Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Flow Control and Optimization interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Flow Control and Optimization Interview

Q 1. Explain the difference between open-loop and closed-loop control systems.

The core difference between open-loop and closed-loop control systems lies in their feedback mechanisms. An open-loop system operates without feedback; it simply executes a pre-programmed action without considering the actual outcome. Think of a toaster: you set the timer, and it runs for that duration regardless of whether the bread is perfectly toasted. The system doesn’t monitor the toast’s condition.

In contrast, a closed-loop system, also known as a feedback control system, uses feedback to continuously monitor and adjust its output. This feedback loop allows the system to correct for errors and maintain a desired setpoint. A thermostat is a classic example; it measures the room’s temperature and adjusts the heating or cooling accordingly to maintain a target temperature. It constantly checks the actual temperature against the desired temperature and adjusts its output to minimize the difference.

In essence, open-loop systems are simpler but less accurate and robust, while closed-loop systems are more complex but provide precise control and adapt to disturbances more effectively.

Q 2. Describe different flow control strategies (e.g., PID, cascade, feedforward).

Several flow control strategies are used, each with its strengths and weaknesses. Let’s explore a few:

- Proportional-Integral-Derivative (PID) Control: This is the workhorse of flow control, widely used for its versatility. It uses three terms to adjust the control output: Proportional (responds to the current error), Integral (addresses accumulated error over time), and Derivative (predicts future error based on the rate of change). The tuning of these parameters (Kp, Ki, Kd) is crucial for optimal performance.

- Cascade Control: This strategy employs a hierarchy of controllers. A primary controller manages a primary variable (e.g., flow rate), while a secondary controller regulates a secondary variable that significantly affects the primary variable (e.g., pressure). Imagine a system where precise flow is required. The secondary controller manages the valve opening pressure to ensure steady, reliable flow, improving the accuracy of the primary controller.

- Feedforward Control: This anticipatory approach uses measured disturbances to predict their impact on the controlled variable and proactively adjusts the output accordingly. This is useful for known disturbances, like changes in feedstock temperature, that can be measured before they affect the flow. The system anticipates the impact of the disturbance and adjusts to compensate in advance.

The choice of strategy depends on factors such as the process dynamics, disturbance characteristics, and the desired level of control accuracy.

Q 3. What are the key performance indicators (KPIs) used to evaluate flow control systems?

Key performance indicators (KPIs) for evaluating flow control systems include:

- Setpoint Tracking: How closely the system maintains the desired flow rate.

- Response Time: How quickly the system reacts to changes in setpoint or disturbances.

- Overshoot: The extent to which the flow rate exceeds the setpoint before settling.

- Stability: Whether the system remains stable and avoids oscillations.

- Offset: The steady-state difference between the actual and desired flow rate.

- Control Effort: The amount of manipulation needed from the control element (e.g., valve).

These KPIs are often analyzed graphically using plots like step responses or frequency responses. They provide quantitative measures for assessing the efficiency and effectiveness of a control system.

Q 4. How do you handle process disturbances in a flow control system?

Process disturbances are inevitable in real-world flow control systems. Handling them effectively requires a multi-faceted approach:

- Robust Control Design: Designing a control system that is inherently insensitive to variations and disturbances is crucial. This often involves selecting appropriate control strategies (like PID with carefully tuned parameters or feedforward control) and employing advanced control techniques.

- Feedback Control: Closed-loop systems with effective feedback mechanisms are essential for detecting and compensating for disturbances. The feedback signal continuously compares the actual value to the setpoint, allowing for corrective actions.

- Disturbance Feedforward: If the disturbances can be measured or predicted, feedforward control can anticipate and compensate for their effect before they impact the controlled variable.

- Adaptive Control: For systems with significant or unpredictable disturbances, adaptive control adjusts the controller parameters online to maintain optimal performance.

The specific approach depends on the nature and frequency of disturbances encountered. Often, a combination of these techniques is employed.

Q 5. Explain the concept of process gain and its importance in control system design.

Process gain quantifies the change in the output variable caused by a unit change in the input variable. In flow control, it represents the relationship between the valve position (input) and the resulting flow rate (output). A high process gain implies a large change in flow rate for a small change in valve position, and vice versa.

Its importance in control system design stems from its impact on controller tuning. High process gain requires more cautious controller tuning to avoid instability, while low gain might result in sluggish response. Understanding the process gain allows engineers to choose the appropriate control strategy and tune the controller parameters effectively for optimal performance and stability. It’s often determined experimentally through step tests or calculated from process models.

Q 6. Describe different types of controllers (e.g., proportional, integral, derivative).

PID controllers are composed of three fundamental control actions:

- Proportional (P): The controller output is proportional to the error (difference between setpoint and measured value). A larger error leads to a larger corrective action.

Output = Kp * Error, where Kp is the proportional gain. - Integral (I): Addresses persistent errors by accumulating the error over time. This eliminates offset (steady-state error) but can cause overshoot if not tuned carefully.

Output = Ki * ∫Error dt, where Ki is the integral gain. - Derivative (D): Anticipates future error by considering the rate of change of the error. It helps to reduce overshoot and improve the speed of response.

Output = Kd * d(Error)/dt, where Kd is the derivative gain.

Each term contributes to the overall control action, with the optimal balance depending on the specific process characteristics. A purely proportional controller might have a persistent offset, while a purely integral controller might be slow and oscillatory.

Q 7. What are the limitations of PID controllers?

Despite their widespread use, PID controllers have some limitations:

- Tuning Complexity: Finding the optimal PID gains (Kp, Ki, Kd) can be challenging and often requires iterative tuning procedures. Different processes require different tuning methods.

- Non-linear Processes: PID controllers are fundamentally linear; their effectiveness can decrease when dealing with processes that exhibit significant non-linear behavior. For example, if the process response is significantly different at varying flow rates.

- Disturbance Rejection Limitations: While PID controllers can handle disturbances, their effectiveness is limited, particularly for unpredictable or large disturbances. Advanced control strategies may offer better performance in such situations.

- Sensitivity to Noise: The derivative action is particularly sensitive to noise in the measurement signal, which can lead to erratic control actions. Filtering techniques are often necessary to mitigate this issue.

These limitations highlight the need for careful consideration of process dynamics and the potential benefits of more advanced control strategies when dealing with complex or demanding applications.

Q 8. How do you tune a PID controller for optimal performance?

Tuning a PID (Proportional-Integral-Derivative) controller involves adjusting its three parameters – Proportional (Kp), Integral (Ki), and Derivative (Kd) – to achieve optimal performance. Optimal performance means minimizing the error between the desired setpoint and the actual process variable, while also ensuring stability and minimizing overshoot and oscillations. Think of it like steering a car: Kp is like your immediate steering response, Ki corrects for long-term drift, and Kd smooths out sudden bumps in the road.

There are several methods for PID tuning, each with its strengths and weaknesses. The Zeigler-Nichols method is a simple, empirical approach that involves pushing the system to its limits to determine the ultimate gain and period. This method is quick but can be less precise. More sophisticated techniques like the Cohen-Coon method or auto-tuning algorithms offer greater accuracy but require more system knowledge.

A common approach is to start with a small Kp, a small Ki and an even smaller Kd, then gradually increase Kp until the system starts to oscillate. Note the oscillation frequency and amplitude. Then reduce Kp slightly to dampen the oscillations, adjust Ki to address steady state error, and fine-tune Kd to reduce overshoot and improve response speed. This iterative process involves observing the system’s response and making adjustments until the desired performance is achieved. It’s often helpful to use visualization tools to monitor the process and see the effects of your adjustments in real-time.

For example, in a temperature control system, a poorly tuned PID might lead to significant temperature swings, while a well-tuned controller maintains a stable temperature close to the setpoint with minimal overshoot.

Q 9. Explain the concept of stability in a control system.

Stability in a control system refers to the system’s ability to return to its equilibrium state after a disturbance. An unstable system will exhibit runaway behavior, increasingly deviating from its setpoint, potentially leading to damage or failure. Imagine a balancing act: a stable system is like a perfectly balanced object that, even when slightly disturbed, quickly returns to its balanced position. An unstable system is like a teeter-totter that, once pushed, keeps tilting further and further.

Stability is often analyzed using techniques like Bode plots and Nyquist plots, which examine the system’s frequency response. Key concepts include gain margin and phase margin, which indicate the system’s tolerance to gain changes and phase shifts before instability occurs. A stable system will have positive gain and phase margins.

Mathematically, stability is often assessed by analyzing the system’s characteristic equation. If all the roots of the characteristic equation have negative real parts, the system is stable. Roots with positive real parts indicate instability.

Q 10. What are some common causes of instability in flow control systems?

Instability in flow control systems can stem from several sources:

- Non-linearities: Flow systems often exhibit non-linear behavior, such as friction, valve hysteresis, or changes in fluid properties with temperature or pressure. These can make linear control techniques ineffective.

- Time delays: Delays in sensor readings, actuator response, or fluid transport can introduce instability. A delay means the controller is reacting to old information, potentially leading to over-correction.

- Unmodeled dynamics: The control system model might not fully capture the complexities of the real system, such as leaks, blockages, or variations in fluid properties.

- Improper tuning: As discussed earlier, incorrect PID parameters can lead to oscillations and instability.

- Disturbances: External factors such as changes in inlet pressure or temperature can perturb the system and trigger instability if the controller is not robust enough.

- Sensor or actuator failures: Faulty sensors or actuators can provide incorrect information or fail to respond correctly, throwing the system out of balance.

Consider a chemical reactor: A sudden surge in feedstock flow, combined with a slow-responding valve and a poorly tuned PID controller, might lead to an uncontrolled rise in temperature and pressure, posing a significant safety hazard.

Q 11. Describe different optimization techniques (e.g., linear programming, dynamic programming).

Optimization techniques aim to find the best solution to a problem, given certain constraints and objectives. Different techniques are suited to different problem types:

- Linear Programming (LP): LP deals with optimizing a linear objective function subject to linear constraints. It’s particularly effective for resource allocation problems, where resources are limited, and the relationships between variables are linear. The simplex method is a common algorithm used to solve LP problems.

Example: Minimizing the cost of producing a product subject to constraints on available raw materials and labor. - Dynamic Programming (DP): DP is used for problems that can be broken down into smaller overlapping subproblems. By solving these subproblems once and storing the solutions, DP significantly reduces computation time compared to solving each subproblem repeatedly. It’s often applied in problems with sequential decision-making, such as optimal control and inventory management.

Example: Finding the shortest path in a network or determining an optimal investment strategy over time. - Nonlinear Programming (NLP): NLP addresses optimization problems with non-linear objective functions or constraints. Algorithms like gradient descent, Newton’s method, and sequential quadratic programming (SQP) are frequently employed.

Example: Optimizing the design of an aircraft wing to minimize drag.

Other notable techniques include gradient descent for finding local minima of a function, simulated annealing for exploring a large solution space, and genetic algorithms for evolutionary optimization.

Q 12. Explain the concept of constraint optimization.

Constraint optimization, also known as constrained optimization, involves finding the best solution to an optimization problem while satisfying certain limitations or restrictions called constraints. These constraints limit the possible values of the variables involved. Imagine trying to build the tallest possible tower using a limited number of LEGO bricks; the number of bricks is a constraint that limits the tower’s height.

Constraints can be equality constraints (e.g., x + y = 10) or inequality constraints (e.g., x ≤ 5). Methods for handling constraints include penalty methods, barrier methods, and Lagrange multipliers. Penalty methods add penalty terms to the objective function for violating constraints. Barrier methods prevent the solution from leaving a feasible region. Lagrange multipliers incorporate constraints into the optimization problem directly.

For instance, optimizing the production schedule of a factory while considering limitations on machine capacity, raw materials, and workforce availability is a classic constraint optimization problem.

Q 13. How do you handle non-linearity in optimization problems?

Handling non-linearity in optimization problems is often more challenging than dealing with linear problems. Linear problems have a nice, predictable structure, whereas non-linear problems can exhibit complex behaviors, including multiple local optima (points that seem optimal but are not globally optimal).

Several techniques can be employed:

- Linearization: Approximating the non-linear functions with linear functions around a specific operating point. This simplifies the problem but may be inaccurate far from the operating point.

- Nonlinear Programming Algorithms: Methods such as gradient descent, Newton’s method, and SQP are designed to handle non-linear functions and constraints. These algorithms often use iterative approaches to gradually improve the solution.

- Global Optimization Techniques: For problems with multiple local optima, techniques like simulated annealing or genetic algorithms are often necessary to explore the solution space more thoroughly and find the global optimum. These methods are generally computationally more expensive.

The choice of technique depends on the specific problem, the degree of non-linearity, and the computational resources available. For example, designing a chemical process with complex reaction kinetics often requires using sophisticated non-linear optimization techniques.

Q 14. What are the advantages and disadvantages of different optimization algorithms?

Different optimization algorithms offer various advantages and disadvantages:

- Gradient Descent: Simple to implement, but can be slow to converge and may get stuck in local optima for non-convex problems.

- Newton’s Method: Fast convergence near the optimum, but requires calculating the Hessian matrix, which can be computationally expensive.

- Simulated Annealing: Can escape local optima, but can be slow and requires careful parameter tuning.

- Genetic Algorithms: Robust and can handle complex problems, but can be computationally expensive and require careful parameter setting.

- Linear Programming (Simplex Method): Efficient for linear problems, but not applicable to non-linear problems.

- Dynamic Programming: Efficient for problems with overlapping subproblems, but can be computationally expensive for large problems.

The best algorithm depends heavily on the problem’s characteristics, such as its size, linearity, and the presence of multiple local optima. A smaller, linear problem might be efficiently solved with the simplex method, while a large, complex non-linear problem might necessitate the use of a more sophisticated method like genetic algorithms or simulated annealing. Often, experimentation and comparison of different algorithms are necessary to find the most effective approach.

Q 15. Explain the concept of sensitivity analysis in optimization.

Sensitivity analysis in optimization helps us understand how changes in input parameters affect the optimal solution. Imagine you’re planning a road trip; sensitivity analysis would tell you how much longer the journey might take if there’s unexpected traffic (a change in travel time, an input parameter), or how much more fuel you’d need if your car’s fuel efficiency drops (a change in fuel consumption rate). It’s crucial because real-world problems rarely have perfectly known parameters; there’s always uncertainty.

We perform sensitivity analysis by systematically varying input parameters (one at a time, or in groups) and observing the changes in the objective function (e.g., the total travel time or cost of the trip) and the optimal solution (e.g., the chosen route). This allows us to identify the most critical parameters – those with the biggest impact on the outcome. Techniques include one-at-a-time methods, and more sophisticated approaches like variance-based methods or gradient-based methods. The results are usually presented graphically (e.g., tornado diagrams) or in tabular format to show the sensitivity of the solution to parameter changes.

For example, in a supply chain optimization problem, sensitivity analysis might reveal that changes in transportation costs have a much greater impact on the total cost than changes in inventory holding costs. This information informs decision-making, allowing us to focus our efforts on managing the most influential factors. It helps in building more robust and reliable optimization models.

Career Expert Tips:

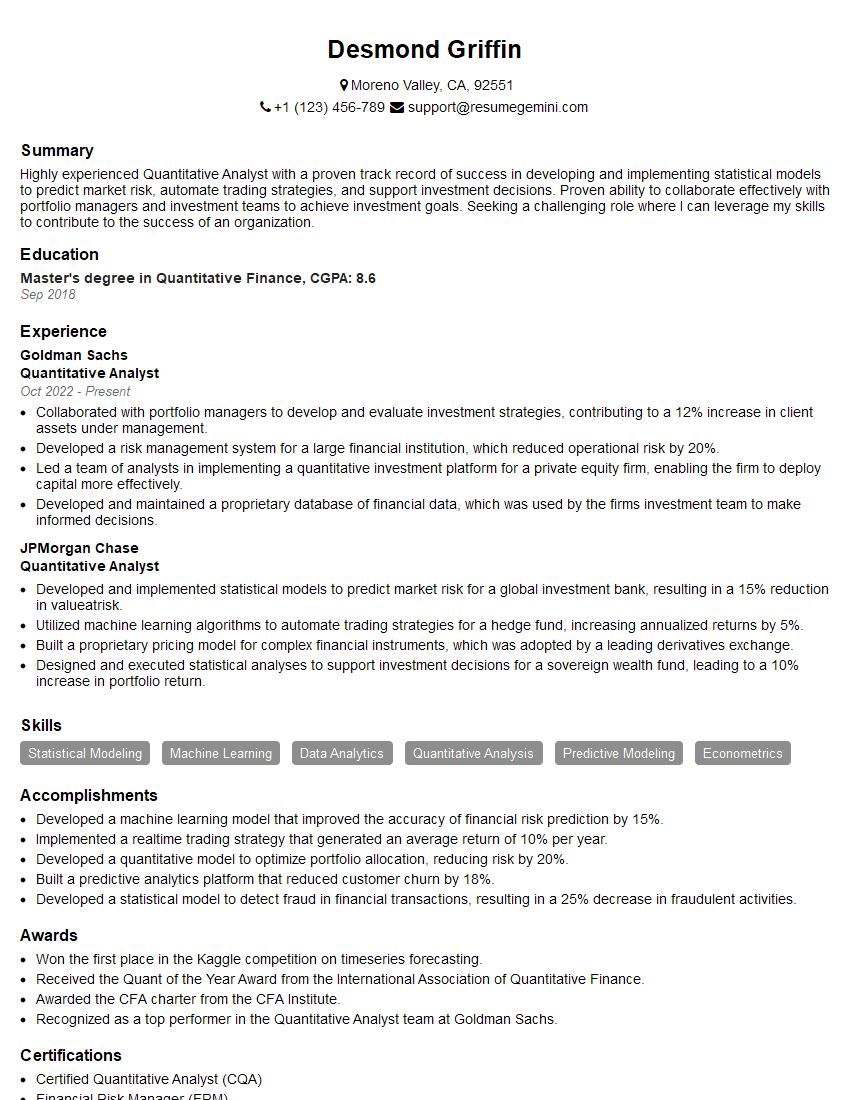

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with simulation tools used for flow control and optimization.

Throughout my career, I’ve extensively used simulation tools for flow control and optimization, primarily focusing on discrete-event simulation and agent-based modeling. I’m proficient with AnyLogic, Arena, and Simio. For example, in a project optimizing the flow of patients in a hospital, I used AnyLogic to model the movement of patients through various departments (emergency room, surgery, recovery). This allowed us to simulate different staffing levels, resource allocation strategies, and queuing policies to find the configuration that minimizes patient wait times and maximizes throughput.

In another project involving traffic flow optimization, I utilized agent-based modeling in NetLogo to simulate the behavior of individual vehicles responding to traffic signals and road conditions. This enabled us to evaluate the effectiveness of adaptive traffic control strategies, helping to reduce congestion and improve traffic flow. Choosing the right simulation tool depends on the specifics of the system being modeled – discrete-event simulation excels in modeling processes with distinct events, while agent-based modeling is better for systems with autonomous agents interacting with each other and their environment.

Q 17. How do you validate optimization models?

Validating optimization models is critical to ensure their accuracy and reliability. A multi-pronged approach is necessary:

- Historical Data Validation: We compare model predictions against historical data. This involves using historical data as input to the model and comparing the model’s output to actual past performance. Discrepancies highlight areas needing improvement in model structure or parameter estimation.

- Sensitivity Analysis (as discussed earlier): Understanding the sensitivity of the model’s output to changes in input parameters helps in assessing the model’s robustness and identifying potential uncertainties.

- Scenario Testing: We test the model’s performance across a wide range of scenarios to see how it responds to various situations. This helps determine the model’s limitations and generalizability.

- Expert Review: Subject matter experts critically assess the model’s assumptions, structure, and results to ensure they align with real-world knowledge and expectations.

- Real-world Implementation and Monitoring: The ultimate validation comes from deploying the model in a real-world setting and monitoring its performance. Continuous monitoring and feedback allow for adjustments and improvements.

For instance, in a logistics optimization model, we might compare predicted delivery times against actual delivery times from historical data. Significant discrepancies might indicate issues with the model’s assumptions about transportation times or other factors.

Q 18. Explain the concept of model predictive control (MPC).

Model Predictive Control (MPC) is an advanced control strategy that uses a model of the system to predict its future behavior and optimize control actions over a receding horizon. Imagine you’re driving a car; MPC is like constantly planning your next few seconds of driving based on your current speed, location, and knowledge of the road ahead. You’re optimizing your steering and acceleration to reach your destination smoothly and safely, continually updating your plan as new information becomes available.

Here’s how it works: At each time step, MPC solves an optimization problem to find the best sequence of control actions over a finite time horizon (the prediction horizon). It uses a model of the system to predict the system’s response to these actions. Only the first control action in the optimal sequence is implemented. Then, at the next time step, the process is repeated with updated measurements and a shifted prediction horizon. This iterative process accounts for disturbances and uncertainties.

MPC has many benefits, including its ability to handle constraints (e.g., limits on actuator inputs, system variables), to manage multiple objectives, and to adapt to changing conditions. It’s widely used in industrial process control, robotics, and traffic management.

Q 19. What are some common applications of flow control and optimization in your field?

Flow control and optimization have numerous applications in my field. Some common examples include:

- Supply Chain Management: Optimizing inventory levels, transportation routes, and warehouse operations to minimize costs and improve efficiency.

- Traffic Management: Designing adaptive traffic control systems to reduce congestion and improve traffic flow. This involves optimizing signal timings based on real-time traffic conditions.

- Manufacturing Processes: Optimizing production schedules, resource allocation, and material flow to maximize throughput and minimize waste. This often involves techniques like linear programming or mixed-integer programming.

- Healthcare Systems: Optimizing patient flow in hospitals, improving appointment scheduling, and allocating resources to minimize wait times and improve patient care.

- Network Optimization: Designing and managing communication networks to ensure efficient data transmission and minimize latency. This involves algorithms for routing and flow control.

In all these areas, the goal is to improve efficiency, reduce costs, enhance resource utilization, and achieve better overall system performance.

Q 20. Describe a time you had to troubleshoot a flow control system issue.

During a project optimizing a water distribution network, we encountered a persistent pressure drop in a specific section of the network. Initial investigations focused on pipe leaks and pump malfunctions, but these checks yielded no results. The problem was intermittent, making diagnosis challenging.

Our troubleshooting involved a multi-step process: First, we meticulously reviewed the system’s operational data, looking for patterns in pressure fluctuations and flow rates. Second, we developed a detailed hydraulic model of the network using EPANET, a widely used water distribution modeling software. We then simulated various scenarios, including changes in water demand, pump operation, and potential valve issues. This helped to pinpoint the source of the problem to a partially closed valve in a less-trafficked section of the network – a scenario that wasn’t easily detectable through on-site inspection alone.

Once the issue was identified, the valve was properly adjusted. The hydraulic model then served as a powerful tool for validating the fix and ensuring the water pressure remained stable. This experience highlighted the importance of combining data analysis, system modeling, and thorough investigation when troubleshooting complex systems.

Q 21. How do you handle conflicting objectives in an optimization problem?

Conflicting objectives are common in optimization problems. For example, in designing a car, we might want to maximize fuel efficiency while also maximizing speed and safety – these goals often compete. We need strategies to handle this trade-off.

Several approaches exist:

- Multi-objective Optimization: This approach aims to find a set of Pareto optimal solutions, where no improvement in one objective can be achieved without sacrificing another. Techniques like weighted sum method, epsilon-constraint method, and evolutionary algorithms are commonly used.

- Prioritization: If one objective is significantly more important than others, we can prioritize it. This might involve formulating the problem to maximize the primary objective subject to constraints on the other objectives.

- Goal Programming: This approach sets targets for each objective and aims to minimize the deviations from these targets. It’s particularly useful when there are hard constraints on some objectives.

- Compromise Solutions: Sometimes, a compromise solution is reached by weighing the relative importance of each objective based on expert judgment or stakeholder input.

The best approach depends on the specific problem and the relative importance of the objectives. Often, a combination of techniques is used to find a satisfactory solution that balances the conflicting goals. Visualizing the trade-offs between objectives, for instance, using a Pareto front, can provide valuable insights and guide decision-making.

Q 22. How do you balance speed and accuracy in optimization algorithms?

Balancing speed and accuracy in optimization algorithms is a crucial aspect of achieving efficient and reliable solutions. It’s often a trade-off; faster algorithms might sacrifice precision, while highly accurate methods can be computationally expensive and time-consuming. The optimal balance depends heavily on the specific application and its constraints.

Consider these strategies:

- Algorithm Selection: Choosing the right algorithm is paramount. For instance, gradient descent is relatively fast but might get stuck in local optima, while simulated annealing is slower but more likely to find the global optimum. The choice depends on the problem’s complexity and the acceptable level of error.

- Parameter Tuning: Many algorithms have parameters that control their speed and accuracy. For example, the learning rate in gradient descent dictates how quickly the algorithm converges. A smaller learning rate increases accuracy but slows convergence; a larger one speeds things up but risks overshooting the optimum. Careful experimentation and tuning are crucial.

- Approximation Techniques: For complex problems, approximation techniques can significantly speed up computations without sacrificing too much accuracy. These include techniques like linearization, sampling, and dimensionality reduction. The key is to choose an approximation that balances computational cost and error tolerance.

- Early Stopping Criteria: Defining clear stopping criteria is essential. Instead of running an algorithm until it converges perfectly (which might take an impractically long time), you can stop when a sufficient level of accuracy is reached or a predetermined time limit is exceeded. This prevents unnecessary computations and saves time.

Example: In real-time traffic optimization, a fast but slightly less accurate algorithm might be preferred over a highly accurate one that takes too long to compute, resulting in outdated solutions. The acceptable error depends on the acceptable delays and congestion.

Q 23. Explain the importance of data quality in flow control and optimization.

Data quality is absolutely fundamental in flow control and optimization. Garbage in, garbage out—this adage holds especially true here. Inaccurate, incomplete, or inconsistent data will lead to flawed models and suboptimal solutions. The quality of your data directly impacts the reliability and effectiveness of your optimization strategies.

Here’s why data quality matters:

- Model Accuracy: Optimization algorithms rely on the data to learn patterns and relationships. Poor data leads to inaccurate models, resulting in incorrect predictions and suboptimal decisions.

- Solution Reliability: If the data is unreliable, the resulting optimization solution will also be unreliable. Decisions based on these solutions could have significant negative consequences.

- Computational Efficiency: Cleaning and pre-processing noisy data can take considerable time and resources. High-quality data reduces the need for extensive pre-processing, leading to more efficient computations.

Example: Imagine optimizing a supply chain. If your data on inventory levels, transportation times, and customer demand is inaccurate, your optimization model will generate an inefficient plan, leading to delays, increased costs, and dissatisfied customers.

Q 24. How do you handle missing or noisy data in optimization problems?

Handling missing or noisy data is a critical part of any real-world optimization problem. Ignoring these issues will invariably lead to poor results. Here’s a multi-pronged approach:

- Missing Data:

- Imputation: Replace missing values with estimated values. Methods include mean/median imputation, k-nearest neighbors imputation, and more sophisticated techniques like multiple imputation. The choice depends on the nature of the data and the missing data mechanism.

- Deletion: If the amount of missing data is small and randomly distributed, you might choose to remove the affected data points. However, this is only appropriate under specific conditions to avoid introducing bias.

- Noisy Data:

- Smoothing: Techniques like moving averages can smooth out short-term fluctuations and reduce noise. The choice of window size will influence the extent of smoothing.

- Filtering: Filters can be used to remove outliers or data points that deviate significantly from the rest of the data. Appropriate filtering methods depend on the characteristics of the noise.

- Robust Optimization: Employing optimization algorithms that are inherently less sensitive to outliers and noise, such as robust regression or methods using L1 regularization, is a powerful strategy.

Example: In a weather forecasting model used for optimizing energy grid operations, missing temperature readings can be imputed using data from nearby stations, while noisy wind speed measurements can be smoothed using a moving average.

Q 25. Describe your experience with different programming languages used for optimization (e.g., Python, MATLAB).

I have extensive experience in using various programming languages for optimization problems. My primary languages are Python and MATLAB, but I’m also proficient in R and have some experience with C++ for performance-critical applications.

- Python: Python’s rich ecosystem of libraries like SciPy, NumPy, and Pandas makes it ideal for data manipulation, analysis, and implementing various optimization algorithms. Its readability and ease of use make it excellent for prototyping and developing complex models. I frequently use libraries like

cvxpyfor convex optimization andscikit-learnfor machine learning-based optimization approaches. - MATLAB: MATLAB’s built-in functions for linear algebra, numerical computation, and optimization algorithms are highly efficient and well-documented. Its visualization capabilities are also invaluable for understanding optimization problems and visualizing results. I often leverage MATLAB’s optimization toolbox for solving challenging nonlinear programming problems.

Example: For a large-scale linear programming problem, I might use Python’s cvxopt library for its efficiency and scalability. For a more complex, nonlinear problem involving visualization, I might opt for MATLAB’s optimization toolbox.

Q 26. Explain the concept of real-time optimization.

Real-time optimization (RTO) involves making optimal decisions in a dynamic environment where conditions are constantly changing. Unlike offline optimization, which deals with static data, RTO requires the ability to quickly adapt to new information and recalculate optimal solutions.

Key aspects of RTO:

- Fast Computation: Algorithms must be computationally efficient to produce solutions in a timely manner, often within milliseconds or seconds.

- Data Acquisition and Processing: Real-time data streams need to be efficiently acquired, processed, and integrated into the optimization model.

- Model Updating: The optimization model should be updated regularly to reflect changes in the system’s state and external conditions.

- Feedback Control: RTO often involves a feedback loop, where the system’s response to the implemented solution is monitored and used to adjust future decisions.

Example: In a smart power grid, RTO is used to balance electricity supply and demand in real-time based on fluctuating renewable energy sources and varying customer demand. The optimization model dynamically adjusts power generation and distribution to maintain grid stability and minimize costs.

Q 27. How do you ensure the scalability of optimization solutions?

Ensuring scalability of optimization solutions is critical, especially when dealing with large datasets and complex problems. Strategies include:

- Algorithmic Choices: Select algorithms with proven scalability. Some algorithms are inherently more scalable than others. For example, distributed optimization algorithms can be used to break down large problems into smaller, manageable subproblems that can be solved in parallel.

- Data Structures: Efficient data structures are vital. Using appropriate data structures can significantly improve the performance of optimization algorithms, especially when dealing with large amounts of data. Sparse matrices, for instance, are highly effective for handling large, sparse datasets.

- Parallel and Distributed Computing: Leverage parallel and distributed computing architectures. This allows you to divide the computational workload across multiple processors or machines, significantly reducing computation time and enhancing scalability.

- Approximation and Decomposition Methods: Employ approximation techniques or decomposition methods to simplify large problems into smaller, more manageable ones. These methods trade off some accuracy for improved computational efficiency and scalability.

Example: When optimizing traffic flow in a large city, a distributed optimization algorithm might be used, with different parts of the city modeled and optimized on separate processors. The results are then combined to obtain a city-wide optimal solution.

Q 28. Describe your approach to continuous improvement in flow control and optimization.

Continuous improvement in flow control and optimization is an iterative process focused on refining models, improving efficiency, and enhancing overall performance. My approach involves:

- Monitoring and Evaluation: Regularly monitor the performance of optimization solutions, tracking key metrics like solution quality, computation time, and resource usage. Identify areas for improvement.

- Data Analysis: Analyze the data used in the optimization process to identify potential biases, inconsistencies, or limitations. Address data quality issues and improve data preprocessing techniques.

- Algorithm Refinement: Continuously explore and evaluate new or improved optimization algorithms, tuning parameters to enhance performance. Explore advanced techniques like machine learning to enhance model accuracy and decision-making.

- Feedback Incorporation: Actively seek feedback from stakeholders and users of the optimization system to identify areas for improvement and address practical limitations.

- Experimentation and A/B Testing: Experiment with different approaches and systematically compare their performance through A/B testing, allowing data-driven decision-making on improvements.

Example: In a manufacturing plant optimizing production schedules, we might monitor production efficiency and identify bottlenecks. Then, we could analyze production data to improve scheduling algorithms, potentially integrating machine learning to predict machine failures and optimize preventative maintenance scheduling, leading to enhanced production efficiency and reduced downtime.

Key Topics to Learn for Flow Control and Optimization Interview

- Control Structures: Understanding and applying fundamental control structures like conditional statements (if-else, switch), loops (for, while, do-while), and exception handling is crucial. Consider the efficiency and readability implications of different approaches.

- Algorithmic Complexity: Mastering Big O notation and analyzing the time and space complexity of algorithms is vital for optimizing code. Practice analyzing various algorithms and identifying bottlenecks.

- Data Structures: Familiarity with relevant data structures such as arrays, linked lists, stacks, queues, trees, and graphs, and their respective strengths and weaknesses in different scenarios is essential for efficient flow control.

- Optimization Techniques: Explore various optimization strategies, including memoization, dynamic programming, greedy algorithms, and heuristics. Understand when and how to apply each technique effectively.

- Concurrency and Parallelism: For many applications, understanding the principles of concurrent and parallel programming is critical for optimization. Be prepared to discuss threads, processes, and synchronization mechanisms.

- Profiling and Debugging: Learn to use profiling tools to identify performance bottlenecks in your code and utilize debugging techniques to resolve issues efficiently. This demonstrates practical problem-solving skills.

- Design Patterns: Understanding and applying relevant design patterns can significantly improve code structure and maintainability, leading to better optimization opportunities. Focus on patterns applicable to flow control and optimization.

- Code Refactoring: Be prepared to discuss strategies for improving code quality and efficiency through refactoring, including techniques for simplifying complex logic and improving readability.

Next Steps

Mastering flow control and optimization is paramount for career advancement in software engineering and related fields. It demonstrates a deep understanding of algorithmic thinking and problem-solving, leading to more efficient and scalable solutions. To significantly boost your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Flow Control and Optimization are available to guide you. Invest time in creating a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good