Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Felling and Bucking Procedures interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Felling and Bucking Procedures Interview

Q 1. Describe the different felling techniques.

Felling techniques are chosen based on the tree’s size, species, lean, and surrounding environment. The primary methods are:

- Humboldt Felling: This is a directional felling technique involving making an undercut, then a backcut to control the direction of fall. It’s ideal for larger trees with a significant lean. Think of it like carefully guiding a falling domino – you’re creating a hinge to control the fall.

- Open-Face Felling: A simpler method, suitable for smaller trees with less lean. It involves making a single backcut, without an undercut, allowing the tree to fall in the direction of the backcut. It’s quicker but requires more precision to avoid uncontrolled falls.

- Notching and Wedging: Used for trees with significant lean or difficult falls. Notching creates a controlled break point, and wedges are used to direct the tree’s fall. This is like creating a controlled fracture in a bone – a precise, powerful method for stubborn cases.

The choice of technique depends heavily on the specific circumstances and the experience level of the feller. Improper technique can lead to dangerous and unpredictable results.

Q 2. Explain the importance of pre-felling assessments.

Pre-felling assessments are crucial for safety and efficiency. They involve a thorough inspection of the tree and its surroundings. This includes:

- Tree Condition: Assessing the tree’s health, decay, lean, and any potential weaknesses (e.g., rot, cracks).

- Surrounding Environment: Identifying obstacles such as other trees, power lines, buildings, or slopes that could impact the fall path.

- Wind Conditions: Strong winds can significantly affect the direction and force of the fall, making careful planning essential.

- Soil Conditions: Loose or unstable soil can increase the risk of the tree falling unexpectedly or causing damage.

A proper assessment allows for choosing the right felling technique, determining the optimal felling direction, and identifying potential hazards. Skipping this step can lead to serious accidents and property damage. For instance, failing to notice a hidden crack could cause the tree to break unexpectedly during felling.

Q 3. What are the safety precautions for felling trees?

Safety is paramount in felling. Essential precautions include:

- Personal Protective Equipment (PPE): This includes safety helmets, eye protection, hearing protection, high-visibility clothing, and appropriate chainsaw chaps or safety pants.

- Clear Escape Path: Ensure a clear escape route, at a 45-degree angle away from the expected fall path, is established before starting work. This provides a safe path to retreat from the falling tree.

- Properly Trained Personnel: Only qualified and experienced personnel should conduct felling operations.

- Controlled Environment: Restrict access to the felling area. Warn others of the impending operation.

- Regular Equipment Maintenance: Ensuring chainsaws are properly maintained and sharp is crucial for safe operation and efficient cutting.

- Weather Conditions: Avoid felling in adverse weather conditions such as high winds, rain, or ice.

Never compromise safety for speed. A thorough risk assessment before every felling operation is crucial.

Q 4. How do you determine the direction of fall?

Determining the direction of fall involves careful consideration of several factors:

- Lean of the Tree: The tree’s natural lean is the primary factor in determining the fall direction.

- Wind Direction and Strength: Wind can significantly influence the direction, so factor in wind speed and gusts.

- Obstacles: Avoid felling the tree towards any obstructions (buildings, other trees, power lines).

- Ground Conditions: Assess soil stability to prevent unexpected movements.

- Use of Felling wedges: These are sometimes necessary to steer the tree’s fall direction and provide extra control.

Imagine the tree as a large pendulum; you need to plan the swing carefully to ensure it lands safely. A slight miscalculation can have severe consequences.

Q 5. Describe your experience with different types of saws.

My experience encompasses various saw types, each with its strengths and weaknesses:

- Chainsaws: These are the primary tool for felling. I’m proficient with various models, from smaller, lighter saws for smaller trees to larger, more powerful saws for larger timber. Different bar lengths and chain pitches are selected based on the job’s demands. I also understand the importance of maintenance and safety features.

- Hand Saws: While less common for large-scale felling, hand saws are useful for precise cuts, limbing, and bucking in confined spaces or when using a chainsaw is impractical.

Choosing the right saw is crucial. A small saw on a large tree is slow and dangerous; a large saw in a cramped space is inefficient and risky. Experience allows selecting the appropriate tool for every situation, ensuring both safety and efficiency.

Q 6. How do you handle unforeseen circumstances during felling?

Unforeseen circumstances are always a possibility. My approach is based on:

- Quick Assessment: Rapidly evaluate the situation to understand the problem. Is it a tree hanging up? Is there a new hazard that wasn’t there before?

- Safety First: Immediately retreat to a safe distance, and warn anyone else in the area of the danger.

- Problem Solving: Determine the best solution. This might involve using wedges, ropes, or other tools to correct the situation. In some cases, it might be necessary to abandon the cut and re-assess the situation.

- Communication: If needed, contact supervisors or other qualified personnel for assistance.

Once I was felling a tree and it unexpectedly hung up on a neighboring tree. I quickly retreated, assessed the situation, and used a rope and pulley system to carefully lower the hanging tree. Safe, controlled action is key.

Q 7. Explain the process of bucking a felled tree.

Bucking is the process of cutting a felled tree into manageable lengths (logs). The process generally involves:

- Limbing: Removing branches from the felled tree, starting from the top and working down. This makes bucking safer and easier.

- Measuring and Marking: Determining the desired log lengths and marking them on the trunk. This ensures efficient utilization of the timber.

- Cutting: Making precise cuts to separate the logs according to the markings. Safety precautions similar to felling are necessary, including maintaining a safe distance from the cutting action.

Efficient bucking maximizes the yield of usable lumber while minimizing waste. Precision and safety are essential throughout the process.

Q 8. What are the different bucking techniques?

Bucking, the process of cutting a felled tree into smaller, manageable lengths, employs several techniques depending on the tree’s size, shape, and the desired log lengths. The most common methods include:

- Hinge Bucking: This involves making a cut on the underside of the log, partially through its diameter, creating a hinge. A second cut, from the top, is then made to sever the log, allowing it to fall predictably onto the hinge. This is crucial for controlling the log’s direction.

- Bore Bucking: Used for larger logs or those with difficult grain patterns, bore bucking entails making two cuts from opposite sides to completely sever the log. It requires more precision to avoid kickback and binding.

- Drop Bucking: This technique is used when a log needs to be dropped a short distance. A single cut is made on the log’s underside, and the log is then allowed to fall under its own weight. This requires careful assessment of the ground conditions to prevent damage or injury.

- Compression Bucking: This advanced technique uses the weight of the log itself, or the weight of another object, to help control the bucking process. This is helpful in situations where a log is trapped or difficult to control.

The chosen technique often depends on the specific circumstances and the arborist’s experience and judgement. For example, I’ve used hinge bucking extensively in smaller-scale timber harvesting operations where precise log placement is crucial, while bore bucking has been invaluable when dealing with particularly large or stubborn hardwoods.

Q 9. How do you ensure the safety of yourself and others during bucking?

Safety during bucking is paramount. It starts with a thorough risk assessment of the area, including the terrain, the presence of obstacles, and the condition of the log. Here’s how I ensure safety:

- Clear the Area: Before making any cuts, I ensure a safe radius is cleared around the log to prevent injury from falling debris or uncontrolled log movement. This includes removing any nearby obstructions.

- Stable Foothold: I always maintain a firm and stable foothold, avoiding slippery or uneven ground. I often use safety boots with good traction and may even utilize specialized safety harnesses if necessary.

- Proper Body Positioning: I keep my body positioned outside of the potential path of the chainsaw chain, ensuring that the log’s movement won’t endanger me.

- Controlled Cuts: I make slow, deliberate cuts, carefully observing the log’s response. Never force the saw. If the saw binds, I immediately stop and re-assess the situation before continuing.

- Communication: When working with a team, clear communication is essential. We use hand signals to indicate the start and stop of cutting and any potential hazards.

Throughout the process, I remain alert and constantly aware of my surroundings, proactively identifying and mitigating any potential risks. Safety is not just a set of rules; it’s a mindset.

Q 10. What are the common hazards associated with felling and bucking?

Felling and bucking are inherently hazardous activities. Common hazards include:

- Kickback: This occurs when the chainsaw chain contacts an object, causing the saw to violently recoil. Proper technique and sharp chains help minimize this risk.

- Pinch Points: When the chain becomes trapped between the wood fibers, the saw can bind, potentially causing injury. Careful observation and appropriate techniques can avoid this.

- Falling Trees: Improper felling techniques or unforeseen circumstances can lead to trees falling unpredictably, creating a serious hazard.

- Falling Branches: During felling, branches can fall unexpectedly, causing injury. A thorough assessment and careful cutting technique minimizes this risk.

- Log Rollover: Logs can unexpectedly roll or shift during bucking, causing crushing injuries.

- Sharp Objects: Debris from cutting and sharp edges of logs can cause cuts or lacerations.

- Exposure to Elements: Weather conditions can pose additional risks, including slips, falls, and hypothermia.

Understanding these hazards and implementing appropriate safety measures is critical to minimizing risks in the field. I consistently practice risk mitigation methods to minimize the potential for injury.

Q 11. Describe your experience with using personal protective equipment (PPE).

PPE is an integral part of my work. I consistently use:

- Safety Helmet: Protecting my head from falling debris.

- Eye Protection: Safety glasses or a face shield protects my eyes from flying wood chips and debris.

- Hearing Protection: Earplugs or earmuffs protect my hearing from the loud noise of the chainsaw.

- Gloves: Protecting my hands from cuts and abrasions.

- Chainsaw Chaps: These are vital protective gear designed to prevent injury from a chainsaw kickback. They significantly reduce the impact of a chain contacting the legs.

- High-visibility Clothing: This improves visibility, especially when working in groups or near moving equipment.

- Steel-toed Boots: Protecting my feet from falling objects and potential crushing hazards.

I inspect my PPE before each use and ensure it’s in good condition. Regular maintenance and replacement are critical to maximizing its effectiveness. In my years of experience, my PPE has been critical in preventing serious injuries, many times unexpectedly saving me from harm.

Q 12. How do you maintain your chainsaw?

Maintaining my chainsaw is crucial for its performance, safety, and longevity. My maintenance routine includes:

- Daily Inspection: Before each use, I inspect the chain for damage, sharpness, and proper tension. I also check the fuel and oil levels.

- Regular Cleaning: After each use, I clean the chainsaw, removing sawdust and debris from the bar and chain.

- Chain Sharpening: I regularly sharpen the chain using a high-quality file or a power sharpener, ensuring it remains sharp to minimize kickback and improve cutting efficiency. A dull chain is more dangerous.

- Bar Lubrication: I ensure the bar is properly lubricated with bar oil to reduce friction and wear.

- Air Filter Cleaning: I regularly clean or replace the air filter to maintain the engine’s performance and longevity. A clogged filter can lead to engine damage.

- Spark Plug Inspection: I periodically inspect and clean or replace the spark plug to ensure optimal engine performance.

I keep detailed records of all maintenance activities, which helps in tracking its performance and predicting future needs. This proactive approach greatly reduces the risk of mechanical failures and enhances safety on the job.

Q 13. How do you identify and avoid hazards like snags and deadwood?

Identifying and avoiding hazards such as snags and deadwood requires careful observation and a proactive approach. My strategy includes:

- Visual Inspection: Before felling a tree, I carefully inspect the tree and its surroundings for any snags (broken or weakened branches) or deadwood that might fall during the process. I also assess the overall health and stability of the tree.

- Tree Assessment: I assess the tree for lean, decay, rot, and other structural weaknesses that could pose risks. Sometimes this requires specialized tools such as a tree-climbing harness.

- Hazard Marking: I mark any potential hazards, such as snags or deadwood, that need to be removed or accounted for during felling and bucking.

- Strategic Felling: I plan the felling direction carefully, considering the wind direction, the terrain, and the location of any potential hazards. I always choose the safest felling direction, sometimes requiring additional steps to prepare for it.

- Safety Zones: I ensure a safe working zone is established and maintained at all times to minimize the potential exposure to falling debris or unpredictable movements.

Careful observation and risk assessment are not just safety precautions; they’re an integral part of my decision-making process before any cutting begins. Many times, an extra minute of careful observation can prevent a serious injury.

Q 14. What is your experience with different tree species and their felling characteristics?

My experience encompasses a wide range of tree species, each possessing unique felling characteristics. For instance:

- Hardwoods (e.g., Oak, Maple): These trees often have dense, strong wood, requiring more powerful saws and careful consideration of grain patterns to avoid binding. They sometimes exhibit unexpected stress points or hidden weaknesses.

- Softwoods (e.g., Pine, Fir): Generally easier to fell than hardwoods, but can still pose challenges, particularly if they have rot or insect damage hidden beneath the bark.

- Decayed Trees: These pose a high risk due to unpredictable structural weaknesses. Extra care and cautious assessment is required, and sometimes felling should be avoided altogether.

I have extensive experience working with various species across different terrains and climatic conditions. I always adapt my techniques to the specific characteristics of each tree and the environment. For instance, when working with a leaning tree, I have to carefully consider the lean’s direction, weight distribution, and potential for a significant fall to ensure a safe and controlled felling process.

Q 15. Describe your experience with felling in challenging terrain.

Felling in challenging terrain demands extra caution and planning. Steep slopes, uneven ground, and obstacles like rocks or undergrowth significantly increase the risk of accidents. My experience involves carefully assessing the terrain before starting any felling operation. This includes identifying escape routes, potential hazards, and the best felling direction to minimize the risk of the tree rolling or falling onto unstable ground. For example, on a steep slope, I’d prioritize felling uphill to allow the tree to roll away from me, but only if it’s safe to do so. I would always use extra support tools like additional wedges or even winch lines to control the fall path and prevent uncontrolled movement. I also utilize specialized equipment, such as longer felling bars or even smaller, more maneuverable saws depending on the conditions. Safety is paramount—if the risk is too high, I wouldn’t hesitate to consult with a more experienced colleague or postpone the operation until conditions improve.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle large-diameter trees?

Handling large-diameter trees requires a systematic approach emphasizing safety and precision. First, I thoroughly assess the tree for defects, lean, and potential hazards. Then, I choose the appropriate equipment – a larger chainsaw with sufficient power and bar length is crucial. I often use a two-person saw crew for enhanced safety and efficiency. Strategic undercutting and felling cuts are essential to control the direction of the fall, and I utilize wedges frequently to ensure a clean break and prevent binding. The felling process itself involves careful control and observation to ensure a predictable and safe outcome. It’s about precise cuts, not brute force. One instance involved a 5-foot diameter oak; we used a combination of precise undercutting and multiple wedges to control its descent and prevent it from splitting or binding during the fall.

Q 17. Explain your understanding of felling angles and hinge cuts.

Felling angles and hinge cuts are critical for directing the tree’s fall. The hinge, a portion of the tree left uncut, acts as a pivot point. The felling angle is determined by the tree’s lean, surrounding obstacles, and the desired fall direction. A back cut, made opposite the hinge, completes the felling process. The size of the hinge dictates the control over the fall. A larger hinge provides more control, while a smaller hinge increases the speed of the fall, useful in less space. Think of it like a door: the hinge is the portion that keeps the door attached, while the cut determines which way it swings. For instance, if a tree leans to the right, I’ll make the hinge on the left, angling the back cut to guide the tree’s fall in the desired direction. Incorrect angles can lead to uncontrolled falls, potentially resulting in injury or property damage.

Q 18. What is your experience with using wedges and other felling tools?

Wedges are indispensable tools in felling, particularly for large or stubborn trees. They assist in splitting the wood cleanly, preventing binding, and controlling the direction of the fall. I use various types, including metal and plastic wedges, depending on the wood type and conditions. Other tools like felling levers can further improve control. For example, a tree caught on another branch may require a lever to help direct the fall, or wedges to aid in cleanly separating the bound tree. Using wedges correctly is a skill; if inserted improperly, they can actually hinder the felling process. Experience and precise placement are paramount.

Q 19. Describe your experience with first aid and emergency procedures in the context of felling and bucking.

Safety is my utmost priority. My first-aid training includes treatment for common logging injuries, such as cuts, lacerations, and sprains. I’m proficient in using emergency communication tools, such as radios, to quickly summon assistance in case of an accident. A significant part of safety involves risk assessment, ensuring appropriate personal protective equipment (PPE) is used consistently. The emergency response plan for our crew includes a designated person to immediately call emergency services, and others to assist the injured worker and secure the area to prevent secondary accidents until help arrives. Regular safety briefings and training are essential components of the work environment. We conduct drills covering various scenarios to reinforce our response capabilities.

Q 20. How do you plan and execute a felling operation?

Planning a felling operation begins with a thorough risk assessment. I survey the area to identify hazards like slopes, obstacles, and nearby structures. Then, I determine the best felling direction, considering the tree’s lean, wind direction, and the surrounding environment. This is followed by selecting the right equipment and preparing the workspace. A safe escape route is critical, and I ensure communication methods are ready. The execution phase involves carefully making the cuts, monitoring the tree’s response, and making adjustments as needed. Constant awareness and communication between team members is key to a successful and safe felling operation. For example, in a dense forest, I would consider which trees to fell first to create an adequate working space and minimize the risk of entanglement.

Q 21. What is your experience with different types of logging equipment?

My experience encompasses various logging equipment, including chainsaws of different sizes and power outputs, appropriate to the tree size and conditions. I’m comfortable using felling wedges, mauls, and other hand tools. I also have experience with mechanical equipment such as skidders, loaders, and feller bunchers in larger scale operations; these would be used for bucking and processing trees after they have been felled. Proper maintenance and safe operation of all equipment are critical for productivity and safety. This includes regular sharpening and maintenance of chainsaws and ensuring all mechanical equipment is in proper working order before operation, regularly checking for wear and tear.

Q 22. How do you ensure the accuracy of bucking cuts to meet specific timber dimensions?

Ensuring accurate bucking cuts relies on a combination of precise measurement and skilled technique. Before I even begin, I carefully assess the tree and determine the required log lengths based on the customer’s specifications or market demands. I then use a variety of tools to ensure accuracy. This often includes a measuring tape for initial length determination, but for more complex cuts or when dealing with valuable timber, I may use a specialized bucking scale or even a laser measuring device.

For instance, if I need logs of precisely 16 feet, I’ll mark the tree trunk accordingly before making the cut. I always double-check my measurements to avoid errors. After the initial cut, I carefully inspect the log to ensure it meets the specifications. Minor adjustments can be made using a chainsaw with a precise cutting technique, ensuring a clean and straight cut.

Another crucial aspect is understanding the geometry of the cut and accounting for the slight compression of wood during the cutting process. This experience-based knowledge helps ensure the final log length is as close to perfect as possible. In essence, precision in bucking is a combination of careful planning, accurate measurement, and skilled execution.

Q 23. What are your methods for efficient timber extraction after felling and bucking?

Efficient timber extraction following felling and bucking is critical for minimizing costs and environmental impact. My approach involves a combination of strategies tailored to the specific site conditions. In accessible areas, we might use skidders or forwarders – specialized machines designed to efficiently move logs from the felling site to a landing area. These machines significantly reduce the time and labor involved.

For areas with limited access, such as steep slopes or dense undergrowth, we may employ more traditional methods like horse logging or hand-assisted extraction. This often requires careful planning of skid trails and a detailed understanding of the terrain to avoid damage to the remaining forest. We may also use smaller equipment like mini skidders that have reduced ground pressure to minimize soil disturbance.

Regardless of the method, I prioritize minimizing damage to the remaining trees and the surrounding environment. Proper planning of extraction routes and the use of appropriate equipment are crucial. Regular maintenance of the extraction equipment helps to ensure it’s working at peak efficiency and minimizes the risk of breakdowns.

Q 24. How do you comply with environmental regulations during logging operations?

Compliance with environmental regulations is paramount in logging operations. This includes adhering to all local, state, and federal regulations regarding protected species, water quality, and soil erosion. Before any work begins, I meticulously review all relevant permits and regulations applicable to the site. This includes understanding restrictions on felling areas near waterways, sensitive habitats, or areas designated for conservation.

During operations, I strictly adhere to best practices for minimizing environmental impact. This involves employing techniques that limit soil erosion, such as directional felling to avoid disrupting the soil profile significantly. We carefully mark and protect sensitive areas and avoid disturbing endangered plant or animal species. We also meticulously manage debris and leftover slash, either using it for beneficial purposes or disposing of it responsibly.

We maintain detailed records of all operations, including the location of felled trees, extraction routes, and any measures taken to mitigate environmental impacts. This documentation is crucial for demonstrating compliance with regulations and for future planning.

Q 25. Explain your understanding of sustainable forestry practices.

Sustainable forestry means managing forests in a way that balances the economic benefits of timber harvesting with the ecological integrity of the forest ecosystem. It’s about ensuring a continuous supply of timber for future generations without compromising the health of the forest or its biodiversity. This includes a variety of practices:

- Selective Harvesting: Instead of clear-cutting large areas, selective harvesting involves removing only mature or less desirable trees, allowing the remaining forest to regenerate naturally.

- Reforestation: Planting seedlings or allowing natural regeneration after harvesting to ensure the forest continues to grow.

- Reduced Impact Logging (RIL): Employing techniques that minimize damage to the remaining forest, such as using directional felling and carefully planning extraction routes.

- Forest Health Monitoring: Regularly assessing forest health and taking steps to address potential issues, such as disease or pest infestations.

- Biodiversity Conservation: Protecting and enhancing the biodiversity of the forest ecosystem through habitat preservation and the management of threatened species.

Sustainable forestry isn’t simply about timber production; it’s about recognizing the interconnectedness of the forest ecosystem and the vital services it provides.

Q 26. Describe a time you had to adapt your felling technique due to unforeseen circumstances.

During a logging operation, I encountered a situation where a large tree I was about to fell was leaning heavily against another large tree. My initial felling plan wouldn’t have worked safely due to the risk of the leaning tree causing the second tree to fall unexpectedly. My standard felling technique involved notching and using wedges to control the direction of the fall. However, the risk of the leaning tree complicating the fall was too high.

To adapt, I consulted with my crew and we decided to use a different approach. We used a climbing harness and ropes to carefully cut sections of the leaning tree, reducing its weight and tension. We then used small, controlled cuts to slowly release the tension between the two trees before proceeding with the standard felling technique on the main tree. This meticulous process ensured both trees were felled safely and efficiently, avoiding damage to surrounding trees. This experience highlighted the importance of adaptability and careful risk assessment when working in complex forest environments.

Q 27. How do you manage risks associated with weather conditions during felling and bucking?

Managing weather-related risks during felling and bucking is crucial for safety and operational efficiency. High winds, heavy rain, and snow significantly impact the safety and feasibility of the operation. My approach involves monitoring weather forecasts closely and suspending operations if conditions are too hazardous.

For example, high winds increase the risk of trees falling in unpredictable directions. In such conditions, I would postpone operations until the wind subsides. Heavy rain can make the ground muddy and slippery, increasing the risk of accidents. We may use specialized equipment to improve traction or pause operations if conditions become too dangerous. Similarly, snow and ice accumulation on trees and the ground can create dangerous conditions, requiring the use of additional safety equipment or the postponement of work.

Furthermore, I carefully assess the condition of the trees themselves, being especially cautious in wet or icy conditions. Waterlogged wood can be more brittle and susceptible to unexpected breakage, increasing the risk of injury. Effective risk management during challenging weather conditions involves careful planning, close monitoring, and the commitment to prioritizing safety above all else.

Q 28. What is your experience with using GPS and other mapping tools for logging operations?

I have extensive experience using GPS and mapping tools in logging operations. These technologies have significantly enhanced efficiency and precision. GPS receivers allow us to accurately mark tree locations, plan efficient extraction routes, and track the progress of operations.

For instance, we use GPS to map out the locations of trees to be felled, avoiding areas designated as environmentally sensitive or containing protected species. The data is then used to plan the most efficient routes for skidders and forwarders, minimizing ground disturbance. This technology also helps in boundary delineation, preventing accidental trespassing or harvesting outside designated areas.

Other mapping tools, such as GIS software, allow us to visualize and analyze the forest’s terrain and vegetation, assisting in planning for efficient timber extraction. This integration of technology into logging practices not only improves efficiency but also contributes to more environmentally responsible logging and better forest management.

Key Topics to Learn for Felling and Bucking Procedures Interview

- Tree Assessment and Hazard Recognition: Understanding tree anatomy, identifying potential hazards (disease, decay, lean, etc.), and assessing environmental factors affecting felling techniques.

- Felling Techniques: Mastering various felling techniques (e.g., directional felling, undercut techniques) based on tree characteristics and surrounding environment. Practical application includes understanding the use of wedges and felling tools.

- Safety Procedures and Regulations: Thorough knowledge of safety regulations, personal protective equipment (PPE) usage, and emergency procedures. This includes understanding safe working distances and escape routes.

- Bucking Procedures: Understanding different bucking techniques for efficient timber processing, considering factors like wood grain and log size. Practical application involves knowledge of different saw types and their appropriate use.

- Equipment Operation and Maintenance: Safe and efficient operation and maintenance of chainsaws, other power tools, and safety equipment. This includes understanding preventative maintenance schedules.

- Environmental Considerations: Understanding the environmental impact of felling and bucking, and best practices for minimizing damage to surrounding vegetation and wildlife.

- Problem-solving and Decision-Making: Ability to analyze situations quickly, adapt techniques to unexpected challenges (e.g., difficult terrain, unforeseen tree conditions), and make sound judgments to ensure safety and efficiency.

Next Steps

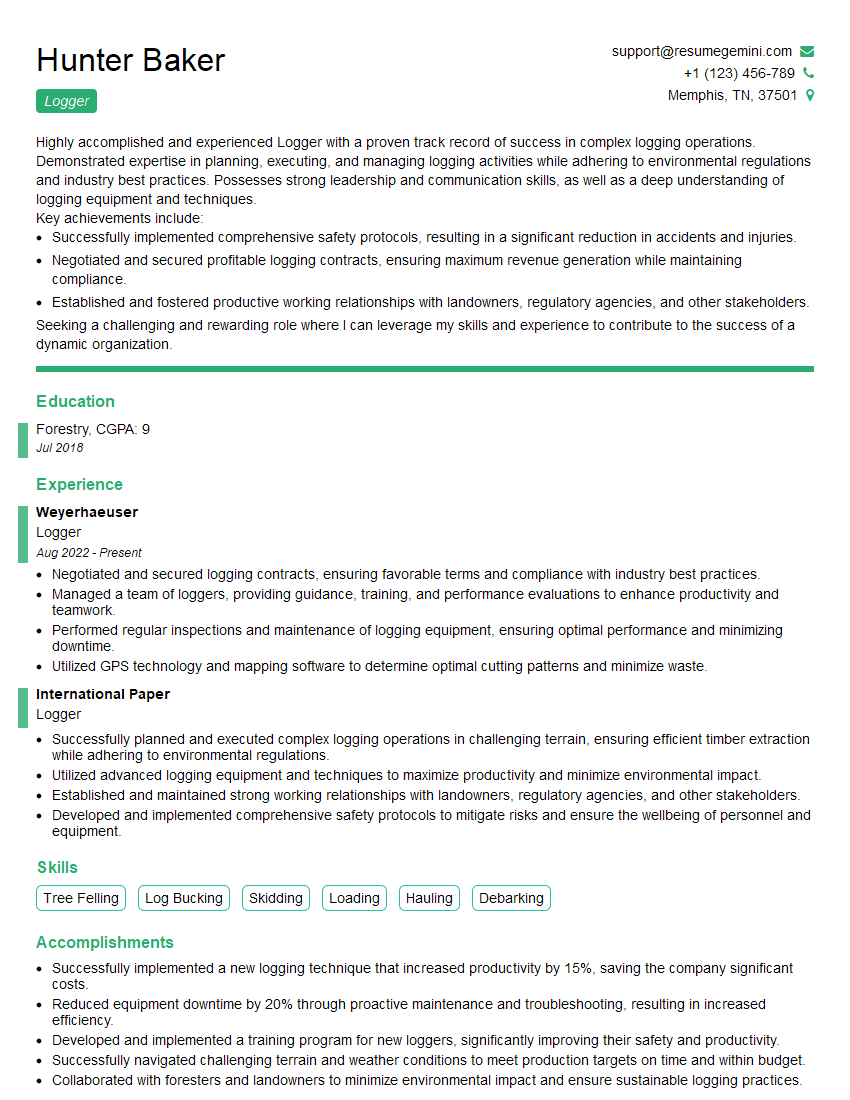

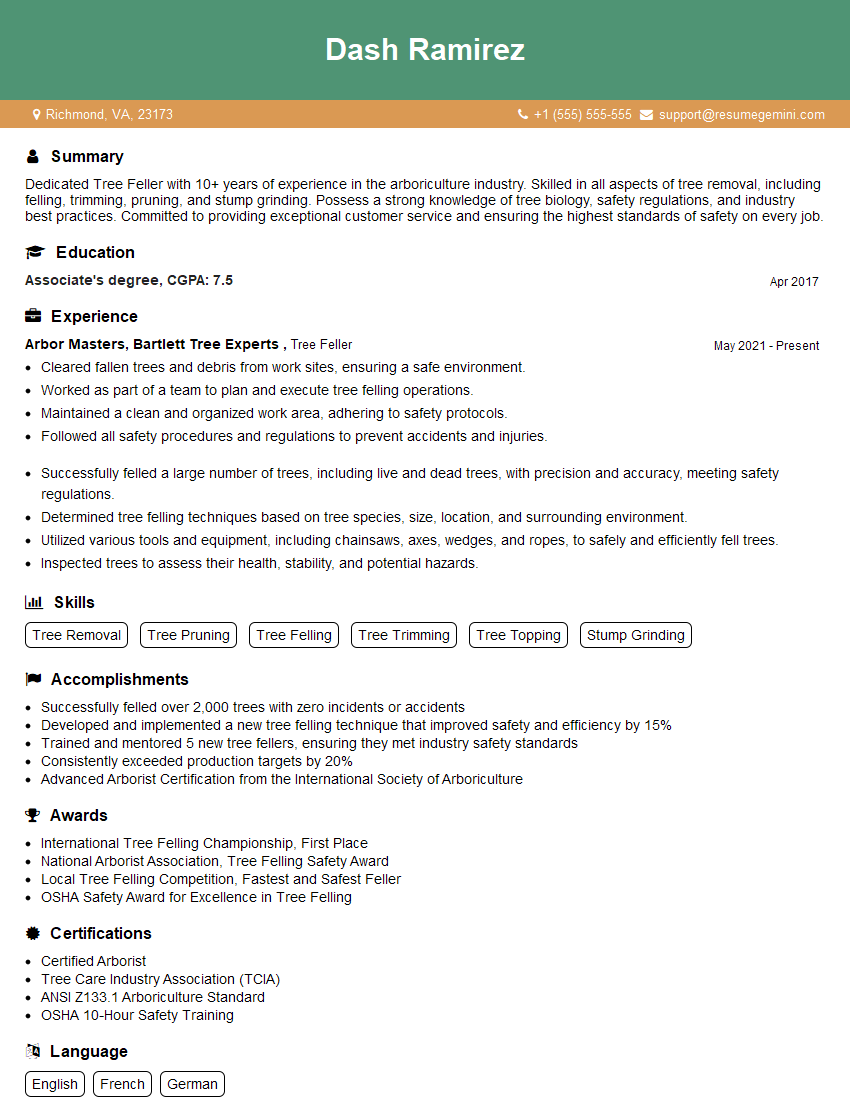

Mastering Felling and Bucking Procedures is crucial for career advancement in forestry, logging, and related industries. A strong understanding of these procedures demonstrates your commitment to safety, efficiency, and environmental responsibility, leading to increased job opportunities and higher earning potential. To significantly boost your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Felling and Bucking Procedures are available to guide you in crafting a compelling application. Invest the time to create a resume that truly represents your capabilities – it’s a vital step in securing your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good