Preparation is the key to success in any interview. In this post, we’ll explore crucial Filleting Fish interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Filleting Fish Interview

Q 1. What are the different filleting techniques for various fish species?

Filleting techniques vary significantly depending on the fish species. The key differences lie in bone structure, skin thickness, and the overall shape of the fish. For example, filleting a delicate fish like flounder requires a gentler approach than filleting a robust fish like a tuna.

- Flat Fish (e.g., flounder, sole): These fish are filleted by making a single cut along the spine, then carefully separating the fillet from the bone. Because of their flat shape, there’s less maneuvering required.

- Round Fish (e.g., cod, snapper): These usually require a more complex approach. A common method involves cutting behind the head, following the backbone down to the tail. After that the fillet is separated by cutting along the ribcage.

- Fatty Fish (e.g., salmon, mackerel): These often require additional attention to prevent excessive tearing. A sharper knife and a controlled, steady hand are crucial. The fat content can make the fillets more prone to slippage.

In every case, the goal is to produce clean, even fillets with minimal waste and maximize the yield. The experience comes from learning to adapt the basic techniques to the specific characteristics of each species.

Q 2. Describe the proper sanitation procedures during fish filleting.

Sanitation is paramount in fish filleting to prevent cross-contamination and maintain food safety. This includes meticulous attention to every stage, from preparation to cleanup.

- Hand Hygiene: Wash hands thoroughly with soap and hot water before, during (especially after touching raw fish), and after handling fish. Use hand sanitizer as a backup if appropriate.

- Equipment Cleaning: Knives, cutting boards, and all other tools must be thoroughly cleaned and sanitized between each fish. Hot, soapy water is essential; a sanitizer solution can further enhance safety.

- Surface Cleaning: Work surfaces must be cleaned and sanitized before and after filleting. Any spills should be cleaned immediately.

- Waste Disposal: Fish waste must be disposed of properly and promptly to avoid attracting pests or causing unpleasant odors. This often involves separate containers for efficient disposal.

- Temperature Control: Keep raw fish at a safe temperature (below 40°F or 4°C) to prevent bacterial growth. This is particularly critical if you’re not immediately processing the fish.

I always emphasize the importance of following HACCP (Hazard Analysis and Critical Control Points) guidelines, ensuring a safe working environment and minimizing risks.

Q 3. How do you identify and remove pin bones from a fillet?

Pin bones, those small, often-sharp bones embedded in the fillet, are a common challenge. Identifying and removing them is critical for a quality product.

- Visual Inspection: Carefully examine the fillet against a light source to spot the pin bones. They frequently appear as small, slightly raised lines or points.

- Tweezers or Pin Bone Pliers: Using specialized tweezers or pliers, gently grasp each pin bone and pull it out. Be careful not to tear the fillet.

- Fingers (with caution): With practice, it is sometimes possible to carefully feel and remove pin bones with your fingers. However, this approach should only be used if the fillet is not overly delicate and if the pin bones are large enough to be easily felt. This method increases the risk of damaging the fillets.

Proper pin bone removal is a skill honed with experience. It’s about developing a keen eye and a light touch.

Q 4. What are the common quality standards for filleted fish?

Quality standards for filleted fish are stringent, focusing on appearance, texture, and safety.

- Appearance: Fillets should be whole, free of blemishes, and have a uniform color and thickness consistent with the species.

- Texture: They should be firm, moist, and elastic to the touch, indicating freshness. A mushy or slimy texture suggests spoilage.

- Odor: Fresh fish should have a pleasant, slightly salty, or seaweed-like scent, depending on the species. A strong ammonia-like smell indicates spoilage.

- Bone-free: The fillet should be completely free from any bones, especially pin bones. Thorough deboning is essential.

- Size and weight consistency: Depending on the customer needs, fillets should meet weight and size requirements for uniformity in packaging and sales.

Adherence to these standards ensures customer satisfaction and safeguards against potential food safety issues.

Q 5. Explain your experience with different types of filleting knives.

My experience encompasses a variety of filleting knives, each suited to specific tasks and fish types.

- Flexible Filleting Knives: These knives, with their thin, flexible blades, are ideal for navigating the curves of fish, especially round fish. The flexibility allows the blade to conform to the fish shape without excessive force.

- Rigid Filleting Knives: These knives are often preferred for thicker-skinned fish or when precision is paramount. The stiffness provides more control, particularly when making initial cuts.

- Electric Filleting Knives: While not always preferred for all types of fish, they can increase speed and efficiency, particularly for high-volume processing. However, care is required to prevent excessive damage to the fillet.

The choice of knife is a matter of preference and depends largely on the type of fish being processed and the volume required. I’ve found that having multiple knives at hand is essential for optimal efficiency.

Q 6. How do you ensure efficient and consistent filleting speed?

Consistent and efficient filleting speed is a result of practice, proper technique, and the right tools.

- Sharp Knives: A sharp knife significantly reduces the effort required and minimizes the risk of tearing the fillet. Dull knives require more force and cause more damage.

- Efficient Work Flow: Organize your workspace to minimize unnecessary movements. Have all your tools readily accessible.

- Proper Technique: A smooth, controlled motion is crucial. Avoid sawing or jerky movements, which can tear the fillets.

- Practice: Consistent practice is key to developing speed and precision. The more fish you fillet, the faster and more proficient you will become.

My experience shows that efficiency isn’t just about speed, but also about minimizing waste and maximizing the quality of the final product. Speed comes naturally with repetition and a focus on accuracy.

Q 7. Describe your experience working with various fish sizes and types.

My experience spans a wide range of fish sizes and types. I’ve worked with everything from small, delicate sole to large, robust tuna. This variety has honed my adaptability and broadened my filleting skills. Each fish presents unique challenges – from the delicate bones of a flounder to the thick skin of a salmon. I’ve found that understanding the anatomy of each species is essential for efficient and effective filleting.

Working with different sizes required adjusting my techniques accordingly. Smaller fish require a more delicate touch, while larger fish demand strength and precision to navigate through the various cuts.

The diversity has made me a more versatile and capable fish filleter, allowing me to tackle any fish species with confidence.

Q 8. How do you handle fish spoilage and waste management?

Fish spoilage is a critical concern in filleting, impacting both quality and safety. My approach is multifaceted, prioritizing prevention and minimizing waste. It begins with careful selection of fresh fish – I check for bright eyes, firm flesh, and a pleasant, sea-like odor. Once received, fish are immediately stored at the correct temperature, typically between 30°F and 38°F (-1°C and 3°C). This chilling slows bacterial growth and extends shelf life. We also meticulously maintain hygiene throughout the process, ensuring all surfaces and tools are thoroughly cleaned and sanitized. Any fish showing signs of spoilage (discoloration, slime, foul odor) is immediately rejected, preventing contamination. Waste management involves separating trimmings and byproducts for proper disposal according to local regulations. Often, these trimmings are used for stock or sold to local businesses that use them for pet food or other purposes. By implementing these strategies, we minimize losses and maintain the highest standards of quality and food safety.

Q 9. What safety precautions do you take while using filleting knives?

Filleting knives are incredibly sharp, requiring utmost caution. My safety practices are paramount. I always use a cutting board with a non-slip surface to prevent accidental slips. I keep my fingers tucked away from the blade’s path, using a pinching motion to guide the fish. I regularly sharpen my knives to ensure clean cuts, minimizing the risk of slips and injuries. If a knife becomes dull, it requires more force, increasing the chance of error. Furthermore, I maintain a clean and clutter-free workstation. A clear workspace reduces the risk of bumping or knocking into objects while concentrating on the delicate process of filleting.

Q 10. How do you maintain the quality and presentation of fish fillets?

Maintaining the quality and presentation of fish fillets involves attention to detail at every stage. Immediately after filleting, I rinse the fillets under cold, running water to remove any remaining blood or debris. This improves both appearance and taste. I then carefully inspect each fillet, trimming away any imperfections or discolorations. For optimal presentation, I arrange the fillets neatly in ice-lined containers, ensuring they are spaced to prevent them sticking together. This maintains freshness and reduces bruising. Proper packaging is crucial; I use breathable packaging to prevent moisture buildup and discoloration, while preserving freshness. Packaging methods vary depending on the type of fish and intended use. Vacuum sealing is common for longer storage and for ensuring the highest quality.

Q 11. Explain your knowledge of different cuts and styles of fish fillets.

My expertise spans various fish cuts and styles. I’m proficient in creating classic fillets, butterfly fillets (where the fillet is cut nearly in half but remains hinged), steaks (thick slices cut perpendicular to the spine), and portions (pre-cut pieces for specific applications). The specific cut depends on the type of fish and its intended use. For example, delicate fish like flounder are typically filleted, whereas firmer fish like tuna might be cut into steaks. I’m also familiar with specialized cuts like the ‘pin bone’ removal technique commonly used with salmon fillets to enhance the eating experience. I can also adapt to requests for specific fillet sizes and thicknesses based on client specifications. The best cut maximizes yield while preserving the integrity of the fish.

Q 12. Describe your experience with automated filleting equipment (if applicable).

While my primary experience is in manual filleting, I have worked with automated equipment on several occasions. I’ve assisted in the operation and maintenance of automated filleting machines, particularly on high-volume production lines. This experience has provided valuable insights into the capabilities and limitations of such equipment. Automated systems offer significant advantages in terms of speed and consistency, particularly for high-volume processing. However, I recognize that the quality of the finished product can vary depending on the machine’s calibration and the quality of the raw fish. Manual filleting still offers the advantage of precise control and the ability to handle more delicate fish more carefully. Often, a balance between automated and manual methods is the most efficient solution in a professional setting.

Q 13. How do you adapt to different filleting demands based on order volume?

Adapting to varying order volumes requires flexibility and planning. For smaller orders, I can efficiently manage the filleting process manually. For larger orders, I can utilize automated equipment or adjust my workflow to maximize efficiency, possibly involving additional staff to meet deadlines. This includes prioritizing tasks and organizing the workflow to minimize downtime. For example, I might pre-portion fish for faster processing during peak times. Careful planning and efficient organization are key to consistent high-quality results regardless of order size. Communication with the team is crucial, and I actively seek feedback to optimize our filleting operations.

Q 14. What is your experience with filleting both whole and pre-cut fish?

My experience encompasses filleting both whole and pre-cut fish. Filleting whole fish requires a greater understanding of fish anatomy and a deft touch to navigate the bones and remove the fillets efficiently. This involves skillful maneuvering of the knife to follow the natural lines of the fish to ensure a high yield and consistent product. Pre-cut fish generally simplifies the process as much of the initial preparation has already been done, enabling more rapid processing. However, I still need to check for imperfections, remove any remaining bones or unwanted parts, and ensure consistent quality and presentation. Regardless of whether I start with whole or pre-cut fish, maintaining hygiene and quality control is always a top priority.

Q 15. How do you ensure accurate yield and minimize waste during filleting?

Maximizing yield and minimizing waste in filleting is crucial for both economic efficiency and sustainability. It’s a balance of precision and understanding the fish’s anatomy. My approach involves a thorough inspection of the fish before beginning. I identify the pin bones, the location of the fillet, and any areas of damage.

I use sharp, flexible filleting knives to make clean, precise cuts, following the natural lines of the fish to avoid tearing the flesh. This minimizes the amount of muscle tissue lost. I carefully remove the skin, leaving as much edible flesh attached as possible. Once the fillets are removed, I trim away any unwanted parts like fins or bloodlines.

For smaller fish, I might utilize a different technique such as a single-cut method to maximize yield. For larger fish, I might process them into portions, optimizing the cuts based on the desired product. Regular sharpening of my knives is paramount. A dull knife requires more force, leading to ragged cuts and significant waste. Regularly assessing my technique and making adjustments based on fish size and type ensures consistent high yield.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your problem-solving approach when encountering difficult filleting tasks.

Encountering difficult filleting tasks, like dealing with a particularly bony fish or one with irregular shape, requires a methodical and adaptable approach. My first step is careful observation. I examine the fish to identify the challenge, whether it’s excessive bone structure, unusually thick skin, or damage to the flesh.

Then, I adjust my technique. If it’s a bony fish, I might use a smaller, more precise knife to carefully maneuver around the bones. If the skin is tough, I employ specialized skinning tools and techniques tailored to that species. For damaged fish, I carefully assess the extent of the damage and adjust my cuts to salvage as much usable fillet as possible, potentially separating damaged portions to avoid contamination.

I regularly consult resources, including diagrams, videos and experienced colleagues if needed. Learning from previous experiences allows me to refine my technique over time. For instance, I learned a specialized technique for removing pin bones in salmon by observing a master filleteur; this technique dramatically improved my yield and consistency.

Q 17. What measures do you take to prevent cross-contamination during filleting?

Preventing cross-contamination is critical for food safety. My filleting station is organized to ensure a clear workflow, minimizing the risk of cross-contamination from raw to cooked products, or between different types of fish. I start with a thorough cleaning and sanitization of my workspace, knives, cutting boards, and other tools before beginning.

I use separate cutting boards for different fish species, especially if there is a risk of parasites or diseases. I maintain separate containers for the fillets and waste to avoid any accidental mixing. My hands are washed thoroughly and frequently. I also change my gloves regularly to avoid transferring bacteria or pathogens. I ensure the fillets are kept at the correct temperature (below 40°F/4°C) to minimize bacterial growth. Following these procedures helps to guarantee the safety and quality of the final product.

Q 18. How do you identify and handle fish with parasites or diseases?

Identifying and handling fish with parasites or diseases requires careful observation and adherence to food safety regulations. I visually inspect each fish for any abnormalities, including discoloration, unusual lesions, or the presence of parasites (like worms or lice). A thorough understanding of common fish diseases and parasites in the local area is essential.

If I detect a problem, I immediately separate the affected fish from the healthy ones. I discard or properly dispose of any fish exhibiting clear signs of disease. In some instances, more careful processing might be needed – potentially requiring removal of the affected area or even discarding it completely. This prevents contamination of other fish and ensures the final product is safe for consumption. Maintaining good sanitation practices helps to reduce the risk of parasitic infestations as well.

Q 19. What is your experience with different types of fish scales and skin removal techniques?

My experience with different types of fish scales and skin removal techniques is extensive. Fish scales vary dramatically in size, thickness, and adherence to the skin. Some, like salmon, have relatively small, easily removed scales, while others, like some types of catfish, have embedded, thorny scales requiring different tools and methods.

I utilize a variety of techniques for scale and skin removal, including scaling knives (for smaller scales), a specialized scaler (like a fish scraper), and careful manual removal. For skin removal, I employ sharp filleting knives, making incisions along the edge of the fillet, and then carefully working the knife to separate the skin from the flesh. Different fish species may require different skinning approaches – some skin may be easily removed with one continuous cut, while others may require multiple cuts or specialized tools. This experience provides me with the flexibility to handle a wide variety of fish types efficiently and effectively.

Q 20. How do you maintain a clean and organized filleting workspace?

Maintaining a clean and organized filleting workspace is fundamental for both efficiency and food safety. My workflow is designed for smooth and sanitary processing. I start by ensuring all surfaces are clean and sanitized before starting work. Tools are kept organized and readily accessible. Sharp knives are crucial, so I maintain a sharpening station nearby.

I have designated areas for different stages of processing: scaling, filleting, and waste disposal. This prevents cross-contamination and streamlines the process. I regularly clean and sanitize my tools and workspace during the filleting process. Waste materials are disposed of promptly and correctly. This well-organized approach optimizes workflow and ensures that the entire process is efficient, hygienic and maintains food safety standards.

Q 21. Describe your experience working under pressure and meeting deadlines.

Working under pressure and meeting deadlines is a regular part of my job. I’ve worked in high-volume processing environments where speed and accuracy are paramount. My approach involves prioritizing tasks based on urgency and importance. Effective time management is crucial, including breaking down large tasks into smaller, manageable steps.

I am skilled at adapting to changing circumstances. If an unexpected issue arises, I adjust my schedule accordingly and communicate effectively with my team or supervisor. Maintaining a calm and efficient workflow under pressure is critical; I focus on maintaining consistency and accuracy, even when working at a faster pace. Experience has shown me that precision and organization are essential for achieving efficiency and meeting deadlines, even under pressure.

Q 22. How do you handle disagreements or conflicts with colleagues?

Disagreements are inevitable in any team environment. My approach focuses on open communication and collaborative problem-solving. I believe in actively listening to understand my colleague’s perspective before expressing my own. If a conflict arises, I try to identify the root cause, focusing on the issue rather than personalities. For example, if there’s a disagreement about the best filleting technique for a specific fish, I’d suggest a trial run using both methods, comparing yield and quality to reach a data-driven conclusion. I also value seeking mediation from a supervisor if necessary, ensuring a fair and objective resolution. Ultimately, maintaining a professional and respectful demeanor is crucial for maintaining positive working relationships.

Q 23. How do you adapt to new filleting techniques and technologies?

The seafood industry is constantly evolving, so adapting to new filleting techniques and technologies is essential for maintaining competitiveness and efficiency. I actively seek opportunities for professional development, such as attending industry workshops and training sessions on new equipment like automated filleting machines or improved knife handling techniques. I’m a quick learner and enjoy experimenting with different methods, always prioritizing safety and quality. For instance, when our company introduced a new automated scaling machine, I volunteered to be among the first to learn its operation. By understanding its mechanics and limitations, I was able to identify and troubleshoot minor issues, contributing to smoother integration within the team. I also believe in continuous learning through online resources and industry publications to stay informed about the latest advancements.

Q 24. What are your career goals in the seafood processing industry?

My career goals center on becoming a highly skilled and respected filleting expert, contributing significantly to the efficiency and quality of seafood processing. I aim to progress into a supervisory role, mentoring and training newer team members. Ultimately, I envision myself contributing to innovation in the industry, perhaps by developing and implementing new, more efficient filleting methods or contributing to the research and development of improved technologies. My long-term aspiration is to become a key player in a company committed to sustainable and ethical seafood practices.

Q 25. What is your understanding of HACCP (Hazard Analysis and Critical Control Points)?

HACCP, or Hazard Analysis and Critical Control Points, is a systematic preventive approach to food safety. It identifies potential hazards in the food production process and establishes control measures to minimize or eliminate risks. In filleting, this involves identifying potential hazards such as cross-contamination from different types of fish, improper temperature control leading to bacterial growth, and using contaminated equipment. Critical control points might include the cleaning and sanitization of equipment, temperature monitoring during storage and processing, and the proper handling of waste. Understanding and implementing HACCP ensures that our final product is safe for consumption and meets regulatory standards. My experience includes thorough training in HACCP principles and practical application in the workplace. We regularly conduct HACCP audits and implement corrective actions to maintain compliance.

Q 26. What is your experience with food safety regulations and compliance?

Throughout my career, I’ve worked consistently within the framework of relevant food safety regulations, such as those outlined by the FDA and other governing bodies. This includes maintaining a thorough understanding of regulations concerning hygiene, temperature control, and proper labeling. For example, I am intimately familiar with procedures for preventing cross-contamination, ensuring proper sanitation of equipment between different fish types to prevent bacterial transfer. I am comfortable completing the required paperwork and documentation for regulatory compliance, such as temperature logs and product traceability records. I actively participate in company training sessions to stay updated on any changes or new regulations to ensure continued compliance.

Q 27. Describe a time you had to troubleshoot a problem during the filleting process.

During a particularly busy processing shift, one of our automated filleting machines malfunctioned, causing a significant backlog. Initially, I checked for obvious issues like power supply and blade alignment. When those proved normal, I consulted the machine’s manual and contacted the supplier’s technical support. Through a process of elimination, we discovered a minor software glitch requiring a simple reset. By systematically troubleshooting the problem, we quickly resolved the issue, minimizing production downtime and preventing waste. This experience reinforced the importance of both practical troubleshooting skills and access to technical support networks.

Q 28. How do you prioritize tasks to ensure efficient and timely completion of filleting duties?

Prioritizing tasks in filleting involves a balance of speed and quality. I typically begin by assessing the day’s orders and the available resources. Higher-priority tasks, such as processing time-sensitive orders or handling delicate fish species, are tackled first. I also consider the required preparation steps, such as scaling and gutting, ensuring a smooth flow through the filleting process. I use a combination of written task lists and visual cues to manage workload, and I’m always attentive to potential bottlenecks, adjusting my approach as needed to maintain efficiency and avoid delays. A systematic approach, careful planning, and adaptability are essential to meet deadlines and maintain high quality.

Key Topics to Learn for Filleting Fish Interview

- Fish Anatomy and Physiology: Understanding the internal structure of various fish species is crucial for efficient and safe filleting. This includes locating bones, organs, and identifying different muscle groups.

- Filleting Techniques: Mastering various filleting methods (e.g., pin bone removal, skinning techniques) for different fish types is essential. Practical experience and dexterity are highly valued.

- Hygiene and Safety: Understanding and applying food safety regulations, proper knife handling techniques, and maintaining a clean work environment are paramount in this field. This includes understanding cross-contamination prevention.

- Yield and Waste Minimization: Efficient filleting maximizes the usable portion of the fish while minimizing waste. This demonstrates both skill and cost-effectiveness.

- Equipment Knowledge: Familiarity with different filleting knives, scaling tools, and other relevant equipment is expected. Knowing how to maintain and safely use these tools is crucial.

- Quality Control: Understanding the visual and tactile cues that indicate the quality and freshness of the fish, and knowing how to identify defects are essential for consistent quality output.

- Different Fish Species: Experience with a variety of fish species and their unique filleting requirements showcases adaptability and comprehensive skillset.

Next Steps

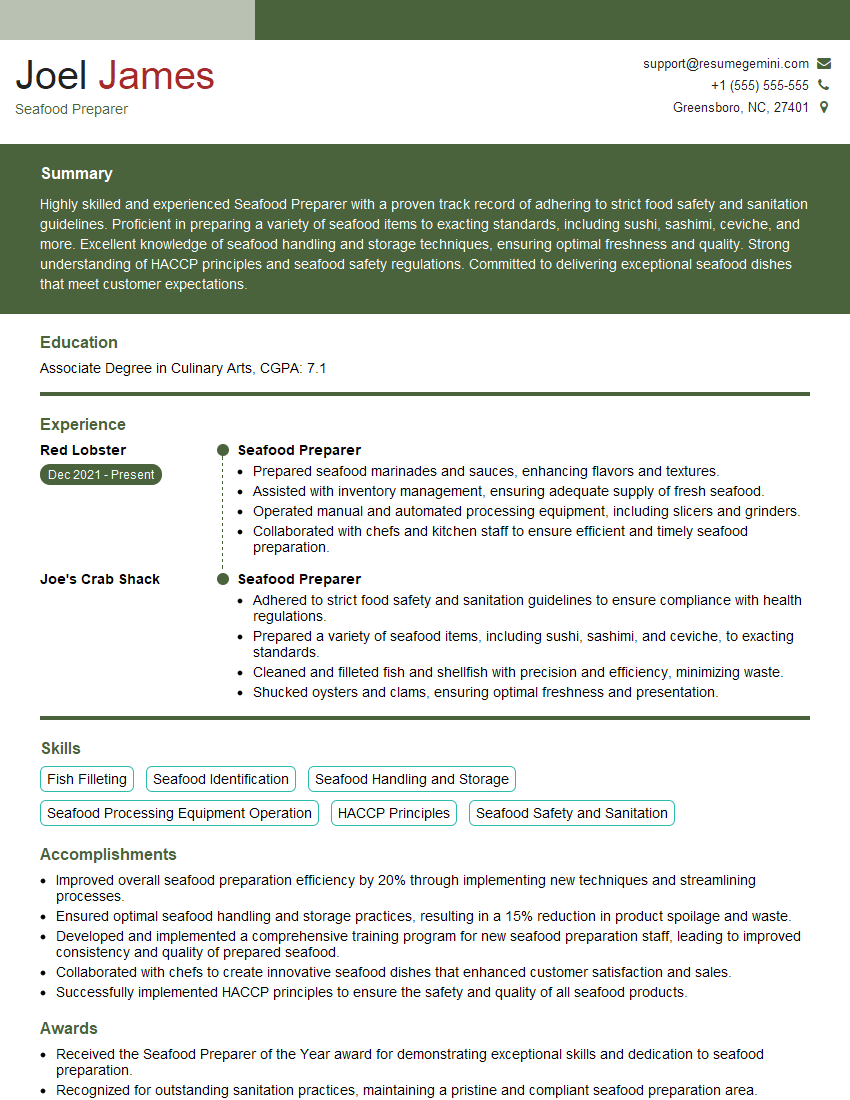

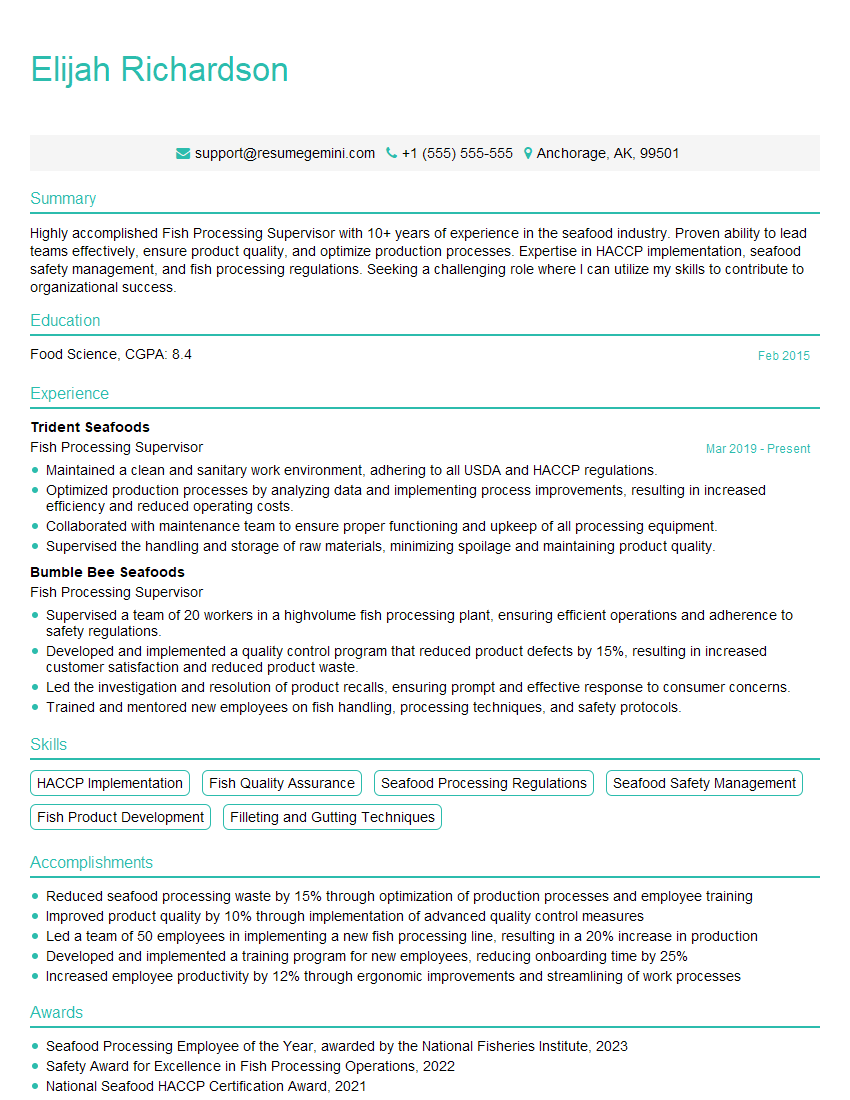

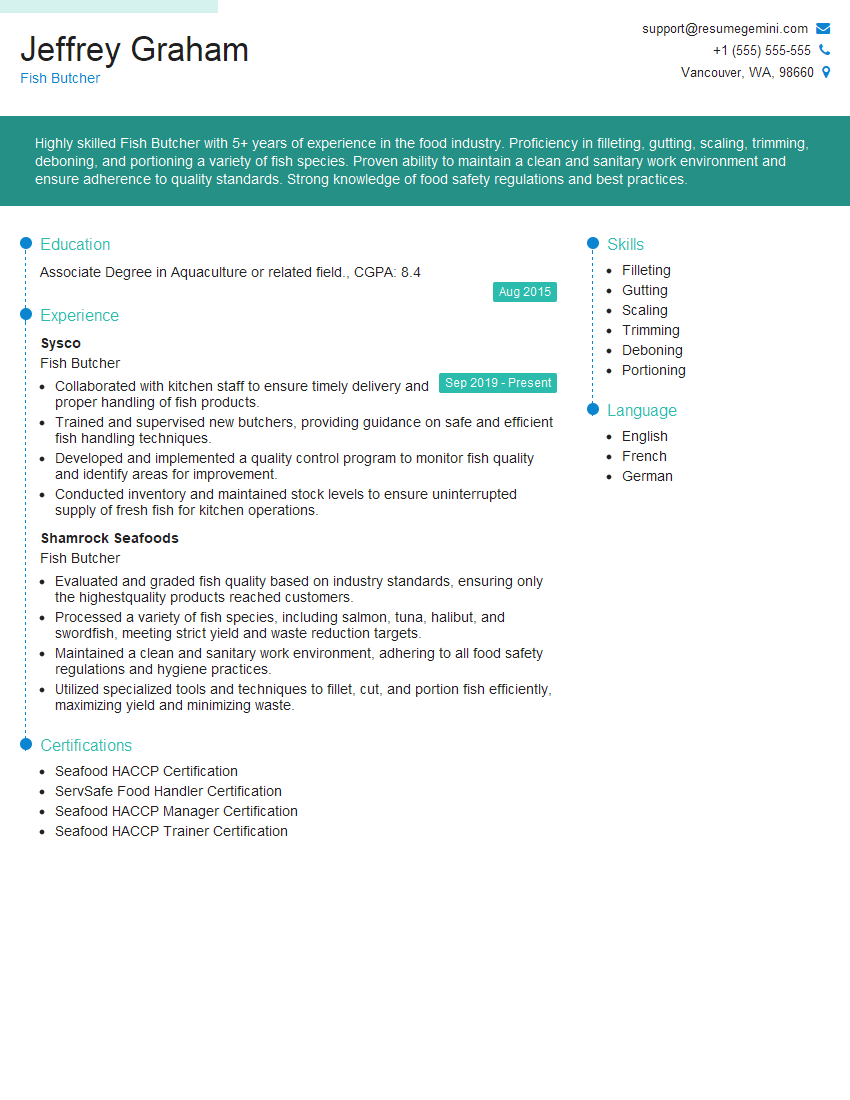

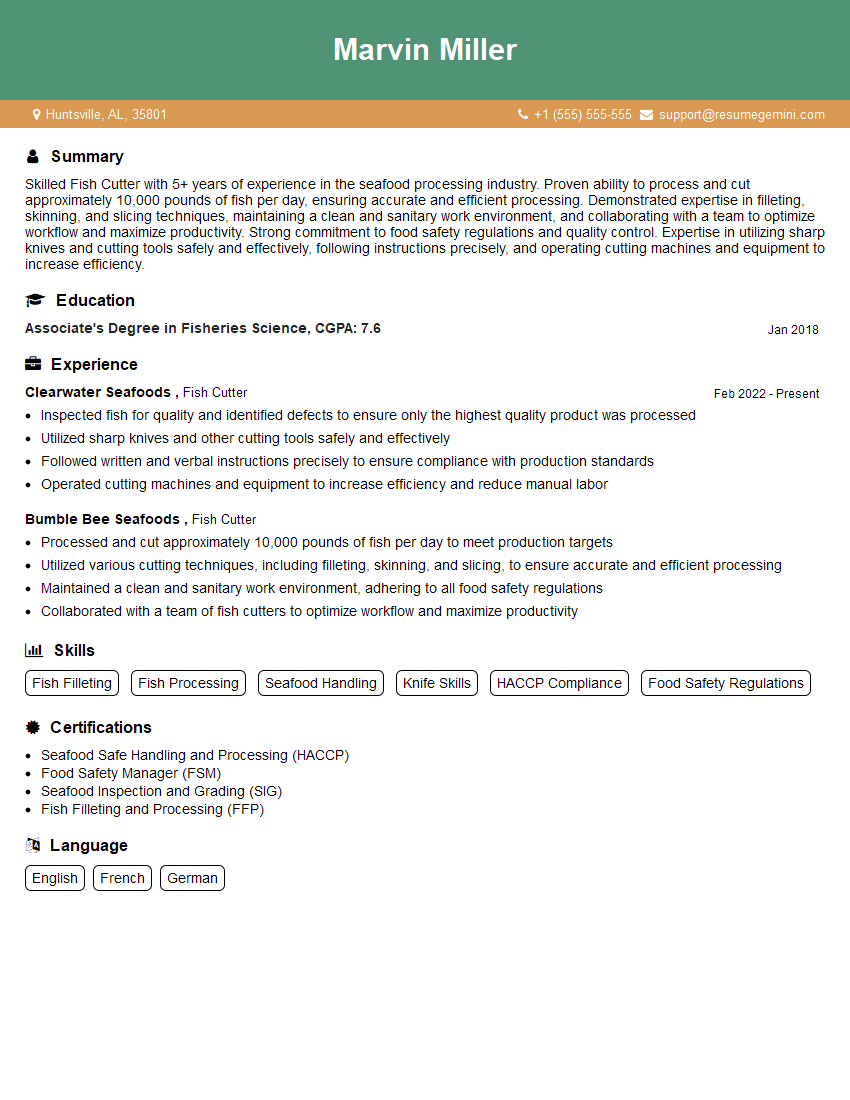

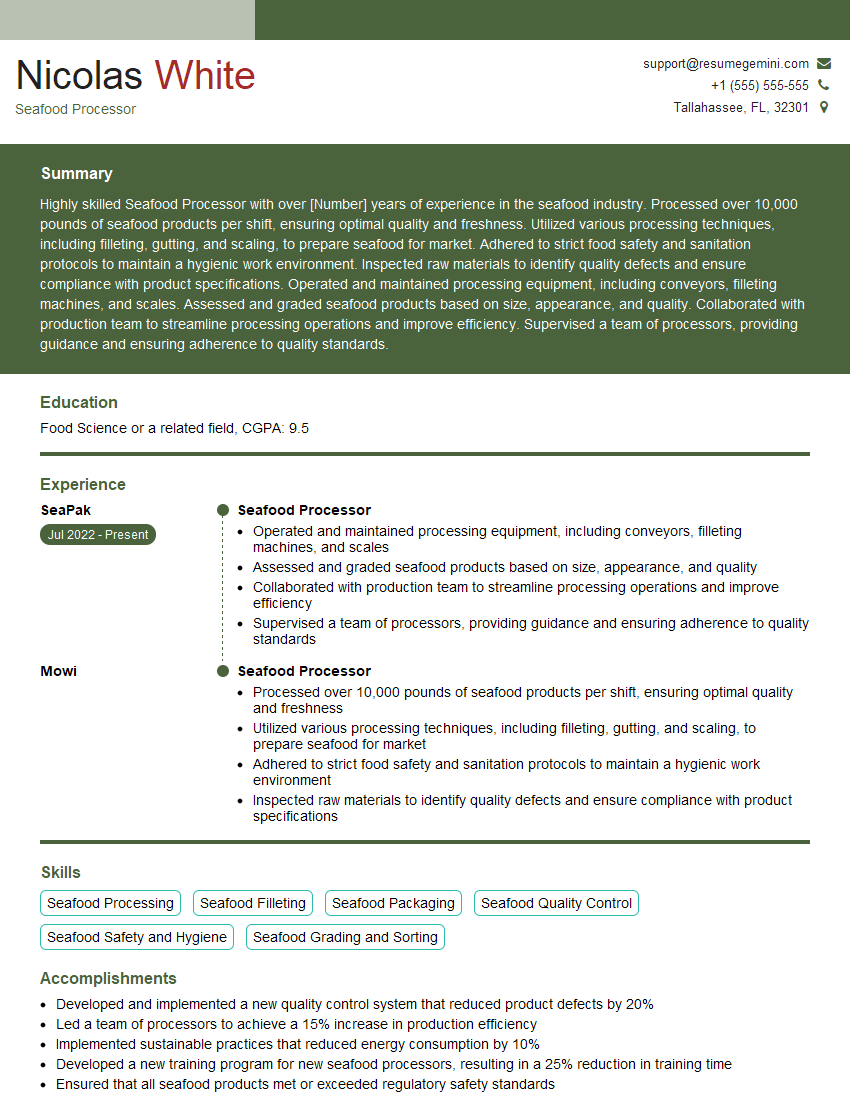

Mastering the art of filleting fish opens doors to exciting opportunities in the culinary and seafood industries, offering diverse career paths and potential for growth. To maximize your job prospects, crafting a strong, ATS-friendly resume is key. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, tailored to highlight your skills and experience in filleting fish. Examples of resumes specifically designed for this field are available, showcasing how to effectively present your qualifications.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi I am a troller at The aquatic interview center and I suddenly went so fast in Roblox and it was gone when I reset.

Hi,

Business owners spend hours every week worrying about their website—or avoiding it because it feels overwhelming.

We’d like to take that off your plate:

$69/month. Everything handled.

Our team will:

Design a custom website—or completely overhaul your current one

Take care of hosting as an option

Handle edits and improvements—up to 60 minutes of work included every month

No setup fees, no annual commitments. Just a site that makes a strong first impression.

Find out if it’s right for you:

https://websolutionsgenius.com/awardwinningwebsites

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good