Cracking a skill-specific interview, like one for Finishing Surfaces, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Finishing Surfaces Interview

Q 1. Explain the difference between solvent-based and water-based finishes.

The primary difference between solvent-based and water-based finishes lies in their respective solvents. Solvent-based finishes, as the name suggests, utilize organic solvents like mineral spirits or lacquer thinner to dissolve the resin and allow for even application. These solvents evaporate, leaving behind the hardened finish. Water-based finishes, on the other hand, use water as the solvent. They are generally considered more environmentally friendly due to lower VOC (Volatile Organic Compound) emissions.

Key Differences Summarized:

- Solvent-Based: Strong odor, faster drying time, often harder and more durable finish, higher VOCs, requires specialized cleanup (solvents).

- Water-Based: Lower odor, slower drying time, potentially less durable (depending on formulation), lower VOCs, easier cleanup (water).

For example, a traditional lacquer finish would be solvent-based, while many modern acrylic paints are water-based. The choice depends on the desired durability, environmental considerations, and application method.

Q 2. Describe your experience with various surface preparation methods (sanding, priming, etc.).

Surface preparation is paramount to achieving a high-quality finish. My experience encompasses a wide range of methods, starting with sanding. I’m proficient in using various grits of sandpaper, from coarse for removing imperfections to fine for achieving a smooth surface. I carefully select the appropriate grit based on the substrate and the desired finish. This might involve hand sanding for intricate details or using power sanders for larger areas, always ensuring consistent pressure to avoid creating uneven surfaces.

Priming is another crucial step. I’m experienced with various primers, including oil-based and water-based formulations, selected based on the substrate and the topcoat to be used. Primers improve adhesion, seal porous surfaces, and provide a uniform base for the finish coat. I also have expertise in other preparation techniques, such as filling imperfections with wood filler or spackle, followed by careful sanding to create a seamless surface.

For example, on a project involving a complex, carved wooden piece, I would meticulously hand-sand all surfaces before applying a specialized primer designed for wood, ensuring superior adhesion and a beautifully smooth final finish.

Q 3. What are the key considerations for selecting the appropriate finish for a specific substrate?

Selecting the appropriate finish depends heavily on several factors related to the substrate:

- Material Type: Wood requires different finishes than metal or plastic. Wood finishes need to consider grain orientation and porosity. Metal finishes might prioritize corrosion resistance. Plastic finishes often focus on impact resistance and UV protection.

- Intended Use: A finish for outdoor furniture needs to withstand sun exposure, rain, and temperature changes, requiring greater durability than a finish for indoor furniture. A finish for a food-contact surface needs to be food-safe.

- Desired Aesthetic: The sheen level (gloss, semi-gloss, satin, matte) and color are important aesthetic choices. Some finishes accentuate wood grain, while others provide a uniform color.

- Environmental Concerns: The VOC content of the finish is a crucial factor for indoor applications and environmentally conscious projects. Water-based finishes are generally preferred here.

For instance, I wouldn’t use a water-based polyurethane on outdoor furniture as it may degrade quickly; an oil-based spar varnish would be a better choice.

Q 4. How do you ensure consistent finish quality across multiple parts or projects?

Consistency is key in finishing. To achieve this across multiple parts or projects, I follow a rigorous, standardized process. This begins with meticulous surface preparation, employing the same methods and materials across the board. I maintain consistent environmental conditions, especially temperature and humidity, as these affect drying times and finish appearance.

I use calibrated spray equipment to ensure even application and consistent film thickness. I also frequently monitor the finish application, making minor adjustments as needed to maintain uniformity. For example, regular cleaning of spray equipment prevents clogging and inconsistent spray patterns. Careful attention to detail and adherence to established procedures are crucial for producing consistent results.

Finally, careful documentation of the process and the materials used ensures repeatability in future projects. Using standardized color mixing systems, keeping meticulous records and using sample boards for color matching and finish testing are vital steps to maintain high quality.

Q 5. Describe your experience with different types of spray equipment (HVLP, airless, etc.).

My experience includes various spray equipment types, each suited for different applications:

- HVLP (High Volume, Low Pressure): HVLP sprayers utilize high air volume at low pressure, minimizing overspray and resulting in less material waste. They are ideal for smaller projects and detailed work, producing a fine finish.

- Airless: Airless sprayers atomize paint using high pressure, allowing for fast application of thick materials over large areas. These are efficient for large-scale projects but require more skill to avoid runs and sags.

- Conventional Spray Guns (pressure feed): This is a more traditional approach using compressed air to atomize the paint. It offers good control and is adaptable to various materials. However, proper regulation of the air pressure is critical for consistent results.

I am proficient in adjusting the spray pattern, fluid viscosity, and air pressure on all equipment types to achieve the desired finish. Selecting the right equipment depends on the project’s scale, complexity, and the properties of the finish being applied.

Q 6. Explain the importance of proper ventilation and safety precautions when working with finishes.

Proper ventilation and safety precautions are crucial when working with finishes. Many finishes contain volatile organic compounds (VOCs) which can be harmful if inhaled. I always work in well-ventilated areas, using respirators appropriate for the specific finish, such as organic vapor respirators for solvent-based finishes and particulate respirators when sanding. I also ensure adequate eye protection and gloves are worn.

The workspace should be well-ventilated, either naturally through open windows and doors or with a dedicated ventilation system, especially when using solvent-based products. Flammable finishes require extra caution; I ensure no open flames or sparks are present, and I am always aware of the flashpoint of the materials I am working with. Proper storage of finishes, away from ignition sources and in designated areas, is equally important for safety. Regular cleanup of spills and disposal of waste according to local regulations are vital aspects of responsible finishing practices.

Q 7. How do you troubleshoot common finishing problems such as runs, sags, or orange peel?

Troubleshooting finishing problems requires careful observation and understanding of the factors influencing the finish. Common issues and their solutions:

- Runs and Sags: These usually result from applying too much finish at once, improper viscosity, or insufficient drying time between coats. Solutions include thinning the finish (according to manufacturer’s recommendations), reducing the amount of finish applied per pass, and ensuring adequate drying time. The surface angle also plays a role; avoid applying finish to vertical surfaces without allowing sufficient time for the previous coat to set.

- Orange Peel: This textured appearance can be caused by incorrect spray gun settings (too high air pressure or too low fluid pressure), poor atomization, or too much air pressure. Adjust spray gun settings, ensuring the paint is properly atomized. The ambient temperature also affects drying time and may exacerbate this issue.

- Dust Nibs: These small imperfections are due to airborne particles landing on the wet finish. Solutions involve working in a clean environment or using a clean air filtration system. A tack cloth can be used to remove dust before applying the finish.

A systematic approach, where each possible cause is investigated and eliminated, is crucial for effective troubleshooting. If a problem persists, consulting the finish manufacturer’s technical documentation may help pinpoint the underlying issue and find effective solutions.

Q 8. What are your methods for identifying and correcting surface defects before finishing?

Identifying and correcting surface defects before finishing is crucial for achieving a high-quality, durable finish. My approach involves a multi-step process, starting with a thorough visual inspection under various lighting conditions to detect imperfections like scratches, dents, pits, or inconsistencies in the substrate. I then utilize specialized tools like magnifying glasses or even microscopes for closer examination, depending on the material and the level of detail required. For example, on a high-gloss automotive paint job, even microscopic imperfections are amplified and need to be addressed.

Next, depending on the nature of the defect, I employ appropriate correction methods. Minor scratches might be sanded down with progressively finer grits of sandpaper, followed by careful cleaning. Deeper dents might require filling with a suitable filler, carefully leveled and sanded smooth. For larger or more complex issues, I collaborate with the fabrication team to discuss pre-finishing solutions, such as reworking the part if necessary. The final step is always a meticulous cleaning to remove any dust or debris generated during the repair process, ensuring a clean surface ready for the finishing process.

- Visual Inspection: Checking for scratches, dents, pits, and other imperfections.

- Tool-Assisted Inspection: Using magnifying glasses or microscopes for detailed analysis.

- Defect Correction: Sanding, filling, reworking, as needed.

- Cleaning: Removing dust and debris after repairs.

Q 9. What experience do you have with powder coating?

I have extensive experience with powder coating, having worked with various powder coating systems for over [Number] years. My expertise covers the entire process, from surface preparation and pre-treatment to application and curing. I’m proficient in selecting the appropriate powder coating type based on the substrate material, desired finish, and environmental conditions. For example, I’ve worked with polyester, epoxy, and polyurethane powder coatings on various metals such as steel, aluminum, and zinc, ensuring optimal adhesion and corrosion resistance. My experience also extends to troubleshooting common issues like orange peel, pinholes, and uneven coating thickness. I’m well-versed in optimizing the powder coating process parameters such as gun settings, oven temperature, and dwell time to achieve consistent and high-quality results.

I am also familiar with different types of powder coating equipment, including automated powder coating systems and manual spray booths. My skills include understanding and managing the critical aspects of electrostatic charging, powder flow, and application techniques. Furthermore, I’ve worked with various safety procedures and regulations associated with powder coating, prioritizing both environmental responsibility and worker safety.

Q 10. Describe your familiarity with different types of coatings (e.g., polyurethane, epoxy, lacquer).

My familiarity with different types of coatings is comprehensive. I understand the properties, applications, and limitations of various coatings, including polyurethane, epoxy, and lacquer.

- Polyurethane: Known for its excellent durability, flexibility, and UV resistance, making it suitable for exterior applications and high-wear areas. I’ve worked with both water-based and solvent-based polyurethane coatings, adjusting my application techniques based on their unique characteristics.

- Epoxy: Prized for its chemical resistance and hardness, epoxy coatings are frequently used in industrial settings for protection against corrosion and abrasion. I have experience with both two-part epoxy systems requiring careful mixing ratios and single-component epoxies for ease of application.

- Lacquer: A fast-drying, versatile coating option often chosen for its ease of application and beautiful finish, particularly on wood. I understand the importance of proper ventilation when working with lacquer due to its volatile organic compounds.

Beyond these, I have experience with acrylics, melamine, and other specialized coatings. My selection of coating is always guided by the specific needs of the project, considering factors such as substrate, desired aesthetics, and environmental exposure. For example, choosing a UV-resistant coating for outdoor furniture is crucial for long-term protection.

Q 11. How do you maintain and clean your finishing equipment?

Maintaining and cleaning finishing equipment is paramount for consistent, high-quality results and the longevity of the equipment. My routine includes daily cleaning of spray guns, using appropriate solvents and brushes to remove any dried coating. I meticulously inspect for any wear and tear on nozzles and other components, replacing them as needed. After each use, the spray booth is thoroughly cleaned, removing overspray and any accumulated debris. This typically involves vacuuming and wiping down surfaces. Filters are checked and replaced regularly to maintain efficient air circulation.

For larger equipment, such as ovens, regular maintenance schedules are followed. This includes inspections of heating elements, fans, and safety systems. I keep detailed records of all maintenance activities, including date, type of maintenance, and any parts replaced. This ensures preventative maintenance and minimizes downtime. Regular calibration of equipment, such as measuring instruments used for controlling temperature and pressure, is also part of my standard procedure to maintain accuracy and consistency.

Q 12. What is your experience with color matching and mixing?

Color matching and mixing is a crucial aspect of my work. I have extensive experience in accurately matching colors using various methods, including spectrophotometers for precise color readings and visual comparison techniques for subtle adjustments. I am adept at utilizing color mixing systems, understanding color theory, and employing both computerized and manual mixing techniques. For instance, in a recent project, I had to precisely match a custom color specified by the client, which required carefully adjusting the ratios of different pigments in the base coat and clear coat. My experience also includes managing color consistency across large batches and troubleshooting color discrepancies. I am proficient in using color formulas to maintain a consistent color over time, which is essential in ensuring uniformity across multiple production runs.

Q 13. Describe your understanding of curing processes for different finishes.

Understanding curing processes for different finishes is critical for ensuring the durability and performance of the final product. Curing involves a chemical or physical change that solidifies the coating, providing hardness, adhesion, and resistance to environmental factors. The specific curing process depends on the type of coating. For example, lacquer typically cures through evaporation of solvents, while epoxy and polyurethane coatings often require heat curing in ovens to reach optimal properties.

My experience includes managing curing processes in various types of ovens, including convection ovens, infrared ovens, and UV curing systems. I carefully monitor and control temperature, time, and airflow during the curing process to ensure consistent and even curing across the entire surface. I also understand the impact of various factors like humidity and substrate temperature on the curing process. For example, higher humidity can prolong drying times, while lower substrate temperatures might prevent proper crosslinking of the coating. Proper curing is essential for achieving the desired properties of the finish, ensuring its lasting quality.

Q 14. How do you manage your time and prioritize tasks in a fast-paced finishing environment?

Managing time and prioritizing tasks effectively in a fast-paced finishing environment requires a structured approach. I utilize several techniques to ensure efficiency and meet deadlines. I start with a detailed review of the production schedule, identifying all tasks and their due dates. Then, I prioritize tasks based on urgency and importance, focusing on critical items with tight deadlines first.

I often employ Kanban or similar visual management systems to track progress, identify bottlenecks, and ensure smooth workflow. Effective communication with colleagues and the production team is vital for coordinating tasks and minimizing delays. I break down large tasks into smaller, manageable steps, allowing for efficient progress tracking and easier delegation if necessary. I regularly review my schedule throughout the day to ensure I’m on track and adjust priorities as needed based on unforeseen events or changing demands. Furthermore, maintaining a clean and organized workspace is critical for efficiency and prevents unnecessary delays.

Q 15. Explain your experience with quality control procedures in a finishing process.

Quality control in finishing is crucial for ensuring a consistent, high-quality product. My experience involves implementing and overseeing a multi-stage process, starting from raw material inspection to final product verification. This includes:

Visual Inspection: Checking for defects like scratches, dents, inconsistencies in color or texture, and ensuring proper surface preparation before finishing.

Dimensional Checks: Using calibrated instruments to verify that finished pieces meet specified dimensions, particularly crucial in precision applications.

Adhesion Testing: Employing methods like the cross-hatch adhesion test to assess the bond strength between the finish and the substrate. This is crucial to prevent peeling or flaking.

Thickness Measurement: Measuring the thickness of applied coatings using a wet film comb or dry film thickness gauge to ensure consistent application and durability. This is vital for meeting regulatory requirements and providing expected performance.

Statistical Process Control (SPC): Implementing SPC charts to monitor key parameters throughout the process, allowing for early detection of trends and process deviations, enabling timely corrective actions. For instance, charting the number of defects per batch helps identify potential issues with the finishing process or raw materials.

Documentation and Reporting: Maintaining detailed records of inspection results and any corrective actions taken. This provides a historical record for continuous improvement.

In a recent project involving automotive parts, meticulous quality control ensured a defect rate below 0.5%, exceeding client expectations and demonstrating the effectiveness of our procedures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of wood finishing techniques?

My expertise spans a wide range of wood finishing techniques, from traditional methods to advanced contemporary approaches. This includes:

Oil Finishes: Working with various oils like linseed, tung, and walnut oil, understanding their penetration properties, drying times, and the resulting finishes. Oil finishes offer a natural look and feel, enhancing the wood grain.

Lacquer Finishes: Experience with spray and brush application of various lacquers, understanding their fast drying times and the need for proper ventilation and safety precautions. Lacquers offer a durable, glossy finish.

Varnish Finishes: Working with different types of varnish, including polyurethane, spar varnish, and shellac, each with its unique properties and applications. Varnishes provide good protection and can achieve varied sheens.

Stain Finishes: Applying various stains to alter the color of the wood, understanding pigment vs. dye-based stains and their compatibility with different finishes. Stains allow for customization and highlight wood grain.

French Polishing: This traditional technique involves rubbing shellac onto the wood surface with a pad, creating a smooth, high-gloss finish. It’s a time-consuming but rewarding process, resulting in a beautiful, durable surface.

For example, I recently oversaw a project that restored antique furniture using a combination of French polishing and shellac, resulting in a beautiful finish that preserved the historical integrity of the pieces.

Q 17. How do you ensure the adherence of finishes to meet specified standards?

Ensuring finish adherence to specified standards involves a combination of meticulous preparation, precise application, and rigorous testing. This includes:

Substrate Preparation: Proper surface preparation is paramount. This includes sanding to the correct grit, cleaning to remove dust and contaminants, and applying appropriate primers or sealers to promote adhesion.

Application Techniques: Using the appropriate application method (spraying, brushing, dipping, etc.) and ensuring proper film build-up to achieve the desired thickness and appearance. This often involves multiple coats with adequate drying time between applications.

Environmental Control: Maintaining consistent temperature and humidity during application and curing to avoid defects such as bubbling, orange peel, or poor adhesion. This is especially important for moisture-sensitive finishes.

Conformance Testing: Performing regular tests like adhesion, thickness, and gloss measurements to ensure the finish meets specified standards. This involves using calibrated instruments and comparing results to pre-defined acceptance criteria. Out-of-specification results lead to immediate investigation and corrective actions.

For instance, in a recent project producing high-gloss automotive trim, we implemented a strict quality control process with regular testing and feedback loops, resulting in a consistent high-quality finish that met stringent industry standards.

Q 18. What are the environmental concerns associated with certain finishing materials?

Many finishing materials carry significant environmental concerns. These include:

Volatile Organic Compounds (VOCs): Many solvents and coatings release VOCs, contributing to air pollution and smog formation. Regulations like those set by the EPA often dictate permissible VOC levels.

Hazardous Air Pollutants (HAPs): Some finishing materials contain HAPs, which are toxic air pollutants linked to various health problems. Proper ventilation and personal protective equipment are vital when working with these materials.

Waste Disposal: Spent solvents, paint sludge, and other finishing waste can contaminate soil and water if disposed of improperly. This necessitates responsible waste management practices.

Heavy Metals: Some finishes may contain heavy metals like lead or chromium, which are toxic and pose significant environmental risks. Alternatives with lower environmental impact are increasingly favored.

Switching to water-based coatings, using low-VOC solvents, and implementing proper waste management protocols are crucial steps in mitigating these environmental impacts. These environmentally friendly practices are becoming increasingly important in the industry and are a major focus of our operations.

Q 19. How do you handle waste materials responsibly in a finishing operation?

Responsible waste handling is crucial for minimizing environmental impact and ensuring worker safety. Our approach encompasses:

Waste Segregation: Separating different waste streams—solvents, solids, etc.—for proper disposal or recycling.

Solvent Recovery: Employing solvent recovery systems to recapture and reuse solvents, reducing waste and costs.

Recycling: Recycling metal scraps, plastic containers, and other recyclable materials.

Hazardous Waste Disposal: Partnering with licensed hazardous waste disposal companies to manage materials containing hazardous substances, ensuring compliance with all local, state, and federal regulations.

Spill Response Plan: Having a detailed plan in place to effectively handle spills of finishing materials, minimizing environmental damage and protecting worker health.

Through diligent waste management, we have significantly reduced our environmental footprint, achieving a waste reduction rate of over 60% in the past two years.

Q 20. Describe your experience with different types of metal finishing techniques.

Metal finishing techniques vary significantly depending on the metal and desired outcome. My experience covers several key processes:

Electroplating: Applying a thin layer of metal (e.g., chromium, nickel, zinc) onto a substrate using an electrochemical process to enhance corrosion resistance, appearance, or conductivity. This requires precise control of current, voltage, and solution chemistry.

Anodizing: An electrochemical process used to create a protective oxide layer on aluminum surfaces, increasing durability and corrosion resistance. Different anodizing processes produce varying colors and finishes.

Powder Coating: Applying a dry powder coating to a metal surface, then curing it in an oven to create a durable, protective, and aesthetically pleasing finish. Different powder coatings offer varied textures, colors, and gloss levels.

Chemical Conversion Coatings: Using chemical reactions to create a protective layer on the metal surface. Common examples include phosphating and chromating, which improve paint adhesion and corrosion resistance. However, many chromate-based processes are being phased out due to environmental concerns.

Polishing and Buffing: Mechanical methods to improve the surface finish of metals, enhancing their luster and smoothness. This often involves different grades of abrasives and polishing compounds.

In one project, we used a combination of electroplating and powder coating to create a highly durable and aesthetically pleasing finish for exterior automotive parts, resisting corrosion and maintaining their appearance for years.

Q 21. What is your experience with automated finishing systems?

My experience with automated finishing systems includes working with and overseeing robotic spray painting systems, automated powder coating lines, and conveyorized finishing systems. This experience has given me a broad understanding of the advantages and challenges of automated finishing.

Robotic Spray Painting: These systems offer superior consistency, reduced material waste, and improved throughput compared to manual spraying. Programming and maintenance of these complex systems require specialized knowledge.

Automated Powder Coating Lines: These systems automate the entire powder coating process, from pre-treatment to curing, improving efficiency and consistency. Integrating and maintaining such lines requires a thorough understanding of process parameters.

Conveyorized Systems: These systems move parts through various finishing stages automatically, reducing manual handling and improving throughput. Managing throughput, optimizing timing, and ensuring smooth operation are key aspects of overseeing such systems.

PLC Programming and Control: In many cases, programmable logic controllers (PLCs) are used to control and monitor automated systems. My experience includes troubleshooting and programming PLCs to manage automation sequences.

The implementation of an automated powder coating line in a previous role resulted in a 30% increase in production output while simultaneously reducing material waste and improving finish consistency. These improvements highlight the benefits of well-integrated and maintained automated finishing systems.

Q 22. Describe your experience working with different types of substrates (wood, metal, plastic, etc.).

My experience spans a wide range of substrates, each demanding a unique approach to finishing. Working with wood requires understanding the grain, density, and species to select appropriate stains, sealants, and topcoats. For instance, a fine hardwood like cherry might benefit from a French polishing technique for a deep, lustrous finish, while a coarser wood like pine might require a more robust paint system to mask imperfections. Metal finishing, on the other hand, involves processes like powder coating, electroplating, or anodizing, requiring meticulous surface preparation to achieve adhesion and corrosion resistance. I’ve worked with various metals, from aluminum (requiring careful anodizing for durability and color) to steel (often powder-coated for scratch and chip resistance). Plastics present their own challenges. The type of plastic dictates the appropriate finishing method; some plastics readily accept paints, while others might require specialized primers or adhesives. I’ve successfully applied finishes to ABS, acrylic, and polycarbonate plastics, using techniques that ensure both aesthetic appeal and functional integrity.

In each case, I carefully assess the substrate’s properties and the desired outcome before selecting the most suitable finishing system. This includes considering factors like the environment the finished product will be exposed to (UV radiation, moisture, abrasion), the desired level of durability, and the aesthetic requirements.

Q 23. How do you ensure the longevity and durability of applied finishes?

Ensuring the longevity and durability of finishes requires a multi-faceted approach, beginning with proper surface preparation. This involves thorough cleaning, sanding (to achieve the correct surface profile), and often, the application of primers to enhance adhesion and provide a uniform base for the topcoat. The selection of high-quality materials is crucial. Using durable paints, lacquers, or other coatings specifically formulated for the substrate and intended application environment is essential. For example, marine-grade finishes are essential for outdoor applications to withstand UV degradation and moisture.

The application process itself is vital. Proper application techniques, such as even coats and appropriate drying times, are crucial for optimal film build and durability. Finally, post-finishing care can significantly extend the lifespan of the finish. Regular cleaning and occasional maintenance, such as reapplication of wax or sealant as needed, can protect the finish from wear and tear.

Q 24. Explain your understanding of different finishing standards and regulations.

My understanding of finishing standards and regulations encompasses a range of industry and regulatory requirements, including those relating to VOC (Volatile Organic Compound) emissions, health and safety standards, and specific industry standards for durability and performance. For example, I am familiar with ASTM (American Society for Testing and Materials) standards for various testing methods, such as adhesion, impact resistance, and UV resistance. Understanding these standards allows me to select appropriate materials and processes to ensure the final product meets the required specifications. Furthermore, I am well-versed in local and national regulations concerning hazardous waste disposal and proper handling of finishing materials. This includes understanding safety data sheets (SDS) and adhering to all workplace safety protocols.

Compliance with these regulations is not merely a matter of legal compliance; it’s a critical component of producing a high-quality, safe product. My experience ensures that the final product meets all regulatory requirements and exceeds customer expectations for quality and safety.

Q 25. How do you resolve conflicts or disagreements with colleagues in a finishing team?

Conflict resolution within a team is crucial for maintaining productivity and a positive work environment. My approach involves open and honest communication. I believe in listening to everyone’s perspective before offering solutions. I focus on finding common ground and understanding the root cause of the disagreement. For instance, if a disagreement arises concerning finishing techniques, I would advocate for a trial run to compare different approaches, allowing us to evaluate outcomes based on objective data. If personalities are involved, I try to mediate, fostering respectful dialogue and finding compromise. My goal is always to reach a mutually acceptable solution that benefits the team and the project. If the conflict persists, I’m comfortable escalating to a supervisor only after all attempts at internal resolution have been exhausted.

Q 26. Describe a time when you had to solve a complex finishing problem.

One challenging project involved finishing a batch of custom-made wooden furniture pieces with a high-gloss, piano-black finish. The client specified a flawless, mirror-like sheen, which proved extremely difficult to achieve consistently across all pieces due to variations in wood grain and porosity. The initial attempts resulted in uneven gloss and some minor imperfections. To solve this, I implemented a multi-stage process that involved meticulous surface preparation, including several rounds of sanding and filling with fine-grit materials to create a flawlessly smooth surface. I also experimented with different application techniques, ultimately adopting a combination of spraying and hand-rubbing with high-quality lacquer to achieve the desired depth and uniformity of gloss. This meticulous approach, combined with careful attention to environmental conditions (temperature and humidity) during the curing process, resulted in a consistently flawless finish that met the client’s high expectations.

Q 27. How do you stay updated on the latest advancements in finishing technologies and techniques?

Staying current in the dynamic field of finishing technologies and techniques requires proactive engagement with industry resources. I regularly read trade publications, attend industry conferences and workshops, and participate in online forums and webinars focused on surface finishing. I also maintain professional affiliations with relevant organizations to receive updates on the latest advancements. Furthermore, I actively seek out opportunities to experiment with new materials and techniques in controlled environments to evaluate their effectiveness and practicality. This constant learning ensures I’m always at the forefront of the latest developments, enabling me to leverage the most efficient and effective methods for each project.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, reflecting the market value of a highly skilled and experienced finishing professional. I’m open to discussing a competitive salary range based on the specific details of the position and the company’s compensation structure. I am more interested in a package that reflects the value I bring to the company and offers opportunities for professional growth.

Key Topics to Learn for Finishing Surfaces Interview

- Surface Preparation: Understanding different surface preparation methods (cleaning, sanding, priming) and their impact on final finish quality. Practical application: Knowing when to use different abrasives and primers based on substrate and desired finish.

- Coating Application Techniques: Mastering various application methods (spraying, brushing, rolling) and their suitability for different coatings and surfaces. Practical application: Troubleshooting common application issues like orange peel, runs, and sags.

- Finishing Materials: In-depth knowledge of different coating types (e.g., paints, varnishes, lacquers, stains) and their properties (durability, gloss level, VOC content). Practical application: Selecting appropriate materials for specific projects and understanding their limitations.

- Quality Control and Inspection: Implementing quality control measures throughout the finishing process and identifying defects. Practical application: Understanding industry standards and using appropriate inspection tools.

- Safety and Environmental Regulations: Adherence to safety protocols and environmental regulations related to finishing materials and processes. Practical application: Proper handling, storage, and disposal of hazardous materials.

- Troubleshooting and Problem Solving: Diagnosing and resolving common finishing problems, such as adhesion issues, color inconsistencies, and surface imperfections. Practical application: Applying problem-solving methodologies to identify root causes and implement effective solutions.

- Industry Standards and Best Practices: Familiarity with relevant industry standards and best practices for finishing surfaces. Practical application: Understanding and applying industry certifications and quality control systems.

Next Steps

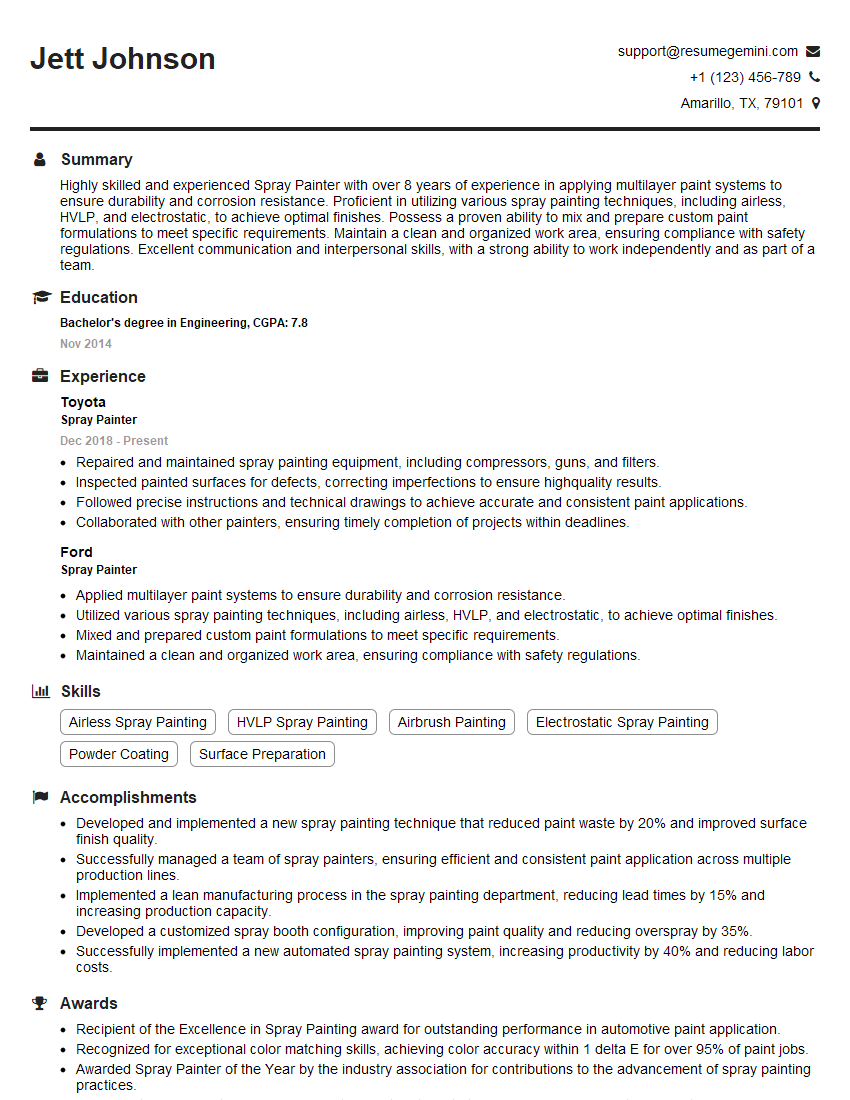

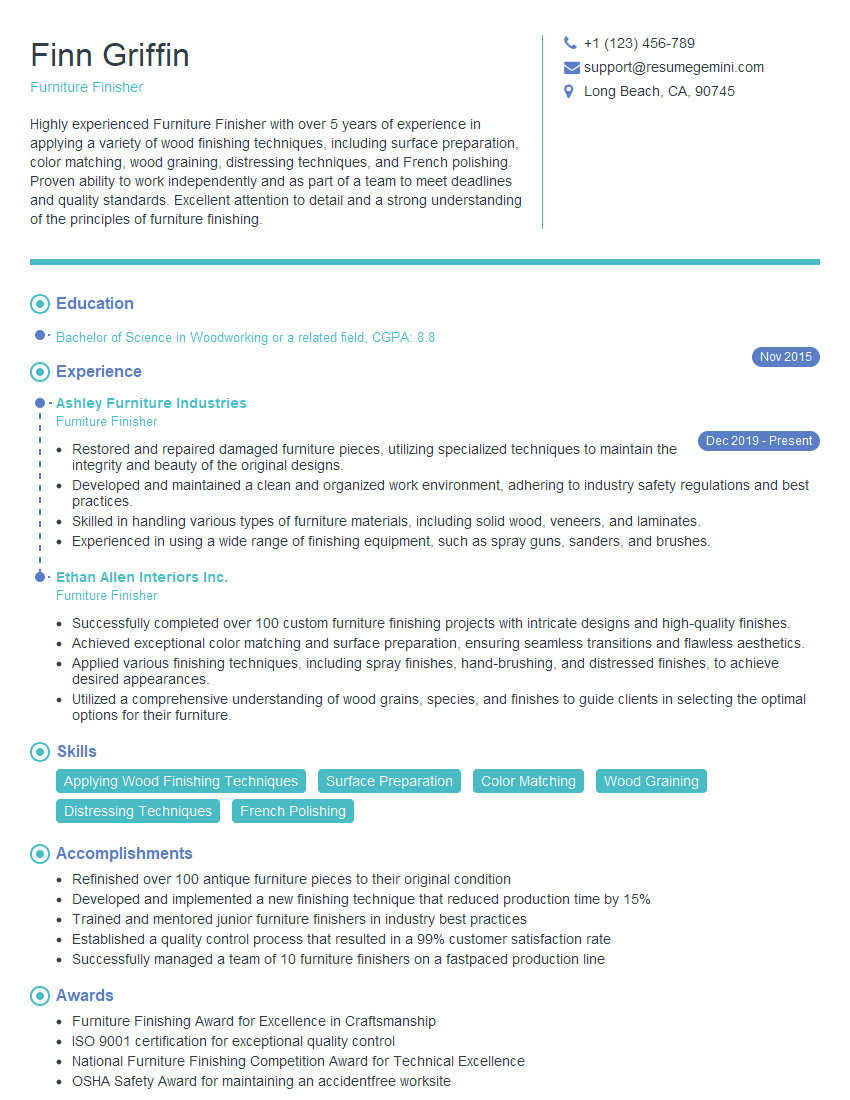

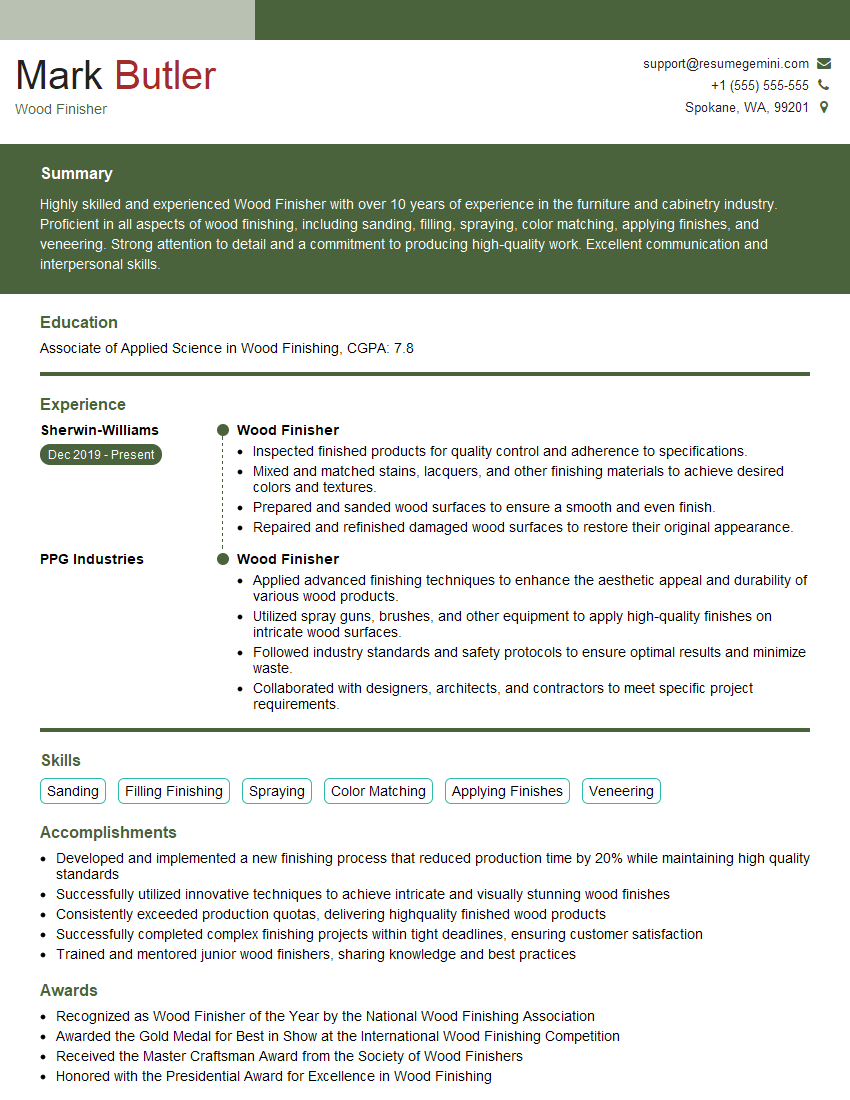

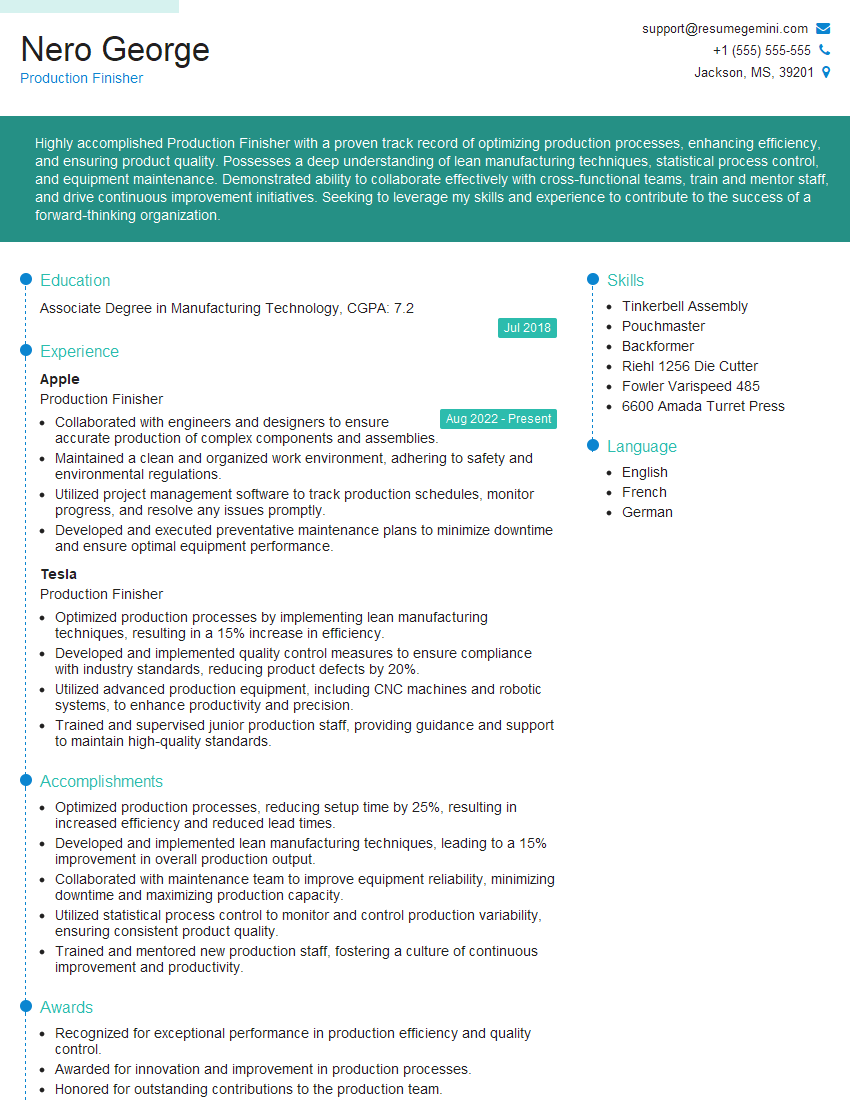

Mastering finishing surfaces techniques is crucial for career advancement in manufacturing, construction, and various other industries. A strong understanding of these processes demonstrates valuable skills and opens doors to higher-level positions and increased earning potential. To maximize your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Finishing Surfaces are available to guide you, ensuring your qualifications shine through.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good