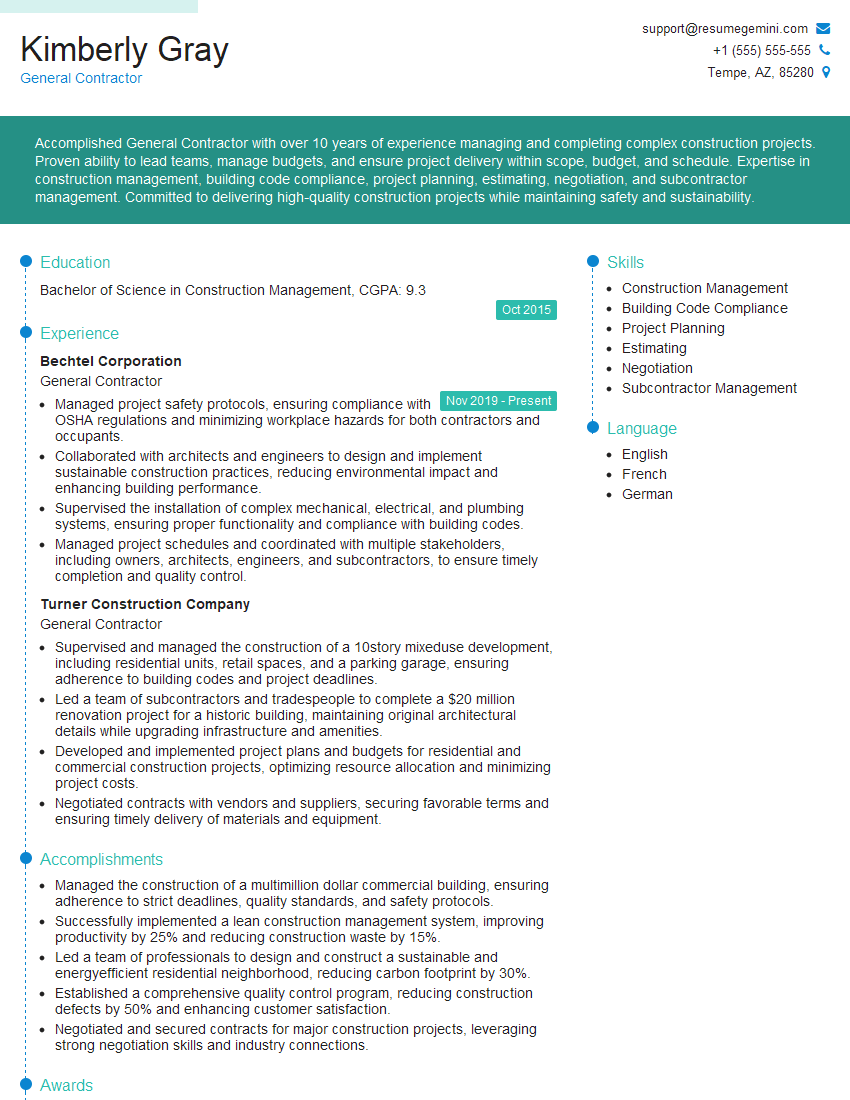

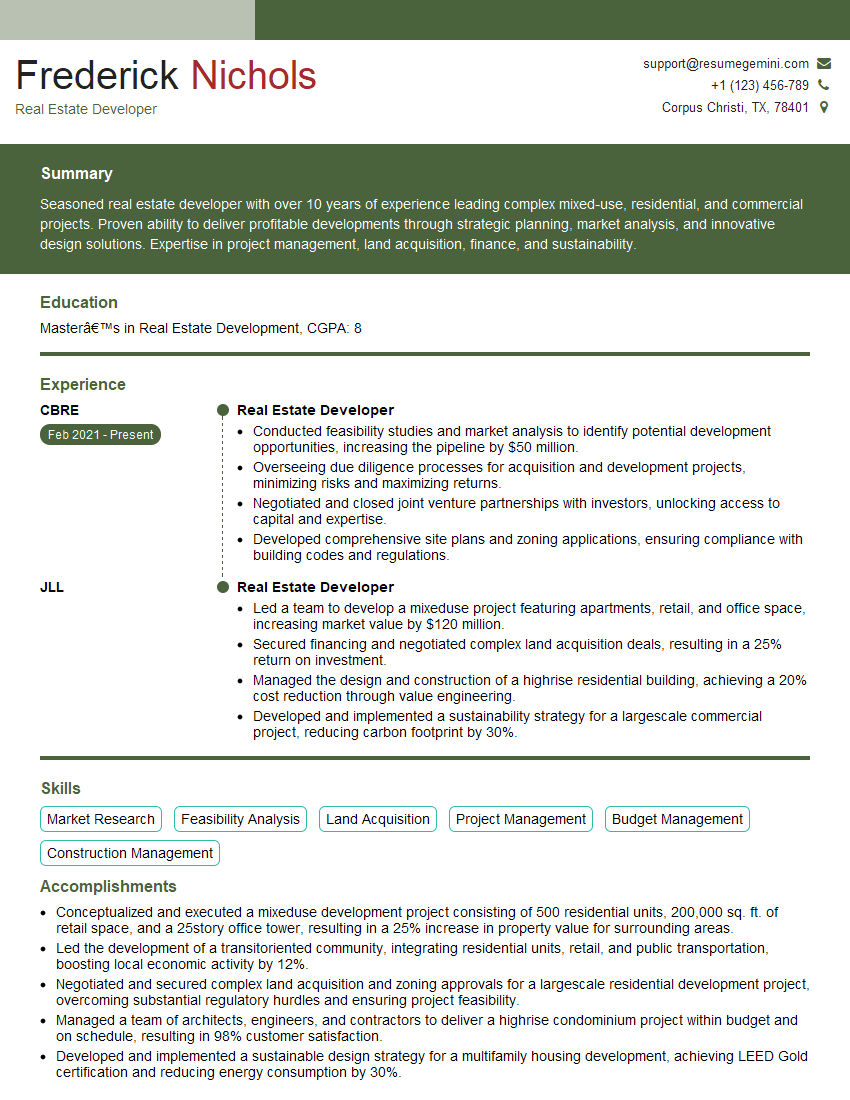

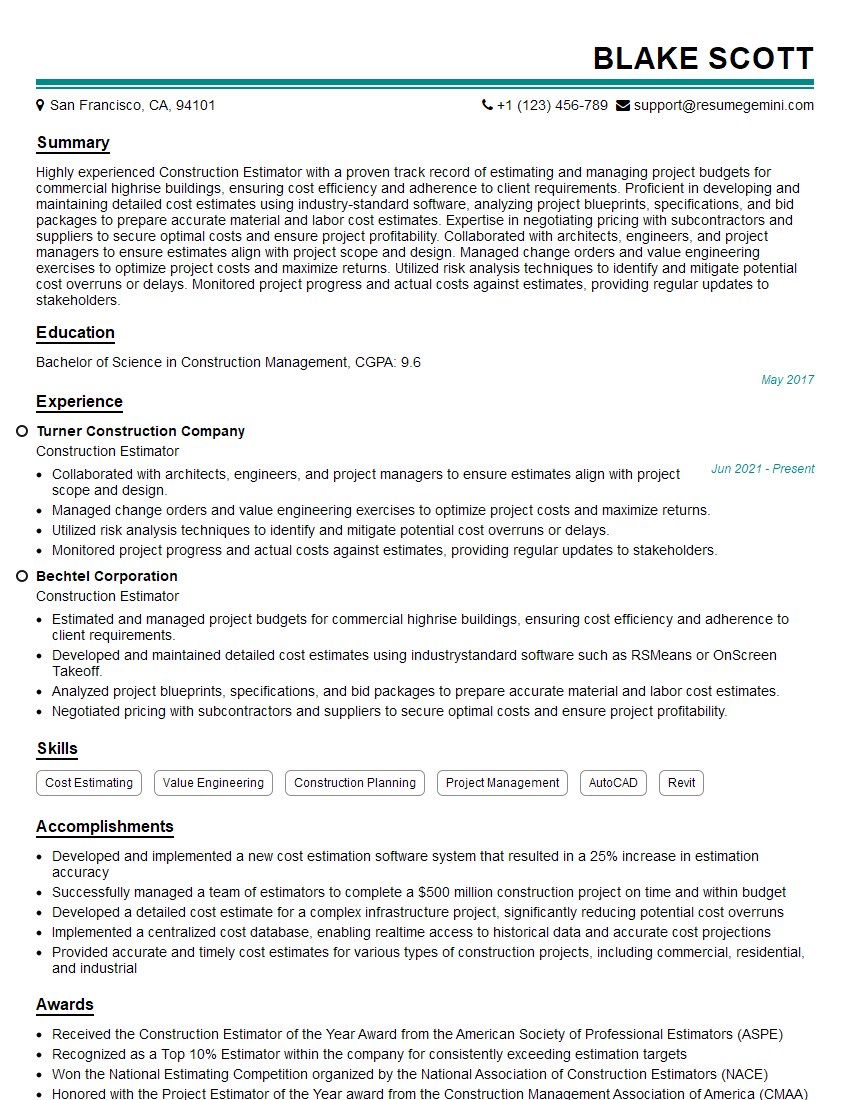

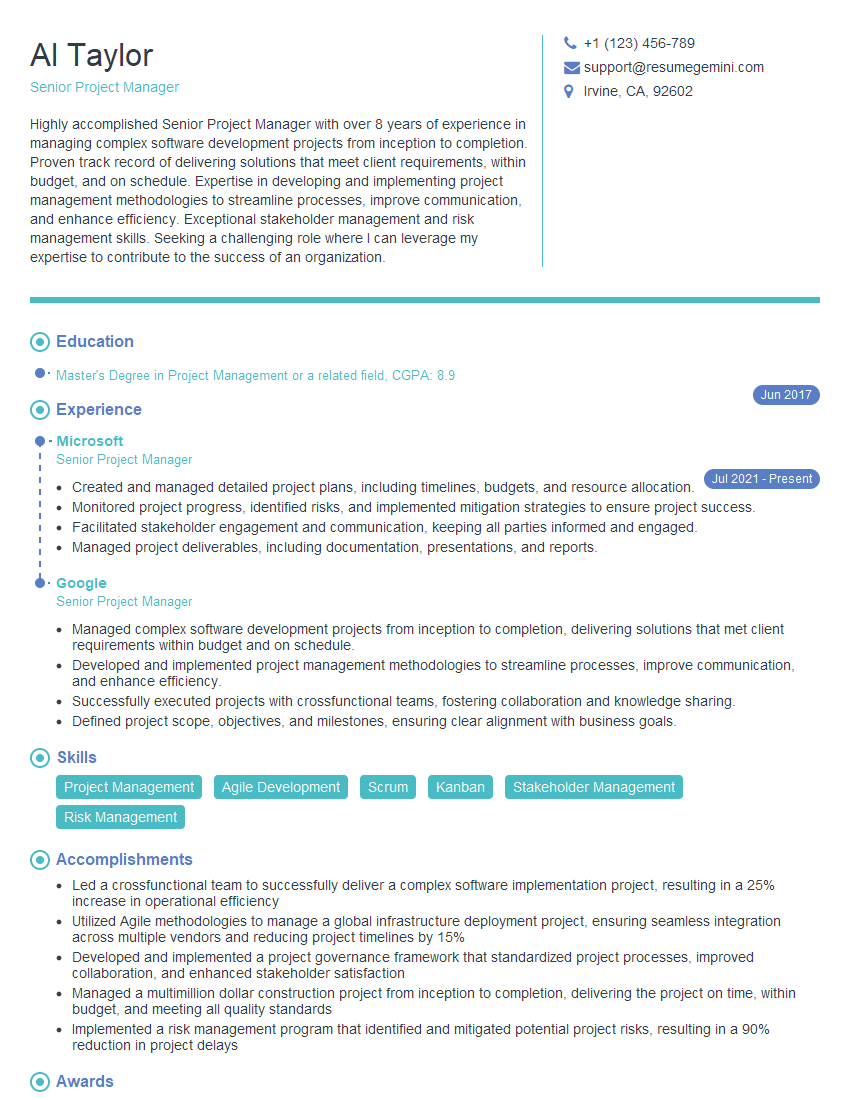

Mastering these key areas significantly enhances your career prospects in the construction industry, opening doors to more challenging and rewarding opportunities. A well-crafted resume is crucial for showcasing your skills and experience effectively to potential employers. To maximize your chances, focus on creating an ATS-friendly resume that highlights your relevant accomplishments and keywords. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to your experience with residential and commercial construction are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good