The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Foundry Pattern Design interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Foundry Pattern Design Interview

Q 1. Explain the different types of foundry patterns.

Foundry patterns are the templates used to create molds for casting metal parts. They come in various types, each suited to different production needs and casting processes. The choice depends on factors like the complexity of the casting, the number of castings required, and the material being cast.

- Wooden Patterns: These are the most common, economical, and versatile type, ideal for single castings or small production runs. They’re easy to modify and relatively inexpensive to produce.

- Metal Patterns: Made from materials like aluminum, steel, or cast iron, they offer superior durability and dimensional accuracy, making them suitable for high-volume production. Their higher cost is justified by their longevity and the precision they provide.

- Plastic Patterns: These patterns offer a good balance between cost and durability. They are lightweight, resistant to moisture and are often preferred for intricate designs.

- Expanded Polystyrene (EPS) Patterns: These are foam patterns that are melted away during the casting process, making them ideal for investment casting.

- Composite Patterns: These patterns combine different materials to leverage the advantages of each. For instance, a wooden core might be combined with a metal outer shell.

Each pattern type has its strengths and weaknesses, and selecting the appropriate type is a crucial decision in the foundry process.

Q 2. Describe the process of creating a wooden pattern.

Creating a wooden pattern is a skilled process that involves several steps. Think of it like sculpting a three-dimensional negative of your final casting.

- Design and Drawings: The process starts with detailed engineering drawings that specify the dimensions, tolerances, and features of the casting.

- Material Selection: Hardwoods like mahogany or maple are often preferred due to their strength, stability, and ability to hold fine detail.

- Rough Shaping: Using tools like bandsaws, chisels, and planes, the pattern maker roughly shapes the wood to the overall dimensions of the casting.

- Finishing and Detailing: Precise shaping and fine details are added using various hand tools and specialized woodworking machinery.

- Surface Finishing: The pattern is carefully sanded and smoothed to ensure a smooth surface and prevent defects in the casting. This often includes the application of parting agents like shellac or varnish to facilitate the removal of the pattern from the mold.

- Inspection: The final pattern undergoes rigorous inspection to verify its accuracy and adherence to the design specifications. This typically involves precise measurements and comparisons against the original drawings.

Experienced pattern makers use their expertise and knowledge of woodworking techniques to ensure that the final pattern meets the required quality standards.

Q 3. What are the advantages and disadvantages of using metal patterns?

Metal patterns offer significant advantages, but they also have drawbacks compared to other pattern types.

- Advantages:

- High Durability: They can withstand repeated use in high-volume production, significantly reducing the cost per casting over time.

- Excellent Dimensional Accuracy: Metal patterns offer superior dimensional stability and accuracy, leading to consistently high-quality castings.

- Smooth Surface Finish: They produce smoother casting surfaces compared to wooden patterns.

- Faster Mold Making: The durability means less time spent making and repairing patterns.

- Disadvantages:

- High Initial Cost: Metal patterns require specialized machinery and skilled labor to manufacture, resulting in a higher initial investment.

- Difficult to Modify: Making changes to a metal pattern is much more challenging and expensive than modifying a wooden pattern.

- Weight: Metal patterns can be heavy and difficult to handle, requiring specialized equipment for larger patterns.

The decision of whether to use metal patterns hinges on balancing the higher initial cost against the long-term benefits of durability, accuracy, and efficiency in high-volume production scenarios.

Q 4. How do you ensure the accuracy of a pattern?

Ensuring pattern accuracy is paramount for producing quality castings. Several methods are employed to maintain precision:

- Precise Measurements: Using precision measuring instruments like calipers, micrometers, and height gauges throughout the pattern making process.

- Template Use: Using templates or jigs during the pattern construction process to ensure consistent dimensions and angles.

- Regular Inspection: Performing frequent inspections and checks against the original design drawings to catch any deviations early on.

- Coordinate Measuring Machine (CMM): Using a CMM for complex patterns to provide accurate 3D measurements and identify any dimensional inaccuracies.

- Master Pattern: Creating a master pattern from which multiple copies are produced. This ensures that all patterns are identical.

- Proper Material Selection: Selecting stable materials that are less prone to shrinkage, warping, or damage will reduce inaccuracies over time.

A combination of these methods is often employed to guarantee that the final pattern aligns perfectly with the specifications and meets the stringent quality control criteria.

Q 5. What are the different types of pattern allowances?

Pattern allowances compensate for the changes that occur during the molding and casting process. These allowances are added to the pattern to ensure that the final casting achieves the desired dimensions. Common allowances include:

- Shrinkage Allowance: Accounts for the contraction of the metal as it cools and solidifies. This allowance varies depending on the type of metal being cast.

- Draft Allowance: Provides a slight taper to the pattern, enabling easy removal of the pattern from the mold.

- Machining Allowance: Added to the pattern to allow for subsequent machining operations on the casting to achieve final dimensions and surface finish.

- Shaking Allowance: Compensates for the slight compression of the molding sand during the molding process.

- Rapping Allowance: Accounts for the slight expansion of the mold after rapping (tapping) the pattern to loosen it before removal.

The specific allowances required will depend on the casting material, casting process, and the complexity of the part.

Q 6. Explain the concept of draft angles in pattern making.

Draft angles are the slight tapers incorporated into the sides of the pattern. They’re crucial for ensuring that the pattern can be easily removed from the mold without damaging either the pattern or the mold. Imagine trying to pull a perfectly cylindrical object out of a snug-fitting hole—it’s practically impossible.

Draft angles typically range from 1° to 7°, depending on the material of the pattern, the casting process, and the complexity of the part. Steeper draft angles are necessary for deeper cavities or undercuts. The draft is applied to all vertical surfaces of the pattern to facilitate easy removal, minimizing the risk of damage or distortion.

The absence or insufficient draft angle can lead to pattern breakage, mold damage, or defective castings. Properly calculated draft angles are essential for smooth and efficient pattern removal, ensuring the integrity of both the mold and the final casting.

Q 7. Describe the process of creating a core box.

A core box is a pattern used to create cores, which are essentially internal shapes within a casting. These cores form hollow spaces, recesses, or other internal features that can’t be created simply by the main pattern. For example, the hollow space inside a pipe or the channels inside a cylinder head would require cores.

Creating a core box is similar to pattern making, but focused on the internal features. The process generally involves:

- Design: The design of the core box is based on the required internal shape and dimensions of the casting.

- Material Selection: Similar to patterns, wood, metal, or plastic can be used based on production volume and accuracy requirements.

- Construction: The core box is constructed to create a cavity that is the exact negative of the desired core shape.

- Finishing: Careful finishing ensures a smooth surface to facilitate the easy removal of the core and prevent defects in the casting.

- Draft Angles: Draft angles are critical in core boxes to enable the easy removal of the core from the box.

- Inspection: The core box is thoroughly inspected to ensure its accuracy and functionality.

Core boxes are essential for creating intricate castings with internal features and are often made as a separate component, alongside the main pattern, to form the complete mold.

Q 8. What materials are commonly used for making patterns?

Pattern materials must be strong enough to withstand handling and the molding process, yet easily removable from the mold without damage. The choice also depends on the number of castings needed.

- Wood: Traditionally used for its ease of working and cost-effectiveness, especially for small to medium-sized castings. It’s suitable for simpler designs, but susceptible to moisture absorption and warping. Think of a classic wooden pattern for a simple gear.

- Metal: Offers superior durability and accuracy for high-volume production. Aluminum and steel are common choices. Metal patterns can withstand many castings, but they are more expensive to create initially. Imagine using a metal pattern for mass-producing engine blocks.

- Plastic: Provides a good balance between cost and durability. Common plastics include ABS and polyurethane. Plastics are less prone to warping than wood but may not be as robust as metal for extreme production runs. A plastic pattern might be used for intricate components with many undercuts.

- Epoxy: Offers excellent dimensional stability and surface finish, especially for complex shapes. This can be expensive and requires specialized skills in production. For highly detailed castings requiring precision, an epoxy pattern would be a good choice.

Q 9. How do you select the appropriate material for a specific pattern?

Selecting the right pattern material involves considering several factors:

- Number of castings: For a small number of castings, wood or plastic might suffice. For mass production, metal is preferred.

- Complexity of the casting: Intricate designs might require epoxy for accuracy, while simpler shapes can use wood or plastic.

- Casting material: The pattern material needs to be compatible with the molten metal to prevent reactions or damage. For example, a wood pattern wouldn’t be appropriate for exceptionally high-temperature alloys.

- Cost: The cost of the pattern material needs to be balanced against production costs.

- Dimensional accuracy required: For high-precision castings, metal or epoxy patterns are better options.

For example, a large, simple iron casting might utilize a wooden pattern for its initial runs, while a high-precision, small aluminum die-casting might need a metal or epoxy pattern to ensure dimensional stability and longevity.

Q 10. Explain the importance of proper gating and risering systems.

Proper gating and risering systems are crucial for successful casting. They control the flow of molten metal into the mold cavity, ensuring complete filling and minimizing defects.

Gating system: Directs the molten metal from the pouring basin into the mold cavity. It needs to be designed to minimize turbulence, prevent air entrapment, and provide a controlled flow rate to avoid erosion or splashing.

Risering system: Compensates for the shrinkage that occurs as the metal cools and solidifies. Riser(s) are reservoirs of molten metal that feed the casting as it shrinks, helping to prevent shrinkage cavities. Poor risering can lead to significant defects.

A well-designed gating and risering system is like a carefully planned water distribution network – ensuring smooth, controlled flow to all parts of the system and maintaining consistent pressure. Without it, you risk incomplete filling or significant casting defects.

Q 11. Describe different types of molding sands and their applications.

Molding sands are crucial for creating the mold cavity. Different sands offer unique properties:

- Green Sand: A mixture of silica sand, clay, and water. It’s widely used due to its cost-effectiveness and moldability, but its strength and permeability depend on moisture content. This is a good choice for simple castings.

- Dry Sand: Green sand that has been baked or dried after the mold is formed. This increases strength and permeability, resulting in better surface finish and dimensional accuracy, suitable for more complex shapes and higher-quality castings.

- Oil-Sand: Uses oil as a binder instead of clay, offering improved strength, collapsibility, and reusability. It is often used for larger castings and intricate designs.

- Synthetic Sands: Made from manufactured materials, they offer controlled properties like higher strength, better permeability, and consistent quality. These sands are used for more sophisticated casting processes and when specific properties are required.

The choice of molding sand depends on factors like the casting size, complexity, and required surface finish. For example, a small, simple part might be molded using green sand, while a large, intricate casting might require oil-sand or a synthetic sand for better control and dimensional accuracy.

Q 12. What are the common defects found in castings and their causes?

Casting defects can be costly and time-consuming. Some common ones include:

- Shrinkage Cavities: Form due to insufficient molten metal to compensate for volume reduction during cooling.

- Porosity: Gas bubbles trapped within the solidified metal, leading to weakness and reduced mechanical properties.

- Hot Tears: Cracks formed due to internal stresses during cooling. Often occur in thick sections.

- Cold Shut: Incomplete fusion of two streams of molten metal. Often seen in thicker sections where the metal doesn’t flow properly.

- Misruns: Incomplete filling of the mold cavity, often due to improper gating or insufficient fluidity of the molten metal.

- Surface Defects: Sand inclusions, scabs (surface irregularities), or wash (erosion of the mold surface).

Causes of these defects vary but often involve improper mold design, inadequate gating and risering, poor molding practices, or improper metal composition or temperature.

Q 13. How do you prevent shrinkage cavities in castings?

Preventing shrinkage cavities requires careful design of the risering system. Strategies include:

- Proper Riser Design: Use appropriately sized and positioned risers to ensure sufficient molten metal supply as the casting solidifies. The riser should solidify after the casting, feeding molten metal into the shrinking regions.

- Riser Placement: Place risers strategically in the thickest sections of the casting, where the most shrinkage is expected.

- Chill Design: Use chills (metal inserts) in the mold to accelerate cooling in specific areas, directing the flow of molten metal to the riser.

- Mold Material Selection: Use appropriate molding sand with adequate permeability to ensure proper heat transfer. Permeable sand allows escaping gases to vent easily.

- Proper Pouring Temperature: Ensure the molten metal is at the correct temperature to maintain fluidity and minimize gas entrapment.

Thinking about it like a balloon slowly deflating – the riser acts as a reservoir to keep the balloon filled as it shrinks.

Q 14. Explain the role of CAD/CAM in pattern design.

CAD/CAM plays a pivotal role in modern pattern design, greatly improving efficiency and accuracy.

CAD (Computer-Aided Design): Allows for the creation of 3D models of the patterns. This enables precise control over dimensions, geometry, and surface features. Designers can easily make modifications and simulations before physical production, reducing errors and iterations.

CAM (Computer-Aided Manufacturing): Uses the CAD model to generate instructions for manufacturing the pattern. This could involve CNC machining for metal patterns, 3D printing for plastic or epoxy patterns, or even instructions for wood pattern creation.

Benefits include improved accuracy, reduced lead times, enhanced design complexity, and better collaboration within design teams. For instance, imagine a complex turbine blade design; CAD/CAM would allow for precise creation of the pattern, enabling intricate details impossible to achieve manually.

Q 15. What software are you proficient in for pattern design?

My proficiency in pattern design software spans several leading industry applications. I’m highly skilled in using Autodesk Inventor for 3D modeling and creating detailed pattern designs. Its powerful features for creating complex geometries and generating detailed manufacturing drawings are essential for my work. I also have significant experience with SolidWorks, which I utilize primarily for its excellent assembly modeling capabilities, particularly helpful when designing multi-part patterns. Finally, I’m familiar with AutoCAD for 2D drafting and detail drawing creation, crucial for communicating design specifications to the manufacturing floor. Each software has its strengths; I choose the most appropriate tool depending on the project’s complexity and specific needs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret engineering drawings for pattern making?

Interpreting engineering drawings for pattern making requires a keen eye for detail and a thorough understanding of foundry practices. My process starts with a careful review of the casting design, noting critical dimensions, tolerances, draft angles, and core locations. I then consider the casting material, as this dictates the pattern’s size and allowances for shrinkage and machining. For example, gray iron castings have a higher shrinkage rate than aluminum, requiring a larger pattern. I then analyze the drawing for any special features, such as undercuts or complex internal cavities, planning the appropriate gating and riser systems. Finally, I determine the best pattern type – wood, metal, or foam – based on the casting’s complexity and production volume. Think of it like translating a recipe into a specific set of cooking instructions. The engineering drawing is the recipe; my interpretation creates the actionable steps to build the pattern.

Q 17. Describe your experience with CNC machining in pattern making.

My experience with CNC machining in pattern making is extensive. I’ve used CNC routers and milling machines to create high-precision patterns from various materials, including wood, polyurethane, and aluminum. I’m proficient in programming CNC machines using CAM software like Mastercam, translating my 3D CAD models into machine-readable instructions. For instance, I recently used a CNC router to machine a complex wooden pattern for a large pump housing, achieving tolerances of ±0.2mm. CNC machining significantly improves accuracy, repeatability, and efficiency, particularly for intricate designs that would be challenging or time-consuming to create manually. It’s like having a highly skilled, tireless assistant that ensures consistency across every pattern.

Q 18. Explain your experience with different pattern finishing techniques.

Pattern finishing techniques are critical for ensuring the quality and durability of the final casting. My experience encompasses a range of techniques, starting with basic sanding and smoothing to remove machining marks. I’m adept at applying various coatings, such as parting agents (to prevent sticking) and sealants (to protect against moisture), selected based on the pattern material and casting process. For intricate patterns, I employ fine-detail hand finishing, often using specialized tools to achieve a smooth, accurate surface. For large-scale patterns, I utilize automated sanding and finishing systems to improve speed and consistency. I also have experience with applying specialized finishes like epoxy coatings or polyurethane to improve wear resistance and prolong the life of the pattern. It’s important to choose finishing methods carefully. A poorly finished pattern can lead to defects in the final casting.

Q 19. How do you handle complex geometries in pattern design?

Handling complex geometries in pattern design requires a systematic approach and a deep understanding of 3D modeling techniques. I typically begin by simplifying the geometry into manageable components, using features like Boolean operations (union, subtraction, intersection) in CAD software to construct the pattern from basic shapes. For intricate details, I leverage surface modeling techniques to create smooth, accurate representations. I then utilize advanced simulation tools to check for potential issues like undercuts or draft angle problems before proceeding to manufacturing. For example, a turbine blade pattern requires careful attention to intricate curves and thin sections. By breaking it down into manageable segments, creating each section separately, and then digitally assembling them, I can manage the geometric complexity effectively. Accurate modeling is crucial; errors at this stage can have costly consequences later.

Q 20. Describe your process for troubleshooting pattern-related issues.

Troubleshooting pattern-related issues requires a methodical approach. I start by carefully examining the casting defect, correlating it to possible sources in the pattern. This may involve inspecting the pattern for damage, checking dimensions against the engineering drawing, or analyzing the mold filling simulation. If the issue is related to pattern design, I revise the model in CAD and re-machine or modify the pattern accordingly. If the problem lies in the molding process, I would collaborate with the foundry personnel to identify and correct any issues related to sand preparation, core setting, or gating systems. A systematic approach of review, investigation, and correction ensures quick resolutions. Documenting all changes and the root cause analysis is crucial to prevent the recurrence of similar problems.

Q 21. How do you manage multiple projects simultaneously in a fast-paced foundry environment?

Managing multiple projects simultaneously in a fast-paced foundry environment requires excellent organizational and time management skills. I utilize project management software to track deadlines, resource allocation, and progress. I prioritize tasks based on urgency and impact, focusing on the most critical aspects of each project. Effective communication with the foundry team and clients is key to keeping everyone informed and aligned. This involves regular progress updates, open communication channels, and proactive problem-solving. I also delegate tasks where appropriate, ensuring a smooth workflow. Think of it like a conductor of an orchestra; every player needs direction and support to create a harmonious outcome. Prioritization, communication, and delegation are crucial to success in a high-pressure environment.

Q 22. How do you ensure the quality and accuracy of your patterns?

Ensuring pattern quality and accuracy is paramount in foundry work, as it directly impacts the final casting’s quality. My approach is multifaceted and begins even before the design phase. I meticulously study the engineering drawings and specifications, clarifying any ambiguities with the engineering team upfront. This includes a thorough understanding of dimensional tolerances, surface finish requirements, and any special features or internal complexities.

During the pattern-making process itself, I utilize precision tools and techniques, including Computer Numerical Control (CNC) machining for intricate details and complex geometries. For wood patterns, I employ skilled craftsmanship and utilize precise measurement tools at each stage. After the pattern is completed, I perform rigorous quality checks, using inspection tools such as calipers, micrometers, and surface roughness gauges. Any deviations from the design specifications are documented and addressed immediately. Furthermore, I often create master patterns for smaller, more repetitive castings, ensuring consistency and reducing errors in subsequent pattern production. This multi-stage approach ensures that the resulting pattern is a faithful representation of the desired casting.

Q 23. Describe your experience with different casting processes (sand casting, investment casting, etc.)

My experience encompasses a range of casting processes, each with its own unique characteristics and applications. Sand casting, the most traditional method, is invaluable for its versatility and cost-effectiveness, particularly for large or simple castings. I’m proficient in both green sand and resin-bonded sand molding, understanding the nuances of mold preparation, gating systems, and riser design. I have extensive experience in investment casting (lost-wax casting), which allows for intricate details and complex geometries not achievable with sand casting. This process demands a higher level of precision in pattern design due to the investment shell’s fragility. My experience also includes die casting, suited for high-volume production of smaller, simpler parts and requiring specific pattern designs optimized for die life and ejection mechanisms. The choice of casting process always depends on factors like part complexity, production volume, and desired surface finish.

Q 24. What safety precautions do you take while working in a foundry?

Safety is paramount in a foundry environment. My daily practice includes adhering to strict safety protocols, including wearing appropriate Personal Protective Equipment (PPE) such as safety glasses, hearing protection, gloves, and steel-toed boots. I am trained in the safe handling of molten metal, aware of the dangers of burns and splashes, and meticulously follow procedures for pouring and cooling. I regularly inspect equipment for damage or malfunctions, reporting any issues immediately. Understanding the risks associated with specific materials is crucial. For example, working with certain alloys requires additional precautions due to toxicity or flammability. I’m familiar with emergency procedures and know how to use fire extinguishers and other safety equipment. Moreover, I consistently emphasize and uphold safety awareness amongst my team members, reinforcing safe practices through regular training and discussions.

Q 25. Describe your experience working with different types of metals.

I have worked extensively with a wide array of metals, including aluminum alloys, various steel grades (stainless, carbon, tool steels), cast iron (grey, ductile), bronze, and brass. Each metal has unique properties influencing pattern design. For example, aluminum’s tendency to shrink significantly requires larger patterns with strategically placed risers, while steel’s higher melting temperature necessitates a robust mold and gating system. Cast iron’s propensity for shrinkage and solidification stresses dictates specific design considerations for minimizing internal defects. My experience allows me to tailor the pattern design to the specific metal’s characteristics, ensuring optimal casting quality and minimizing defects. Understanding the thermal properties, fluidity, and shrinkage rates of each metal is crucial in creating a successful pattern.

Q 26. How do you stay up-to-date with the latest advancements in foundry technology?

Staying current in foundry technology is crucial for maintaining a competitive edge. I actively participate in industry conferences and workshops, attending seminars and presentations on new materials, processes, and software. I’m a member of professional organizations such as the American Foundry Society (AFS), providing access to publications, online resources, and networking opportunities. I regularly read industry journals and publications, keeping abreast of the latest research and innovations. I also leverage online learning platforms and educational resources to expand my knowledge on topics such as additive manufacturing and advanced simulation techniques. Furthermore, I actively seek out opportunities to learn from colleagues and experienced professionals, both within my organization and across the industry.

Q 27. Explain your experience with quality control procedures in a foundry setting.

Quality control is integral to the foundry process. My experience involves a comprehensive approach starting from the initial design phase, checking for dimensional accuracy and adherence to specifications. During pattern making, rigorous quality checks are conducted at every stage. This involves dimensional inspection using precision measuring instruments, verifying surface finish, and checking for any defects or inconsistencies. In the casting phase, I actively participate in inspecting the castings themselves, looking for defects such as porosity, shrinkage, and cracks. I am proficient in interpreting radiographic images and conducting other non-destructive testing (NDT) methods to detect internal flaws. Data from these inspections is meticulously documented and used for process improvement, helping identify areas where adjustments are needed to maintain consistent quality. The goal is always to minimize defects, reducing material waste and ensuring customer satisfaction.

Q 28. Describe a challenging pattern design project you worked on and how you overcame the challenges.

One challenging project involved designing a pattern for a highly intricate pump impeller with thin, complex blades and internal channels. The primary challenge lay in creating a pattern that could withstand the molding process without breaking, while accurately capturing the intricate details required for the smooth flow of fluids within the pump. Traditional methods proved insufficient. To overcome this, I utilized 3D modeling software to design the pattern, employing advanced techniques like rapid prototyping to create a durable master pattern from a strong resin. This allowed for intricate details and complex geometries to be replicated precisely. The use of multiple parting lines and specialized core boxes was also necessary to ensure proper mold assembly and casting fill. Through careful planning and the use of innovative technologies, we successfully produced a functional and high-quality casting. This project underscored the importance of employing advanced design techniques and collaboration with other foundry professionals in addressing intricate and complex casting requirements.

Key Topics to Learn for Foundry Pattern Design Interview

- Pattern Design Principles: Understanding fundamental design principles like draft, shrinkage, and parting lines, and their application in various casting processes.

- Material Selection & Properties: Knowledge of different metals and their casting characteristics, including fluidity, thermal conductivity, and solidification behavior. This includes choosing appropriate materials based on the final product requirements.

- Gating & Risering Systems: Designing efficient gating and risering systems to ensure complete filling of the mold cavity and prevent defects like shrinkage porosity and gas porosity.

- Mold Design & Cavity Preparation: Understanding the complexities of mold design, including considerations for core making, venting, and ensuring dimensional accuracy. Practical experience with different mold materials (sand, metal, etc.) is valuable.

- Casting Defects & Troubleshooting: Identifying common casting defects (cold shuts, hot tears, misruns) and understanding the root causes and preventative measures. This includes practical problem-solving skills in a foundry environment.

- Computer-Aided Design (CAD) for Patterns: Proficiency in using CAD software for pattern design, including 3D modeling and creating detailed drawings for manufacturing.

- Manufacturing Processes & Tolerances: Understanding the limitations and tolerances involved in pattern making and its impact on the final casting. This includes knowledge of various machining and finishing processes.

- Safety Procedures & Regulations: Familiarity with safety procedures and regulations relevant to foundry operations and pattern making.

Next Steps

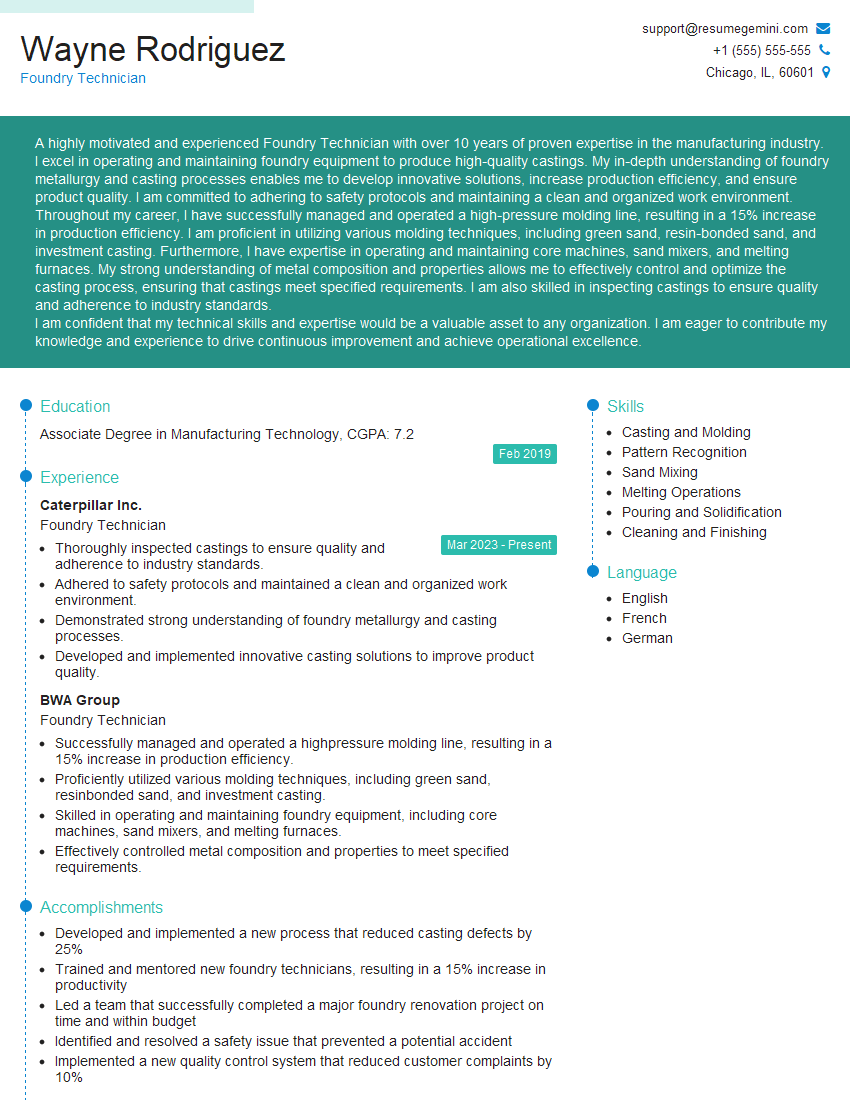

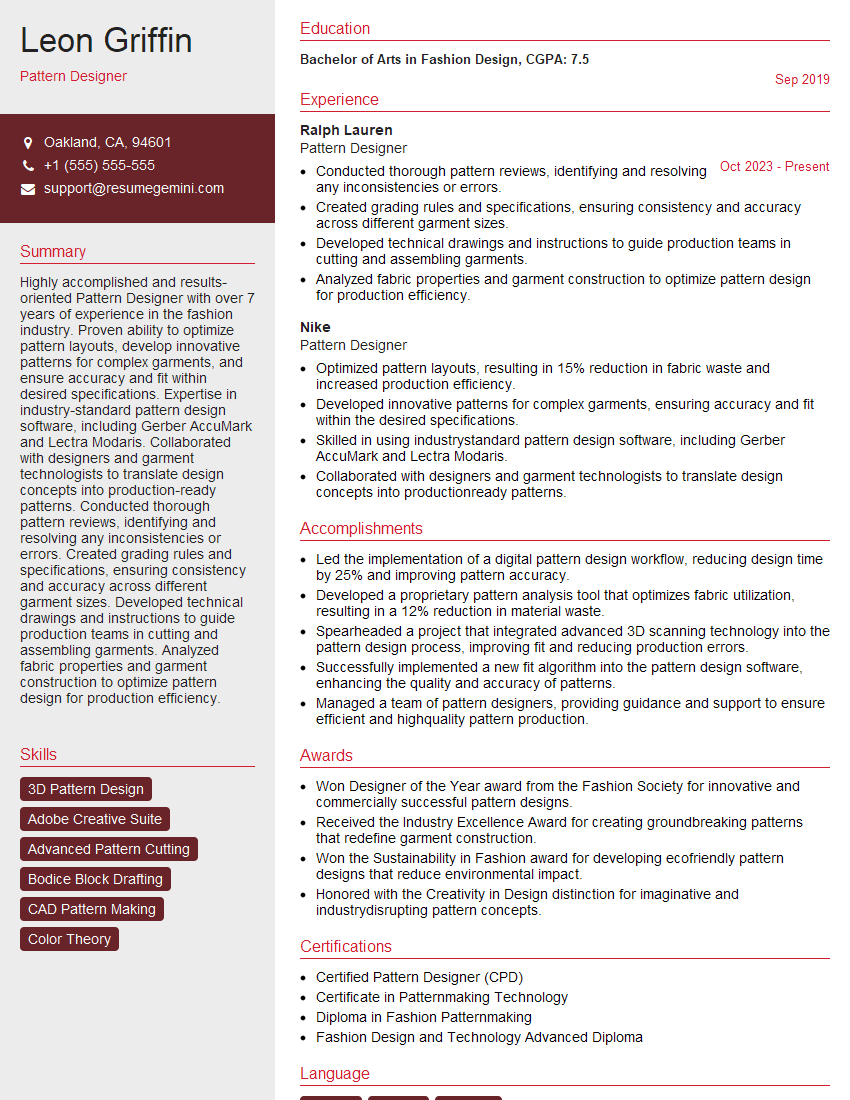

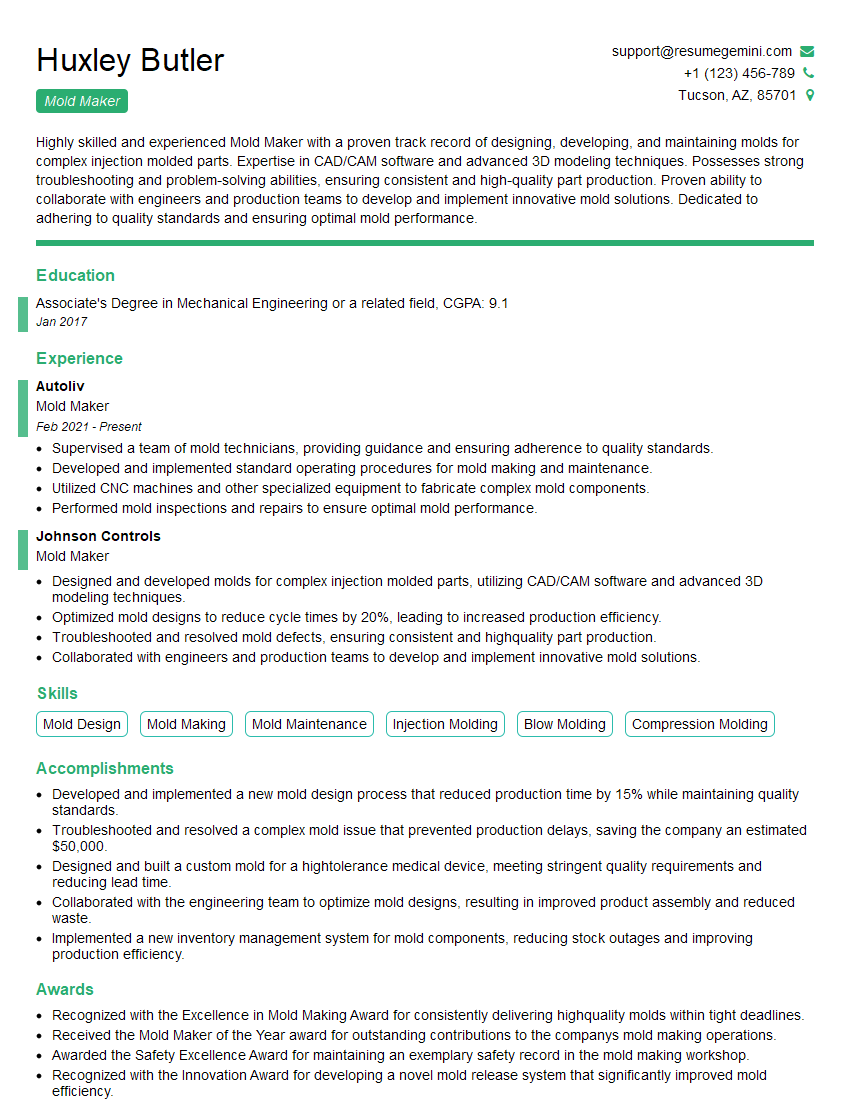

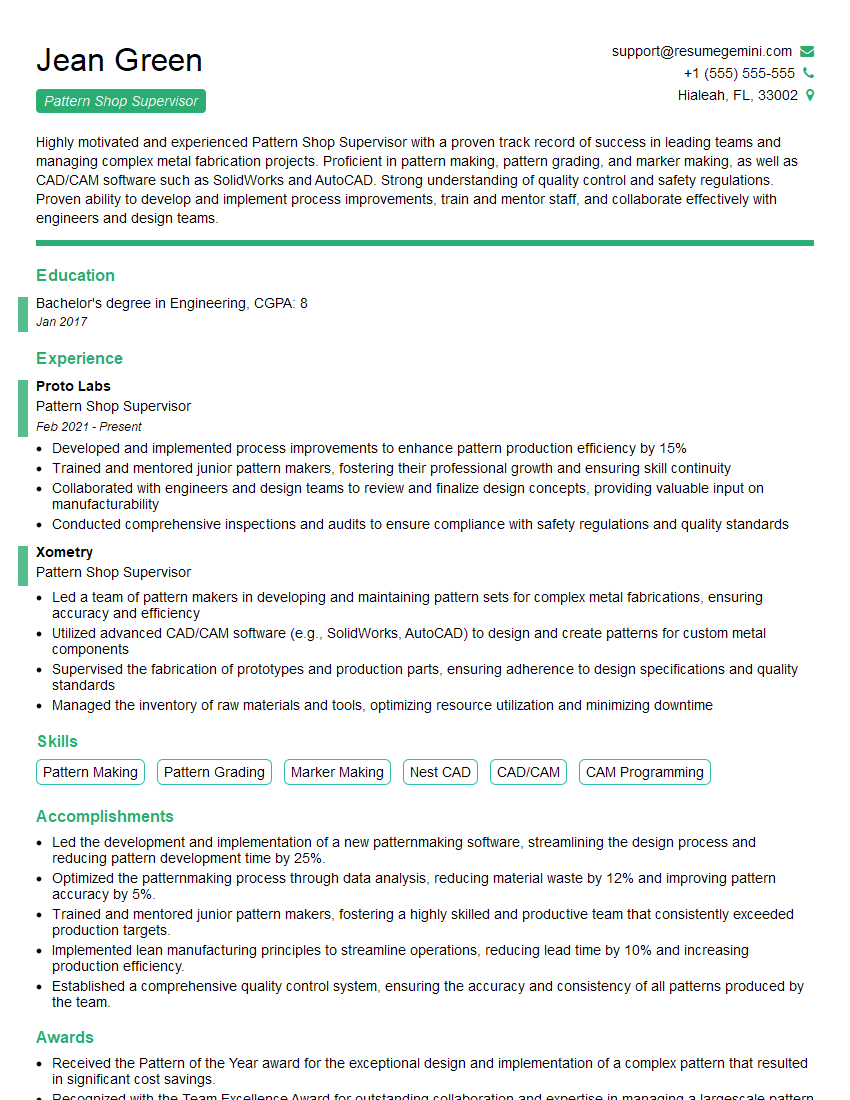

Mastering Foundry Pattern Design opens doors to exciting career opportunities in manufacturing and engineering. A strong understanding of these principles demonstrates your technical expertise and problem-solving abilities, making you a highly sought-after candidate. To maximize your chances, focus on crafting an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to Foundry Pattern Design to guide you through the process, ensuring your qualifications shine.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good