Cracking a skill-specific interview, like one for Fiber Tipping Machine Operation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Fiber Tipping Machine Operation Interview

Q 1. What are the different types of fiber optic connectors?

Fiber optic connectors are the crucial components that allow us to connect fiber optic cables to other equipment, like network devices or transceivers. Choosing the right connector is vital for optimal signal transmission. There are many types, but some of the most common include:

- SC (Subscriber Connector): A push-pull connector known for its reliability and ease of use. It’s a common choice in various applications.

- FC (Ferrule Connector): A threaded connector offering excellent precision and repeatability. Often favored in applications demanding high stability.

- ST (Straight Tip): A bayonet-style connector, quicker to connect than SC but not as robust. Less common now.

- LC (Lucent Connector): A smaller, more compact connector designed for higher-density applications. Increasingly popular due to its space-saving design.

- MT-RJ (Mechanical Transfer-Registered Jack): A dual-fiber connector, allowing two fibers to be terminated in a single connector. Efficient for space saving.

The selection of the connector depends greatly on the application, the required performance, and even the budget. For example, LC connectors are prevalent in data centers where space is at a premium, while SC connectors are reliable workhorses in many other networking scenarios.

Q 2. Explain the process of cleaving a fiber optic cable.

Cleaving a fiber optic cable is a critical step in fiber termination. It involves precisely breaking the fiber to create a perfectly flat and perpendicular end face. This ensures minimal light loss when the fiber is connected. The process typically involves using a fiber cleaver, a specialized tool that scores and then cleanly breaks the fiber. Think of it like carefully snapping a pencil – you need a clean break for a good connection.

The process usually involves:

- Inserting the fiber: Carefully place the fiber into the cleaver’s clamping mechanism, ensuring it is securely held and the end is aligned correctly.

- Scoring the fiber: Activate the cleaver’s scoring mechanism, creating a tiny scratch on the fiber’s surface. This scratch weakens the fiber at the precise point of the cleave.

- Cleaving the fiber: The cleaver mechanism then creates a controlled break, resulting in a perfectly smooth and perpendicular end face. A poor cleave will lead to light loss and connection problems.

- Inspecting the cleave: Using a microscope, inspect the cleave for any imperfections such as chips or cracks. These imperfections significantly degrade signal quality.

Proper cleaving is crucial for reliable fiber connections. A poorly cleaved fiber will result in high insertion loss and potentially lead to network issues.

Q 3. Describe the steps involved in preparing a fiber for termination.

Preparing a fiber for termination involves several meticulous steps to ensure a strong, low-loss connection. Think of it as preparing a wall for painting – you need a clean, even surface for the best result. These steps include:

- Cutting the cable: Use a cable cutter to cut the fiber optic cable to the desired length, leaving enough slack for termination.

- Stripping the cable jacket and buffer coating: Carefully remove the outer jacket and the buffer coating using the appropriate stripping tools, without damaging the fiber itself.

- Cleaning the fiber: Clean the fiber using a lint-free cloth and isopropyl alcohol to remove any dust or debris. Cleanliness is critical for a proper connection.

- Cleaving the fiber: As described earlier, use a fiber cleaver to create a perfectly flat and perpendicular end face on the fiber.

- Inspecting the cleave: Use a microscope to visually inspect the cleaved end, ensuring there are no chips or cracks.

- Preparing the connector: Depending on the connector type, you’ll prepare the connector body (e.g., installing the ferrule).

- Connecting the fiber to the connector: Carefully insert the cleaved fiber into the prepared connector body, ensuring proper alignment.

- Curing (if applicable): Some connectors require a curing process, usually involving an adhesive, to ensure a strong and secure connection.

- Testing the connection: After termination, always test the connection to confirm low insertion loss and good signal quality.

Each step is critical. Skipping a step or being careless can lead to connection failures and signal degradation.

Q 4. What are the common causes of fiber optic cable damage?

Fiber optic cables, while robust, are susceptible to damage from various sources. Understanding these causes is crucial for prevention and troubleshooting. Common causes include:

- Physical damage: Bending, crushing, or cutting the cable. This is the most common cause.

- Microbending: Repeated bending or flexing of the cable, causing microscopic stress on the fiber which increases attenuation.

- Excessive tension: Pulling or stretching the cable too tightly during installation.

- Improper handling: Rough handling, dropping, or dragging the cable across abrasive surfaces.

- Environmental factors: Exposure to extreme temperatures, moisture, or chemicals.

- Rodents: Rodents chewing through the cable jacket.

- Improper termination: Poorly terminated connections are a significant source of problems, leading to signal loss.

Preventive measures, like proper cable management and careful handling, significantly minimize the risk of damage.

Q 5. How do you test the continuity of a fiber optic cable?

Testing the continuity of a fiber optic cable involves verifying its physical integrity and assessing its transmission characteristics. Unlike electrical cables, we can’t simply use a multimeter. Instead, we employ specialized tools like an Optical Time Domain Reflectometer (OTDR). An OTDR sends light pulses down the fiber and measures the amount of light that returns. It helps identify breaks, splices, and other impairments. A visual fault locator (VFL) can also assist in identifying the location of a break.

The OTDR provides a visual representation of the fiber’s condition, indicating the presence of faults or breaks. A successful test will show a clean trace, without significant attenuation or reflections.

If you are only checking for a simple break or complete failure and don’t need detailed fault location, a simple light source and power meter can suffice. If light passes through the fiber and is detectable at the other end, it indicates the absence of a major break.

Q 6. What safety precautions should be taken when working with fiber optic cables?

Safety when working with fiber optic cables is paramount. The fibers themselves are not electrically hazardous, but there are several safety considerations:

- Eye protection: Always wear appropriate eye protection, as looking directly into a high-powered light source can cause serious eye damage. Even a low-power laser can cause harm with prolonged exposure.

- Cable management: Properly manage cables to prevent tripping hazards or accidental damage.

- Proper tools: Use appropriate tools for cutting, stripping, and cleaning the fibers.

- Cleanliness: Maintain a clean workspace to avoid fiber contamination.

- Static electricity: Be mindful of static electricity, as it can damage sensitive fiber optic components.

- Sharp objects: Be cautious around sharp objects that could damage the fibers.

- Laser safety: With higher-power laser systems, be mindful of potential eye or skin exposure from the laser. Follow all safety guidelines provided by the manufacturer.

Following these precautions helps ensure a safe and productive working environment.

Q 7. Explain the difference between fusion splicing and mechanical splicing.

Both fusion splicing and mechanical splicing are methods for joining two fiber optic cables. However, they differ significantly in their technique and performance characteristics.

- Fusion splicing: This method uses heat and pressure to melt the ends of two fibers together, creating a permanent, virtually seamless connection. It results in the lowest loss and highest reliability. Think of it like welding two pieces of metal together.

- Mechanical splicing: This method uses a mechanical connector to align and hold the two fiber ends together. While quicker and simpler than fusion splicing, mechanical splices generally have higher insertion loss and lower reliability. They are more susceptible to environmental factors and mechanical stress.

Fusion splicing offers superior performance, with significantly lower signal loss, making it the preferred method for high-bandwidth applications. Mechanical splicing, however, provides a faster and less expensive solution that’s suitable for applications where slightly higher loss is acceptable. The choice depends heavily on the application’s performance requirements and budget constraints.

Q 8. What is the function of a fiber optic cleaner?

A fiber optic cleaner is crucial for maintaining the pristine condition of fiber optic connector end faces. Think of it like a specialized lens cleaner for your microscope – any dust, debris, or fingerprints on the end of the fiber will severely impact signal transmission. The cleaner removes these contaminants, ensuring a strong, reliable connection. Different cleaners utilize various methods, from dry wipes (using swabs and cleaning solutions) to wet cleaning with specialized fluids, depending on the level of contamination.

For instance, a common scenario is encountering dust or debris after field termination. A simple cleaning with a fiber optic cleaning pen or a pre-saturated swab effectively resolves this, preventing signal loss and potential connection failure. Regular cleaning is a crucial part of preventative maintenance.

Q 9. How do you identify different types of fiber optic cables?

Identifying fiber optic cables involves looking at several key characteristics. Firstly, the cable jacket color often indicates the fiber type within – for example, orange often represents single-mode fiber and yellow might denote multi-mode. However, this isn’t a universal standard, so relying solely on color can be misleading. More reliable identification comes from the cable markings themselves, typically printed on the jacket. This marking will specify the fiber type (e.g., SMF-28, OM4), core diameter, and other crucial details. Finally, you can use a fiber identifier tool. These instruments shine a light into the fiber and use the return signal to detect fiber type and mode.

In a practical example, I once encountered a cable labeled only with an ambiguous color code. Using a fiber identifier confirmed it as OM3 multi-mode fiber, allowing me to select the appropriate tools for termination. Always check the cable markings and consider using an identifier for confirmation.

Q 10. What are the limitations of a fiber tipping machine?

While fiber tipping machines are invaluable for preparing fiber ends for splicing, they do have limitations. Primarily, the machine’s precision is dependent on the quality of the cleave, the positioning accuracy, and the sharpness of the blade. A poorly cleaved fiber will result in a suboptimal tip and lead to higher splice loss, irrespective of the machine’s capabilities. Furthermore, the machine itself can become misaligned or its blade can dull over time, compromising the quality of the tip. Regularly maintaining and calibrating the machine is paramount to mitigate these limitations. Finally, not all fiber types are equally compatible with every tipping machine.

For example, if the blade is dull or misaligned, even a perfectly cleaved fiber will produce a poor tip, leading to a high splice loss. Regular maintenance, including blade replacement and alignment checks, addresses this limitation.

Q 11. Describe the process of aligning fibers for splicing.

Aligning fibers for splicing is a crucial step that directly impacts the quality of the splice. It involves precise alignment of the fiber cores to minimize insertion loss. This process typically utilizes a fusion splicer, which employs either an active alignment method (via cameras and algorithms) or a passive alignment method (manual adjustments). The process involves carefully cleaving both fiber ends, cleaning them meticulously, and then inserting them into the splicer’s V-grooves. The splicer then accurately aligns the fiber cores using either its automated system or manual adjustment, based on its design. Accurate alignment is crucial for ensuring minimum light loss at the splice point.

Imagine trying to connect two straws – if they aren’t perfectly aligned, the flow of liquid is restricted. Similarly, misaligned fibers restrict the light signal, resulting in signal attenuation.

Q 12. What is the significance of the cleave quality in fiber splicing?

The quality of the fiber cleave is paramount to achieving a low-loss fiber splice. A good cleave produces a perfectly perpendicular and smooth end face, maximizing the surface area for efficient light transmission. Conversely, a poor cleave results in a fractured, uneven end face, leading to higher insertion losses. Irregularities at the cleaved end act as obstacles, reflecting or scattering light and weakening the signal strength. This ultimately results in higher attenuation, potentially requiring costly re-splicing. Therefore, achieving a high-quality cleave is an essential step in the fiber splicing process.

Imagine trying to join two perfectly cut pieces of wood versus two roughly broken pieces – the clean cut ensures a tight and secure joint, similar to a high-quality fiber cleave.

Q 13. How do you troubleshoot a fiber optic connection problem?

Troubleshooting fiber optic connection problems requires a systematic approach. Begin with visual inspection; check for any physical damage to the cable or connectors, paying attention to bends, kinks, or debris. Then use an optical power meter and light source to measure signal loss throughout the network. Identify the exact point of failure by checking signal levels at different points in the connection path. Further diagnostics might involve using an OTDR (Optical Time-Domain Reflectometer) to pinpoint breaks or other faults within the fiber. A simple visual inspection and power readings will often identify common problems like loose connectors or bent fibers.

For example, if you have a signal loss between two points, systematically test the connection from each point and gradually work towards the faulty section. This isolates the issue for efficient repair.

Q 14. What are the different types of fiber optic attenuation?

Fiber optic attenuation refers to the loss of optical power as light travels through the fiber. Several factors contribute to this attenuation. Absorption losses occur when the fiber material absorbs some of the light energy. Scattering losses are caused by microscopic imperfections and impurities in the fiber, which cause light to scatter in different directions, thus losing strength. Bending losses occur due to excessive bending of the fiber, which can cause the light to escape from the core. Lastly, connector and splice losses are introduced at connection points due to imperfect alignment or poor cleaves. Each loss mechanism contributes to the total attenuation, affecting the overall signal quality.

Understanding the various types of attenuation helps in identifying the source of the problem. For instance, high bending losses point towards cable handling issues, while absorption losses might indicate aging or damage to the fiber.

Q 15. Explain the concept of Optical Return Loss (ORL).

Optical Return Loss (ORL), often expressed in decibels (dB), measures the ratio of the power reflected back from a fiber optic connector or splice to the power initially transmitted. Think of it like this: you shout into a canyon (transmitting power). Some of your shout bounces back (reflected power). ORL quantifies how much of your shout returns compared to what you initially shouted. A higher ORL value (more negative dB) indicates less reflected light, which is desirable for a good connection. A low ORL signifies significant light reflection, potentially leading to signal degradation and performance issues.

For example, an ORL of -50 dB is excellent, indicating minimal reflection. An ORL of -20 dB, however, suggests a significant problem that needs immediate attention and potentially re-termination or cleaning of the connector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the purpose of an optical time-domain reflectometer (OTDR)?

An Optical Time-Domain Reflectometer (OTDR) is a crucial tool for testing and troubleshooting fiber optic cables. It works by sending a light pulse down the fiber and measuring the amount of light that is reflected back at different points along the cable. These reflections reveal information about the fiber’s condition, identifying potential problems such as bends, breaks, splices, and connector quality. Imagine it as a sophisticated ‘sonar’ for fiber optic cables, allowing us to ‘see’ inside the cable without physically inspecting it.

The OTDR helps pinpoint faults, measure cable length, assess connector loss, and verify overall fiber quality, ensuring optimal network performance. It’s indispensable for installation, maintenance, and troubleshooting in any fiber optic network.

Q 17. How do you interpret OTDR results?

Interpreting OTDR results requires understanding the trace displayed on the screen. The trace shows the power level of the back-reflected light plotted against distance. Key features to analyze include:

- Events: Significant changes in the trace, typically sharp peaks or valleys, representing connectors, splices, or faults. The magnitude of these events indicates the amount of loss or reflection.

- Attenuation: A gradual decline in the trace, indicating signal loss due to fiber attenuation. Excessive attenuation signifies problems like bending or aging.

- Reflections: Sharp peaks that indicate significant reflections. These can be caused by poorly cleaned connectors or damaged fiber.

For example, a large reflection near the end of the cable might indicate a dirty or damaged connector, while a gradual attenuation throughout the cable could be due to aging or a bent section. By carefully examining the trace, we can pinpoint exact locations of issues and determine their severity.

Q 18. What are the common problems encountered when using a fiber tipping machine?

Common problems with fiber tipping machines include:

- Clogged epoxy dispensing system: Epoxy can thicken or clog the dispensing nozzle, leading to inconsistent tips.

- Poor connector alignment: Improper alignment during the tipping process can result in poor connection quality and high return loss.

- Insufficient curing time: Improper curing of the epoxy can lead to weak or brittle tips, easily damaged during handling or use.

- Malfunctioning heating element (for some models): A faulty heating element can lead to inconsistent epoxy curing, affecting the tip’s integrity.

- Damaged or worn tooling: Over time, the machine’s tooling can wear down, leading to inconsistent tips.

Addressing these issues often involves regular cleaning and maintenance, accurate machine setup, and proper usage of consumables like epoxy and ferrules.

Q 19. How do you maintain and clean a fiber tipping machine?

Maintaining and cleaning a fiber tipping machine is crucial for consistent performance and longevity. Regular maintenance should include:

- Cleaning the epoxy dispensing system: Regularly clean the nozzle and associated tubing with appropriate solvents to remove any dried or hardened epoxy.

- Cleaning the heating element (if applicable): Check and clean the heating element periodically to ensure proper functionality.

- Inspecting and replacing worn tooling: Replace any worn-out or damaged tooling, such as polishing pads or ferrules, regularly.

- Regular inspection of the machine: Conduct visual inspections for any loose components or signs of wear and tear.

- Calibration checks: Periodic calibration checks ensure the machine is dispensing the correct amount of epoxy and aligning the connectors accurately.

Following the manufacturer’s instructions and creating a regular maintenance schedule will greatly extend the machine’s lifespan and ensure reliable performance.

Q 20. Describe your experience with different types of fiber tipping machines.

My experience encompasses a range of fiber tipping machines, from manual benchtop models to automated high-throughput systems. I’ve worked extensively with machines from various manufacturers, each possessing unique features and capabilities. I’m familiar with machines using different epoxy dispensing mechanisms, heating methods, and connector alignment systems. This includes working with machines designed for different fiber types and connector styles. This varied experience enables me to effectively troubleshoot and operate machines across various manufacturers’ specifications, focusing on optimizing processes for consistent, high-quality results.

Q 21. How do you ensure the proper alignment of connectors during termination?

Ensuring proper connector alignment is paramount for minimizing insertion loss and maximizing signal transmission. This is typically achieved using a combination of mechanical alignment mechanisms within the tipping machine and careful preparation. The machine itself usually utilizes precision alignment pins or guides to ensure the fiber is correctly positioned within the connector ferrule. Prior to insertion, the fiber end should be precisely cleaved to a perfect perpendicular angle; this is often done with a dedicated fiber cleaver. Proper cleaning of the fiber end before insertion is also very important to remove any debris or contamination that can affect the final connection. After the process, visual inspection using a microscope and further testing (like ORL measurement with an OTDR) are necessary to verify successful alignment and low return loss.

Q 22. What are the common issues associated with improper connectorization?

Improper connectorization in fiber optics leads to a range of issues, primarily impacting signal quality and network performance. Think of it like trying to connect a garden hose with a mismatched nozzle – water (your signal) will leak or not flow properly.

- High insertion loss: Poorly cleaved fibers or misaligned connectors create significant signal loss, weakening the signal and potentially causing connectivity problems. This is like having a partially blocked hose – less water gets through.

- Increased back reflections: Imperfect connections reflect light back towards the source, causing interference and signal degradation. Imagine the water bouncing back from a kink in the hose.

- Increased attenuation: The signal weakens over distance due to the imperfections in the connection, much like water pressure decreases over a long, leaky hose.

- Connection failure: In severe cases, the connection might fail completely, leading to network outages. This is like the hose completely disconnecting, resulting in no water flow.

- Increased susceptibility to environmental factors: A poorly terminated fiber is more vulnerable to dust, moisture, and temperature changes, further compromising signal quality. This is like a poorly sealed hose connection being vulnerable to dirt and damage.

These issues manifest as slow speeds, data loss, intermittent connectivity, and ultimately, network downtime. Preventing these problems requires meticulous attention to detail during the termination process, including precise fiber cleaving, accurate connector alignment, and thorough cleaning.

Q 23. How do you handle a situation where a fiber is broken during termination?

A broken fiber during termination is a setback, but it’s manageable. The first step is to assess the damage – how much of the fiber is broken and where? Is it close to the connector or further up the cable?

If the break is close to the connector, and you have sufficient spare fiber, you can carefully strip back the outer jacket and cladding, recleave the fiber using a quality cleaver, and restart the termination process. It’s crucial to use a new connector. If the break is far from the connector, unfortunately, you will likely need to splice the cable or replace a significant length, depending on your available resources and the overall fiber length.

Prevention is key. Using the correct tools, working in a clean environment and taking your time prevents most breakage issues. Careful handling of the fiber at all stages minimizes risk.

Q 24. What is the importance of proper labeling and documentation?

Proper labeling and documentation are paramount for efficient troubleshooting and network management. Imagine a massive tangle of wires with no labels – a nightmare! Clear labeling and documentation prevent confusion and save valuable time and resources.

- Easy identification: Clear labels on both ends of the fiber cable, as well as patch panels and equipment, allow for quick identification of each fiber and its connection point.

- Simplified troubleshooting: In case of issues, accurate documentation helps quickly locate and resolve problems. Knowing exactly where each fiber goes greatly speeds up diagnosis.

- Network planning and expansion: Good documentation enables efficient network planning and future expansion. You’ll know where spare capacity exists and where to add new fibers.

- Compliance and safety: In many industries, detailed documentation is a regulatory requirement for safety and network reliability.

I use a standardized labeling system and maintain a detailed database. This ensures all fibers are easily traceable, leading to reduced downtime and improved overall network management.

Q 25. Describe your experience working with different types of fiber optic cable jackets.

My experience includes working with various fiber optic cable jackets, each with its own characteristics and handling requirements. The jacket material impacts the termination process – some are easy to strip, while others require more care.

- Loose Tube: This type features individual fibers within a loose tube, offering flexibility but requiring careful handling to avoid fiber damage during stripping.

- Tight Buffer: Fibers are tightly buffered individually, providing strength and protection. Stripping requires precision to avoid damaging the fiber.

- Ribbon: Multiple fibers are bundled together in a ribbon structure, simplifying mass termination but requiring specialized tools and procedures.

- Armored Cable: Offers significant protection, but stripping requires extra care and the use of appropriate tools to avoid damaging the fibers underneath.

I am proficient in handling all these cable types, ensuring the fiber is protected throughout the termination process, regardless of the jacket material.

Q 26. How do you deal with different types of connectors (e.g., SC, FC, LC)?

Different connectors (SC, FC, LC, etc.) each have specific termination procedures and handling requirements. While the basic principles remain consistent – cleaving, preparation, insertion, polishing – the specific steps vary.

For example, an SC connector requires a different ferrule preparation technique compared to an LC. The physical size and mechanism vary, impacting the tools required and the way the connector is handled. I use the appropriate tools and adapt my technique to each connector type, ensuring precise alignment and a robust connection. Familiarization with each connector’s design is crucial for efficient and error-free termination. This also includes understanding the connector’s specific tolerances and their implications on signal quality.

Q 27. How do you ensure the cleanliness of the fiber during the termination process?

Maintaining fiber cleanliness is critical to preventing connection issues. Dust, oil, or other contaminants on the fiber end face can significantly increase insertion loss and back reflections, degrading the signal. Think of it like trying to connect two pipes with dirt blocking the ends—the water won’t flow properly.

My process involves using isopropyl alcohol (IPA) wipes and fiber optic cleaning pens to thoroughly clean both the fiber end face and the connector ferrule before connection. I inspect the fiber under magnification to ensure complete cleanliness before final termination. I also take care to avoid touching the fiber end face to prevent contamination during handling. A clean environment, minimizing airborne dust, is also crucial.

Q 28. Describe a time you had to troubleshoot a complex fiber optic problem.

In one instance, we experienced intermittent connectivity problems on a long-haul fiber link. Initial tests revealed high insertion loss, but the specific location of the problem was unclear. We used an Optical Time Domain Reflectometer (OTDR) to pinpoint the fault, which indicated a high reflection at a specific splice location.

We went to the affected site and investigated the splice. It turned out that there was a tiny piece of debris within the splice, causing the high reflection. We carefully removed the debris using a specialized cleaning tool and re-spliced the fiber. This solved the connectivity problem completely. This experience highlighted the importance of using OTDRs for fault location and the necessity for meticulous clean-room practices during splicing and connectorization. A thorough process of elimination also guided us to the faulty splice, improving our overall troubleshooting efficiency.

Key Topics to Learn for Fiber Tipping Machine Operation Interview

- Machine Setup and Calibration: Understanding the process of setting up the fiber tipping machine, including adjustments for different fiber types and desired tip shapes. This includes pre-operational checks and safety procedures.

- Fiber Handling and Feeding Mechanisms: Knowledge of how different fiber types are fed into the machine, troubleshooting common feeding issues (e.g., jams, inconsistencies), and optimizing the feeding process for efficiency and quality.

- Tipping Process and Parameters: A thorough understanding of the tipping process itself, including control parameters like temperature, pressure, and speed. This includes knowing how these parameters affect the final product quality.

- Quality Control and Inspection: Understanding the methods for inspecting the tipped fibers for defects, identifying common flaws, and adjusting machine settings to minimize imperfections. This also includes documentation and reporting procedures.

- Maintenance and Troubleshooting: Familiarity with routine maintenance tasks, identifying common machine malfunctions, and performing basic troubleshooting procedures to minimize downtime. This includes knowing when to escalate issues to more experienced technicians.

- Safety Procedures and Regulations: Complete understanding of all safety protocols associated with operating the fiber tipping machine, including personal protective equipment (PPE) requirements and emergency procedures.

- Production Efficiency and Optimization: Strategies for maximizing output while maintaining high quality standards. This includes understanding production targets and identifying areas for improvement in the operation.

Next Steps

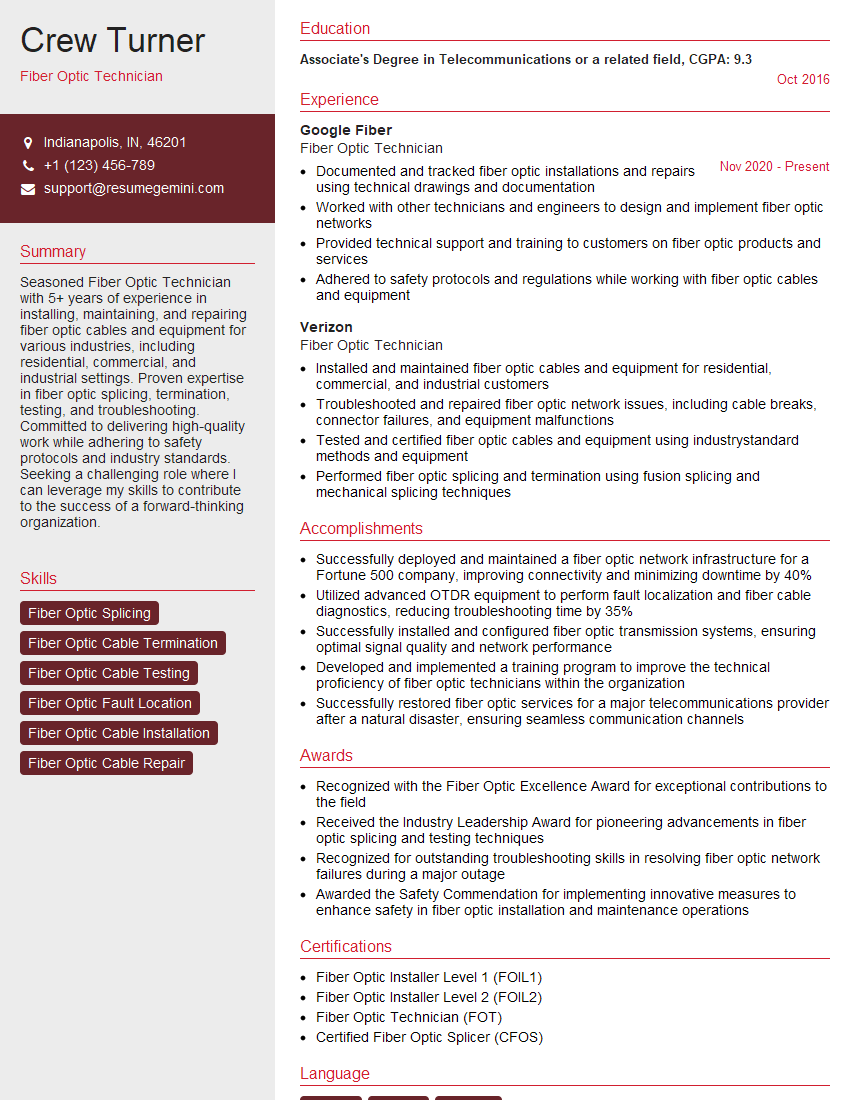

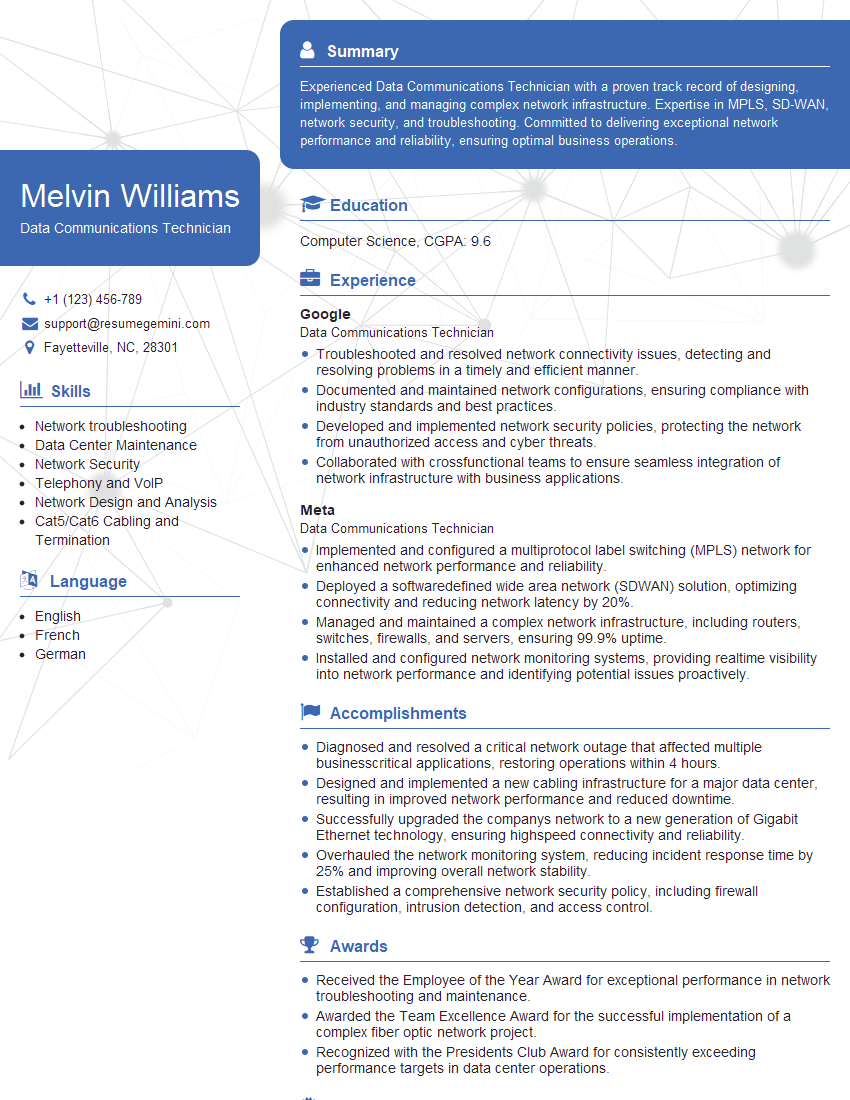

Mastering Fiber Tipping Machine Operation opens doors to rewarding careers in manufacturing and advanced materials processing, offering opportunities for advancement and specialization. To make the most of these opportunities, a strong and effective resume is crucial. Creating an ATS-friendly resume significantly improves your chances of getting noticed by potential employers. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to Fiber Tipping Machine Operation to guide you in crafting the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good