Are you ready to stand out in your next interview? Understanding and preparing for FrontEnd Loader Operation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in FrontEnd Loader Operation Interview

Q 1. Describe your experience operating a front-end loader.

I have over 10 years of experience operating various front-end loaders, from smaller skid-steer loaders used in landscaping to large wheel loaders employed in construction and demolition projects. My experience encompasses a wide range of tasks including material handling, excavation, loading trucks, and site preparation. I’m proficient in operating loaders with different attachments and am comfortable working in diverse environments and weather conditions. For instance, I’ve successfully managed the loading and unloading of thousands of tons of materials for large-scale construction projects, ensuring efficiency and safety throughout the process. I am also adept at judging ground conditions and adjusting operation accordingly to prevent damage or accidents.

Q 2. What are the different types of front-end loaders and their applications?

Front-end loaders come in various types, each suited to specific applications. Here are a few:

- Wheel Loaders: These are the most common type, characterized by their large wheels and powerful engines. They are highly versatile and used for moving large quantities of materials like dirt, gravel, and snow. Think of the iconic loaders you see on construction sites.

- Skid-Steer Loaders (SSLs): Smaller and more compact than wheel loaders, SSLs are highly maneuverable and ideal for confined spaces. They are frequently used in landscaping, agriculture, and smaller construction projects. Their compact size allows for work in tight areas where larger equipment wouldn’t fit.

- Compact Track Loaders (CTLs): These offer the maneuverability of an SSL but with the added benefit of tracks instead of wheels. Tracks provide superior traction and stability, especially on uneven or soft terrain. They are perfect for landscaping, utility work, and even light demolition.

- Telehandlers: Also known as telescopic handlers, these loaders have a boom that extends and lifts materials to significant heights. They’re used for high-reach applications such as placing materials on roofs or lifting heavy loads onto upper floors.

The choice of loader depends entirely on the job requirements, the terrain, and the size and weight of the materials being handled. Each type offers unique advantages and disadvantages.

Q 3. Explain the safety procedures you follow before operating a front-end loader.

Safety is paramount. Before operating any front-end loader, I always adhere to the following procedures:

- Pre-Operational Inspection: A thorough check of the machine’s fluids, tires, lights, and all operational components.

- Personal Protective Equipment (PPE): Ensuring I have the necessary PPE – hard hat, safety glasses, hearing protection, and high-visibility clothing.

- Site Assessment: Evaluating the work area for potential hazards, including uneven terrain, overhead obstructions, and the presence of other personnel or equipment.

- Communication: Establishing clear communication with other workers on the site using hand signals or radios, especially in situations with limited visibility.

- Understanding Load Limits: Being acutely aware of the loader’s load capacity and never exceeding it.

- Proper Training and Certification: Having completed all necessary training and holding any required certifications for operating the specific type of loader.

These procedures help minimize risks and ensure a safe working environment for myself and others.

Q 4. How do you perform pre-operational checks on a front-end loader?

Pre-operational checks are crucial for preventing accidents and ensuring efficient operation. My routine includes:

- Fluid Levels: Checking engine oil, transmission fluid, hydraulic fluid, and coolant levels.

- Tire Pressure: Inspecting tire pressure and condition for proper inflation and any signs of damage.

- Lights and Signals: Verifying the functionality of headlights, brake lights, turn signals, and warning lights.

- Brakes: Testing the responsiveness of both the service and parking brakes.

- Steering and Controls: Checking the smooth operation of the steering, throttle, and all other controls.

- Bucket/Attachment Condition: Inspecting the bucket or attachment for damage, wear, and proper attachment to the loader.

- Leaks: Checking for any hydraulic, oil, or fuel leaks.

I meticulously document any issues found and will not operate the machine unless all components are functioning correctly and safely.

Q 5. Describe your experience with different loader attachments (e.g., buckets, forks).

I’ve worked extensively with various loader attachments, including:

- Buckets: Different sized buckets for handling various materials, from light-weight landscaping materials to heavy rock and debris.

- Forks: For handling pallets and other materials requiring precise lifting and placement.

- Grapples: For moving logs, scrap metal, and other irregularly shaped materials.

- Snow Plows: For clearing snow during winter months.

Each attachment requires a different operating technique and understanding of its capabilities and limitations. For instance, using the wrong bucket for the material could result in spills or damage to the loader or the material.

Q 6. How do you ensure the stability of the loader during operation?

Maintaining loader stability is crucial for preventing tipping and accidents. I achieve this through several methods:

- Smooth Operations: Avoiding sudden movements or jerky actions that could disrupt balance.

- Load Awareness: Never exceeding the loader’s rated capacity and being mindful of the weight distribution.

- Ground Conditions: Assessing the ground conditions and adjusting operation speed and technique accordingly. Soft or uneven terrain requires extra caution and slower speeds.

- Counterweighting: Understanding how the position of the loader’s boom and bucket affects stability and adjusting accordingly.

- Safe Working Practices: Avoiding turning or maneuvering at steep angles, especially when carrying a load.

Essentially, it’s about anticipating the machine’s reactions and making adjustments to maintain a low center of gravity and prevent imbalance.

Q 7. Explain your understanding of load capacity and weight distribution.

Understanding load capacity and weight distribution is fundamental for safe and efficient loader operation. The manufacturer’s specifications provide the maximum load the loader can handle, and exceeding this limit can lead to tipping and serious accidents. Weight distribution refers to how the load is positioned within the bucket and its impact on the loader’s stability. An unevenly distributed load can shift the center of gravity, making the machine more prone to tipping.

For example, if I’m loading a truck with gravel, I’ll carefully ensure the material is evenly distributed within the bucket to maintain balance. I’ll also consider the overall weight of the material and ensure it’s within the loader’s capacity. Ignoring these factors could result in tipping, damage to the equipment, or serious injury.

Q 8. How do you handle different types of terrain while operating a front-end loader?

Operating a front-end loader effectively across varied terrains requires adapting your technique to maintain stability and efficiency. Think of it like driving a car – you wouldn’t drive the same way on ice as you would on a dry highway.

- Soft Ground: On soft ground, like mud or loose soil, I reduce speed significantly, avoid sudden movements, and spread the load across the tires to minimize ground pressure. This prevents sinking and ensures controlled maneuvering. I might also opt for a wider tire configuration if available. Imagine trying to walk across a bog – you’d take slow, deliberate steps.

- Steep Grades: On inclines or declines, I use lower gears for better control and braking power. I maintain a steady speed, avoid sharp turns, and always assess the grade before proceeding. I never operate on slopes steeper than what is deemed safe in the machine’s operating manual – safety is paramount. It’s like carefully navigating a winding mountain road.

- Rocky Terrain: When working with rocks or uneven surfaces, I proceed slowly and cautiously, carefully choosing my path to avoid potential damage to the machine’s undercarriage or tires. I might also engage a lower gear to increase control and torque.

- Hard Surfaces: On paved or compacted surfaces, maintaining a moderate speed, smooth operation, and paying close attention to the load are key. Sudden braking or abrupt movements could lead to tire slippage or damage to the machine or surrounding area.

In every instance, assessing the terrain before operation and adjusting my technique accordingly is critical to both efficient operation and safety.

Q 9. What are the common causes of front-end loader malfunctions?

Front-end loader malfunctions can stem from various sources, often linked to wear and tear, improper maintenance, or operator error. Common culprits include:

- Hydraulic System Issues: Leaks, faulty pumps, or damaged hoses can significantly impact loader performance and operation. A slow or unresponsive bucket could be a sign.

- Engine Problems: Overheating, fuel system issues (clogged filters, low fuel), or electrical malfunctions can cause the engine to stall or underperform.

- Transmission Problems: Worn gears, low transmission fluid, or internal damage can lead to difficulty shifting or sudden jerking movements.

- Tire Problems: Flat tires, excessive wear, or improper inflation drastically affect stability and handling.

- Structural Damage: Impacts or stress from overloading can lead to frame damage, bucket damage, or even component failure.

Regular inspections and preventative maintenance significantly reduce the likelihood of these problems.

Q 10. How do you troubleshoot common loader problems?

Troubleshooting involves a systematic approach, starting with a thorough visual inspection. For example:

- Identify the symptom: Is the bucket unresponsive? Is the engine stalling? Does the machine overheat? Pinpoint the specific problem.

- Check the obvious: Begin with simple checks, like fluid levels (hydraulic fluid, engine oil, transmission fluid, coolant), tire pressure, and fuel levels. Often, a simple low fluid level is the root cause.

- Listen carefully: Unusual sounds, like grinding, squealing, or banging, can pinpoint the source of a problem. These clues are like signals indicating a specific issue.

- Consult the operator’s manual: The manual contains troubleshooting guides and diagrams that often lead to quick solutions.

- Systematic inspection: If the issue isn’t immediately apparent, a detailed check of all systems is necessary. Look for leaks, loose connections, damaged components.

- Seek professional help: If the problem remains unresolved, it’s crucial to consult a qualified mechanic. Don’t attempt repairs beyond your skillset.

Remember, safety is paramount. Never attempt repairs on a running machine.

Q 11. Describe your experience with preventative maintenance on a front-end loader.

Preventative maintenance is the cornerstone of reliable front-end loader operation. I follow a rigorous schedule that includes:

- Daily inspections: This includes checking all fluid levels, tire pressure, examining for any visible damage, and testing all controls.

- Regular lubrication: All grease points and lubrication points are checked and lubricated according to the manufacturer’s schedule.

- Scheduled maintenance: Following the manufacturer’s recommended service intervals is vital. This includes things like oil changes, filter replacements, and more detailed inspections.

- Component checks: Regular checks of critical components like hydraulic cylinders, hoses, and belts help catch problems before they escalate.

- Documentation: Keeping detailed records of all maintenance performed is vital for tracking issues, identifying trends, and ensuring compliance with regulations.

Proactive maintenance is like regular check-ups for a person – small efforts prevent bigger problems later.

Q 12. What are your procedures for refueling and lubricating a front-end loader?

Refueling and lubricating a front-end loader require adhering to safety procedures and manufacturer recommendations.

- Refueling: I always ensure the engine is turned off and cooled before refueling. I use the correct type of fuel and avoid spills. I then check the fuel level regularly to prevent running out of fuel during operation.

- Lubrication: I lubricate all designated grease points using the correct type and amount of grease. I never over-grease, as it can damage seals and components. I also keep detailed records of when and where lubrication was performed.

Adherence to these steps ensures the machine remains in optimal condition and extends its lifespan, minimizing downtime and maintenance costs. Safety is paramount.

Q 13. How do you ensure the safety of other workers in the vicinity?

Ensuring the safety of others is my top priority. I use a multi-pronged approach:

- Visibility: I make sure the loader is clean and well-lit, especially at night or in low-visibility conditions. If necessary, I use additional lighting or safety flags. This ensures that I am easily visible to other workers.

- Communication: Clear communication is key. Before starting work, I will confirm the locations of other workers and agree on signals or communication methods. I use horns and lights to warn people of my movements. It’s like working in a team, where clear communication prevents accidents.

- Awareness: I am always aware of my surroundings, checking for other workers or equipment before making any movements. Blind spots are carefully considered and addressed. I never assume others will see me.

- Safe operating procedures: I strictly adhere to all safe operating procedures outlined by the company and the manufacturer, ensuring I follow all rules and regulations for safe loader operation.

Safety is a shared responsibility, and by adhering to these practices, I create a safer work environment for everyone.

Q 14. Explain your understanding of traffic control procedures related to loader operation.

Traffic control procedures around a front-end loader operation are critical for safety. This requires planning and clear communication:

- Designated routes: Establish clear, designated routes for the loader to follow, minimizing the risk of collisions with other equipment or personnel. This is like planning a route for a delivery truck.

- Safety personnel: Employing flagmen or spotters is essential, especially in busy areas or when visibility is poor. These individuals guide the loader and warn others of its movements.

- Warning signs and signals: Appropriate signage and signals clearly inform other workers of the loader’s presence and operational areas. These help to alert people of potential danger.

- Communication: Clear and consistent communication between the loader operator and ground personnel is crucial to prevent accidents. This includes hand signals, radio communication, and established procedures for emergency stops.

- Speed limits: Maintaining appropriate speed limits while operating the loader in proximity to other workers and equipment is paramount for safety. The speed should always be adjusted to suit the conditions.

By implementing these procedures, we create a safe and organized work environment, minimizing the risk of accidents and maximizing productivity.

Q 15. How do you load and unload different materials efficiently and safely?

Efficient and safe loading and unloading depend heavily on understanding the material’s properties and employing the right techniques. For example, loading loose materials like sand or gravel requires a different approach than handling palletized goods or large rocks.

- Loose Materials: I always start by positioning the bucket close to the pile, ensuring stability before engaging. Slow, controlled movements are crucial to avoid spillage and maintain balance. The bucket should be filled gradually, avoiding overloading. Unloading involves a similar slow and controlled approach, carefully positioning the bucket above the desired location.

- Palletized Goods: These require precision. I use the loader’s forks or specialized attachments, ensuring the forks are securely under the pallet before lifting. Gradual lifting and precise placement are essential to prevent damage to the goods or the loader. Unloading involves mirroring the loading process with reverse motions.

- Large, Heavy Objects: Safety is paramount. I assess the weight and center of gravity carefully before attempting to lift. I’ll use straps or slings if necessary for extra security. Lifting and moving must be done slowly, making sure the load is stable and secure throughout the process. I prioritize clear communication with spotters if needed.

Throughout the process, I always maintain awareness of my surroundings, checking for obstacles and personnel. Safe operating procedures are always followed, including maintaining visibility and avoiding abrupt movements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with operating a front-end loader in confined spaces.

Operating in confined spaces necessitates heightened awareness and precision. It’s not just about the loader’s dimensions but also the surrounding environment – obstacles, people, and potential hazards.

In such situations, I prioritize slow and deliberate movements. I’ll use smaller bucket loads to improve maneuverability, regularly checking my surroundings for any changes or obstructions. My experience includes working in tight construction sites where millimeter-perfect movements were required to avoid collisions with walls, other equipment, or personnel. I often used the loader’s mirrors and cameras to gain a wider view of my surroundings, and always relied on clear communication with other workers.

For example, when working in a warehouse loading containers, I had to carefully maneuver the loader around pillars and within extremely narrow aisles, constantly adjusting my trajectory and speed to avoid damaging the goods or causing accidents.

Q 17. How do you handle unexpected situations or emergencies while operating a loader?

Preparedness is key. My response to unexpected situations depends on the nature of the emergency.

- Mechanical Failure: If the loader malfunctions, I immediately shut down the engine, assess the problem, and follow the established emergency procedures. This usually involves contacting maintenance or the supervisor.

- Spillage or Accident: In case of spillage or a minor accident, I immediately secure the area, prevent further incidents, and assess any potential hazards or injuries. Clear communication with colleagues and supervisors is crucial.

- Environmental Hazards: If faced with unexpected environmental challenges, such as sudden weather changes or unstable ground, I prioritize safety and immediately stop operations. I’ll reassess the situation and seek advice from supervisors before resuming work.

In all cases, maintaining a calm and controlled demeanor is critical, focusing on problem resolution while ensuring the safety of myself and others. I always prioritize safety over speed or efficiency.

Q 18. What are the different types of buckets and their suitable applications?

Front-end loaders utilize a variety of buckets, each suited to specific materials and tasks.

- General Purpose Buckets: These are versatile, used for a wide range of materials. They offer a good balance between capacity and maneuverability.

- Light Material Buckets: With a larger capacity and lighter construction, these are ideal for handling materials like sand, gravel, and topsoil.

- Heavy-duty Buckets: These robust buckets are designed for handling rocks, demolition debris, and other heavy materials. They offer increased durability but reduced capacity.

- Forklift Buckets: These come equipped with forklift tines for carrying palletized goods.

- Clamshell Buckets: With two hinged sections, these are used for digging and precise handling of materials. They’re ideal for material that might otherwise spill out of a general purpose bucket.

- Special Purpose Buckets: Some specialized buckets are used for handling specific materials like asphalt, snow, or waste.

Q 19. How do you select the appropriate bucket for a specific task?

Bucket selection depends on several factors:

- Material Type: The density, size, and consistency of the material are key considerations. Loose materials require a wider, shallower bucket while denser materials need a stronger, more robust one.

- Task Requirements: The nature of the task influences the type of bucket required. Digging might require a clamshell bucket, while carrying pallets demands a forklift bucket.

- Loader Capacity: The loader’s lifting capacity limits the size and weight of the bucket. Selecting a bucket that exceeds this capacity is unsafe.

- Operating Environment: Conditions such as confined spaces or challenging terrain may require adjustments in bucket size and type.

For example, moving topsoil would require a light material bucket with a wide mouth for efficient filling, whereas moving large rocks would necessitate a heavy-duty bucket with a smaller, more robust design for secure transport and lift capabilities.

Q 20. Explain your experience working with different types of loading materials.

My experience encompasses a broad range of loading materials, each requiring a specific approach:

- Aggregates (sand, gravel, stone): I’ve extensively handled aggregates, utilizing techniques to maximize bucket fill while minimizing spillage. Understanding the material’s flow characteristics is key to efficient loading and unloading.

- Soil and Topsoil: Working with soil requires different bucket types and loading techniques to avoid compaction. Maintaining consistent depth and controlling the rate of movement are important aspects.

- Demolition Debris: Handling demolition debris requires a focus on safety and efficient sorting of materials for disposal or recycling. This includes dealing with varied sizes and types of materials.

- Recyclable Materials: I have experience loading and transporting recyclable materials, ensuring they are properly separated and transported according to regulations.

Adaptability and careful planning are key. I adapt my techniques based on each material’s characteristics and the specific demands of the task.

Q 21. Describe your experience working with GPS guidance systems on a front-end loader.

My experience with GPS guidance systems on front-end loaders has significantly enhanced efficiency and precision. The system helps with tasks such as:

- Precise Positioning: GPS guidance helps to accurately position the loader for optimal loading and unloading, reducing errors and improving cycle times.

- Automated Steering: In some systems, the GPS can assist with steering the loader along a pre-defined path, decreasing operator fatigue and maintaining consistency.

- Improved Efficiency: By optimizing movement patterns and reducing wasted movements, GPS guidance helps increase overall productivity.

- Reduced Material Waste: Precise placement reduces material spillage and waste, increasing efficiency and minimizing cleanup.

For instance, in a large-scale earthmoving project, the GPS guidance enabled me to consistently fill the truck precisely to the desired level, resulting in fewer trips and more efficient use of fuel and time.

Q 22. How do you maintain proper visibility while operating a front-end loader?

Maintaining proper visibility while operating a front-end loader is paramount for safety and efficiency. It involves a multi-faceted approach.

- Pre-operational Checks: Before starting, I always thoroughly inspect the machine. This includes checking mirrors, wipers, lights, and ensuring there’s no obstruction to my view, such as mud or debris on the windows or a damaged bucket that could hinder vision.

- Safe Operating Practices: I constantly scan my surroundings—360 degrees—before making any movement. I use my mirrors frequently, especially when reversing or turning. I avoid operating in blind spots whenever possible and always be aware of pedestrians and other equipment.

- Understanding Load Limitations: Overloading the bucket restricts visibility. I ensure the load is within the loader’s capacity, maintaining a balanced, manageable load for clear vision of my surroundings.

- Proper Positioning: I position myself to maximize my view. This might mean adjusting the seat to ensure optimal sightlines. The operator’s positioning is crucial in avoiding accidents.

- Weather Conditions: Adverse weather, like heavy rain or fog, drastically reduces visibility. In such situations, I either slow down considerably, use extra caution, or halt operations altogether until conditions improve.

Imagine this: I’m loading a truck with gravel. Before moving the loader, I check my mirrors, slowly rotate the machine to make sure the path is clear of people and obstructions. Then, I carefully approach the truck and raise the bucket at a safe speed, ensuring I maintain a clear sightline to the truck bed to prevent spillage or collision.

Q 23. What are the regulations and safety standards related to front-end loader operation?

Regulations and safety standards for front-end loader operation are stringent and vary slightly depending on location (country, state, etc.), but several key aspects are universal.

- Licensing and Certification: Operating a front-end loader often requires specific licensing or certification, demonstrating competency and understanding of safety protocols.

- Pre-Shift Inspections: Before every shift, a thorough pre-operational inspection is mandatory, documented and addressing mechanical issues, fluid levels, and safety features like lights, horns, and emergency brakes.

- Personal Protective Equipment (PPE): Always mandatory, this includes hard hats, safety glasses or goggles, high-visibility clothing, gloves, and steel-toe boots.

- Safe Operating Procedures: Following established procedures is non-negotiable. This includes maintaining safe speeds, avoiding sudden movements, and respecting load limits.

- Site-Specific Rules: Each construction site has its own safety regulations, which must be followed. This might involve designated walkways, speed limits, or communication protocols.

- Regular Maintenance: Regular maintenance of the loader is crucial to prevent mechanical failures which could lead to accidents. This includes checking hydraulic fluid levels, brakes, tires, and other critical systems.

- Emergency Procedures: Everyone on site must be familiar with emergency procedures in case of an accident, including how to contact emergency services.

Non-compliance with these standards can lead to severe penalties, including fines and even jail time in some cases. The safety of the operator and others on the site are the highest priorities.

Q 24. How do you communicate effectively with other crew members on a construction site?

Effective communication is essential on a construction site, especially when operating heavy machinery like a front-end loader. I use a combination of methods to ensure clear and concise communication:

- Hand Signals: I’m proficient in using standard hand signals, understood by everyone on the site, to indicate my intentions (e.g., backing up, moving forward, stopping).

- Two-Way Radios: Radios are essential for longer distances or when hand signals aren’t visible. I make sure to confirm communications before undertaking any maneuver.

- Visual Cues: I use visual cues like flashing lights or horn signals to alert others to my presence and actions.

- Pre-Task Briefings: Before starting a task, a briefing with the team helps to clarify roles, responsibilities, and potential hazards.

- Clear and Concise Language: I use clear and concise language and avoid jargon when communicating, ensuring everyone understands my instructions or requests.

For instance, if I need to back up to a certain position, I’d first use my radio to inform the spotter and then confirm their acknowledgment before slowly reversing. I also use hand signals and maintain constant eye contact with the spotter for optimal communication and accident prevention.

Q 25. Describe a situation where you had to solve a problem involving a front-end loader.

During a large-scale excavation project, the front-end loader’s hydraulic system malfunctioned, causing the bucket to unexpectedly drop a large load of earth. This created a dangerous situation, potentially damaging equipment or injuring workers.

Problem-Solving Steps:

- Safety First: I immediately secured the area, warning nearby workers and halting operations. My priority was to prevent further accidents.

- Assessment: I carefully examined the loader, identifying the cause of the hydraulic failure as a leak in a hose.

- Temporary Fix: I used available clamps and materials to create a temporary fix, allowing me to carefully lift the fallen earth and clear the obstruction. This was a time-sensitive measure to minimize downtime and hazards.

- Reporting: I reported the incident and the temporary repair to the supervisor, along with photographic evidence of the leak and the temporary fix. This ensured that a qualified mechanic could perform a proper and permanent repair.

- Permanent Repair: The mechanic arrived promptly and replaced the damaged hydraulic hose, restoring the machine to full functionality.

This experience highlighted the importance of regular maintenance and quick-thinking in emergency situations. The ability to assess, adapt, and prioritize safety is essential in this profession.

Q 26. Explain your knowledge of hydraulic systems in a front-end loader.

Hydraulic systems are the backbone of a front-end loader, powering the lifting, tilting, and digging functions of the bucket. My understanding encompasses the following:

- Hydraulic Pumps: These pumps generate the pressure needed to move hydraulic fluid.

- Hydraulic Cylinders: These convert hydraulic pressure into linear motion, enabling the movement of the bucket arms and tilt mechanisms. I understand the importance of their proper extension and retraction.

- Hydraulic Valves: These control the flow and direction of hydraulic fluid, allowing for precise and controlled movements of the loader’s components.

- Hydraulic Fluid: I know the importance of maintaining proper fluid levels and using the correct type of fluid to ensure efficient operation and prevent damage to the hydraulic system. I’m familiar with regular checks, including monitoring the fluid’s color and cleanliness for potential issues.

- Troubleshooting: I’m capable of performing basic troubleshooting, identifying issues such as leaks, faulty valves, or low fluid levels. More complex repairs are left to qualified mechanics.

Imagine the hydraulic system as a circulatory system. The pump is the heart, the cylinders are the muscles, the valves are the veins, and the fluid is the blood. A problem in any part can disrupt the entire system. Therefore, regular checks and maintenance are critical.

Q 27. What is your experience with different types of transmissions in a front-end loader?

Front-end loaders typically utilize various types of transmissions to transfer power from the engine to the wheels, each with its own advantages and disadvantages.

- Power Shift Transmissions: These offer quick and smooth shifting between gears, providing efficient operation during heavy-duty tasks. They are commonly found in larger loaders.

- Powershift with torque converter: This utilizes a torque converter, acting as a clutch, which enables smoother starts and reduced shock loading during operation.

- Hydrostatic Transmissions: These use hydraulic power to move the wheels, enabling infinitely variable speeds and improved control. They are particularly helpful for precise maneuvering. These systems use hydraulic motors to provide a variable speed without changing gears.

My experience includes operating loaders with both power shift and hydrostatic transmissions. I understand the operational characteristics of each, appreciating the differences in responsiveness, efficiency, and maneuverability they provide depending on the work at hand.

Q 28. How do you manage your time effectively to complete tasks efficiently?

Efficient time management is crucial for maximizing productivity in front-end loader operation. My approach involves several key strategies:

- Planning & Prioritization: Before starting the day, I review the tasks and prioritize them based on urgency and importance. This helps me focus on the most critical tasks first.

- Efficient Movement: I plan my movements carefully, minimizing unnecessary travel time. Understanding the site layout and optimal routes is essential.

- Continuous Workflow: I aim for a continuous workflow. I anticipate my needs, avoiding unnecessary stops or delays. This might involve having a pre-determined spot for dumping materials to minimize down time.

- Load Optimization: I optimize load sizes to balance efficiency with safety. Too small a load is inefficient; too large a load compromises safety and maneuverability. There’s a fine balance to be found.

- Regular Breaks: Taking short, regular breaks helps to maintain focus and prevent fatigue. Fatigue affects productivity and, crucially, safety.

For example, if I’m tasked with moving a large amount of dirt from one location to another, I plan the route, taking the shortest and safest path. I optimize the bucket size, ensuring I’m not overburdening the machine nor making too many inefficient trips. Through efficient loading and unloading, combined with planned movements, I can complete the task in optimal time.

Key Topics to Learn for FrontEnd Loader Operation Interview

- Machine Operation & Safety: Understanding the controls, pre-operational checks (including safety inspections), and safe operating procedures for front-end loaders. This includes understanding load capacity and stability limitations.

- Attachment Usage & Maintenance: Knowledge of different attachments (buckets, forks, etc.), their proper application, and basic maintenance procedures to ensure optimal performance and safety.

- Material Handling Techniques: Efficient and safe techniques for loading, unloading, and transporting various materials, considering factors like terrain, weight distribution, and material type.

- Troubleshooting & Problem Solving: Identifying and addressing common mechanical issues, understanding preventative maintenance, and applying problem-solving skills to unexpected situations on the job.

- Environmental Awareness: Understanding environmental regulations related to operation, such as minimizing soil erosion or managing waste materials. Safe and efficient fuel management practices.

- Communication & Teamwork: Effective communication with supervisors and other team members to coordinate tasks and ensure safety on the job site.

- Regulations & Compliance: Familiarity with relevant safety regulations and operating permits.

Next Steps

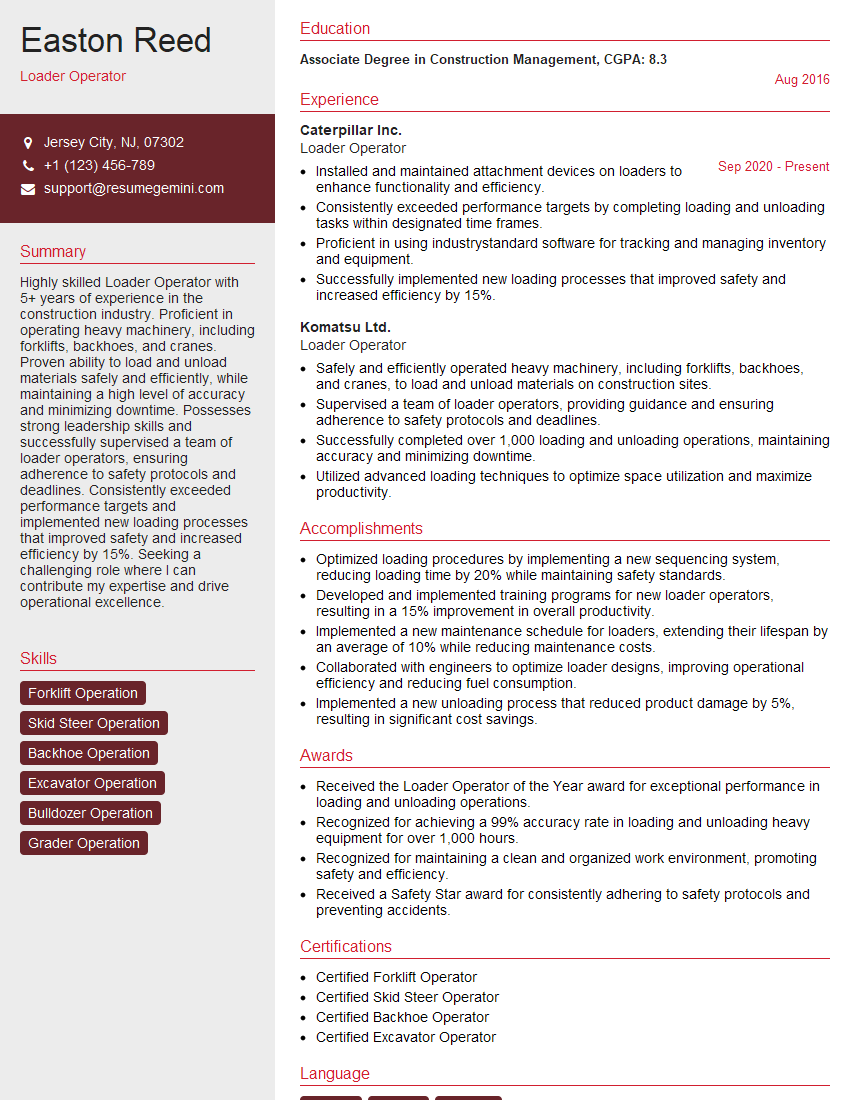

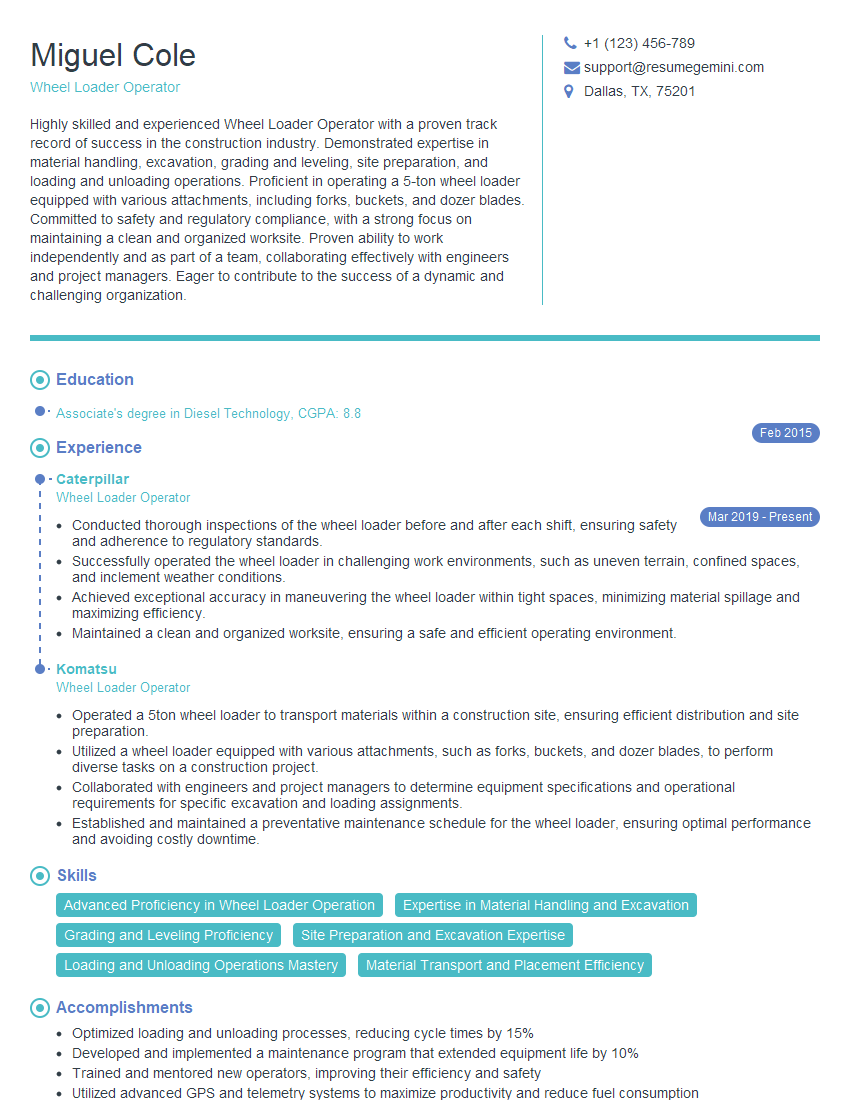

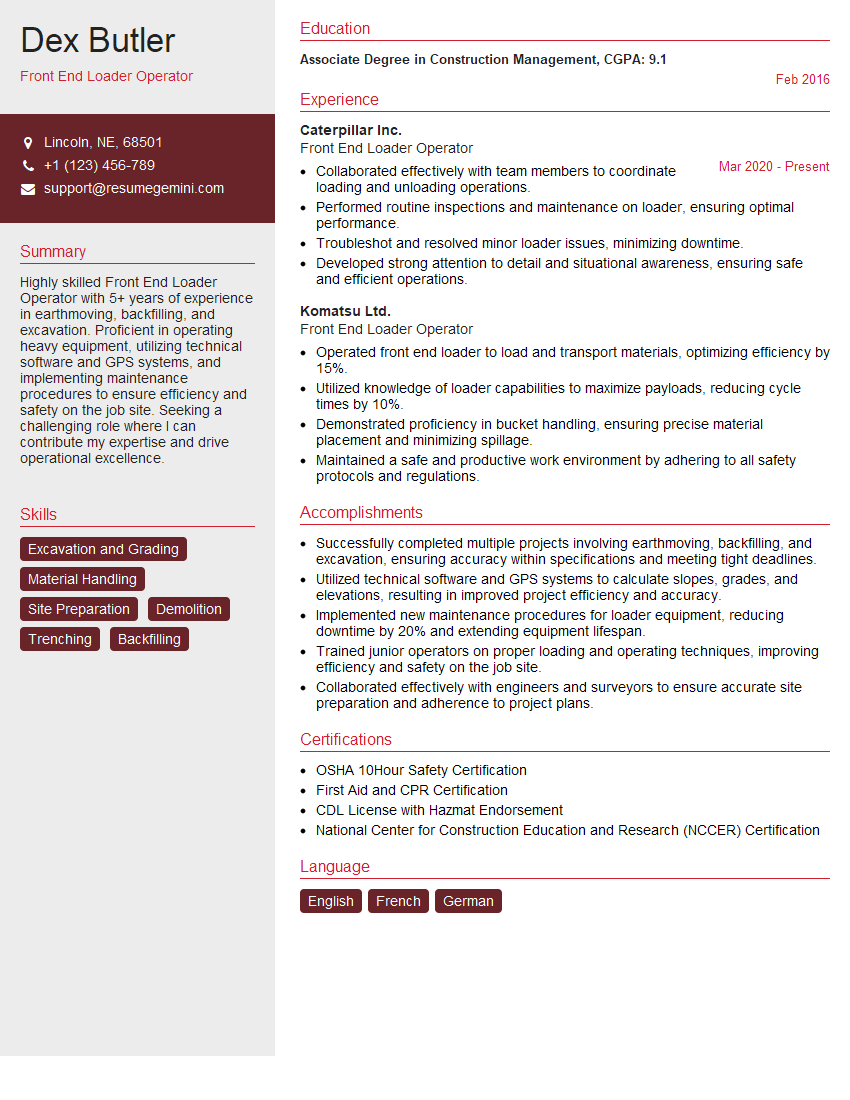

Mastering FrontEnd Loader Operation opens doors to a rewarding career with excellent earning potential and opportunities for advancement within the construction, agriculture, or materials handling industries. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by employers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your qualifications shine. Examples of resumes tailored to FrontEnd Loader Operation are available to help guide you through the process. Invest the time to create a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good