Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Folding and Binding interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Folding and Binding Interview

Q 1. What types of folding machines have you operated?

Throughout my career, I’ve operated a wide variety of folding machines, from simple hand-fed folders ideal for small-scale projects to high-speed automated machines capable of processing thousands of sheets per hour. This includes experience with:

- Sheet-fed folders: These machines process single sheets of paper, offering various folding patterns like letter folds, half folds, and more complex configurations. I’m proficient in operating both single-knife and multiple-knife folders within this category.

- Roll-fed folders: I’ve worked extensively with roll-fed folders, commonly used for high-volume printing jobs, like newspapers or magazines. These require a different skill set, focusing on roll paper handling, tension control, and jam prevention specific to continuous paper feed.

- Insert folders: These specialized machines are designed to insert folded sheets into larger envelopes or other documents, requiring precise timing and adjustment to guarantee accurate insertion.

My experience encompasses both manual setup and adjustment of these machines as well as troubleshooting and maintenance.

Q 2. Describe your experience with perfect binding.

Perfect binding is a common binding method for books, magazines, and other documents. It involves gluing together the edges of the pages and then applying a cover. My experience with perfect binding includes:

- Preparation: This involves ensuring the pages are accurately collated and the spine is prepared for gluing. This step is crucial for a clean and professional final product. I often check for any inconsistencies, like missing pages, before proceeding.

- Gluing: I’m skilled in using both hot melt and PUR (polyurethane reactive) adhesive systems. The choice of adhesive depends on the paper stock and desired durability. Precise application of adhesive is crucial to ensure proper binding without excess glue showing on the spine.

- Cover application: After the glued spine is dried, the cover is carefully attached, often requiring precise alignment and trimming. I am familiar with various cover materials, each requiring its own approach to ensure a secure and professional bond.

- Quality control: After binding, I meticulously check for any issues such as uneven glue application, misalignment, or loose pages. This ensures the highest quality end product.

For example, in one project involving a high-end coffee table book, the use of PUR adhesive was crucial for its superior bond strength and flexibility, ensuring the book would withstand frequent handling without damage.

Q 3. Explain the process of saddle stitching.

Saddle stitching is a binding method where folded sheets of paper are secured together using wire staples along the spine. It’s ideal for documents with a relatively low page count, such as brochures or booklets.

The process involves:

- Folding: The pages are folded according to the desired format, often using a folding machine.

- Collating: The folded sheets are collated in the correct order.

- Stapling: The collated sheets are fed into a saddle stitching machine, which inserts wire staples through the folded spine.

The key is to ensure accurate collation and consistent stapling pressure to prevent misaligned staples or jams. I’ve found that paying close attention to the machine settings, especially the depth and pressure of the staples, is critical for producing a consistently well-stitched product.

I once had a project requiring a high-quality brochure. To avoid staple marks showing through the high-gloss paper, we experimented with different staple sizes and pressures to find the optimal settings that ensured secure binding while minimizing visual impact.

Q 4. How do you troubleshoot common folding machine jams?

Troubleshooting folding machine jams requires a systematic approach. My first step is always safety: switching off the machine before any investigation. Then I follow these steps:

- Identify the type of jam: Is the paper jammed at the infeed, during folding, or at the outfeed? This helps narrow down the potential causes.

- Check the paper: Ensure the paper is of appropriate weight and moisture content for the machine. Wrinkled or damp paper is a frequent cause of jams.

- Inspect the rollers and belts: Check for any obstructions, debris, or wear and tear. Clean or replace components as needed.

- Examine the folding mechanism: Inspect the knives, rollers, and other moving parts for any misalignment or damage. Small adjustments often resolve the problem.

- Check the feeder tray: Ensure the paper is properly aligned and not overlapping.

- Review machine settings: Verify that the machine settings, such as paper size and fold type, are correctly configured.

If the problem persists, consulting the machine’s manual or contacting a qualified technician is essential. Often a seemingly minor issue, like a slightly misaligned roller, can cause significant problems. Preventative maintenance, such as regular cleaning and lubrication, minimizes the frequency of jams.

Q 5. What are the different types of binding methods?

There’s a wide variety of binding methods, each suited to different needs and document types. They range from simple to highly specialized:

- Perfect Binding: (Already described above)

- Saddle Stitching: (Already described above)

- Wire-O Binding: (To be described in the next answer)

- Spiral Binding (Coil Binding): Uses a plastic or metal comb to bind the pages. Suitable for documents needing to lay flat, like calendars or notebooks.

- Case Binding: A robust method used for hardback books. Involves sewing the pages together, then attaching them to a cover board. Offers superior durability.

- Thermal Binding: Uses heat to melt glue into the spine, creating a secure bond. Suitable for a variety of paper types and page counts.

- Mechanical Binding: Uses metal or plastic fasteners to punch through the pages and secure them together. Offers various aesthetics.

The choice of binding method depends on factors like the number of pages, the desired durability, the budget, and the aesthetic requirements.

Q 6. What is your experience with wire-O binding?

Wire-O binding, also known as double-loop wire binding, creates a professional and durable binding using double-loop wire that is punched through the pages. This allows the book to lay flat, making it ideal for calendars, notebooks, and other documents that need to be easily written in.

My experience includes:

- Punching: Accurately punching holes in the pages using a wire-o binding machine is crucial for a smooth, clean finish. Incorrect punching can result in a poorly bound document or damage to the pages.

- Wire insertion: I am skilled at inserting the wire into the punched holes using various techniques. This ensures a secure closure.

- Closure: Closing the wire is a key step, ensuring the wire is tightly closed while avoiding any damage to the pages. This requires a deft hand and the right tools.

- Quality control: I carefully check the finished product for misaligned holes, crooked wire, or any other defects that would affect the quality and functionality.

I recall a project where precise wire-o binding was essential. The client needed a high-quality notebook for its annual meeting. The clean, professional look of the wire-o binding perfectly complemented the overall branding of the client.

Q 7. How do you ensure quality control in folding and binding?

Quality control in folding and binding is crucial. I employ a multi-stage approach starting from the beginning:

- Incoming material inspection: Checking the quality of paper, ensuring consistent weight and moisture content, avoiding issues later on in the process.

- Machine setup and calibration: Precise calibration of folding and binding machines is vital. Regular checks ensure accuracy and consistency.

- In-process checks: Regularly monitoring the process while it’s running, looking for issues like misaligned folds or uneven glue application. Spotting and correcting problems early saves time and resources.

- Final inspection: A thorough review of the completed product is essential. Checking for issues such as missing pages, crooked folds, poorly applied glue, or any visible defects.

- Sampling and testing: Random sampling and testing ensure the quality standards are consistently met. This may involve durability tests for certain binding types.

Documentation is also key, I always maintain detailed records of each job, which includes machine settings and quality control checks. This is important for troubleshooting and continuous improvement.

Q 8. What safety precautions do you follow when operating binding machinery?

Safety is paramount when operating binding machinery. Before operating any equipment, I always ensure I’ve received the necessary training and understand the machine’s specific safety features. This includes thoroughly reading the operator’s manual and completing any required safety certifications. I always wear appropriate personal protective equipment (PPE), which typically includes safety glasses, gloves, and closed-toe shoes.

Before starting any machine, I conduct a thorough inspection, checking for any loose parts, malfunctions, or potential hazards. I also ensure the area around the machine is clear of obstructions and that other personnel are maintaining a safe distance. During operation, I remain vigilant, monitoring the machine’s performance and immediately stopping it if any unusual sounds or vibrations occur. Regular maintenance, following the manufacturer’s recommendations, is critical for preventing accidents and ensuring the equipment functions optimally. Finally, I always prioritize following the company’s safety procedures and reporting any near misses or incidents immediately.

Q 9. Explain the difference between in-line and off-line finishing.

In-line and off-line finishing refer to the timing of these processes relative to the printing process. In in-line finishing, the folding and binding processes are integrated directly into the printing workflow. Imagine a continuous flow: paper prints, then immediately folds, then binds, all in one connected system. This is efficient for high-volume jobs but less flexible for customized projects. Think of a large newspaper printing operation; everything happens seamlessly and quickly.

Off-line finishing, on the other hand, is a separate process. Printed sheets are first gathered, then moved to a different area for folding and binding. This allows for greater flexibility in terms of binding types, handling different paper stocks, and accommodating smaller, more diverse projects. Imagine a small print shop producing brochures; they might print a batch of leaflets, then later fold and saddle-stitch them according to customer requirements.

Q 10. Describe your experience with case binding.

I have extensive experience with case binding, a method ideal for high-quality books, journals, and similar publications. This involves creating a rigid cover (the case) which is then glued to the text block. My experience encompasses all stages: from preparing the text block (often involving perfect binding), to creating and attaching the case, and finally adding any finishing touches like embossing or foil stamping. I’m proficient in using various types of casemaking machinery, including automated casemakers and manual techniques for smaller runs. I understand the importance of accurate measurements and precise gluing for a professional, durable finish. I’ve worked on projects ranging from small academic publications to large-scale fiction releases, adapting my techniques to match the client’s specifications and the project’s scale.

For example, on a recent project involving a high-end coffee table book, we opted for a cloth-covered case with a custom-designed foil stamping on the cover. Precise measurements and attention to detail were crucial to ensure a perfectly fitted case that reflected the book’s premium quality.

Q 11. How do you handle large-volume folding and binding projects?

Handling large-volume folding and binding projects requires careful planning and efficient workflow management. My approach involves several key steps: first, a detailed analysis of the project specifications, including paper type, quantity, binding method, and turnaround time. This informs the choice of equipment and personnel allocation. For example, large-volume projects often utilize high-speed automated machinery such as perfect binders or saddle stitchers. I also focus on optimizing the workflow to eliminate bottlenecks, which might include setting up multiple workstations, implementing quality checks at various stages, and coordinating with different teams.

Another crucial aspect is quality control. We employ rigorous quality checks throughout the process to ensure consistency and accuracy. This could involve regular inspections of folded signatures, checking for misaligned pages, and inspecting the finished product for defects before packaging. Finally, effective communication with the client throughout the project is essential to manage expectations and resolve any unforeseen issues.

Q 12. What is your experience with different paper types and their suitability for various binding methods?

My experience encompasses a wide range of paper types, including coated, uncoated, textured, and specialty papers. Understanding the properties of each paper type is critical for selecting the appropriate binding method. For example, heavier papers might be suitable for case binding, while thinner papers might be better suited for saddle stitching or wire-o binding. Coated papers often present a smoother surface, making them ideal for high-quality printing but potentially more challenging for certain binding methods.

I’ve worked with various paper weights and finishes, understanding their impact on the final product’s aesthetics and durability. This includes considering the paper’s absorbency for glue application and its ability to withstand the stresses of different binding processes. For instance, attempting to perfect bind a very thin, flimsy paper might lead to pages tearing or the spine failing.

Q 13. How do you calculate the cost-effectiveness of different binding options?

Cost-effectiveness analysis for different binding options involves considering several factors. The most significant are the initial cost of the binding materials (e.g., glue, wire, covers), the labor costs associated with each method (including machine operation and finishing), and the equipment costs (including depreciation and maintenance). Furthermore, production speed impacts cost; faster methods often mean lower labor costs per unit. Finally, we need to factor in the potential for waste and spoilage, which can significantly increase the cost of a project.

I usually create a spreadsheet comparing the costs of each binding option for a specific project. This spreadsheet helps visualize and compare the total cost per unit for each method, making informed decisions that are not just focused on the initial material cost but on the overall financial impact.

Q 14. Describe your experience with spiral binding.

Spiral binding, also known as coil binding, is a versatile method suitable for documents requiring frequent opening and closing, such as notebooks, calendars, or reports. My experience with spiral binding includes selecting the appropriate coil size and color, accurately punching the holes in the document, and skillfully inserting and closing the coil. I’m familiar with both manual and automated coil binding machines, adapting my technique to the scale of the project. I also understand the importance of consistent hole punching to ensure the coil lies flat and the document opens smoothly.

One memorable project involved creating hundreds of custom-designed notebooks for a corporate event. The client specified a specific coil color to match their branding, and the consistent, high-quality spiral binding was essential to ensure a polished, professional impression.

Q 15. How do you maintain and clean folding and binding machinery?

Maintaining and cleaning folding and binding machinery is crucial for ensuring consistent, high-quality output and prolonging the equipment’s lifespan. It’s a multi-step process that involves both daily and periodic maintenance.

- Daily Maintenance: This includes removing dust and debris from all accessible areas, lubricating moving parts according to the manufacturer’s instructions (often using specialized lubricants), and checking for any signs of wear or damage, such as loose screws or frayed belts. A quick visual inspection is key here.

- Periodic Maintenance: This involves more in-depth cleaning, potentially including disassembling certain components for thorough cleaning. This might involve using specialized cleaning solutions appropriate for the materials involved. For example, using compressed air to remove dust from hard-to-reach areas, or using a lint-free cloth and isopropyl alcohol to clean delicate electronics. Regular checks of the rollers and belts for wear and tear are essential; these are common wear points.

- Preventative Measures: Proper training of operators is paramount to minimize the likelihood of damage from misuse. Following the manufacturer’s recommended operating procedures diligently helps prevent problems. Also, keeping the surrounding area clean and organized minimizes the introduction of dust and debris into the machinery.

Think of it like maintaining a car – regular oil changes, tire rotations and inspections prevent major breakdowns. Similarly, consistent maintenance of binding equipment prevents costly downtime and ensures quality output.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key considerations for selecting the appropriate binding method for a specific project?

Choosing the right binding method hinges on several key factors: the document’s length, the desired look and feel, the budget, and the intended use. Each method offers different advantages and disadvantages.

- Document Length: Saddle stitch binding is ideal for booklets under 64 pages, while perfect binding is better suited for longer documents. Wire-O and coil binding can accommodate a variety of page counts but are less suitable for very thick documents.

- Aesthetic Considerations: Perfect binding gives a professional, book-like finish. Saddle stitch binding is simple and cost-effective, while wire-O and coil binding are durable and allow for lay-flat pages. The choice depends on the desired image for the final product.

- Budget: Saddle stitch binding is generally the most economical option, followed by perfect binding. Wire-O and coil binding can be more expensive, particularly for larger projects.

- Intended Use: A high-use document might benefit from the durability of wire-O or coil binding, whereas a less frequently used document may only need saddle stitch binding.

For example, a short brochure would be perfectly suited to saddle stitching, whereas a textbook would likely require perfect binding for a professional and durable finish.

Q 17. How familiar are you with different types of folding patterns (e.g., half-fold, letter fold)?

I’m very familiar with a wide range of folding patterns. The choice of folding pattern depends on the desired size and format of the finished piece, as well as the number of panels needed.

- Half-fold: A simple fold in half, resulting in a single panel. Commonly used for brochures or leaflets.

- Letter Fold: A three-fold pattern, often used for letters or smaller brochures. It involves folding in thirds to create three panels.

- Roll Fold: Parallel folds in one direction to create multiple panels, often used for long, narrow pieces like maps or posters.

- Gate Fold: A multi-panel fold often used for brochures or invitations, creating a visually engaging and dynamic presentation.

- Parallel Fold: Consecutive folds in the same direction to create multiple panels. This is highly versatile depending on the desired number of folds.

Understanding the nuances of each fold, including the proper paper orientation and the positioning of content across panels, is crucial for achieving the desired result. This knowledge allows for the efficient and accurate creation of high-quality folded materials.

Q 18. Explain your experience with automated binding systems.

My experience with automated binding systems is extensive. I’ve worked with a variety of machines, including high-speed perfect binders, wire-O binding machines, and coil binding machines. I understand the importance of proper setup, maintenance, and troubleshooting of these systems. My skills encompass both the mechanical aspects of operation and the software interfaces used for managing production parameters.

For example, I’ve successfully implemented and optimized automated workflows in high-volume production environments. This involved programming the machines with specific settings for paper type, thickness, and binding specifications. I can also trouble shoot issues, such as jams or malfunctions in the machinery in order to ensure smooth operation.

Working with automated systems has significantly increased productivity and improved the consistency of our output. The ability to quickly adapt to different machine models and software is a key strength.

Q 19. How do you handle customer requests and feedback regarding finished products?

Handling customer requests and feedback is a critical aspect of my role. I believe in proactive communication and a customer-centric approach.

- Clear Communication: I maintain open communication with clients throughout the project, clarifying their requirements and providing regular updates on progress.

- Addressing Feedback: I carefully review all feedback, both positive and negative, to identify areas for improvement and ensure customer satisfaction. This feedback is carefully analyzed and used to improve future jobs.

- Problem Solving: If there are issues with a finished product, I work collaboratively with the customer to find solutions. This may involve reprinting, rebinding, or making adjustments to the process to avoid similar problems in the future.

- Documentation: I meticulously document all communication, requests, and feedback to ensure accountability and consistency across projects.

A recent example involved a customer who was unhappy with the color consistency in a large print run. After investigating the issue, we determined it was a minor problem with the ink supply, and we were able to quickly remedy the situation by reprinting the affected pages, ensuring complete customer satisfaction.

Q 20. How do you manage your time effectively in a fast-paced bindery environment?

Time management in a fast-paced bindery is crucial. I utilize a combination of strategies to ensure efficiency and meet deadlines.

- Prioritization: I prioritize tasks based on urgency and importance, ensuring that the most time-sensitive jobs are completed first.

- Workflow Optimization: I constantly look for ways to streamline our workflows, identifying bottlenecks and implementing solutions to improve efficiency. This might involve reorganizing equipment, redesigning processes, or using different software.

- Teamwork: I collaborate closely with my colleagues, ensuring tasks are distributed effectively and supporting one another when needed.

- Technology: I utilize project management software and other tools to track progress, manage deadlines, and communicate effectively within the team.

For instance, we recently implemented a new scheduling system that improved our turnaround times by 15% by optimizing the flow of jobs through the bindery.

Q 21. Describe a time you had to solve a complex problem in the bindery.

One time, we encountered a major problem with a new high-speed perfect binder. It was repeatedly jamming during a high-volume job with a tight deadline. This threatened to delay the entire project, impacting our client and our reputation.

I approached the problem systematically:

- Isolate the Issue: I systematically checked every component of the binder, starting with the simplest potential issues.

- Gather Data: I observed the machine’s operation during several jams, noting the precise point of failure each time.

- Troubleshooting: Once I identified the problem (a faulty sensor causing misalignment), I consulted the machine’s manual and contacted the manufacturer’s technical support.

- Solution Implementation: We eventually needed to replace the sensor. The team helped to re-calibrate and realign the machine to ensure consistent performance.

- Preventative Measures: After resolving the issue, I implemented regular preventative maintenance checks on the sensor to mitigate future problems.

By effectively troubleshooting and implementing solutions, we not only averted a major setback but also learned valuable lessons regarding preventative maintenance that helped prevent similar issues in the future.

Q 22. What are the common challenges faced in folding and binding and how do you overcome them?

Challenges in folding and binding are multifaceted, often stemming from material properties, equipment limitations, and project specifications. For instance, paper jams are a common occurrence, particularly with thicker or unusually textured stocks. Creasing inconsistencies can lead to an unprofessional finish, and misaligned folds affect the overall aesthetics and functionality. Binding challenges might include improper glue application resulting in pages falling out, or difficulties with perfect binding due to uneven page thickness.

To overcome these, a multi-pronged approach is necessary. This includes:

- Preventive Maintenance: Regular cleaning and lubrication of folding and binding machinery are crucial. This minimizes jams and ensures consistent performance.

- Material Selection: Choosing appropriate paper weight and type for the intended binding method is vital. Heavier stocks might require specific folding techniques or binding methods.

- Operator Training: Well-trained operators are adept at identifying and addressing potential issues proactively. Proper training on machine operation and troubleshooting significantly reduces errors.

- Quality Control Checks: Implementing rigorous quality checks at various stages (pre-press, during folding/binding, and post-binding) helps catch defects early and prevents large-scale problems.

- Process Optimization: Analyzing the workflow for bottlenecks and inefficiencies allows for adjustments to improve speed and accuracy. This might include adjusting machine settings or re-sequencing operations.

For example, if we experience consistent misalignment in a particular folding machine, we would first check the machine’s calibration, then examine the paper feed mechanism for any obstructions. If the problem persists, we may need to consult the manufacturer’s documentation or call for technical support.

Q 23. What software or systems are you familiar with related to finishing and binding?

My experience encompasses a range of software and systems used in the finishing and binding process. I’m proficient with pre-press software like Adobe Acrobat and other PDF editors for creating print-ready files, ensuring proper imposition and bleed settings are correctly applied, which directly impacts the folding and binding outcome. I also have extensive experience with various pre-flighting tools to catch potential issues before they reach the production floor.

Regarding production control systems, I’m familiar with MIS (Management Information Systems) software used for job tracking, scheduling, and cost management within the bindery. This includes software that integrates with our folding and binding machinery to monitor performance, track material usage, and generate reports. In some cases, we use specialized software to manage the parameters of specific binding machines, such as those used for saddle stitching or perfect binding, enabling us to fine-tune the process for optimal results. Finally, for quality control, we utilize specialized software that allows us to track the quality indicators such as misaligned folds, binding inconsistencies, and other defects throughout the process.

Q 24. Describe your experience with quality control checks throughout the folding and binding process.

Quality control is an integral part of my workflow. It’s not a single check but a series of checks throughout the process. Before folding, I visually inspect the paper stock for defects like tears or creases. During folding, I periodically sample folded sections to ensure accuracy of folds and consistency. For binding, quality checks include verifying proper glue application and ensuring all pages are securely bound. Post-binding, I perform a final inspection, looking for imperfections, misalignment, and any signs of damage.

We use statistical process control (SPC) charts to track key metrics, allowing us to identify trends and potential problems before they escalate. For example, if we notice a rise in misfolded pages, we can investigate the cause (e.g., machine malfunction, incorrect paper feed) and take corrective action.

Documentation is key. We maintain detailed records of each job, including material specifications, machine settings, and quality control results. This data is invaluable for continuous improvement and troubleshooting.

Q 25. How do you prioritize tasks when dealing with multiple projects with different deadlines?

Prioritizing tasks with multiple projects and deadlines involves a structured approach. I utilize project management techniques such as:

- Prioritization Matrix: I assess each project based on urgency and importance (Eisenhower Matrix). Urgent and important tasks get immediate attention.

- Gantt Charts: Visual representation of project timelines helps in identifying potential conflicts and allocating resources effectively.

- Work Breakdown Structure (WBS): Breaking down large projects into smaller, manageable tasks allows for better organization and tracking.

- Critical Path Method (CPM): Identifying the longest sequence of tasks in a project helps in focusing on the most time-sensitive aspects.

Communication is vital. I maintain open communication with clients and team members to manage expectations and address potential delays proactively. Flexibility is crucial; sometimes, adjustments to the schedule are necessary to accommodate unforeseen circumstances.

Q 26. What are your strategies for preventing errors in the folding and binding process?

Preventing errors is a proactive strategy encompassing several measures:

- Standardized Operating Procedures (SOPs): Clearly defined procedures for each task reduce variability and human error.

- Regular Machine Maintenance: Preventative maintenance significantly reduces the likelihood of equipment malfunctions leading to errors.

- Operator Training and Certification: Well-trained operators are less prone to mistakes.

- Visual Aids and Checklists: Checklists at each stage ensure all steps are completed accurately.

- Quality Control at Every Stage: Regular checks at each step of the process identify and correct errors early on.

- Pre-flighting: Thoroughly checking digital files before printing helps catch errors in imposition, bleed, and other critical aspects.

For example, a simple visual aid like a color-coded diagram illustrating the correct folding sequence can drastically reduce errors during manual folding operations.

Q 27. Explain your understanding of different paper weights and their impact on folding and binding.

Paper weight, usually measured in gsm (grams per square meter), significantly impacts folding and binding. Lighter papers (e.g., 60-80 gsm) are easier to fold but may tear more readily and are unsuitable for certain binding methods. Heavier papers (e.g., 120 gsm and above) are more durable, offering better quality and suitable for demanding applications, but they require more robust machinery and techniques. They are less prone to creasing inconsistencies but might be difficult to fold sharply and require careful planning of folds and binding to avoid issues.

The choice of paper weight also influences the binding method. Perfect binding might work well for heavier papers with enough thickness to create a sturdy spine, but lighter papers are more suitable for saddle stitching or other methods. The impact on finishing, from cutting and trimming to scoring, also needs to be considered. Thicker sheets will demand stronger machinery and sharp tools.

Q 28. How do you stay updated with the latest advancements in folding and binding technology?

Staying updated in this rapidly evolving field requires a multi-faceted approach:

- Industry Publications and Trade Shows: Attending industry trade shows (like drupa) and reading specialized publications provides insights into the latest technologies and trends.

- Professional Organizations: Membership in professional organizations like the Graphic Arts Technical Foundation (GATF) offers access to resources, training, and networking opportunities.

- Online Resources and Webinars: Utilizing online resources, webinars, and industry blogs keeps me abreast of new developments and best practices.

- Manufacturer Websites and Documentation: Staying updated on advancements from machinery manufacturers through their websites and technical documentation helps in effective machine operation and troubleshooting.

- Networking with Colleagues: Engaging with peers and experts in the field through conferences and professional forums provides valuable insights and perspectives.

For example, I recently attended a webinar on the advancements in digital finishing and learned about new automated solutions for inline finishing that optimize the entire print-to-finish process. This knowledge has been directly applicable to improving efficiency and reducing costs in our bindery.

Key Topics to Learn for Your Folding and Binding Interview

- Paper Handling and Properties: Understanding different paper types (weight, texture, finish), their suitability for various folding and binding techniques, and potential challenges in processing them.

- Folding Techniques: Mastering various folding methods (e.g., parallel folds, gate folds, roll folds) and their applications in different projects. Consider the impact of fold design on the final product’s aesthetics and functionality.

- Binding Methods: Familiarize yourself with different binding techniques (e.g., saddle stitch, perfect binding, wire-o binding, coil binding) and their appropriate uses based on document size, page count, and desired aesthetic.

- Finishing Processes: Understanding post-binding processes like trimming, cutting, and cover application, and their impact on the overall quality and presentation of the finished product.

- Equipment Operation and Maintenance: Demonstrate knowledge of common folding and binding machinery, including their operation, safety procedures, and basic maintenance requirements. Be prepared to discuss troubleshooting common equipment malfunctions.

- Quality Control and Inspection: Discuss your understanding of quality control procedures, including identifying defects and implementing corrective actions to ensure consistent product quality.

- Production Planning and Efficiency: Explore how to optimize production workflows, including job scheduling, material handling, and minimizing waste to improve efficiency and reduce costs.

- Safety Procedures and Regulations: Highlight your understanding and adherence to relevant safety regulations and best practices in a folding and binding environment.

Next Steps

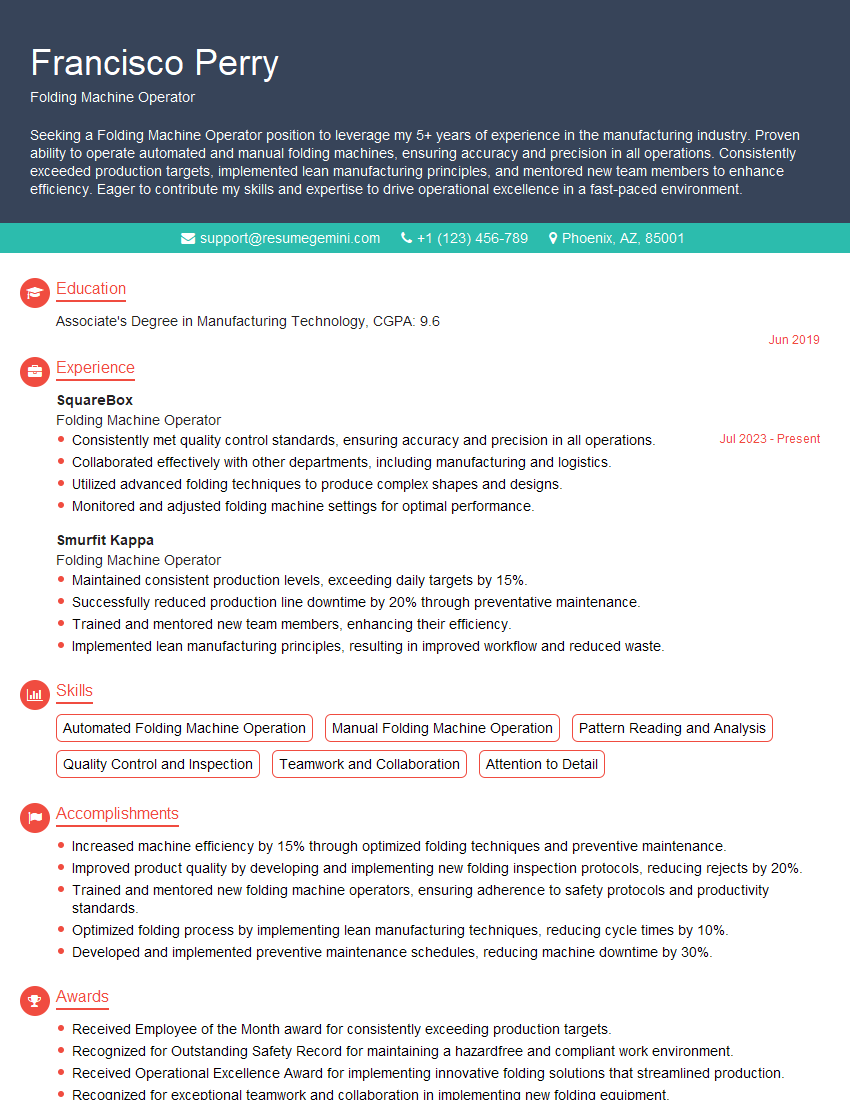

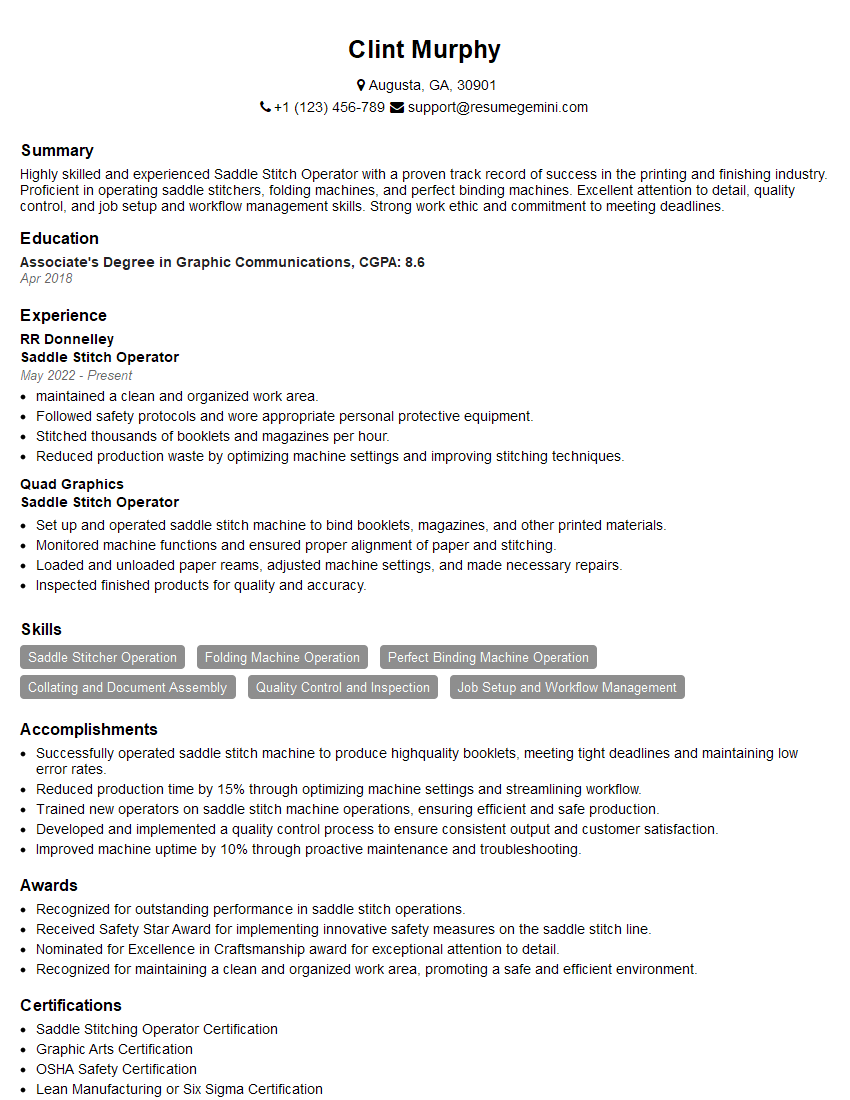

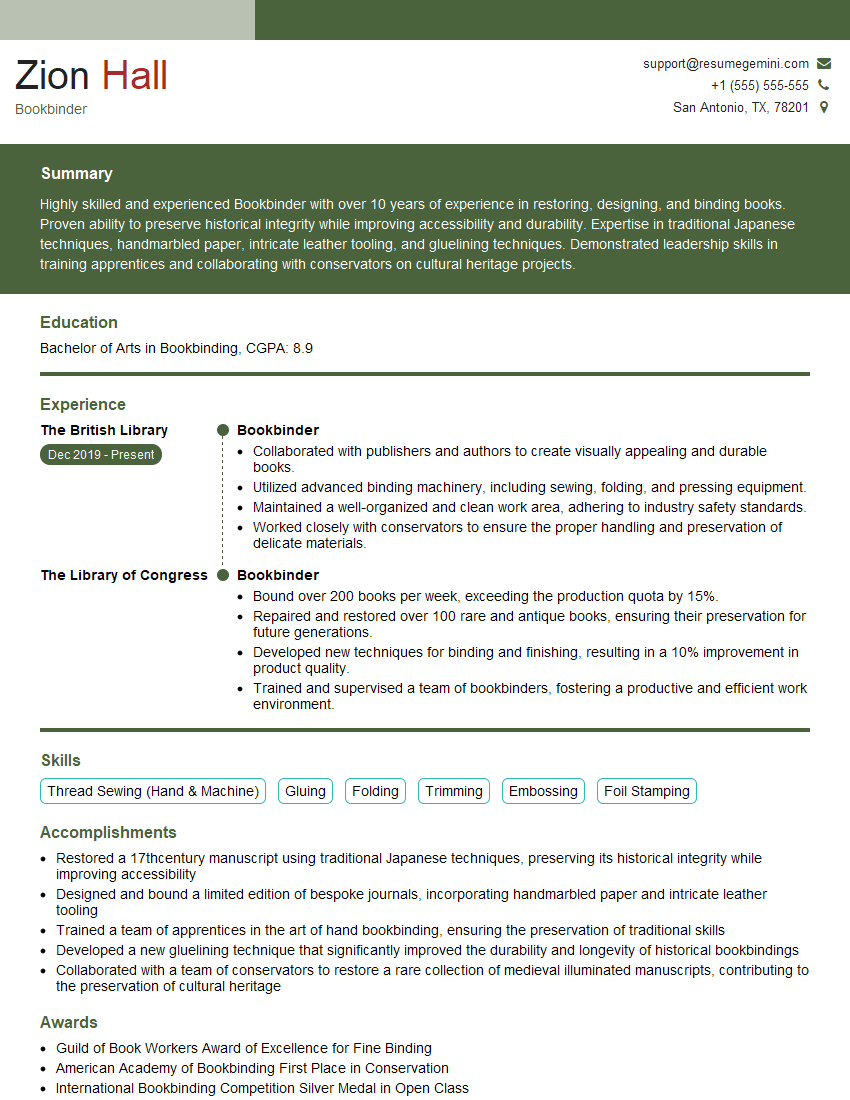

Mastering the art of folding and binding is crucial for a successful career in print finishing and related fields. It opens doors to diverse opportunities and showcases your attention to detail and technical expertise. To significantly increase your chances of landing your dream job, invest time in crafting an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specifics of the Folding and Binding industry. Examples of resumes tailored to this field are available to further guide your preparation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good