Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Feeding fabric or material to a stitching machine interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Feeding fabric or material to a stitching machine Interview

Q 1. Describe your experience feeding fabric to a variety of sewing machines.

My experience encompasses feeding a wide variety of fabrics to numerous sewing machine types, from basic domestic machines to industrial models like heavy-duty flatbed and cylinder arm machines. I’ve worked with machines employing different feed mechanisms, which I’ll detail later. This experience spans diverse projects, including apparel construction, upholstery, quilting, and even some specialized textile applications. My expertise extends to recognizing the unique feeding requirements of each fabric and machine combination for optimal results and preventing damage to the fabric or machine.

Q 2. Explain the proper techniques for feeding different types of fabrics (e.g., knits, wovens, leather).

Feeding fabrics correctly depends heavily on their type. Woven fabrics, like cotton or linen, generally feed smoothly. The key is to maintain even tension and a consistent feed rate. Knits, however, are more elastic and require gentler handling to avoid stretching or distortion. I often use a walking foot for knits to ensure both layers feed evenly. Leather presents a different challenge entirely; its thickness and rigidity require a strong, even feed with specialized needles and possibly a roller foot to prevent slippage. Consider this analogy: imagine feeding a delicate silk scarf versus a thick leather belt – each requires a different approach for optimal results.

- Wovens: Straightforward feeding; maintain even tension.

- Knits: Use a walking foot; gentle, even pressure.

- Leather: Strong, even feed; specialized needles and potentially a roller foot.

Q 3. How do you maintain a consistent feed rate while operating a sewing machine?

Maintaining a consistent feed rate is crucial for achieving straight seams and preventing puckering. It’s a balance between machine speed and manual guidance. I use a combination of techniques: First, I select an appropriate stitch length for the fabric and project. Second, I adjust the machine’s speed dial, often starting slow and gradually increasing speed as I assess the fabric’s response. Finally, and most importantly, I use my hands to guide the fabric evenly, ensuring smooth and consistent movement through the feed dogs. Think of it like driving a car – you adjust your speed based on road conditions (the fabric) to maintain a smooth, controlled ride.

Q 4. What are some common problems encountered while feeding fabric and how do you troubleshoot them?

Common problems include skipped stitches, puckering, fabric bunching, needle breakage, and uneven seams. Troubleshooting involves systematically checking several aspects:

- Skipped stitches: Check the needle, thread tension, and feed dogs. A bent needle, incorrect thread tension, or clogged feed dogs can all cause this.

- Puckering: This often stems from uneven feeding or incorrect tension. Adjust the feed rate and tension accordingly. A walking foot can also help.

- Fabric bunching: Reduce machine speed, check for obstructions in the feed mechanism, and ensure the fabric is fed smoothly and evenly.

- Needle breakage: Use the correct needle type for the fabric. Dull needles are a common cause. Check for obstructions beneath the needle plate.

- Uneven seams: This suggests inconsistent feeding. Pay close attention to guiding the fabric and maintaining even tension.

Sometimes, a combination of factors can contribute to a problem. A systematic approach ensures each potential cause is addressed.

Q 5. How do you handle fabric wrinkles or puckers during the feeding process?

Wrinkles and puckers are often the result of inconsistent feeding or tension. Prevention is key. Before stitching, I carefully smooth out the fabric, paying close attention to areas prone to wrinkling. During stitching, I gently guide the fabric, ensuring it moves smoothly and evenly. For stubborn wrinkles, I might use a walking foot, which helps to prevent puckering by gripping both layers of fabric equally. If a pucker already exists, I sometimes need to carefully unpick the stitches and restart, focusing on maintaining a consistent feed and avoiding pulling or stretching the fabric.

Q 6. Describe your experience with different types of sewing machine feeds (e.g., walking foot, feed dogs).

I have extensive experience with various feed mechanisms. Standard feed dogs are common on domestic machines and provide a basic feed. A walking foot, however, has multiple feed dogs that move in unison, improving fabric control, especially with multiple layers or slippery fabrics. Industrial machines may have more specialized feeds, such as a roller feed system for heavy materials or specialized feeds for particular types of stitch work. Each feed mechanism has its advantages and disadvantages, and selecting the appropriate type depends heavily on the fabric and desired result.

Q 7. How do you adjust fabric feed settings based on fabric type and stitch length?

Adjusting fabric feed settings is crucial for achieving quality results. For example, heavier fabrics typically require a slower feed rate and shorter stitch length to ensure strength and prevent breakage. Conversely, lighter fabrics may allow for faster speeds and longer stitches. The optimal settings also depend on the stitch type. For instance, decorative stitches may require a slightly slower feed rate for better clarity. It’s an iterative process; I often start with a conservative setting and adjust based on the results. Experience and careful observation are key to achieving the right balance.

Q 8. How do you ensure the fabric is properly aligned before and during stitching?

Proper fabric alignment is crucial for consistent stitching and a professional finish. Before stitching, I meticulously check that the fabric edges are aligned with the machine’s needle and feed dogs. This often involves using guiding tools like seam guides or even simple markings on the fabric itself. During stitching, maintaining alignment relies on consistent feeding. I use a gentle, even pressure on the fabric to guide it smoothly through the feed dogs, preventing any pulling or skewing. Think of it like steering a car – smooth, controlled movements ensure a straight path.

For example, when sewing a straight seam, I’ll ensure both fabric layers are perfectly matched at the edge before starting. During the process, I’ll pay close attention to prevent one side from feeding faster than the other, causing the seam to become uneven.

With curved seams, maintaining alignment requires more attention and sometimes involves careful manipulation of the fabric to ensure it follows the needle’s path consistently. Sometimes, I use my fingers to gently guide the fabric around curves to prevent bunching or puckering.

Q 9. Explain your process for dealing with fabric jams or breakages.

Fabric jams and breakages are unfortunately part of the process, especially with certain fabrics. My approach is methodical and prioritizes safety. First, I immediately turn off the machine and unplug it. Then, I carefully examine the area of the jam or breakage, identifying the cause. Is the thread tangled? Is the fabric caught? Is the needle bent?

Common causes I’ve encountered include: using the wrong needle/thread combination, incorrect tension settings, or too much fabric being fed at once. Once the cause is identified, I address it systematically. This might involve carefully removing the jammed fabric, replacing a broken needle, cleaning lint from the bobbin case, or rethreading the machine.

For instance, if the thread breaks repeatedly, I’ll check the tension settings and ensure the thread is properly wound. If the fabric jams frequently, I’ll adjust the feed dogs or the pressure foot to ensure a smoother feed. Prevention is also key; regularly cleaning the machine and using appropriate needles for the fabric type significantly reduces these issues.

Q 10. What safety measures do you follow while operating a sewing machine?

Safety is paramount. Before operating any sewing machine, I ensure the area is clear of obstructions, and I’m wearing appropriate clothing – nothing loose or dangling near moving parts. I always turn off and unplug the machine before performing any maintenance or cleaning.

I’m careful to never reach into the machine while it’s running. I regularly inspect the machine’s condition, paying particular attention to the needle, bobbin, and motor, to ensure everything is in good working order. If anything seems amiss – a loose part, a strange noise, or anything that feels off – I stop immediately and don’t use the machine until it’s been checked by a qualified technician. Think of it as car maintenance: regular checks and immediate attention to any warning signs prevent accidents.

Q 11. How do you maintain a clean and organized workspace?

A clean and organized workspace enhances efficiency and safety. I start by ensuring all materials – fabric, threads, patterns, etc. – are neatly organized and easily accessible. I keep the machine itself clean, regularly removing lint and dust from its interior and exterior. I use designated containers for scraps, needles, and other small items, preventing accidents and maintaining a professional look. Keeping the floor clean and free of clutter helps prevent tripping hazards.

This organized approach has drastically improved my workflow – it’s easy to find things, making projects more efficient and reducing stress. An example is color-coding my thread spools, making selection much faster.

Q 12. How do you identify and address inconsistencies in fabric feed?

Inconsistencies in fabric feed can lead to uneven stitching, puckering, or even fabric breakage. Identifying the root cause is key, and often involves a systematic approach. I first check the thread tension – is it too tight or too loose? Next, I inspect the feed dogs; are they clean and moving freely? I’ll also check the pressure foot for proper pressure adjustment.

Sometimes, the fabric itself is the issue; very thick or slippery fabrics require adjustments to pressure foot and speed. The needle itself can cause uneven feeding if it’s dull or bent. A common problem is using the incorrect needle size for the fabric – a blunt needle can cause skipped stitches and uneven feed.

My problem-solving approach involves eliminating possibilities. If adjusting the pressure foot doesn’t work, I move onto checking the needle and so on, until the root cause is found.

Q 13. Describe your experience working with high-speed sewing machines.

I have extensive experience with high-speed sewing machines, mainly in industrial settings. Operating these machines requires precision, skill, and a strong understanding of machine mechanics. The higher speeds demand even more precise fabric feeding and consistent attention to detail. Safety is paramount – understanding the machine’s limitations and following all safety protocols is essential. I’ve worked with machines capable of several thousand stitches per minute, requiring precise control and continuous monitoring.

One example was working on a production line assembling garments. The speed was demanding, but using consistent technique and maintaining a focus on correct fabric placement helped me maintain accuracy and production efficiency. My experience also includes performing regular maintenance checks on the high-speed equipment, ensuring they remained in optimal working order.

Q 14. What is your experience with different types of needles and threads?

My experience with needles and threads is broad, encompassing various types and sizes. Understanding the relationship between needle type, thread type, and fabric type is critical for achieving consistent, high-quality results. Different fabrics require different needles; for example, delicate fabrics need fine needles, whereas heavier fabrics need heavier needles. The thread also must match the fabric and needle – using a heavy thread with a fine needle will damage the needle and fabric.

I’m familiar with various needle types: sharps, ballpoints, stretch needles, jeans needles, embroidery needles – each suited to particular fabric types. Similarly, I have experience with various thread types: cotton, polyester, silk, rayon – each with its own properties in terms of strength, durability, and sheen. Choosing the right combination is crucial for a clean, professional outcome. It’s much like selecting the correct tools for a specific job in carpentry. A specific type of screw requires a specific type of screwdriver. Similarly, fabric needs the right needle and thread.

Q 15. How do you handle different fabric weights and thicknesses?

Handling different fabric weights and thicknesses requires adjusting the machine’s settings and feeding technique. Think of it like driving a car – you wouldn’t drive a Formula 1 car the same way you’d drive a truck. Lighter fabrics, like silk or chiffon, require a gentler touch and potentially lower feed dog pressure to prevent puckering or damage. Conversely, heavier fabrics like denim or canvas need a more aggressive feed and potentially higher pressure to ensure consistent movement through the machine.

- Lighter Fabrics: I reduce the presser foot pressure, use a smaller stitch length, and feed the fabric slowly and evenly. I might also use a walking foot attachment for added control and even feeding.

- Heavier Fabrics: I increase the presser foot pressure, potentially use a stronger needle, and adjust the feed dogs to ensure adequate grip. I might also employ techniques like easing the fabric into the machine to avoid bunching.

- Multiple Layers: When working with multiple layers of fabric, I carefully align the layers and use techniques to reduce bulk, such as using a different needle or a more powerful machine.

The key is to always observe the fabric’s behavior as it passes through the machine and make adjustments as needed. Experience helps develop an intuitive sense of the correct settings and feeding technique for various fabrics.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain quality control while feeding fabric?

Maintaining quality control during fabric feeding is crucial for consistent results. It’s a multi-step process that begins before the fabric even reaches the machine. I start by carefully inspecting the fabric for flaws, ensuring it’s free of tears, stains, or other imperfections. Then, I meticulously prepare the fabric, smoothing it out and ensuring there are no wrinkles or creases that could affect the stitching process. During the actual feeding, I maintain a steady, even pace, regularly checking the alignment of the fabric under the needle. Regular cleaning of the machine’s feed dogs prevents any buildup of lint or dust that could interfere with consistent feeding.

I also regularly check the stitch quality, looking for inconsistencies such as skipped stitches or uneven tension. If I notice any issues, I immediately address the root cause—whether it’s the machine’s settings, the fabric itself, or my feeding technique—to prevent defects from accumulating. Think of it like baking a cake: attention to detail at each stage ensures a perfect outcome.

Q 17. How do you ensure consistent stitch quality during the feeding process?

Consistent stitch quality depends on several factors, but proper fabric feeding is paramount. Uneven feeding directly translates to uneven stitches and potential fabric damage. I ensure consistent stitch quality by first correctly setting the stitch length and tension appropriate for the fabric type and desired stitch pattern. I always use needles of the correct size and type for the fabric.

- Consistent Speed: I maintain a steady feeding speed to prevent inconsistencies in stitch length and tension.

- Precise Alignment: I ensure the fabric is aligned correctly under the needle to avoid skipped stitches or uneven stitching.

- Regular Maintenance: Regular cleaning and maintenance of the sewing machine, including lubrication and needle changes, are essential for optimal performance and stitch quality.

I always perform test runs on scrap material before starting on the actual product to fine-tune the settings and check the stitch quality. By using this method, I ensure that the final product meets the quality standards.

Q 18. Describe your experience working in a team environment.

I thrive in team environments. In my previous role, we worked closely as a team to meet demanding production deadlines for a large order of custom-designed upholstery. Effective communication was key; we held daily briefings to discuss progress, identify potential bottlenecks, and ensure everyone was on the same page. I actively contributed to brainstorming solutions to challenges, such as developing new techniques for handling a particularly difficult fabric.

My strengths in a team setting include my willingness to collaborate, my ability to contribute effectively even under pressure, and my proactive approach to problem-solving. I am always ready to lend a hand to my teammates and share my expertise to achieve shared goals. I also actively listen to feedback and am always open to learning from others.

Q 19. How do you handle pressure and meet deadlines in a fast-paced environment?

Fast-paced environments are part and parcel of the garment industry. My approach is to prioritize tasks effectively, focusing on the most urgent ones first. I use time management techniques, such as breaking down large tasks into smaller, manageable steps. For example, during peak seasons, I might create a detailed production schedule to allocate time efficiently for each phase of the process. Proactive communication is crucial; I make sure to alert my supervisor of any potential delays or issues early on to allow for adjustments to the schedule.

When faced with increased pressure, I take short breaks to reset and regain focus. Maintaining a calm and organized approach is essential to avoid errors and maintain quality. I find that staying organized and focusing on one task at a time helps me manage pressure and meet deadlines effectively. Think of it like navigating a maze—a methodical approach helps you reach the destination efficiently.

Q 20. What are your strengths and weaknesses related to operating sewing machines?

My strengths include my proficiency in operating a wide range of sewing machines, from basic models to those with advanced features. I’m adept at troubleshooting common machine problems and quickly adapting to different stitch types and fabric weights. I am also highly efficient and accurate in my work, producing high-quality results consistently. Moreover, I am always keen to learn new techniques and expand my skill set.

My weakness, if I had to identify one, would be my occasional tendency to be overly meticulous, which can sometimes lead to slower production speeds on less complex tasks. However, I am actively working to manage this by prioritizing tasks based on complexity and urgency, while maintaining my high standard of quality. This ensures I am still efficient while upholding my commitment to excellence.

Q 21. How do you adapt to changes in production requirements?

Adaptability is key in this industry. I approach changes in production requirements with a proactive and solution-oriented mindset. When presented with a new task or change in production, I carefully review the specific requirements and identify any potential challenges. I thoroughly study the new techniques or processes before attempting them on actual products. I use my experience and understanding of sewing machine operation to assess what adjustments are necessary to meet the new requirements.

For example, if there is a change in fabric type or stitch design, I adjust the machine settings accordingly, perhaps even experimenting with different needles or presser feet. I am always eager to learn new techniques and welcome opportunities to enhance my skills. This approach allows me to quickly and efficiently adapt to new challenges, ensuring smooth transitions and continued high-quality production.

Q 22. What is your experience with different sewing machine brands and models?

Throughout my career, I’ve worked extensively with various sewing machine brands and models, from industrial giants like Juki and Singer to more specialized brands like Pfaff and Brother. My experience spans both single-needle and multi-needle machines, including flatbed, cylindrical, and post bed machines. I’m familiar with their unique feeding mechanisms, stitch capabilities, and potential maintenance needs. For instance, I’ve worked extensively with Juki’s high-speed industrial machines, known for their robust feeding systems, and I’ve also handled more delicate Brother machines used for intricate embroidery. This broad exposure allows me to adapt quickly to different equipment and optimize settings for various fabrics and projects.

- Juki DU-1181N: Experienced in high-speed operation and complex feed dog adjustments.

- Singer 4411 Heavy Duty: Proficient in handling thicker fabrics and making adjustments for consistent feed.

- Brother PQ1500SL: Skilled in its use for embroidery and more delicate fabric handling.

Q 23. Describe a time you had to troubleshoot a fabric feeding problem.

I once encountered a frustrating situation where a new batch of silk fabric was causing inconsistent feeding on a high-speed Juki machine. The stitches were bunching up in some areas and skipping in others. My initial troubleshooting steps included checking the machine’s tension, ensuring the needle was correctly installed and sharp, and verifying that the feed dogs were clean and functioning properly. However, the problem persisted. I then realized the issue was related to the silk’s slippery nature. It wasn’t gripping the feed dogs effectively. The solution involved using a specialized Teflon foot, reducing the machine’s speed, and slightly increasing the presser foot pressure. This combination dramatically improved the fabric feed, resulting in even, consistent stitches.

This experience highlighted the importance of considering the specific properties of the fabric and how they interact with the machine’s feeding mechanism. It’s not always a simple mechanical adjustment; sometimes it requires a deeper understanding of material science and machine dynamics.

Q 24. How do you prioritize tasks when working on multiple sewing machines or projects?

When juggling multiple sewing machines and projects, I prioritize tasks based on several factors: deadlines, project complexity, and machine capabilities. I use a Kanban-style system, visually tracking tasks on a whiteboard. Urgent orders with tight deadlines take precedence. Projects requiring specialized machines are tackled first when that machine is available. I also group similar tasks together to optimize workflow. For example, I might complete all the cutting for a set of projects before moving on to stitching. This minimizes setup time and allows for efficient use of my time and resources.

Think of it like orchestrating a symphony – each machine and project has its own tempo and demands. Effective prioritization ensures a smooth, harmonious workflow.

Q 25. Describe your experience with different types of seams and stitches.

My experience encompasses a wide range of seams and stitches, from basic straight stitches and zigzag stitches to more complex techniques like blind hems, French seams, and decorative stitches. I’m proficient in creating different types of seams, including flat felled seams for durability, and decorative seams for aesthetic purposes. I understand how stitch length and width impact the seam’s strength and appearance. For example, a shorter stitch length provides greater durability, while a wider stitch is better suited for stretchy fabrics. I can adapt my stitch selection based on the fabric type, project requirements, and desired aesthetic.

- Straight Stitch: Used for seams requiring strength and durability.

- Zigzag Stitch: Used for finishing seams, preventing fraying and providing elasticity.

- Overlock Stitch: Used for professional-looking seam finishes and preventing fraying in stretchy fabrics.

- Blind Hem Stitch: Creates an almost invisible hem.

Q 26. How do you ensure efficient fabric utilization to minimize waste?

Efficient fabric utilization is crucial for minimizing waste and maximizing profitability. I employ several strategies, including careful planning of patterns and layouts, using efficient cutting techniques, and maximizing fabric remnants for smaller projects. Before cutting, I carefully analyze the pattern pieces to determine the most efficient layout on the fabric, minimizing wasted material. I also utilize computer-aided design (CAD) software where appropriate to optimize fabric usage. Leftover fabric scraps are meticulously saved and repurposed for smaller items or as patches, minimizing waste to an absolute minimum. The goal is to achieve a balance between production efficiency and responsible resource management.

Q 27. What is your understanding of different types of sewing machine maintenance?

Sewing machine maintenance is paramount for ensuring consistent performance and preventing costly breakdowns. My understanding encompasses several key areas: regular cleaning and lubrication to prevent friction and wear; timely replacement of needles, bobbins, and belts; and periodic inspections for any signs of damage or wear. I’m also adept at performing minor repairs, such as adjusting the tension and feed dogs. Proactive maintenance prevents major issues and maximizes machine longevity. I consider preventative maintenance as crucial as the actual sewing process itself. This includes regular oiling of moving parts, cleaning of lint and debris, and checking the timing of the machine regularly.

Q 28. How would you train a new employee on proper fabric feeding techniques?

Training a new employee on proper fabric feeding techniques would involve a phased approach: First, I’d start with a demonstration, showing the correct way to guide the fabric through the machine, highlighting the importance of consistent speed and pressure. Next, hands-on practice with different fabric types would be key. I’d emphasize observing the feed dogs’ movement and adjusting the presser foot pressure based on the fabric’s weight and texture. I’d provide feedback, correcting any inconsistencies, and encourage them to experiment with different settings under supervision. We’d work through various scenarios, including problem-solving potential feeding issues. Finally, ongoing monitoring and mentorship would ensure they maintain proper technique and confidently handle any challenges that arise. The goal is to develop a keen eye for detail and instinctive understanding of fabric behavior under different machine settings.

Key Topics to Learn for Feeding Fabric or Material to a Stitching Machine Interview

- Understanding Fabric Types and Properties: Knowing how different fabrics (e.g., lightweight silk, heavy denim) behave during feeding is crucial. This includes understanding drape, stretch, and thickness.

- Machine Operation and Adjustments: Familiarize yourself with various stitching machine types and their feeding mechanisms. Learn how to adjust stitch length, tension, and feed dogs for optimal fabric handling.

- Efficient Feeding Techniques: Master different feeding methods, including hand-feeding, using guides, and employing specialized attachments. Practice smooth, consistent feeding to avoid puckering or stretching.

- Troubleshooting Common Issues: Learn to identify and resolve problems such as skipped stitches, uneven feeding, fabric bunching, and needle breakage. Develop strategies for preventing these issues.

- Safety Procedures: Understand and adhere to all safety regulations and procedures related to operating stitching machines. This includes proper machine maintenance and handling of sharp objects.

- Quality Control and Inspection: Learn how to inspect the finished product for defects resulting from improper feeding. Develop a keen eye for identifying inconsistencies in stitching and fabric manipulation.

- Production Optimization: Understand how efficient fabric feeding contributes to increased productivity and reduced waste in a manufacturing setting.

Next Steps

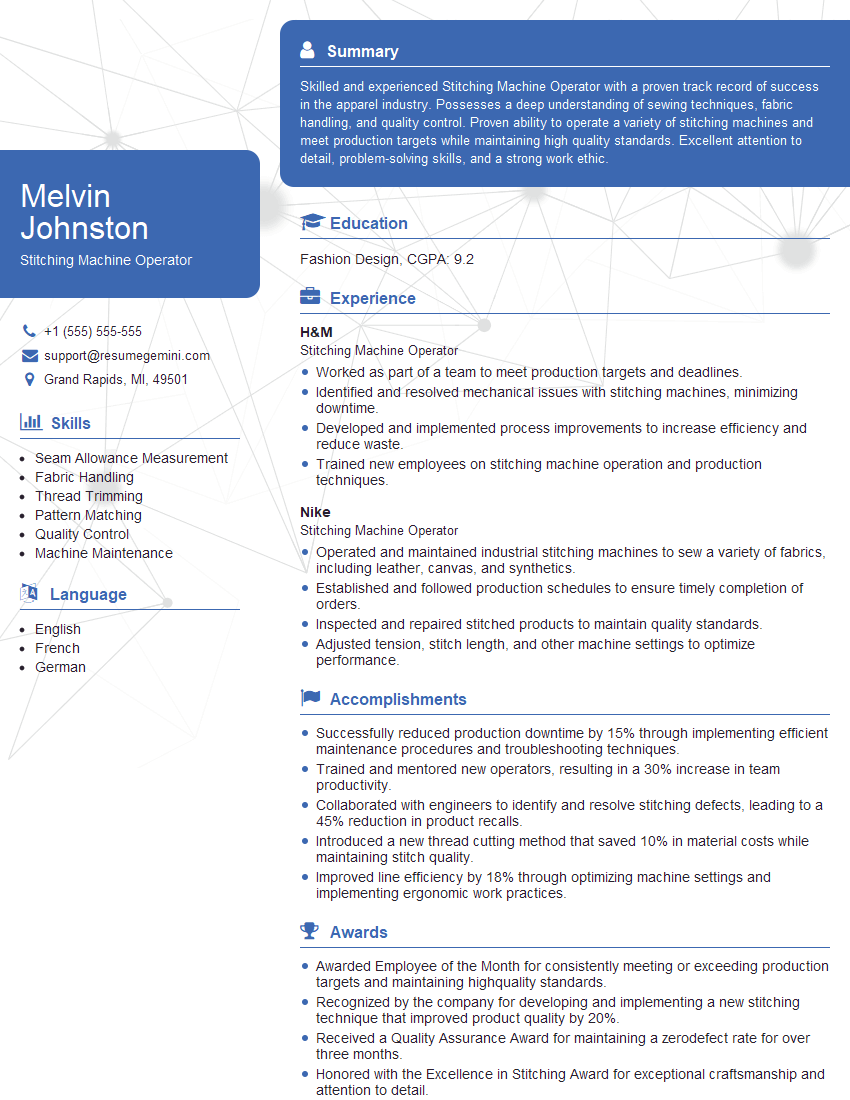

Mastering the art of feeding fabric to a stitching machine is a highly valuable skill in the garment manufacturing industry. Proficiency in this area demonstrates attention to detail, technical aptitude, and a commitment to quality—all highly sought-after qualities by employers. To significantly boost your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you craft a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to this specific skillset are available within ResumeGemini to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).