Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Field Engineering and Inspection interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Field Engineering and Inspection Interview

Q 1. Describe your experience with different types of inspection methods.

My experience encompasses a wide range of inspection methods, from visual inspections – the most basic, yet crucial, first step in any assessment – to more sophisticated techniques. Visual inspections involve carefully examining equipment or structures for obvious defects like cracks, corrosion, or misalignment. I’ve extensively used this method in various settings, from inspecting pipelines for dents and leaks to evaluating the structural integrity of bridges. Beyond visual checks, I’m proficient in dimensional inspections, employing tools like calipers, micrometers, and laser scanners to ensure components meet precise specifications. For instance, I’ve used these methods to verify the accuracy of manufactured parts in a wind turbine assembly facility. I also have considerable experience with operational inspections, where I assess the functionality and performance of systems under actual operating conditions. A recent example includes checking the efficiency of a heat exchanger in a power plant. Finally, I’m skilled in performing specialized inspections leveraging advanced technologies as described in the following answer.

Q 2. Explain your understanding of Non-Destructive Testing (NDT) techniques.

Non-Destructive Testing (NDT) is crucial for evaluating the integrity of components without causing damage. I’m well-versed in several key NDT techniques. Radiographic testing (RT) uses X-rays or gamma rays to reveal internal flaws like cracks or voids. I’ve used RT to inspect welds in pressure vessels, ensuring they are free from defects. Ultrasonic testing (UT) employs high-frequency sound waves to detect subsurface flaws. This is particularly useful for inspecting thick components like pipelines or castings. For example, I utilized UT to identify internal corrosion in a large diameter pipeline. Magnetic particle testing (MT) is effective for detecting surface and near-surface cracks in ferromagnetic materials. I’ve used MT on components like aircraft landing gear to identify stress cracks. Liquid penetrant testing (PT) identifies surface-breaking flaws by using a dye that seeps into the cracks. This is often used for inspecting smaller parts or those with intricate geometries, such as turbine blades. Eddy current testing (ET) uses electromagnetic induction to detect surface and subsurface flaws in conductive materials. I’ve employed ET to inspect aircraft tubing for corrosion and cracks. Choosing the right NDT method depends heavily on the material, the expected type of flaw, and accessibility. The interpretation of NDT results requires a good understanding of the techniques and experience in recognizing patterns. Safety protocols are paramount when using NDT methods, requiring adherence to specific radiation protection measures for RT, or careful handling of chemicals used in PT.

Q 3. How do you handle discrepancies found during a field inspection?

Discrepancies are an inevitable part of field inspections. My approach is systematic and thorough. First, I meticulously document the discrepancy, including photographic or video evidence, precise location, and detailed description of the anomaly. Then, I analyze the significance of the finding, considering its potential impact on safety, operational efficiency, and regulatory compliance. For example, a small scratch on a non-critical surface might be documented but require no immediate action, whereas a significant crack in a pressure vessel demands immediate attention and potentially a shutdown. Next, I communicate my findings to the relevant stakeholders, usually through a concise and well-structured report. This report includes clear recommendations, which may include repairs, replacements, or further investigations. Depending on the severity, I may escalate the issue to higher management or regulatory bodies. Throughout the process, maintaining clear communication with all parties involved is vital. Following up on the corrective actions implemented is critical to ensure the issue is resolved and prevents future recurrence. This might involve site visits to verify repairs or reviewing updated inspection reports.

Q 4. What are your strategies for managing field inspection reports and documentation?

Effective management of field inspection reports and documentation is paramount. I use a combination of digital and physical methods. All data is recorded digitally, usually on a tablet using dedicated inspection software which allows for real-time data entry, photographic integration, and automated report generation. This software often offers features such as GPS location tagging and automated data backup, preventing data loss. Physical copies of key documents, particularly those requiring legal signatures or official approvals, are maintained and stored securely. A clear filing system, both digital and physical, ensures quick and easy retrieval of information. This includes using a consistent naming convention for files and folders. I am meticulous in ensuring reports are complete, accurate, and unambiguous. Regular data backups are critical to prevent loss due to equipment failure or accidental deletion. Furthermore, I adhere to all relevant regulatory and company standards for record-keeping, including data retention policies. This ensures traceability and compliance.

Q 5. Describe your experience with using different inspection tools and equipment.

My experience extends to a broad range of inspection tools and equipment. This includes basic tools like measuring tapes, calipers, levels, and various types of cameras (including thermal cameras), alongside specialized equipment such as ultrasonic flaw detectors, magnetic particle inspection units, and liquid penetrant inspection kits. I am proficient in operating laser scanners for dimensional surveys and using drones equipped with high-resolution cameras for difficult-to-access areas, such as inspecting the condition of overhead power lines. I am also familiar with data acquisition systems which record and analyze data from multiple sources. Proper calibration and maintenance of all equipment are essential to ensure accurate and reliable results. Regular training and certifications maintain my competency in using these tools safely and effectively. Each tool has its own specific use case; knowing when to utilize a specific tool is critical to an effective and efficient inspection.

Q 6. How do you prioritize tasks and manage your time effectively in a field environment?

Prioritizing tasks and managing time effectively in the field requires a structured approach. I typically start with a thorough review of the inspection plan, identifying critical tasks and potential time constraints. I prioritize tasks based on urgency, importance, and potential risk. For example, safety-critical inspections always take precedence. I use scheduling tools and checklists to allocate time effectively for each task, keeping contingency time for unforeseen delays. Communication with the client or team is key to addressing any emerging priorities. During the inspection itself, I adhere to a strict schedule and continuously monitor progress. If unforeseen issues arise that change priorities, I quickly re-evaluate and adjust my schedule, keeping stakeholders informed. Utilizing technology like mobile data entry aids efficiency by immediately logging information, reducing time spent on paperwork later. Regular breaks are crucial for maintaining focus and preventing fatigue, especially during long or physically demanding inspections. This balanced approach ensures efficient task completion while maintaining high standards of work.

Q 7. How do you ensure the safety of yourself and others during field inspections?

Safety is paramount in field inspections. I always begin by conducting a thorough site-specific risk assessment, identifying potential hazards such as hazardous materials, confined spaces, heights, and electrical risks. This assessment guides the development of a detailed safety plan, outlining appropriate control measures. This might include using personal protective equipment (PPE) like hard hats, safety glasses, high-visibility clothing, and fall protection equipment as needed. I always ensure the appropriate safety permits are obtained before commencing work in regulated areas. I never work alone in hazardous environments; I work with at least one colleague, ideally two. Regular safety briefings with the team ensure everyone is aware of potential risks and emergency procedures. We practice emergency response procedures regularly. Continuous monitoring of the work environment for evolving hazards is crucial. I report all incidents, near misses, and potential hazards promptly, ensuring corrective actions are taken to prevent future occurrences. Compliance with all relevant safety regulations and company safety policies is not just a priority, but a non-negotiable requirement.

Q 8. Explain your experience with quality control procedures and documentation.

Quality control (QC) is the systematic process of ensuring that a product or service meets predefined standards. My experience encompasses all phases, from initial material inspection to final project sign-off. This includes developing and implementing QC plans, performing inspections, documenting findings, and recommending corrective actions. I’m proficient in various QC methodologies, including statistical process control (SPC) and ISO 9001 standards.

For example, on a recent bridge construction project, I developed a QC plan outlining procedures for concrete testing, steel reinforcement inspection, and welding quality checks. This included specifying acceptable tolerances, sampling methods, and frequency of inspections. All findings were meticulously documented using digital reporting tools, and any non-conformances were reported through a formal system, triggering corrective actions and preventing future recurrence. This led to a project completion with minimal rework and significant cost savings.

My documentation utilizes a combination of digital and physical records, ensuring clear traceability and auditability. This includes detailed inspection reports, photographic evidence, and non-conformance reports (NCRs). I adhere to strict naming conventions and file organization to ensure easy retrieval and accessibility of information.

Q 9. How do you interpret engineering drawings and specifications in the field?

Interpreting engineering drawings and specifications in the field requires a combination of technical knowledge and practical experience. I start by thoroughly reviewing all available documentation—drawings, specifications, and relevant standards—before heading to the site. This allows me to anticipate potential issues and focus my inspection efforts efficiently.

I typically utilize a layered approach. First, I identify the key components and their relationships as depicted in the drawings. Then, I cross-reference those with the specifications to understand the required tolerances, materials, and construction methods. Finally, I visually inspect the work in progress, comparing what’s actually being built to the design intent.

Consider a scenario where the drawings show a specific type of steel beam but the specifications only mention the minimum load-bearing capacity. I would then cross-check the actual steel being used in the field against both the drawing and relevant material specifications to ensure compliance. If discrepancies are found, I would carefully document them and raise them with the relevant stakeholders.

Q 10. How do you communicate technical information effectively to non-technical personnel?

Communicating technical information to non-technical personnel is crucial in field engineering. My approach involves simplifying complex technical jargon into clear, concise, and relatable language. I avoid technical terms whenever possible, instead opting for analogies and visual aids.

For example, explaining the concept of ‘bearing capacity’ to a non-engineer, I might use the analogy of a chair: “Just like a chair needs strong legs to support weight, this foundation needs sufficient bearing capacity to support the building above.”

I also rely heavily on visual aids like photographs, diagrams, and even short videos to supplement my explanations. Active listening and confirming understanding are equally important. I always ask clarifying questions and ensure the recipient understands the implications of the information before concluding the conversation. Finally, providing written summaries of key findings or action items further aids comprehension and avoids any misinterpretations.

Q 11. Describe a challenging field inspection you encountered and how you overcame it.

During a high-rise building inspection, we encountered unexpected corrosion in critical structural steel elements hidden behind fireproofing. This was not evident from the initial visual inspections. The challenge was identifying the extent of the corrosion and recommending a safe and cost-effective solution without causing further damage or delays.

My approach involved a multi-pronged strategy. First, we used advanced non-destructive testing (NDT) methods, such as ultrasonic testing, to assess the extent of the corrosion without damaging the fireproofing. Next, we consulted with materials engineers to determine the best remediation techniques. Finally, we collaborated with the contractor to develop a phased remediation plan that minimized disruption to the construction schedule while ensuring structural integrity.

This involved carefully removing sections of the fireproofing, treating the affected steel, and then replacing the fireproofing in compliance with all relevant codes and regulations. Thorough documentation, including photographic evidence and NDT reports, was crucial in justifying our course of action and ensuring accountability.

Q 12. What is your experience with various types of construction materials and their defects?

My experience encompasses a wide range of construction materials, including concrete, steel, timber, masonry, and various composites. I am familiar with their typical properties, common defects, and appropriate testing methods. For instance, I know that concrete can suffer from issues such as cracking, honeycombing (voids within the concrete), and alkali-aggregate reaction (a chemical reaction that leads to expansion and cracking).

Similarly, steel can exhibit corrosion, fatigue cracking, and welding defects. I’m adept at identifying these defects through visual inspections, supplemented by NDT techniques. For example, I might use a crack detector to identify hairline cracks in concrete or magnetic particle inspection to detect surface cracks in steel welds. My knowledge extends to understanding the underlying causes of these defects and recommending preventative measures.

In timber construction, I can identify signs of decay, insect infestation, and improper treatments. My understanding of material properties allows me to assess the severity of defects and their impact on the structural integrity of the project.

Q 13. How do you handle conflicts or disagreements with contractors or other stakeholders?

Handling conflicts requires a collaborative and professional approach. My first step is to actively listen to all parties involved, understanding their perspectives and concerns. I then strive to facilitate a constructive dialogue, focusing on finding common ground and identifying the root causes of the disagreement.

I believe in utilizing objective data and industry standards to support my arguments. If disagreements persist, I will escalate the issue through established channels, involving project management and senior stakeholders to mediate. The goal is always to reach a mutually acceptable solution that ensures project quality and adherence to safety regulations. Transparency and open communication are key to resolving conflicts effectively.

For instance, on one project, a disagreement arose regarding the quality of delivered materials. By using independent testing reports, I demonstrated the materials did not meet the project specifications and led to a constructive solution that involved the contractor replacing the substandard materials at their cost.

Q 14. Explain your experience with using field data management software and systems.

I have extensive experience with field data management software and systems, including mobile data collection apps, cloud-based platforms, and specialized inspection software. This allows me to efficiently document inspection findings, generate reports, and track project progress in real-time.

For instance, I’ve utilized software like [mention a specific software, e.g., PlanGrid or Procore] to document inspection results with photos, location data, and detailed comments. This facilitates efficient sharing of information with the project team and ensures accurate record-keeping. The cloud-based aspect allows for real-time collaboration and reduces reliance on paper-based documentation.

I am also comfortable using other data management tools to ensure seamless integration of data from various sources, including GPS coordinates, sensor data, and other relevant project information. My expertise encompasses data analysis using the collected information to identify trends, pinpoint potential problems, and enhance overall project efficiency.

Q 15. How familiar are you with relevant industry codes, standards, and regulations?

My familiarity with industry codes, standards, and regulations is extensive. Throughout my career, I’ve worked extensively with codes like ASME (American Society of Mechanical Engineers), API (American Petroleum Institute), and relevant OSHA (Occupational Safety and Health Administration) regulations, depending on the specific project and industry. For example, during an inspection of a pressure vessel in the oil and gas sector, I meticulously checked its compliance with ASME Section VIII, Division 1, ensuring all welding procedures, material certifications, and Non-Destructive Examination (NDE) reports were compliant and documented. My understanding extends beyond simply knowing the codes; I also understand the rationale behind them and how they contribute to safety and operational efficiency. I regularly attend industry conferences and workshops to stay current with any revisions or new standards that emerge.

Beyond these major codes, I have practical experience with numerous other industry-specific standards, including those related to electrical safety, environmental protection, and specific equipment operation. This broad base ensures I can effectively assess and manage risk across diverse project environments.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with risk assessment and mitigation in field operations.

Risk assessment and mitigation are integral to every field operation I undertake. My approach follows a structured methodology, typically involving a HAZOP (Hazard and Operability) study or similar risk assessment process. This starts with identifying potential hazards, such as equipment failure, environmental conditions, or human error. Then, I analyze the likelihood and severity of each hazard to determine the overall risk level. This assessment involves considering factors like the frequency of potential incidents and the potential consequences (environmental damage, injuries, production downtime).

Mitigation strategies are then developed and implemented to reduce the risks to acceptable levels. This can include using specific safety equipment (e.g., personal protective equipment or PPE), implementing robust work procedures, providing thorough training to personnel, or even modifying the equipment or work environment itself. For example, during a pipeline inspection, I would identify potential risks like corrosion, third-party damage, and ground movement. Then, I’d implement mitigation strategies like using specialized inspection tools (e.g., smart pigs), establishing controlled access zones, and working closely with the land surveyors. Regular safety meetings and documenting all risks, mitigation measures and lessons learned are crucial.

Q 17. How do you ensure compliance with environmental regulations during field work?

Environmental compliance is paramount in my field work. I’m deeply familiar with relevant environmental regulations, such as the Clean Water Act, Clean Air Act, and Resource Conservation and Recovery Act (RCRA), again with specifics depending on location and project type. Before commencing any field activity, I carefully review all permits and environmental plans, ensuring full compliance. This includes proper waste management procedures – segregating hazardous materials, using appropriate containers, and ensuring proper disposal through licensed contractors. We utilize spill kits and containment measures to prevent and mitigate potential environmental incidents. I am also responsible for monitoring environmental parameters (e.g., water quality, noise levels, air emissions) as per the project’s environmental management plan and reporting any deviations immediately to the project leadership.

For example, during a construction project involving soil disturbance, I oversaw the implementation of erosion control measures, like silt fences and sediment basins, to prevent soil erosion and water contamination. Documentation of all environmental measures is crucial; we maintain detailed logs of waste disposal, emissions, and any environmental monitoring data, ensuring a clear audit trail.

Q 18. Explain your experience with commissioning and start-up procedures.

Commissioning and start-up procedures are critical phases of any project, ensuring that equipment operates as designed and safely. My experience spans several aspects of this process. I participate in pre-commissioning activities which involve inspections, testing, and verification that all systems and equipment are correctly installed and ready for operation. This includes reviewing the equipment’s documentation, verifying the integrity of installed systems through the performance of various tests, and documenting findings.

During commissioning, I follow established procedures and checklists. This involves systematically testing individual components and systems, progressively integrating them to verify that they function according to specifications. Start-up often includes a phased approach, beginning with basic functional checks and gradually moving toward full operational capacity. Throughout this process, comprehensive documentation is maintained, including test results, any deviations from the plan, and corrective actions. For example, during the commissioning of a new water treatment plant, I worked with the engineering team to ensure all pumps, filters, and chemical injection systems met performance requirements before handing over to the client. Safety is always the top priority.

Q 19. How do you troubleshoot equipment malfunctions in the field?

Troubleshooting equipment malfunctions in the field requires a systematic approach. I begin by gathering information; this involves reviewing operational logs, examining the affected equipment, and interviewing operators to understand the circumstances leading to the malfunction. I then perform a visual inspection, looking for obvious signs of damage or failure (loose connections, leaks, etc.).

Next, I use diagnostic tools and techniques relevant to the specific equipment to identify the root cause. This may involve using multimeters, pressure gauges, thermal cameras, or specialized software. Once the root cause is identified, I will implement the appropriate repair or replacement procedure, always prioritizing safety. If the problem is beyond my expertise, I will escalate the issue to the appropriate specialist and implement any necessary interim safety measures. For example, I once successfully resolved a pump malfunction in a remote location by identifying a clogged impeller through a visual inspection and clearing it using appropriate tools, preventing significant downtime.

Q 20. What are your problem-solving skills in resolving unexpected issues during inspections?

My problem-solving skills are honed through years of experience in dealing with unexpected issues during inspections. My approach is based on a structured methodology, starting with a clear understanding of the problem: I gather all available information, document observations, and consider potential causes. I use a combination of deductive reasoning, analytical skills, and practical experience to narrow down the possibilities. I always cross-reference my findings with relevant codes, standards, and best practices.

If necessary, I’ll consult with colleagues, engineers, or other experts to brainstorm solutions. Collaboration is key when facing complex or unusual problems. The final solution is always carefully documented, including the root cause analysis, the corrective actions taken, and any lessons learned. I’ve found that maintaining a systematic approach minimizes the impact of unexpected issues and helps prevent future occurrences. Thorough documentation is crucial for continuous improvement and sharing knowledge.

Q 21. How do you maintain accurate records and logs of your field activities?

Maintaining accurate records and logs is critical for accountability, traceability, and continuous improvement. I use a combination of digital and paper-based systems to record my field activities. Digital records often involve using specialized software or mobile applications for data entry, capturing photos and videos, and generating reports. Paper-based records may be used for field notes, sketches, or non-digital inspections. I ensure that all records are clearly labeled, dated, and time-stamped to maintain accuracy.

Regardless of the method, I always ensure the information is complete, accurate and readily retrievable. This includes detailed descriptions of the work performed, observations made, and any deviations from planned procedures. All records are stored securely and managed according to company policies. For example, daily activity logs, inspection reports, test results, and maintenance records are all kept meticulously organized in a consistent format, ensuring clarity and easy access when reviewing project history or preparing future reports.

Q 22. Describe your experience with various types of field instrumentation and sensors.

My experience with field instrumentation and sensors spans a wide range of technologies, encompassing both traditional and modern equipment. I’m proficient in using and troubleshooting various types of sensors, including:

- Temperature Sensors: Thermocouples (Type K, J, T, etc.), RTDs (platinum, nickel), and thermistors. I understand the principles behind different sensor types and their applications in various industrial settings, from monitoring high-temperature processes in refineries to ensuring precise temperature control in pharmaceutical manufacturing.

- Pressure Sensors: Diaphragm, capacitive, and piezoelectric pressure transducers are commonly used in my work. I’m experienced in selecting the appropriate sensor based on the application’s pressure range, accuracy requirements, and environmental conditions. For example, I’ve used high-pressure sensors in pipeline integrity assessments and low-pressure sensors in HVAC system inspections.

- Flow Sensors: I have extensive experience with various flow measurement technologies, including orifice plates, Venturi meters, and ultrasonic flow meters. I know how to interpret flow data to identify potential leaks, blockages, or inefficiencies in systems. A recent project involved optimizing the flow rate in a water distribution network using ultrasonic flow meters and data analysis.

- Level Sensors: I’ve worked with ultrasonic, radar, and hydrostatic level sensors in applications such as tank gauging, reservoir monitoring, and wastewater treatment. Understanding the limitations of each technology is key to accurate level measurement.

- Gas Detection Sensors: I’m familiar with electrochemical and catalytic sensors for detecting various gases, including oxygen, methane, and carbon monoxide. Safety is paramount, and proper calibration and maintenance of these sensors are crucial. I’ve utilized these sensors extensively in confined space entry procedures and hazardous area inspections.

Beyond sensor usage, I’m adept at data acquisition using handheld devices, data loggers, and integrated systems, ensuring accurate data collection and transfer for subsequent analysis.

Q 23. How do you contribute to a positive and collaborative team environment in the field?

I believe in fostering a positive and collaborative team environment through open communication, mutual respect, and a shared commitment to safety and project success. I actively contribute by:

- Facilitating effective communication: I ensure clear and concise communication among team members, stakeholders, and clients through regular briefings, updates, and transparent reporting. This involves active listening and ensuring everyone feels heard and understood.

- Promoting teamwork and collaboration: I encourage a supportive environment where team members feel comfortable sharing ideas, contributing expertise, and helping each other solve problems. I’ve led successful field teams by delegating tasks effectively, recognizing individual strengths, and promoting a collaborative problem-solving approach.

- Prioritizing safety: Safety is always my top priority. I meticulously adhere to safety protocols, provide regular safety briefings, and address any safety concerns immediately. I’ve actively stopped potentially unsafe procedures and advocated for improvements in safety practices.

- Mentoring junior team members: I take pride in mentoring junior engineers, sharing my knowledge and experience to help them develop their skills and grow professionally. This not only enhances individual capabilities, but also strengthens the overall team’s performance.

- Celebrating successes: Recognizing and celebrating team achievements boosts morale and fosters a positive team dynamic. This can be through informal praise, formal recognition, or simply taking time to appreciate a job well done.

Q 24. Explain your proficiency in using various software programs relevant to field engineering.

My proficiency in software relevant to field engineering encompasses data acquisition, analysis, and reporting tools. I’m proficient in:

- Data Acquisition Software: I’m experienced with various data acquisition systems (DAQ) and their associated software for collecting data from various sensors. This includes both hardware-specific software and general-purpose data logging applications.

- Data Analysis Software: I utilize software packages like MATLAB and Python (with libraries such as NumPy, Pandas, and SciPy) for comprehensive data analysis, statistical modeling, and visualization. I can process large datasets, identify trends, and perform complex calculations to draw meaningful conclusions from field inspection data. For example, I’ve used Python to automate the analysis of pipeline inspection data and identify potential corrosion issues.

- CAD Software: I’m familiar with AutoCAD and other CAD software for reviewing drawings, creating sketches, and annotating inspection reports. This is invaluable for visualizing and documenting field findings.

- Reporting and Presentation Software: Microsoft Office Suite (Word, Excel, PowerPoint) and specialized report-writing software are used extensively for creating comprehensive, accurate and easily digestible technical reports and presentations.

- Cloud-Based Data Management Systems: I’m familiar with various cloud platforms for secure data storage, sharing, and collaboration. This enables efficient data management across projects and locations.

Q 25. What is your approach to continuous professional development in the field of inspection?

Continuous professional development is crucial in the ever-evolving field of inspection. My approach involves a multi-faceted strategy:

- Formal Training: I regularly attend conferences, workshops, and training courses to stay updated on the latest technologies, inspection techniques, and industry best practices. Recent examples include a course on advanced non-destructive testing (NDT) methods and a workshop on risk-based inspection techniques.

- Self-Learning: I actively engage in self-learning through online courses, webinars, and technical publications. This allows me to explore specific areas of interest and deepen my expertise in selected technologies and methodologies.

- Industry Certifications: I actively pursue relevant industry certifications to demonstrate my competence and commitment to professional development. Holding these certifications enhances credibility and expands professional opportunities.

- Mentorship and Networking: I actively seek out mentorship opportunities and participate in industry events to network with peers, learn from experienced professionals, and broaden my professional connections.

- Practical Application: I actively seek out opportunities to apply newly acquired knowledge and skills in real-world projects. This practical application reinforces learning and accelerates professional growth.

Q 26. Describe your experience with preparing and presenting technical reports.

Preparing and presenting technical reports is a significant part of my role. My approach is to ensure clarity, accuracy, and completeness. The process generally involves:

- Data Collection and Analysis: Thorough data collection from field inspections is crucial. I then analyze this data, identifying key findings, trends, and potential issues.

- Report Structure and Content: I develop a clear and logical structure for my reports, including an executive summary, introduction, methods, results, discussion, conclusions, and recommendations. Visual aids such as tables, graphs, and photographs are used to enhance clarity and understanding.

- Clarity and Accuracy: I use precise language and avoid jargon where possible, ensuring that the reports are easily understandable by a diverse audience, from technical specialists to non-technical stakeholders. Accuracy is paramount, and I always double-check the data and interpretations presented.

- Presentation: I deliver presentations using visual aids, focusing on key findings and recommendations. I am adept at tailoring the presentation to the audience’s level of technical understanding.

- Feedback and Revision: I actively solicit feedback from colleagues and stakeholders to refine my reports and presentations, ensuring clarity and accuracy.

I’ve presented reports on various projects, ranging from pipeline integrity assessments to structural inspections, always striving for clear, concise, and impactful communication.

Q 27. How do you utilize data analytics to improve inspection efficiency and effectiveness?

Data analytics plays a critical role in improving inspection efficiency and effectiveness. I leverage data analytics to:

- Identify trends and patterns: Analyzing historical inspection data can reveal recurring issues, allowing for proactive maintenance and preventative measures. For example, I’ve used statistical analysis to identify specific locations in a pipeline prone to corrosion, enabling targeted inspections.

- Optimize inspection schedules and resources: By analyzing risk profiles and historical data, I can develop optimized inspection plans that focus resources on high-risk areas, maximizing efficiency and minimizing downtime.

- Improve decision-making: Data-driven insights enable more informed decision-making regarding maintenance, repairs, and capital investments. This leads to better resource allocation and cost-effectiveness.

- Automate data processing and analysis: Using scripting languages like Python, I automate data processing, analysis, and report generation, freeing up time for more complex tasks and reducing the risk of human error. For instance, I’ve developed scripts that automatically analyze sensor data to detect anomalies.

- Predictive maintenance: Combining sensor data with machine learning techniques can enable predictive maintenance, allowing for proactive interventions before equipment failures occur, minimizing disruptions and maximizing asset lifespan.

I’m continuously exploring and implementing new data analytics techniques to further enhance the efficiency and effectiveness of our inspection processes.

Q 28. Explain your experience with managing and tracking field inspection budgets.

Managing and tracking field inspection budgets involves meticulous planning, monitoring, and control. My approach includes:

- Budget Preparation: I collaborate with project managers and stakeholders to develop detailed budgets, considering all anticipated costs, including personnel, equipment, travel, and materials. Contingency planning is crucial to account for unforeseen expenses.

- Cost Tracking: I meticulously track all expenses against the approved budget, utilizing spreadsheets and project management software to monitor progress and identify potential overruns. Regular reporting to management keeps everyone informed about budget status.

- Variance Analysis: I perform regular variance analysis to identify and explain differences between actual and budgeted costs. This enables prompt corrective actions if necessary.

- Resource Allocation: Effective resource allocation is crucial for staying within budget. I optimize resource utilization by carefully scheduling inspections, utilizing efficient travel plans, and maximizing equipment utilization.

- Cost-Saving Measures: I constantly seek opportunities to optimize costs without compromising quality or safety. This may involve negotiating better rates with vendors, exploring alternative technologies, or streamlining processes.

Through careful planning and proactive monitoring, I ensure that field inspection projects remain within budget while delivering high-quality results.

Key Topics to Learn for Field Engineering and Inspection Interview

- Safety Procedures and Regulations: Understanding and applying relevant safety protocols in diverse field environments, including OSHA regulations and company-specific safety guidelines. Practical application includes describing your experience with safety audits and incident reporting.

- Data Collection and Analysis: Mastering techniques for accurate data acquisition using various instruments and software. This includes understanding data integrity, error analysis, and presenting findings clearly and concisely. Practical application involves explaining your experience with different data logging systems and analytical software.

- Equipment Operation and Maintenance: Demonstrating practical knowledge of operating and maintaining relevant field equipment, including troubleshooting common issues and performing preventative maintenance. Practical application includes describing your experience with specific equipment types and maintenance procedures.

- Report Writing and Communication: Effectively communicating technical information through clear, concise, and well-structured reports. This includes presenting data visually and tailoring communication to different audiences (technical and non-technical). Practical application involves showcasing examples of your technical reports and presentations.

- Problem-Solving and Troubleshooting: Applying analytical skills to diagnose and resolve field issues efficiently and effectively. This includes describing your approach to problem-solving, using examples of challenging situations you’ve overcome.

- Relevant Industry Standards and Codes: Demonstrating familiarity with industry-specific standards and codes of practice, showing your understanding of their application in field inspections. Practical application involves citing specific codes relevant to your experience.

- Project Management Fundamentals: Understanding basic project management principles as they relate to field engineering projects; including planning, scheduling, and resource allocation. Practical application involves describing your involvement in field projects, highlighting your contributions.

Next Steps

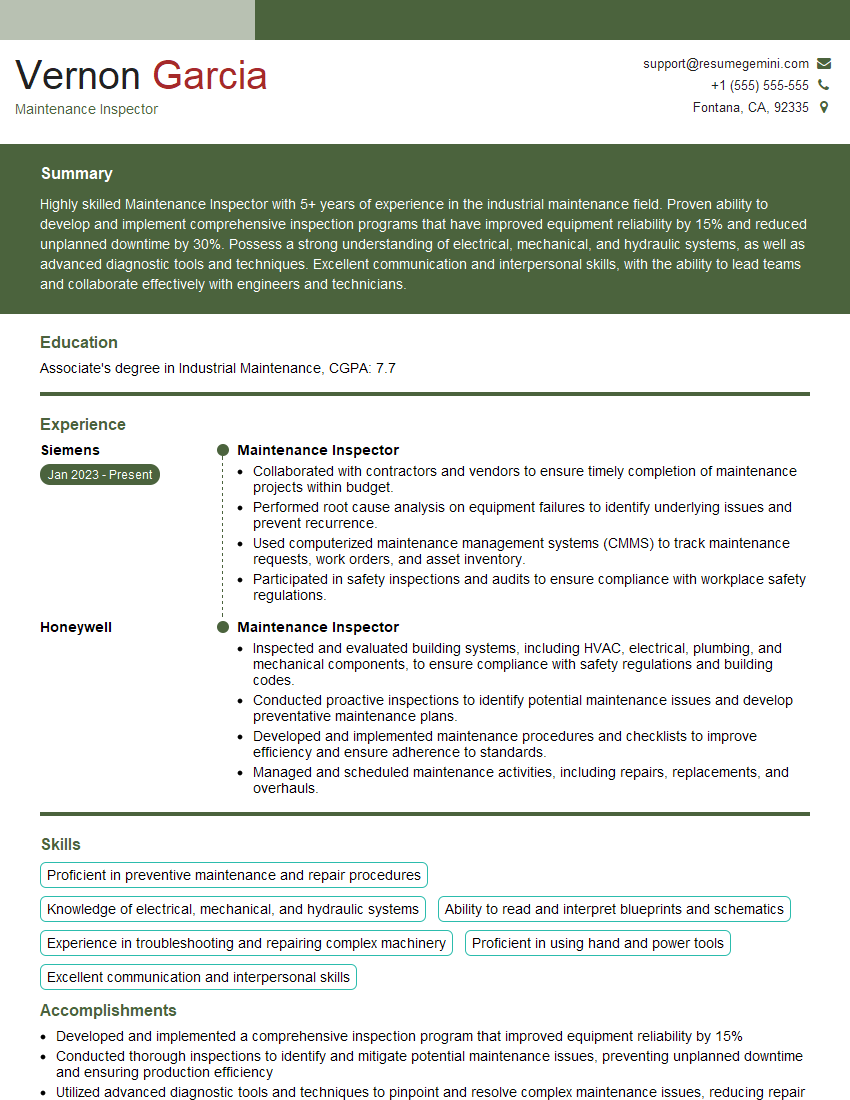

Mastering Field Engineering and Inspection opens doors to a rewarding career with excellent growth potential. You can advance into senior roles, specialized areas, or even management positions within the industry. To significantly improve your chances of landing your dream job, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume, maximizing your visibility to recruiters. ResumeGemini provides examples of resumes tailored to Field Engineering and Inspection to guide your process, allowing you to showcase your skills and experience most effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good