The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Fireproofing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Fireproofing Interview

Q 1. Explain the different types of fireproofing materials and their applications.

Fireproofing materials are broadly categorized based on their composition and application methods. They’re crucial for protecting structural elements from fire damage, extending evacuation time, and preventing structural collapse.

- Intumescent Coatings: These coatings expand significantly when exposed to heat, forming a thick char layer that insulates the underlying steel. Think of it like a fire-resistant sponge that swells up. They are commonly used on steel beams, columns, and decking.

- Sprayed Fire-Resistive Material (SFRM): Often composed of cementitious or gypsum-based materials, SFRM is applied pneumatically to create a protective layer. It’s versatile, suitable for various substrates like steel, wood, and concrete. Think of it as a fire-resistant plaster.

- Fire-Resistive Boards: These prefabricated boards, usually made of gypsum or other fire-resistant materials, are attached directly to structural members. They’re often used for smaller elements or as a supplementary layer to other fireproofing methods.

- Mineral Fiber: This material, often composed of fiberglass or rock wool, offers excellent thermal insulation and fire resistance. It’s used in various applications, including firestopping and cavity filling.

- Concrete Encasement: A straightforward method, this involves completely surrounding a structural member with concrete. It provides robust fire protection, but can be heavy and may impact design aesthetics.

The choice of material depends on several factors including the type of structure, fire rating requirements, substrate material, and aesthetic considerations. For example, intumescent coatings might be preferred for exposed steelwork where aesthetics are important, while SFRM might be more suitable for large surface areas requiring cost-effective protection.

Q 2. Describe the process of installing firestop systems in different building penetrations.

Installing firestop systems in building penetrations is vital to prevent the spread of fire and smoke through openings in fire-rated assemblies. This involves carefully sealing gaps around pipes, conduits, cables, and other penetrations that pierce walls, floors, and ceilings.

The process typically involves:

- Assessment: Identifying all penetrations and determining their fire rating requirements.

- Material Selection: Choosing firestop materials suitable for the penetration type and fire rating needed (e.g., intumescent caulk, firestop putty, firestop collars, or more complex systems).

- Installation: Applying the chosen material according to the manufacturer’s instructions, ensuring complete coverage of gaps and voids. This might involve carefully packing material around cables or using specialized collars for pipes.

- Inspection: After installation, a thorough inspection is required to verify the effectiveness and completeness of the firestop system. This often involves visual inspection and sometimes specialized testing.

Different penetrations require different approaches. For example, a small cable penetration might be sealed with firestop putty, while a large pipe penetration might require a more complex system using firestop collars and sealant.

Proper installation is crucial. I once saw a project where improper installation of firestop around pipe penetrations led to significant fire spread during a test, highlighting the importance of meticulous work and adherence to manufacturer specifications.

Q 3. What are the common fireproofing code requirements and standards (e.g., NFPA, IBC)?

Fireproofing code requirements and standards ensure adequate fire protection in buildings. Key standards include the International Building Code (IBC) and the National Fire Protection Association (NFPA) codes. These codes dictate minimum fire resistance ratings for various structural elements based on their occupancy classification and function.

For example, the IBC specifies required fire resistance ratings for structural members in different occupancies. A hospital might require higher fire resistance ratings than a warehouse due to the different risks and potential consequences. NFPA standards, such as NFPA 252 (Standard Methods of Fire Tests of Building Construction and Materials), provide detailed testing procedures to determine fire resistance ratings.

These codes are enforced by local authorities through building inspections. Non-compliance can result in delays, fines, and even project shutdowns. A thorough understanding of these codes is essential for any fireproofing professional.

Q 4. How do you determine the appropriate fireproofing thickness for a given structural element?

Determining appropriate fireproofing thickness is crucial for achieving the required fire resistance rating. It’s not simply a matter of adding more material; thickness is determined by several factors:

- Fire Resistance Rating: The required fire protection duration (e.g., 1 hour, 2 hours, etc.), as specified by the building codes based on the occupancy and structural element.

- Material Properties: The specific fire-resistive properties of the chosen material, often indicated by its thermal conductivity and density. Different materials have different performance characteristics.

- Structural Element Size and Shape: Larger or more complex shapes may require greater thickness to achieve the desired fire resistance.

- Environmental Conditions: Factors like exposure to moisture or extreme temperatures can impact material performance and therefore influence thickness requirements.

Thickness calculations are often done using engineering analysis and software, considering the above factors and comparing results against fire test data for similar applications. Manufacturers usually provide guidance based on material properties and intended use, but professional engineering judgment is essential.

For instance, a steel column with a required 2-hour fire rating might need a significantly thicker layer of SFRM compared to a beam with a 1-hour rating, considering factors like their respective surface areas and the material properties of the selected SFRM.

Q 5. What are the safety precautions involved in applying fireproofing materials?

Applying fireproofing materials involves several safety precautions. These materials can be hazardous if mishandled, and appropriate safety measures are mandatory.

- Respiratory Protection: Many fireproofing materials produce dust or fumes that can be harmful. Respirators are necessary to prevent inhalation of these particles.

- Eye Protection: Safety glasses or goggles are essential to shield the eyes from dust, splashes, and other debris.

- Skin Protection: Protective clothing such as coveralls, gloves, and boots are critical to prevent skin irritation or exposure to harmful substances. Some materials can cause skin irritation or allergic reactions.

- Fall Protection: When working at heights, proper fall protection measures such as harnesses and safety lines are essential.

- Proper Ventilation: Adequate ventilation is crucial when applying sprayed fire-resistive materials to remove dust and fumes.

- Material Safety Data Sheets (MSDS): Reviewing the MSDS for each material is critical to understanding its hazards and handling precautions.

Ignoring safety precautions can lead to serious health consequences or even accidents. A proactive approach to safety is paramount during every stage of fireproofing application.

Q 6. How do you inspect and maintain fireproofing systems to ensure their effectiveness?

Regular inspection and maintenance of fireproofing systems are crucial to ensure their continued effectiveness. Over time, fireproofing can be damaged by various factors such as impact, moisture, or deterioration.

The inspection process typically involves:

- Visual Inspection: A thorough visual examination to detect any damage, cracking, spalling, or deterioration of the fireproofing material.

- Thickness Measurement: Measuring the thickness of the fireproofing at various points to verify that it meets the required specifications. This may require specialized instruments.

- Testing: In some cases, destructive or non-destructive testing might be necessary to assess the material’s integrity and fire resistance properties.

Maintenance might include repairing damaged areas by removing and reapplying fireproofing material, addressing moisture intrusion, or cleaning surfaces to remove dust and debris. A documented inspection and maintenance program is essential for ensuring long-term performance and compliance with building codes.

Neglecting maintenance can significantly compromise the fire protection provided by the system. Regular inspections help identify issues early on, allowing for timely repairs and preventing larger, more expensive problems down the line.

Q 7. Explain the concept of passive fire protection.

Passive fire protection refers to the structural and material elements designed to prevent or resist the spread of fire and smoke without any active intervention or human operation. It’s the foundation of fire safety and acts as the first line of defense against fire.

Examples of passive fire protection include:

- Fire-resistant walls and floors: These are designed to restrict the passage of fire and smoke for a specified period.

- Fire doors and dampers: These automatically close to prevent fire spread through openings.

- Fireproofing of structural elements: As discussed earlier, protecting steel and wood elements from fire damage prevents structural collapse.

- Compartmentalization: Dividing a building into separate fire-resistant compartments to limit the spread of fire.

- Smoke control systems: Passive measures like smoke vents and smoke barriers aid in natural smoke evacuation.

Passive fire protection works in conjunction with active fire protection systems, such as sprinklers and fire alarms, to provide a complete fire safety strategy. The goal is to contain fire, provide escape time, and limit property damage. It is crucial for building design and safety.

Q 8. What are the limitations and potential failures of different fireproofing methods?

The effectiveness of fireproofing methods hinges on several factors, and failures can stem from various issues. Let’s consider some common limitations and potential failure points:

- Spray-applied fire-resistive materials (SFRMs): These can fail due to improper mixing, application inconsistencies (resulting in thin areas or voids), damage during construction, or inadequate surface preparation. For instance, if the substrate isn’t clean and properly profiled, the SFRM won’t adhere correctly, compromising its fire-resistant properties. Another common problem is over-application, leading to cracking and spalling.

- Intumescent coatings: These expand when exposed to heat, creating an insulating char layer. Failures can arise from inadequate thickness, incompatibility with the substrate, or exposure to moisture before the coating fully cures. Think of it like a poorly baked cake – if the ingredients aren’t properly combined or the baking process is flawed, it won’t rise correctly.

- Fire-resistant boards and blankets: These materials can be damaged by mechanical impacts, improper installation (e.g., gaps between boards), or exposure to excessive moisture. Similar to insulation in your home, if the boards aren’t properly fitted, they won’t provide the intended thermal protection.

- Encapsulated systems: These systems, often used for steel columns and beams, can fail if the protective layer is compromised or if the integrity of the encapsulation is damaged. Think of it like a protective shell around a vulnerable component; any breach compromises the entire system.

Regular inspections and maintenance are crucial to identify and address potential weaknesses before they become major failures.

Q 9. How do you address fireproofing challenges in complex building designs?

Addressing fireproofing in complex designs requires a multifaceted approach, blending meticulous planning with advanced techniques. Here’s how we tackle these challenges:

- 3D Modeling and Coordination: We utilize Building Information Modeling (BIM) to visualize the building’s structure and plan fireproofing application in detail. This allows us to anticipate potential conflicts and optimize material placement.

- Specialized Access Equipment: Complex geometries often demand specialized equipment like scaffolding, aerial lifts, and robotic spraying systems to ensure thorough and safe application.

- Modular Fireproofing Systems: For intricate structures, prefabricated fireproofing components can streamline installation and improve accuracy. This is particularly useful for high-rise projects or where tight deadlines are crucial.

- Phased Approach: We often employ a phased approach, focusing on sections of the building sequentially. This helps manage material handling and access, especially in densely populated spaces.

- Collaboration with Other Trades: Close coordination with other trades such as structural steel fabricators, electricians, and plumbers is vital to ensure that fireproofing doesn’t impede their work or vice versa. This often involves detailed clash detection and resolution using BIM software.

By combining advanced technology with careful planning and a collaborative approach, we can effectively manage fireproofing in even the most challenging architectural designs.

Q 10. Describe the different types of fire-resistant coatings and their properties.

Fire-resistant coatings vary considerably in their composition and properties. Here are some common types:

- Intumescent Coatings: These expand when exposed to heat, forming a thick char layer that insulates the underlying substrate. They are often water-based and environmentally friendly.

- Cementitious Coatings: These are made from a mixture of cement, aggregates, and other additives. They offer good strength and durability but can be heavier than other options and are less aesthetically pleasing.

- Acrylic Coatings: These are polymer-based coatings that provide a decorative finish while offering fire resistance. They are typically thinner than cementitious coatings and easier to apply.

- Epoxy Coatings: Offering exceptional adhesion and chemical resistance, epoxy coatings provide a robust barrier against fire and corrosion. They’re often chosen for industrial applications.

- Mineral Fiber Coatings: These coatings, composed of fibers like fiberglass or rockwool, offer excellent thermal insulation and fire protection.

The choice of coating depends on several factors, including the substrate material, the required fire rating, the environmental conditions, and aesthetic considerations. For example, an intumescent coating might be preferred for steel structures needing a high fire rating and aesthetic appeal, while a cementitious coating might be better suited for concrete columns needing extra strength and durability.

Q 11. What are the environmental considerations associated with fireproofing materials?

Environmental concerns are increasingly important in the selection and use of fireproofing materials. Key considerations include:

- Toxicity: Some fireproofing materials contain hazardous substances that can release toxic fumes during a fire. The use of low-VOC (volatile organic compound) coatings is a significant advancement addressing these concerns.

- Waste Generation: Fireproofing projects generate significant waste, demanding careful management and disposal procedures in compliance with environmental regulations. Recyclable materials are preferred wherever possible.

- Air Quality: The application process can release dust and fumes, necessitating appropriate ventilation and personal protective equipment (PPE) for workers to minimize air pollution.

- Long-Term Environmental Impact: The lifespan and eventual disposal of fireproofing materials must be considered. Materials with low environmental impact throughout their entire lifecycle are becoming increasingly important.

- Water Usage: Some fireproofing application methods require significant water consumption. Employing water-efficient techniques can reduce the environmental footprint of the project.

Sustainable and environmentally friendly alternatives are gaining popularity, such as bio-based materials and coatings with lower embodied carbon.

Q 12. How do you ensure compliance with relevant regulations and standards during a fireproofing project?

Ensuring compliance is paramount. We adhere to a rigorous process:

- Code Review: We thoroughly review all applicable building codes and standards (e.g., IBC, NFPA) to determine the required fire protection levels for different building elements.

- Material Selection: We select fireproofing materials that meet or exceed the specified requirements and have relevant certifications and test reports (e.g., UL listings, FM approvals).

- Detailed Specifications: Precise specifications are developed to guide the application process, including material quantities, application methods, and quality control procedures.

- Qualified Personnel: We utilize only trained and certified applicators with experience in handling and applying specific fireproofing materials.

- Quality Control Inspections: Rigorous inspections are conducted throughout the project, including during and after application, to ensure compliance with specifications and codes. This may include thickness measurements, visual inspections for defects, and sampling for laboratory testing.

- Documentation: Detailed records of materials used, application procedures, and inspection results are meticulously maintained for future reference and audit trails.

Proactive compliance reduces risks, avoids costly rework, and ensures the building’s safety.

Q 13. Describe your experience with fireproofing testing and inspection procedures.

My experience in fireproofing testing and inspection is extensive. I’ve overseen numerous projects involving:

- In-situ testing: This involves measuring the thickness and density of the applied fireproofing using calibrated instruments, ensuring it meets the specified requirements. This also frequently includes visual inspections to check for any damage or irregularities.

- Laboratory testing: Samples of fireproofing materials are sent to accredited laboratories for testing their fire resistance according to relevant standards. This involves exposing samples to controlled fire conditions and assessing their performance.

- Third-party inspections: We frequently engage third-party inspectors to independently verify compliance with codes and specifications. This adds a layer of objectivity and ensures that the fireproofing meets the highest standards.

- Thermal imaging: Thermal imaging cameras can detect thermal anomalies, identifying areas with potential deficiencies in the fireproofing application or possible damage.

By combining various testing and inspection methods, we ensure that the fireproofing system performs as designed and provides the intended level of protection.

Q 14. Explain the importance of proper surface preparation before applying fireproofing materials.

Proper surface preparation is critical; it’s the foundation upon which the entire fireproofing system rests. Think of it as preparing a canvas before painting a masterpiece; a flawed base undermines the final product.

- Cleaning: The substrate must be thoroughly cleaned to remove loose materials, dust, oil, grease, and other contaminants that could impair adhesion. This often involves methods like wire brushing, sandblasting, or high-pressure washing, depending on the substrate and the level of contamination.

- Profiling: For some materials, creating a profile on the surface (creating texture) increases surface area and improves adhesion. This is especially important for spray-applied fireproofing.

- Repairing Defects: Any cracks, holes, or other defects in the substrate must be repaired before applying fireproofing materials. This ensures a uniform and continuous protective layer.

- Moisture Control: The substrate must be dry to prevent delamination and other failures. Moisture meters are often used to verify that the substrate meets the required dryness criteria.

- Priming (When Necessary): In some cases, a primer coat is applied to improve adhesion and ensure compatibility between the substrate and the fireproofing material.

Failure to adequately prepare the surface invariably leads to premature failure of the fireproofing system, compromising the structural integrity and safety of the building. This can result in costly repairs or replacements, not to mention the potential safety risks.

Q 15. What are the common causes of fireproofing failures and how can they be prevented?

Fireproofing failures stem from various issues, often preventable with diligent planning and execution. Common causes include improper material selection (using a product unsuitable for the specific application or environmental conditions), inadequate application (incorrect thickness, uneven coverage, or damage during construction), and insufficient training of applicators (leading to mistakes in mixing, spraying, or troweling). Poor design, neglecting potential thermal bridging, or failing to account for environmental factors like humidity also contribute. Prevention involves:

- Careful Material Selection: Thorough review of building codes and specifications to select the appropriate fireproofing material for the structural member’s type and fire rating requirements. Consider factors like temperature exposure, potential chemical interactions, and anticipated environmental conditions.

- Stringent Application Practices: Adherence to manufacturer’s specifications and industry best practices. This includes precise measurement of material quantities, proper mixing, consistent application thickness, and careful attention to detail, minimizing gaps or thin spots. Regular quality checks throughout the application process are critical.

- Comprehensive Training: Ensuring applicators are fully trained and certified on the correct application techniques for the chosen fireproofing materials. Regular refresher courses and on-site supervision by experienced professionals help maintain a high standard of work.

- Thorough Design and Planning: Integrating fireproofing into the design process from the outset, considering potential conflicts with other building systems and addressing areas prone to thermal bridging. A well-coordinated plan ensures that fireproofing isn’t compromised during other construction phases.

- Regular Inspections: Periodic inspections throughout construction and post-construction to detect any damage or deterioration. This allows for timely repair and prevents small problems from becoming major failures.

For instance, on a recent project, a failure was traced back to inadequate training of the applicators. By implementing a rigorous training program and increased on-site supervision, we prevented similar failures on subsequent projects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage project timelines and budgets in fireproofing projects?

Managing project timelines and budgets in fireproofing requires meticulous planning and proactive management. We begin by developing a detailed project schedule using techniques like critical path method (CPM) to identify tasks that are critical to completing the project on time. This schedule accounts for material delivery times, applicator availability, and potential weather delays. The budget is established by factoring in material costs, labor costs, equipment rental, and contingency funds for unforeseen circumstances. Regular monitoring of both time and cost is essential, using tools like earned value management (EVM) to track progress against the baseline plan. Early detection of variances allows for timely corrective actions, preventing significant cost overruns or project delays.

For instance, on a high-rise project, we implemented a phased approach to fireproofing, allowing for parallel work streams and optimizing the use of resources. This resulted in considerable time and cost savings compared to a traditional sequential approach.

Q 17. How do you handle conflicts or disagreements with other contractors on a construction site?

Conflicts are inevitable on complex construction sites. My approach focuses on proactive communication and collaboration. I believe in open dialogue, ensuring all parties understand each other’s perspectives and concerns. We start by clearly defining roles and responsibilities in a pre-construction meeting, establishing clear lines of communication and escalation procedures. If disagreements arise, I facilitate a collaborative problem-solving process, involving all stakeholders to reach a mutually agreeable solution. Documenting all agreements and decisions is critical for clarity and accountability. If informal resolution fails, we involve the project manager or construction manager to mediate. We always prioritize the safety and integrity of the fireproofing system and the overall project.

In one instance, a disagreement arose with the mechanical contractor regarding access to areas required for fireproofing. Through open communication and collaboration, we developed a schedule that minimized disruption for both teams, ensuring that neither party’s work was unduly impacted.

Q 18. Describe your experience with different fireproofing application methods (e.g., spray-applied, trowel-applied).

I have extensive experience with various fireproofing application methods. Spray-applied fireproofing, typically cementitious or intumescent, is suitable for large surface areas and offers good coverage. It requires specialized equipment and skilled applicators to ensure uniform thickness and avoid voids. Trowel-applied fireproofing, commonly used with cementitious materials, provides excellent control over thickness and is well-suited for intricate detailing. However, it’s more labor-intensive and can be less efficient for large-scale projects. I’ve also worked with other methods such as board-applied, wrap-around systems, and loose-fill insulation. Material selection and application method depend heavily on the substrate, fire rating requirements, and aesthetic considerations.

For example, I managed a project where spray-applied fireproofing was crucial for covering large steel columns efficiently. However, for complex structural components, we employed trowel-applied material to ensure precise coverage.

Q 19. What is your experience with intumescent coatings and their application?

Intumescent coatings are a specialized fireproofing system that expands significantly upon exposure to heat, creating a char layer that insulates the underlying substrate. My experience includes the application of various intumescent coatings, such as water-based and solvent-based formulations, for different substrates like steel and concrete. Proper surface preparation is paramount for effective adhesion. Application often involves multiple coats, with careful attention to achieving the required dry film thickness as specified by the manufacturer. Proper curing time is also vital to ensure complete performance. We utilize specialized equipment such as airless sprayers and rollers to apply intumescent coatings, depending on the project’s scale and complexities. Thorough quality control measures throughout the application process, including inspections for pinholes, thin spots, and runs, are essential for ensuring the coating’s effectiveness.

In a recent project, using a high-performance intumescent coating allowed us to achieve the necessary fire rating while maintaining a sleek aesthetic finish, reducing the need for additional cladding.

Q 20. How do you ensure the quality control of fireproofing work?

Quality control is paramount in fireproofing. Our approach involves multiple checks throughout the process: from material inspection upon delivery, to ensuring proper mixing ratios and application techniques during the application phase, and finally, post-application inspections using techniques like thickness gauging, visual inspections, and, in some cases, destructive testing (core sampling). We maintain meticulous documentation of all inspections, including photographs and test results. We also regularly calibrate our equipment to ensure accuracy. Compliance with relevant codes and standards, like NFPA 252, is paramount. Furthermore, we frequently conduct independent third-party inspections to ensure that our work meets the highest quality standards and provides the necessary level of fire protection.

In one project, a routine thickness check revealed an area with insufficient fireproofing. Early detection allowed for prompt correction, preventing potential fire safety issues.

Q 21. Explain your understanding of fire spread dynamics and how fireproofing impacts them.

Understanding fire spread dynamics is fundamental to effective fireproofing. Fire spreads through three key mechanisms: conduction (heat transfer through direct contact), convection (heat transfer through movement of hot gases), and radiation (heat transfer through electromagnetic waves). Fireproofing primarily works by interrupting these mechanisms. Insulating materials, such as cementitious and intumescent coatings, slow down heat transfer through conduction. They also help to prevent or reduce the formation of flammable gases which reduces heat transfer through convection. The char layer formed by intumescent coatings helps to reduce radiant heat transfer. By controlling the rate of heat transfer, fireproofing extends the time it takes for structural members to reach critical temperatures, allowing for safe evacuation and firefighter intervention. The effectiveness of fireproofing depends on several factors, including the type of material, application thickness, and the specific fire scenario.

For example, in a scenario involving a compartmentalized fire, fireproofing can effectively contain the fire within that area, preventing its rapid spread to other sections of the building. Understanding these dynamics informs the design and application of fireproofing systems to effectively mitigate fire risks.

Q 22. What are the different types of fire barriers and their functions?

Fire barriers are passive fire protection systems designed to compartmentalize a building, restricting the spread of fire and smoke. They come in various types, each serving a specific function. Think of them as fire walls within a building, creating separate zones of safety.

- Fire Walls: These are continuous vertical fire-resistant barriers extending from the foundation to the roof, completely separating different parts of a building. They’re like massive firebreaks, ensuring that a fire in one section won’t easily spread to another. For example, a fire wall might separate a high-rise apartment building’s wings.

- Fire Partitions: Similar to fire walls but don’t extend from the foundation to the roof. They are often used to separate occupancies within a single floor of a building. Imagine a fire partition separating a retail space from an office space within a shopping mall.

- Fire Doors: These are self-closing doors with a fire-resistance rating, preventing fire spread between rooms or compartments. We encounter these regularly in corridors and exits of many buildings.

- Fire Dampers: These are automatically closing valves installed in ductwork to prevent the spread of fire and smoke through ventilation systems. These are critical in preventing the rapid spread of fire through air channels. They’re often hidden but vital for fire safety.

- Fire Stops: These are materials or assemblies designed to prevent the spread of fire through penetrations in fire-rated walls or floors, such as cable openings or pipe runs. Think of them as fire-resistant plugs for holes in fire barriers.

Q 23. How do you interpret and apply fireproofing specifications and drawings?

Interpreting fireproofing specifications and drawings requires a meticulous approach. I start by reviewing the project specifications, which detail the required fire-resistance ratings for different building elements. This usually involves understanding the specific building codes and standards applicable to the location. The drawings then show the exact location and extent of the required fireproofing. It’s crucial to pay close attention to the details, including material types, thicknesses, and application methods. For example, a drawing might specify a 2-hour fire rating for a steel column, requiring a specific type and thickness of intumescent coating. Misinterpretation can lead to significant safety issues.

Once I understand the specifications and drawings, I develop a detailed fireproofing plan, including material selection, quantities, and installation procedures. I then coordinate with other trades to ensure compatibility and avoid conflicts. The plan is often iterative, with adjustments made based on site conditions and any unforeseen challenges that arise.

Q 24. What is your experience with fire-rated assemblies?

I have extensive experience with fire-rated assemblies, which are pre-engineered systems designed to meet specific fire-resistance requirements. This involves working with a variety of systems, including steel and wood framing, wall assemblies, floor/ceiling assemblies, and roof systems. For example, I’ve worked on projects requiring fire-rated floor assemblies for multi-story buildings. This necessitates selecting the correct combination of concrete, decking, and fireproofing materials to achieve the specified rating, ensuring proper installation to maintain the integrity of the assembly during a fire.

My experience extends to testing and verification of fire-rated assemblies. I have been involved in several projects that require witness testing to confirm the fire-resistance rating of specific assemblies according to established standards like ASTM E119. These tests help to validate the designs and ensure compliance with building codes.

Q 25. Describe your experience in working with different types of building materials in relation to fireproofing.

My experience encompasses a wide range of building materials and their fireproofing requirements. I’m comfortable working with steel, concrete, wood, and various composite materials. For instance, steel structures often require the application of intumescent coatings or cementitious fireproofing materials to achieve the necessary fire-resistance rating. These materials expand upon heating, creating an insulating layer and protecting the steel from high temperatures. Concrete itself offers inherent fire resistance but might require additional fireproofing in certain applications. Wood framing often requires fire-retardant treatment or protective wraps.

Choosing the right fireproofing material depends on the material being protected, its fire-resistance requirements, the building’s environment, and aesthetic considerations. For example, a spray-applied cementitious fireproofing might be ideal for steel columns in a warehouse setting, while a thinner, aesthetically pleasing intumescent coating could be preferred for exposed steel beams in an office building.

Q 26. How do you handle unexpected issues or problems during fireproofing installation?

Unexpected issues during fireproofing installation are common. My approach involves a proactive problem-solving strategy. First, I carefully assess the issue to understand its root cause. This might involve conducting additional site inspections, consulting with engineers, or testing the affected materials. For example, discovering unexpected structural steel members not shown on the drawings would require immediate adjustments to the fireproofing plan.

After thorough assessment, I develop a solution that addresses the problem while maintaining compliance with fire safety regulations. This often involves collaborating with the project team, including architects, engineers, and contractors, to find the most practical and effective solution. Documentation of these adjustments is critical for maintaining a clear project record.

Q 27. Explain your experience with fireproofing repairs and maintenance.

Fireproofing repairs and maintenance are crucial for long-term fire safety. My experience in this area includes identifying damaged or deteriorated fireproofing, assessing the extent of the damage, and implementing appropriate repair strategies. This might involve removing and replacing damaged sections, applying additional coatings, or making structural repairs to underlying members. Regular inspections are vital for early detection of issues, such as cracks, delamination, or corrosion, preventing larger, more costly repairs later.

For example, a fireproofing inspection might reveal corrosion on a steel column due to moisture damage. This requires addressing the source of moisture, removing the affected fireproofing, and applying a new protective coating to the cleaned and prepared steel.

Q 28. What are your knowledge and experience with the latest advancements in fireproofing technology?

The fireproofing industry is constantly evolving. I stay abreast of the latest advancements through industry publications, professional development courses, and participation in industry events. Recent advancements include the development of more environmentally friendly fireproofing materials, with reduced VOC emissions and improved sustainability. There’s also significant progress in materials with enhanced performance characteristics, such as higher fire resistance ratings with reduced thickness, improving the efficiency of fire protection systems.

Innovative application techniques are also emerging, such as robotic spray application for greater precision and efficiency. These advancements are constantly reshaping how fire protection systems are designed, installed, and maintained, resulting in safer and more sustainable structures.

Key Topics to Learn for Your Fireproofing Interview

- Fire Resistance Ratings & Codes: Understanding different fire resistance ratings (e.g., ASTM E-119) and relevant building codes is crucial. Be prepared to discuss how these ratings are determined and applied.

- Types of Fireproofing Materials: Become familiar with various fireproofing materials, including sprayed-on fire-resistant materials (SFRM), intumescent coatings, fire-resistant board, and cementitious materials. Know their properties, applications, and limitations.

- Application Techniques & Best Practices: Thorough knowledge of proper application techniques for different materials is essential. This includes surface preparation, mixing ratios, application methods, and quality control procedures.

- Safety Regulations & Procedures: Demonstrate a strong understanding of relevant safety regulations and procedures for handling fireproofing materials and working at heights. This includes PPE requirements and hazard identification.

- Inspection & Testing Methods: Familiarize yourself with common inspection and testing methods used to ensure the integrity and effectiveness of fireproofing systems. This includes visual inspections, non-destructive testing, and fire testing.

- Troubleshooting & Problem-Solving: Be ready to discuss common problems encountered during fireproofing projects and how to effectively troubleshoot and resolve them. This could involve dealing with material defects, surface imperfections, or environmental factors.

- Sustainability & Environmental Considerations: Demonstrate awareness of environmentally friendly fireproofing materials and practices. Discuss the impact of fireproofing on building sustainability.

Next Steps: Ignite Your Career in Fireproofing

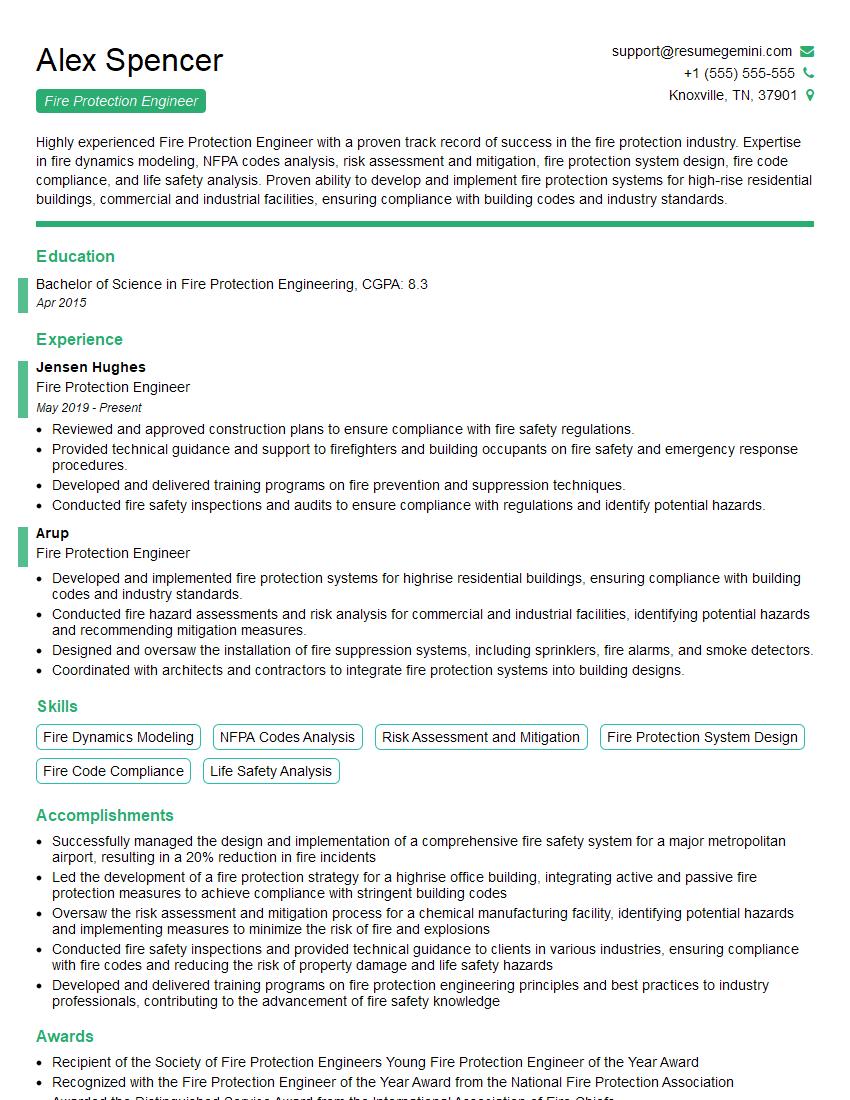

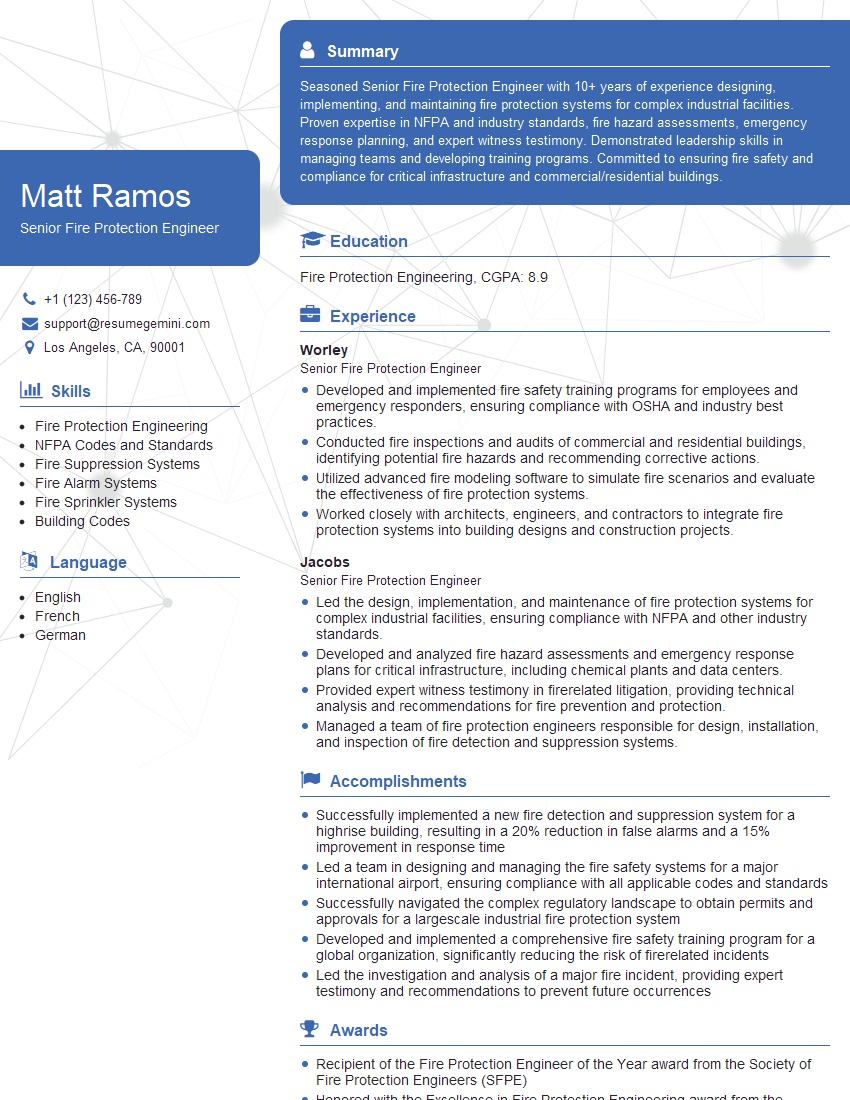

Mastering fireproofing knowledge opens doors to exciting career opportunities and growth within the construction and safety industries. To maximize your job prospects, crafting a strong, ATS-friendly resume is paramount. ResumeGemini can help you create a professional and impactful resume that highlights your skills and experience effectively. We offer examples of resumes tailored specifically to the fireproofing field to guide you in creating a winning application. Take the next step towards your dream career—start building your exceptional resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good