Preparation is the key to success in any interview. In this post, we’ll explore crucial Follow blueprints and specifications interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Follow blueprints and specifications Interview

Q 1. Explain the difference between a blueprint and a specification.

Blueprints and specifications are both crucial for construction and engineering projects, but they serve different purposes. Think of a blueprint as a visual roadmap, a detailed drawing showing the layout, dimensions, and relationships of various components. Specifications, on the other hand, are the written instructions that define the materials, methods, and quality standards required for each part of the project. A blueprint might show where a wall goes, but the specifications detail the exact type of brick, mortar, and insulation to be used.

- Blueprint: A visual representation, primarily showing spatial relationships and dimensions.

- Specification: A written document that outlines technical requirements, materials, and quality standards.

For example, a blueprint might show the location of a window, while the specifications would detail its size, type of glass (e.g., double-paned, tempered), frame material, and energy efficiency rating.

Q 2. How do you identify revisions and updates on a blueprint?

Revisions and updates on blueprints are typically indicated using a revision cloud or a revision block. These highlight the changes made to the original drawing. They often include a revision number (e.g., Rev. A, Rev. B), a date, and a description of the alteration. Sometimes, a letter or symbol will be placed directly on the drawing to show where changes have been made. Always check the title block of the blueprint; it usually contains the revision history.

For instance, if a mistake is found in the original layout of pipes, a revision cloud will surround the incorrect section of the blueprint. Next to it, you’ll find a note like ‘Rev A: Corrected pipe routing.’ This ensures everyone is working with the most up-to-date version.

Q 3. Describe your process for verifying that materials meet specifications.

Verifying materials against specifications involves a multi-step process that begins even before materials arrive on site. First, I carefully review the specifications to understand the exact requirements for each material – this includes material type, dimensions, tolerances, and quality standards (e.g., ASTM standards for steel). Second, I check the material’s accompanying documentation (certificates, test reports) to confirm it meets these specifications. Finally, I might conduct on-site inspections and tests (e.g., measuring dimensions, testing strength) to ensure the material is suitable for its intended purpose.

For example, if the specifications call for a specific type of concrete with a minimum compressive strength of 5000 psi, I’d check the concrete supplier’s certificate to verify that the delivered batch meets this requirement. I might even conduct a compressive strength test on a sample to independently confirm its compliance.

Q 4. What are the common symbols and notations found on blueprints?

Blueprints are full of symbols and notations. Understanding these is key to interpreting them correctly. Common symbols include those for plumbing fixtures (toilets, sinks, etc.), electrical components (switches, outlets, light fixtures), structural elements (beams, columns, walls), and architectural features (doors, windows). Notations might include dimensions (length, width, height), material specifications (e.g., concrete type, lumber grade), and notes explaining design details. There are industry standards (like ANSI) that establish many of these conventions.

- Dimensions: Often shown with arrows and numerical values.

- Materials: Designated by abbreviations or symbols (e.g., ‘C’ for concrete, ‘W’ for wood).

- Plumbing fixtures: Represented by standardized icons.

- Electrical symbols: Specific symbols for outlets, switches, and lighting.

Familiarity with these symbols is essential. It’s like learning a special language specific to the building industry. Many resources, including online databases and handbooks, provide comprehensive lists of these symbols and their meanings.

Q 5. How do you handle discrepancies between a blueprint and verbal instructions?

Discrepancies between blueprints and verbal instructions are a serious issue that demands immediate attention. My approach is always to prioritize the written documentation (the blueprint) unless there’s a documented change order or an official communication amending the original drawings. I would document the discrepancy clearly and immediately communicate it to the appropriate authority (e.g., project manager, architect, engineer). I would never proceed with work based solely on verbal instructions conflicting with the blueprint without proper authorization and updated documentation.

For instance, if the blueprint shows a specific type of pipe but verbal instructions call for a different type, I’d note the discrepancy in a project log and contact the supervisor for clarification. Continuing with the incorrect pipe without resolving this could lead to costly errors later on.

Q 6. Explain your experience using CAD software to interpret blueprints.

I have extensive experience using CAD software (AutoCAD, Revit) to interpret and work with blueprints. My skills include importing blueprints, reviewing 2D and 3D models, identifying design elements, creating sections and elevations, and generating quantity takeoffs. This allows me to perform detailed analyses and identify potential clashes or conflicts before construction begins. I can also use CAD to create my own drawings, add notes, annotate changes and make revisions.

In a recent project, I used Revit to create a 3D model of a complex building from the provided blueprints. The software allowed me to identify potential issues in the original design—for example, a clash between mechanical ductwork and a structural beam. Flagging this issue early saved both time and money.

Q 7. Describe a situation where you had to interpret a complex blueprint.

One project involved interpreting a blueprint for a renovation of a historical building with numerous additions and alterations over the years. The blueprint showed layers of different building codes and construction styles. The challenge was that the drawings weren’t always consistent or well-documented. To overcome this, I systematically analyzed each layer of the blueprint, cross-referencing different sections, and comparing them to existing structural elements on site. I used CAD software to create a 3D model, helping me visually identify conflicts and inconsistencies in the original design. This systematic approach allowed me to create a clear, updated set of drawings that formed the basis for a successful renovation project.

Q 8. How do you ensure compliance with safety regulations while following blueprints?

Ensuring safety compliance while following blueprints is paramount. It’s not just about following the lines; it’s about understanding the implications. My approach involves a multi-step process:

- Pre-work Safety Review: Before even touching tools, I thoroughly review the blueprints for any potential hazards. This includes identifying potential fall risks (indicated by heights or lack of scaffolding details), electrical hazards (power lines, conduit locations), and potential contact with hazardous materials (clearly marked on well-done blueprints).

- PPE Selection: Based on the identified hazards, I select the appropriate Personal Protective Equipment (PPE). This might range from safety glasses and gloves to hard hats, harnesses, and respirators.

- Site Safety Check: I conduct a physical inspection of the worksite to ensure it aligns with the blueprint’s safety notations and that there are no unforeseen risks. This often includes checking for proper site access, securing loose materials, and confirming the location of safety equipment.

- Adhering to Regulations: I strictly follow all relevant safety regulations, including OSHA (Occupational Safety and Health Administration) guidelines or equivalent local regulations, ensuring that all work is performed in compliance. This includes proper lockout/tagout procedures for machinery and following safe lifting techniques.

- Continuous Monitoring: Throughout the project, I constantly monitor the work area for any potential safety issues and address them immediately. This proactive approach helps prevent accidents and ensures a safe working environment.

For example, working on a high-rise building, I would always use appropriate fall protection gear, verifying the safety of harnesses and anchor points. Failing to do so could lead to severe injury or even fatality.

Q 9. What is your approach to identifying potential errors or omissions on a blueprint?

Identifying errors or omissions on a blueprint requires a methodical approach. I employ a checklist and several strategies:

- Cross-referencing: I carefully check for consistency between different sections of the blueprint. Dimensions should match, details should be coherent, and annotations should be clear and consistent.

- Dimensional Checks: I verify all dimensions using mathematical checks (e.g., ensuring that the total length matches the sum of individual segments). Discrepancies here often point to errors.

- Notation Review: I meticulously review all notations, symbols, and legends to ensure a complete understanding of the design intent. Missing or ambiguous notations can lead to serious issues.

- Material Specification Review: I make sure that materials specified are feasible, available and appropriately selected for intended purpose.

- Code Compliance Check: Where applicable, I cross-reference the blueprint with relevant building codes and standards to ensure compliance.

- Seeking Clarification: If any ambiguity or potential error exists, I immediately communicate my concerns to the project lead or designer for clarification before proceeding.

Imagine a situation where two adjacent walls are shown with different thicknesses on the blueprint. This could indicate an error leading to structural issues. Identifying and resolving this before construction starts prevents costly rework later.

Q 10. How do you prioritize tasks when working from multiple blueprints or specifications?

Prioritizing tasks when dealing with multiple blueprints and specifications involves a structured approach. My method uses a combination of dependency analysis and urgency assessment:

- Dependency Mapping: I identify tasks that depend on the completion of others. For instance, electrical work often relies on the completion of framing and drywall work.

For example, in a construction project, the foundation needs to be completed before the framing can begin. This dependency dictates the task priority.

Q 11. How familiar are you with different blueprint scales and their implications?

I am very familiar with different blueprint scales and their implications. Blueprint scales represent the ratio between the drawing dimensions and the actual dimensions. Common scales include 1:10, 1:20, 1:50, etc. Understanding the scale is crucial for accurate measurements and interpretations:

- Scale Conversion: I confidently convert measurements from the blueprint to real-world dimensions and vice-versa using the given scale. This involves simple multiplication or division.

- Scale Implications: I’m aware that inaccuracies in scaling can lead to significant problems if not carefully managed. A minor error on a blueprint can be magnified considerably in reality.

- Scale Selection: I understand the rationale behind choosing different scales depending on the complexity and size of the project. Detailed drawings of smaller components might use a larger scale (1:10), while overall building layouts use smaller scales (1:50 or 1:100).

Imagine a blueprint with a scale of 1:50. If a wall is shown as 10cm long on the blueprint, the actual wall length is 5 meters (10cm * 50).

Q 12. Explain your understanding of tolerance levels in specifications.

Tolerance levels in specifications define the acceptable range of variation from the nominal dimensions or values. These are crucial because achieving perfect precision is often impractical and costly:

- Understanding Tolerance: I understand that tolerance is expressed as a plus or minus value (e.g., ±0.5mm). This means the actual dimension can vary within this range without being considered defective.

- Tolerance Impact: I am aware that tolerances influence the manufacturing process, material selection, and assembly. Stricter tolerances often require more precise manufacturing methods and might increase costs.

- Interpreting Tolerances: I can interpret tolerance specifications correctly and ensure that the final product falls within the acceptable limits. This might involve using measuring instruments with the required accuracy.

For instance, if a bolt is specified as 10mm diameter with a tolerance of ±0.1mm, it means the acceptable diameter range is 9.9mm to 10.1mm. A bolt outside this range would be considered non-compliant.

Q 13. Describe your experience with different types of blueprints (e.g., architectural, mechanical, electrical).

I have extensive experience with various types of blueprints including architectural, mechanical, electrical, and plumbing blueprints:

- Architectural Blueprints: I can interpret floor plans, elevations, sections, and details to understand building layout, structural elements, and finishes.

- Mechanical Blueprints: I can read schematics and diagrams relating to HVAC (Heating, Ventilation, and Air Conditioning) systems, piping systems, and other mechanical equipment.

- Electrical Blueprints: I can interpret wiring diagrams, panel layouts, and power distribution plans to understand electrical systems and safety considerations.

- Plumbing Blueprints: I can interpret plumbing schematics, fixture locations, and piping layouts to understand water supply, drainage, and sanitation systems.

My experience spans across various projects, from residential renovations to large-scale industrial constructions. This has given me a broad understanding of how these different disciplines integrate in a complete project.

Q 14. How do you communicate effectively with team members about blueprint interpretations?

Effective communication regarding blueprint interpretations is vital for teamwork. My approach emphasizes clarity, precision, and active listening:

- Clear and Concise Language: I avoid technical jargon whenever possible, using plain language to convey information. I also provide visual aids (pointing directly to the relevant sections of the blueprint).

- Active Listening and Questioning: I encourage questions and actively listen to team members’ interpretations to address any discrepancies or misunderstandings.

- Documented Communication: I document all key interpretations and decisions in a shared log, ensuring that everyone has access to the same information. This might include detailed notes, sketches, or photos.

- Regular Team Meetings: I participate in regular team meetings where we review progress, discuss challenges, and clarify any ambiguity related to blueprint interpretations.

Imagine a scenario where the location of a critical pipe is unclear on the blueprint. By clearly discussing this with the plumbing team and documenting our final interpretation, we can avoid costly errors and ensure smooth project execution.

Q 15. How do you manage changes to blueprints during a project?

Managing blueprint changes requires a systematic approach. First, any proposed change must be formally documented and reviewed by the relevant stakeholders (e.g., architects, engineers, project managers). This typically involves a change request process, often involving a formal form outlining the proposed alteration, its justification, impact assessment, and the required approvals. Once approved, the blueprint is updated, usually with a revision number clearly indicated to track the changes. All team members are then notified of the revision and provided with the updated documents. We utilize version control systems, like cloud-based storage with revision history, to ensure everyone works with the most current version and historical versions remain accessible for reference. This minimizes confusion and potential errors resulting from outdated blueprints.

For example, if a structural beam’s location needs changing, a change request would detail the new location, the reason for the change (e.g., interference with plumbing), and the potential impact on other elements of the project. After approval, the revised blueprint is distributed, and all construction workers are informed of the change through a meeting or documented notification.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience using various measurement tools in conjunction with blueprints.

My experience with measurement tools alongside blueprints is extensive. I’m proficient in using various tools, from basic measuring tapes and levels to sophisticated laser distance meters and total stations. The choice of tool depends heavily on the task and the level of precision required. For example, a standard measuring tape suffices for verifying overall dimensions, while a laser distance meter offers greater speed and accuracy for precise measurements in challenging locations. I regularly use digital levels to ensure surfaces are perfectly level or plumb, referencing the blueprint’s elevation and alignment specifications. Total stations are invaluable for large-scale projects, offering high-accuracy measurements and data collection that can be directly integrated with CAD software, facilitating a seamless workflow between field measurements and the blueprint.

For instance, when laying out foundation footings, a total station is ideal for ensuring accurate placement relative to the blueprint’s coordinates. Conversely, verifying the size of a door opening would only require a simple measuring tape. The key is selecting the right tool for the job and understanding its limitations and precision capabilities.

Q 17. How do you handle ambiguous or unclear instructions on a blueprint?

Ambiguous or unclear instructions on a blueprint are unacceptable and must be addressed proactively. My approach involves systematically clarifying the ambiguity. First, I’d carefully review the entire blueprint to see if other sections shed light on the unclear area. I’d then consult the blueprint’s accompanying specifications, notes, and any other relevant documentation. If uncertainty remains, I wouldn’t proceed without seeking clarification from the architect or engineer responsible for the design. Open communication is critical here; documenting the ambiguity and the resolution in a log book or project management system is crucial for maintaining a clear audit trail and preventing future misunderstandings.

For example, if a dimension is missing or a symbol is unclear, I’d immediately raise a query to avoid errors. I’d document the query clearly, including a picture of the unclear area and submit it through the appropriate project communication channels. Waiting to address such issues until construction is underway can lead to costly mistakes and delays.

Q 18. How do you ensure accuracy and consistency when following blueprints?

Accuracy and consistency when following blueprints are paramount. I employ several strategies to ensure this. First, careful and methodical review of the blueprints is crucial. Cross-checking measurements, verifying dimensions, and confirming the compatibility of different sections of the plans are essential. Using checklists and pre-construction meetings with the team to discuss the plan and potential challenges helps maintain consistency. Regularly verifying measurements using appropriate tools and comparing them against the blueprint dimensions is essential for identifying deviations early on. This could involve creating a detailed measurement log that records all dimensions and their comparison with the blueprint values.

Maintaining a clean and organized workspace also helps improve accuracy. Clear labeling of materials and components reduces the risk of mistakes, leading to increased precision. Finally, thorough quality control checks at every stage of construction, along with regular communication and collaboration with the design team, are key to ensuring that the final product accurately reflects the blueprint.

Q 19. What are some common problems encountered when following blueprints?

Common problems encountered when following blueprints include:

- Inconsistent scaling or missing dimensions: This can lead to inaccurate measurements and misalignments.

- Ambiguous or unclear notations: Vague instructions can result in incorrect interpretations and costly errors.

- Conflicts between different sections of the blueprint: Discrepancies between drawings can cause delays and rework.

- Outdated or revised blueprints not being communicated effectively: Working with an outdated version of the blueprint can have significant consequences.

- Poor blueprint quality or readability: Faded lines or illegible text can easily lead to mistakes.

Addressing these requires careful pre-planning, thorough review, clear communication channels, and a proactive approach to resolving ambiguities or inconsistencies.

Q 20. How do you troubleshoot issues that arise from incorrect blueprint interpretation?

Troubleshooting issues arising from incorrect blueprint interpretation begins with identifying the source of the error. This involves carefully comparing the construction work with the blueprint, looking for deviations. Next, I’d trace back the steps of the construction process to pinpoint where the error occurred. A thorough review of the blueprint, including its notes, specifications, and relevant sections, is then conducted. If uncertainty still exists, consulting with the architect or engineer is essential. A detailed record of the issue, its cause, and the corrective actions taken must be maintained to prevent similar problems in the future. Often, this involves measuring the actual construction work and comparing it to the blueprint to determine the degree of deviation and the necessary adjustments. Finally, solutions must be approved by the relevant authorities before implementation.

For example, if a wall is built out of alignment, I’d carefully trace the construction steps and compare actual measurements to blueprint dimensions to identify the root cause. This might uncover a misinterpretation of a dimension or a misalignment during initial layout. Corrective actions might involve removing and rebuilding a section of the wall or making adjustments to adjacent components.

Q 21. Describe a time you had to adapt to unexpected changes in blueprint specifications.

In a recent project, we encountered an unexpected change in the blueprint specifications during the framing stage. The original plan called for a traditional wood-frame structure. However, due to a material shortage, a change order was issued to incorporate steel framing for a portion of the building. Initially, this presented a significant challenge, as our team’s expertise lay primarily with wood framing. However, we responded effectively by working closely with a steel framing subcontractor. We held collaborative meetings to review the revised blueprints and ensure everyone understood the implications of the change. We thoroughly reviewed the steel framing specifications and adapted our work schedule to accommodate the new materials and construction techniques. We carefully verified all measurements and connections to ensure compatibility with the rest of the structure. This experience highlighted the importance of adaptability, collaboration, and meticulous attention to detail when dealing with unforeseen changes to blueprint specifications. The project was successfully completed on time despite the unexpected switch in framing material, demonstrating the team’s ability to efficiently handle and integrate such unforeseen circumstances.

Q 22. How do you maintain organized records of blueprints and specifications?

Maintaining organized records of blueprints and specifications is crucial for efficient project management and seamless collaboration. My approach involves a multi-layered system combining digital and physical organization.

- Digital Organization: I utilize a cloud-based document management system (DMS) like Autodesk BIM 360 or similar platforms. This allows for version control, easy access for team members, and efficient searching using keywords and metadata. I categorize documents meticulously using a consistent naming convention (e.g., Project Name_Drawing Number_Revision_Date).

- Physical Organization: For hard copies, I employ a robust filing system using clearly labeled folders and binders. This ensures quick retrieval of physical blueprints when needed, particularly in situations with limited internet access.

- Metadata & Indexing: Each blueprint and specification is meticulously tagged with relevant metadata including project name, date, revision number, author, and relevant keywords. This facilitates efficient searching and retrieval within the DMS.

This dual approach ensures redundancy and easy access, regardless of whether I’m working in the office or on a site.

Q 23. What software or tools are you proficient in using to work with blueprints?

Proficiency in blueprint-related software is essential. My expertise spans several platforms, each tailored to specific needs.

- AutoCAD: This is my primary tool for reviewing, annotating, and manipulating 2D drawings. I’m adept at using its various tools for dimensioning, layering, and creating detailed annotations.

- Revit: For 3D modeling and BIM (Building Information Modeling) projects, I am proficient in Revit. This allows me to navigate and understand complex building models, extract information, and coordinate with other disciplines.

- Bluebeam Revu: This is invaluable for collaboration, markups, and PDF management. I use it extensively for reviewing documents, adding comments, and tracking changes across revisions.

- Navisworks: For complex projects involving multiple disciplines and large datasets, I use Navisworks for model coordination and clash detection.

Beyond these, I’m also comfortable using various PDF readers and editors for basic annotation and markup.

Q 24. How do you ensure the timely completion of tasks based on blueprint instructions?

Ensuring timely completion relies on meticulous planning and proactive task management.

- Detailed Breakdown: I begin by breaking down the project into manageable tasks, directly referencing the blueprints and specifications for each step. Each task is assigned a realistic timeframe.

- Gantt Charts/Project Management Software: I use project management software (like MS Project or Asana) or create Gantt charts to visualize the timeline, dependencies between tasks, and potential bottlenecks.

- Regular Monitoring & Adjustment: I regularly monitor progress against the schedule and make necessary adjustments, reporting any delays or challenges proactively.

- Prioritization: I prioritize tasks based on critical path analysis to ensure the project stays on track.

For example, if a blueprint requires specific material procurement that takes longer than initially estimated, I immediately communicate this and adjust the schedule accordingly, preventing cascading delays.

Q 25. How do you identify and report potential safety hazards from blueprints?

Safety is paramount. My process for identifying and reporting hazards from blueprints involves a systematic review.

- Detailed Examination: I meticulously review each blueprint, paying close attention to details that might indicate potential hazards. This includes checking for proper fall protection measures, electrical safety protocols, confined space entries, and emergency exits.

- Compliance Checks: I verify the blueprint’s compliance with relevant safety regulations and codes, such as OSHA standards.

- Risk Assessment: I conduct a risk assessment to evaluate the likelihood and severity of identified hazards. This may involve identifying potential pinch points in machinery, lack of proper guarding, or inadequate lighting.

- Reporting and Documentation: I immediately report any identified hazards through the appropriate channels, using clear and concise language to detail the issue, its location, and potential consequences. I document all findings and corrective actions taken.

Imagine a blueprint showing scaffolding without proper guardrails – I would immediately flag this as a high-risk hazard and recommend corrective measures before construction begins.

Q 26. What methods do you use to verify the completeness and accuracy of blueprints?

Verifying the completeness and accuracy of blueprints is vital to prevent costly errors and delays. My approach involves several checks.

- Cross-referencing: I cross-reference information across multiple drawings and specifications to ensure consistency. For example, I would verify that dimensions mentioned in one drawing are consistent with related drawings.

- Dimension & Calculation Checks: I perform calculations and dimensional checks to confirm accuracy. This involves verifying areas, volumes, and ensuring dimensions are logical and consistent.

- Material Specifications Review: I meticulously review material specifications to ensure they meet project requirements and industry standards.

- Review with Stakeholders: I collaborate with engineers, architects, and other relevant stakeholders to review the blueprints and identify potential issues collaboratively.

This multi-faceted approach ensures that the blueprints are not only complete but also accurate and suitable for construction.

Q 27. Describe your experience in following industry-specific standards and codes while working from blueprints.

Adherence to industry-specific standards and codes is fundamental to my work.

- Code Familiarity: I am familiar with relevant building codes, such as IBC (International Building Code) and local ordinances. My understanding extends to relevant electrical codes (NEC), plumbing codes (IPC), and fire safety codes.

- Reference Materials: I readily utilize code books and online resources to clarify any ambiguities or ensure compliance with specific requirements.

- Collaboration: I collaborate with engineers and architects to ensure that the designs meet all applicable codes and standards.

- Documentation: I maintain a detailed record of the codes and standards followed for each project, ensuring traceability and accountability.

For instance, when working on a project requiring ADA compliance, I meticulously check all drawings to ensure that they meet the requirements for accessibility, relying on the ADA standards and referencing relevant sections throughout the process. This ensures the project is not only structurally sound but also legally compliant and safe for all users.

Key Topics to Learn for Follow Blueprints and Specifications Interviews

- Understanding Blueprint Terminology: Mastering the language of blueprints, including common symbols, notations, and abbreviations, is crucial. This includes understanding different blueprint types (e.g., architectural, mechanical, electrical).

- Interpreting Drawings and Diagrams: Practice interpreting various drawing types, such as floor plans, elevations, sections, and details. Focus on extracting relevant information and identifying potential conflicts or ambiguities.

- Spatial Reasoning and Visualization: Develop strong spatial reasoning skills to accurately visualize three-dimensional structures from two-dimensional drawings. This is essential for understanding relationships between different components.

- Specifications Analysis: Learn to effectively analyze written specifications to understand material requirements, tolerances, and construction methods. Practice identifying inconsistencies between blueprints and specifications.

- Problem-Solving and Critical Thinking: Develop your ability to identify potential issues, propose solutions, and justify your approach based on blueprints and specifications. Practice working through hypothetical scenarios.

- Collaboration and Communication: Understand how blueprints and specifications facilitate collaboration among different teams and stakeholders. Practice explaining complex technical details clearly and concisely.

- Relevant Software and Tools: Familiarize yourself with commonly used software for working with blueprints and specifications (if applicable to the role). This could include CAD software or project management tools.

- Safety Regulations and Compliance: Understand the safety regulations and compliance standards relevant to the industry and how they are reflected in blueprints and specifications.

Next Steps

Mastering the ability to follow blueprints and specifications is fundamental for success in many technical roles, demonstrating attention to detail, problem-solving skills, and the ability to translate technical documents into action. A strong understanding of this skillset significantly enhances your career prospects and opens doors to more advanced positions.

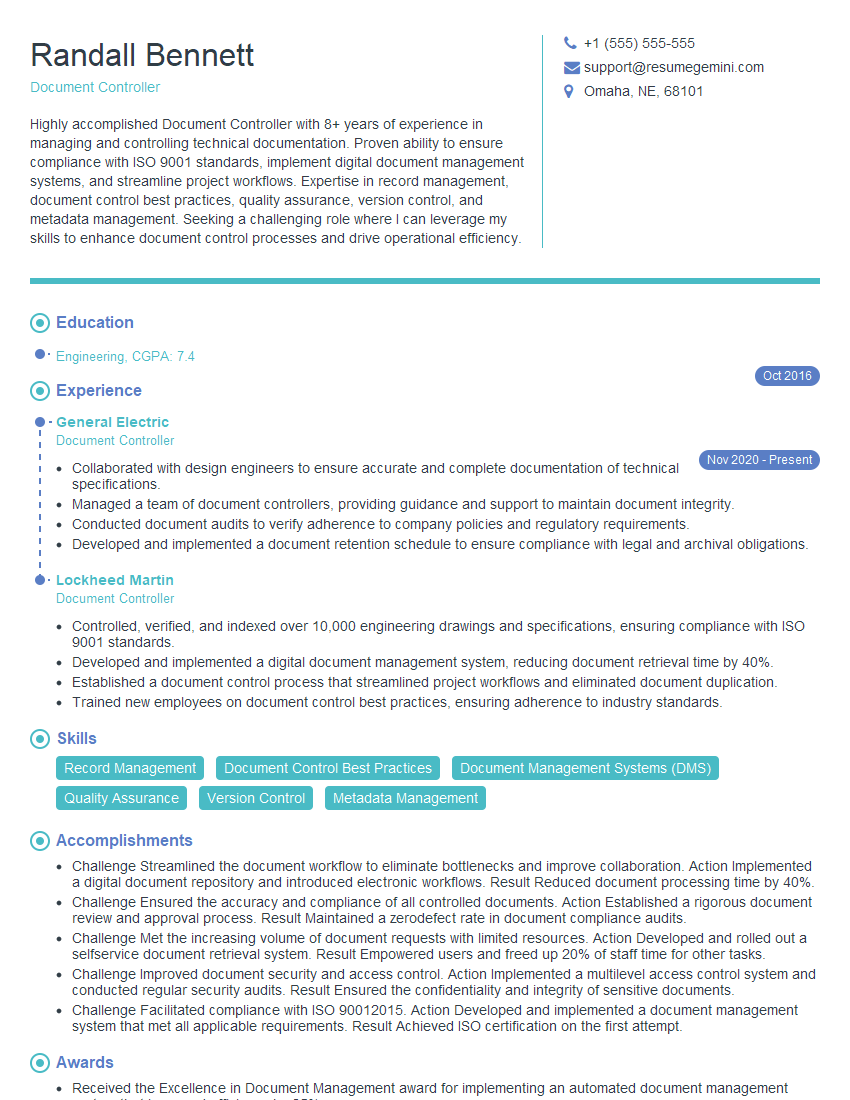

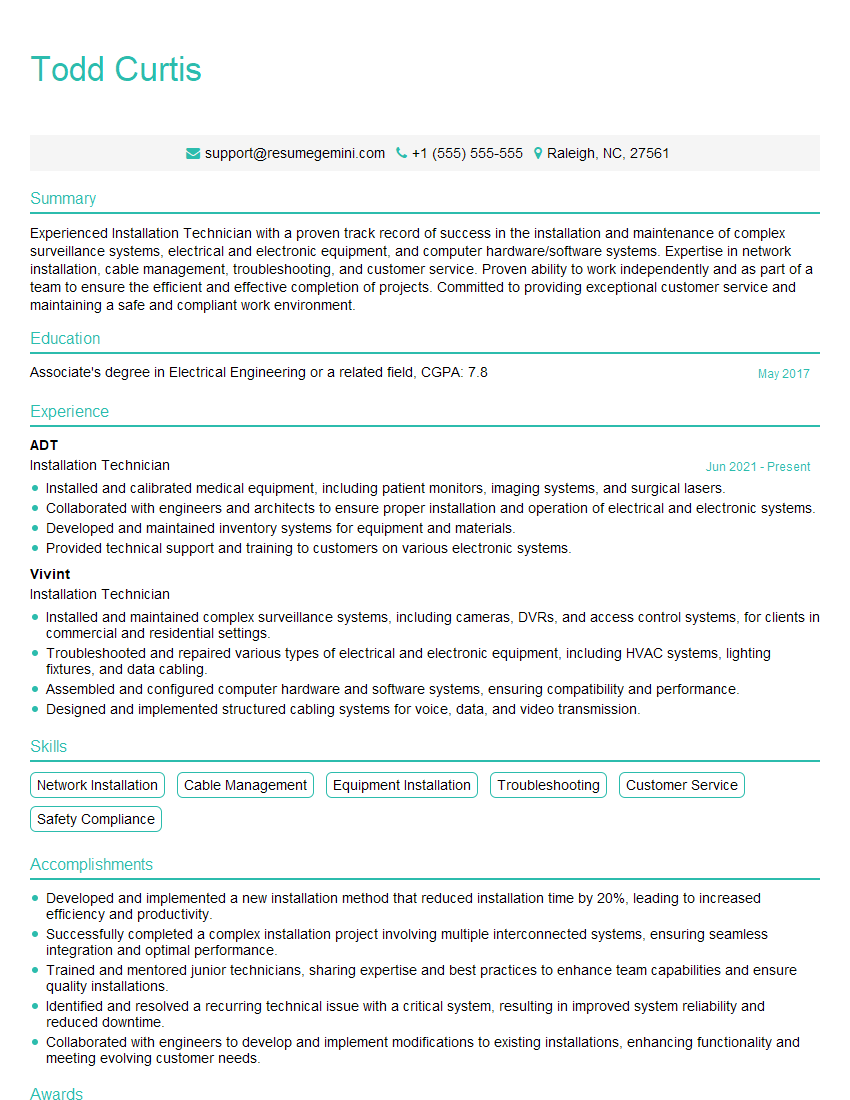

To increase your chances of landing your dream job, creating an ATS-friendly resume is essential. A well-structured resume highlights your skills and experience effectively to Applicant Tracking Systems (ATS), maximizing your visibility to recruiters. We recommend using ResumeGemini, a trusted resource for building professional and impactful resumes. Examples of resumes tailored to highlight expertise in following blueprints and specifications are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good