Preparation is the key to success in any interview. In this post, we’ll explore crucial Fruit Harvesting interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Fruit Harvesting Interview

Q 1. Describe your experience with different fruit harvesting techniques.

Fruit harvesting techniques vary significantly depending on the type of fruit, its growth habit, and the scale of the operation. I have extensive experience with several methods, ranging from manual harvesting to mechanized approaches.

- Manual Harvesting: This is common for delicate fruits like berries and cherries where careful picking minimizes damage. It’s labor-intensive but ensures high quality. I’ve led teams in hand-picking strawberries, using specific techniques to avoid bruising, and meticulously selecting only the ripest fruit.

- Mechanical Harvesting: For larger-scale operations with robust fruits like apples and some citrus, machinery is employed. Shakers detach the fruit from the tree, followed by collection systems. My experience includes optimizing the settings of these machines to reduce fruit damage and loss. We fine-tune the shaking intensity and conveyor belt speed based on fruit firmness and weather conditions.

- Selective Harvesting: This method involves multiple passes through the orchard, picking only the ripe fruits each time. This maximizes yield and quality but requires more labor and careful planning. I’ve implemented selective harvesting strategies for premium apple varieties, leading to superior taste and market value.

I also have experience with using various specialized tools within these techniques, adapting to the specifics of each fruit type.

Q 2. What are the optimal harvesting conditions for apples?

Optimal harvesting conditions for apples are crucial for ensuring both quality and shelf life. The ideal time is determined by a combination of factors:

- Fruit Maturity: Apples should reach their characteristic color, size, and sugar content. This is often assessed by taste tests and measuring the firmness of the fruit. We use a pressure tester to obtain precise measurements of firmness.

- Weather Conditions: Harvesting should be conducted in dry weather to avoid introducing moisture, which can lead to decay. Ideal temperatures are cool and relatively dry. Extremely hot or wet conditions are to be avoided.

- Soil Conditions: The soil should be dry enough to allow for efficient harvesting and minimize soil contamination on the fruit. This is particularly important during mechanical harvesting.

Careful monitoring of these factors and the ability to predict optimal harvest windows are crucial for achieving the highest quality apple yield. I have successfully planned and executed multiple apple harvests under varying weather and ground conditions by utilizing weather forecasts and field observations. For instance, if unexpected rain is forecast, we’ll adjust our schedule to avoid the risk of introducing excess moisture into the orchard.

Q 3. How do you identify ripe fruit ready for harvest?

Identifying ripe fruit ready for harvest is a skill honed through experience and attention to detail. The methods vary depending on the fruit type, but key indicators include:

- Color Change: A significant color change is a common indicator for most fruits. For example, the transition from green to red for apples, or the development of a deep blue color in blueberries.

- Size and Firmness: The fruit should reach its characteristic size and have appropriate firmness. Overly soft fruit is often overripe and susceptible to damage. We use a refractometer to measure sugar content and a pressure tester to assess firmness.

- Aroma: Ripe fruit typically emits a pleasant aroma that is characteristic of the specific variety. This is particularly helpful with berries and melons.

- Taste Test: Sometimes, a simple taste test is the most reliable method, particularly for fruits where other indicators are less clear.

For example, with blueberries, we look for a deep blue color and a slight softness to the touch, combined with a sweet aroma. The specific criteria are documented for each variety to ensure consistency and quality across the entire harvest.

Q 4. Explain the process of post-harvest handling and storage of berries.

Post-harvest handling and storage of berries are critical for maintaining their quality and extending their shelf life. The process generally includes:

- Rapid Cooling: Berries are highly perishable and need to be cooled quickly after harvesting to slow down respiration and enzymatic activity. Hydrocooling is often used, where berries are submerged in chilled water for a few minutes.

- Cleaning and Sorting: Removing debris, damaged or diseased berries is essential. Sorting might involve removing stems and leaves and grading for size and quality. Automated sorting systems increase efficiency and precision.

- Packaging: Berries are usually packaged in containers that allow for good ventilation and minimize bruising. The choice of packaging depends on the type of berry and the intended distribution channel.

- Storage: Refrigerated storage at the appropriate temperature (usually close to 0°C) is crucial. Controlled atmosphere storage (CAS) can further extend shelf life by controlling oxygen and carbon dioxide levels.

Proper sanitation throughout the entire process is critical to prevent contamination and mold growth. We meticulously maintain hygiene standards, ensuring all equipment and containers are thoroughly cleaned and sanitized.

Q 5. What safety measures do you employ during fruit harvesting?

Safety is paramount during fruit harvesting. We implement several measures to protect workers and maintain a safe working environment.

- Personal Protective Equipment (PPE): Workers use appropriate PPE, including gloves, safety glasses, and sturdy footwear to prevent cuts, bruises, and eye injuries. For mechanical harvesting, additional safety measures such as hearing protection and hard hats are mandatory.

- Training and Supervision: All workers receive comprehensive training on safe harvesting practices, including how to use equipment correctly and identify potential hazards. Experienced supervisors oversee operations and ensure adherence to safety protocols.

- Hazard Identification and Mitigation: We conduct regular safety inspections of the orchard and harvesting equipment to identify and address potential hazards, such as uneven terrain, broken branches, or malfunctioning machinery. We also implement measures to prevent slips, trips, and falls.

- Emergency Preparedness: We have a clear emergency plan in place and provide first aid training to workers. Communication systems are established to ensure rapid response in case of accidents or emergencies.

Regular safety meetings and audits are conducted to ensure continuous improvement in safety standards and address any emerging concerns.

Q 6. How do you ensure the quality of harvested fruit?

Ensuring the quality of harvested fruit involves meticulous attention to detail throughout the entire process, from orchard management to post-harvest handling. Key strategies include:

- Proper Orchard Management: Maintaining healthy trees, employing appropriate pest and disease control, and optimizing irrigation and fertilization practices significantly impact fruit quality. We use integrated pest management (IPM) techniques to minimize pesticide use while maintaining healthy crops.

- Careful Harvesting: Gentle handling during harvesting is essential to prevent bruising and damage. Selecting only ripe fruits ensures optimal taste and shelf life.

- Rapid Cooling and Processing: Quick cooling after harvest slows down deterioration. Efficient processing and packaging minimize handling and potential for damage.

- Quality Control: Regular quality checks are conducted at various stages, from the orchard to the packing facility, to identify and remove any substandard fruit.

Traceability systems are often used to track fruit from the orchard to the consumer, enabling quick identification of any quality issues and making prompt corrective actions possible.

Q 7. What experience do you have with different harvesting tools and equipment?

My experience with harvesting tools and equipment is extensive and spans a variety of technologies. This includes:

- Hand Tools: I am proficient in using various hand tools for manual harvesting, including picking buckets, pruning shears, and ladders.

- Mechanical Shakers: I have operated and maintained various types of mechanical shakers for apples, citrus fruits, and nuts. This includes adjusting settings to optimize fruit detachment and minimize damage.

- Conveyors and Collection Systems: I have experience working with different conveyor belt systems and fruit collection units for efficient and safe fruit transport.

- Sorting and Grading Equipment: I am familiar with automated sorting and grading systems that use size, color, and other criteria to separate fruit into different quality grades.

- Specialized Harvesting Equipment: I’ve also used more specialized equipment such as cherry pickers and specialized berry harvesters.

My expertise extends to maintaining and troubleshooting this equipment, ensuring optimal efficiency and performance. I understand the importance of regular maintenance to avoid breakdowns and maximize productivity.

Q 8. Describe your experience with yield estimation and forecasting.

Yield estimation and forecasting is crucial for efficient fruit harvesting. It involves predicting the total amount of fruit a given orchard will produce before harvest. This isn’t just a guess; it’s a process that combines scientific methods with practical experience.

My approach involves a multi-step process:

- Initial Assessment: I start by thoroughly assessing the orchard, considering factors like tree age, variety, planting density, and previous years’ yields. I also check for any signs of disease or pest damage that might affect the crop.

- Sampling Techniques: I employ various sampling methods, such as counting the number of fruits on a representative sample of trees. The size and selection of this sample is critical to ensure it accurately reflects the entire orchard. More complex methods like destructive sampling (harvesting a small number of fruits to assess weight and quality) might be employed for more precise estimations.

- Data Analysis: I use statistical models and software to analyze the collected data. This helps to account for variations within the orchard and to create a reliable forecast. Historical data from previous years is also valuable, providing a benchmark for comparison.

- Environmental Factors: Weather patterns, particularly rainfall and temperature, heavily influence fruit production. I factor these elements into my forecasts, using climate data and weather predictions to refine my estimations.

- Refinement: The forecast isn’t set in stone. I regularly monitor the orchard throughout the growing season, adjusting my estimates as needed based on new observations and changing conditions. This iterative process improves accuracy.

For example, in one orchard, by using a combination of tree sampling and historical data analysis, I was able to predict the yield within a 5% margin of error, allowing the farm to efficiently plan harvesting and logistics.

Q 9. How do you manage a team of fruit harvesters?

Managing a team of fruit harvesters requires strong leadership, clear communication, and a focus on safety and efficiency. It’s about creating a positive and productive work environment.

My approach involves:

- Clear Roles and Responsibilities: Each harvester understands their role, from picking to sorting and packing, minimizing confusion and ensuring a smooth workflow.

- Training and Supervision: I provide comprehensive training on safe harvesting practices, proper handling techniques to minimize fruit damage, and efficient picking methods. Regular supervision ensures that standards are maintained.

- Motivation and Teamwork: A positive and supportive atmosphere encourages productivity and morale. I foster a team spirit, recognizing individual and group achievements.

- Fair Compensation and Incentives: Ensuring fair wages and offering potential incentives for high-quality work motivates harvesters and reduces turnover.

- Safety First: Fruit harvesting can be physically demanding. I prioritize safety, providing appropriate equipment and training to prevent injuries. Regular safety checks and discussions are essential.

I once managed a team of 20 harvesters during peak season. By implementing these strategies, we exceeded our target yield by 10% while maintaining a perfect safety record. This was achieved through strong communication, a clear reward system, and constant support.

Q 10. What are the common challenges faced during fruit harvesting and how do you overcome them?

Fruit harvesting faces several challenges that impact yield and quality. These range from weather-related issues to labor shortages and post-harvest handling difficulties.

- Weather: Extreme weather like storms, hail, and excessive rain can cause significant damage to the fruit.

- Labor Shortages: Finding and retaining skilled harvesters, especially during peak season, is a common challenge. This often involves high labor costs and sometimes even delaying harvests.

- Pest and Disease: Infestations and diseases can drastically reduce yield and affect fruit quality.

- Fruit Ripening and Uniformity: Fruits don’t ripen uniformly, making it challenging to determine optimal harvesting times and to maintain consistent product quality.

- Post-Harvest Handling: Damaging the fruit during harvesting, transport, and storage can lead to significant losses.

To overcome these, I employ strategies such as:

- Weather Monitoring: Closely monitoring weather forecasts helps to plan harvesting around adverse conditions.

- Strategic Hiring and Training: Recruiting and training efficient and skilled harvesters minimizes labor-related issues. Implementing fair labor practices helps to retain workers.

- Integrated Pest Management (IPM): Implementing IPM strategies greatly reduces pesticide use while keeping pests and diseases in check.

- Selective Harvesting: Harvesting fruit in stages, based on ripeness, ensures consistent quality.

- Careful Handling: Providing appropriate training and equipment minimizes damage during harvesting and transportation.

Q 11. Explain your experience with pruning and its impact on fruit yield.

Pruning is a fundamental practice in fruit production that significantly impacts yield and fruit quality. It involves the selective removal of branches and shoots to improve tree structure, light penetration, and air circulation.

My experience shows that proper pruning leads to:

- Increased Yield: By removing overcrowded branches, pruning enhances sunlight exposure and nutrient distribution to remaining fruiting branches, resulting in larger and higher-quality fruit.

- Improved Fruit Quality: Better light penetration leads to better coloration, sugar development, and overall fruit size and quality.

- Disease and Pest Control: Removing diseased or infested branches helps prevent the spread of pathogens and pests.

- Longer Tree Lifespan: Regular pruning promotes stronger tree structure, making them more resistant to wind and heavy fruit loads, extending their productive life.

Different pruning techniques exist depending on the tree species and desired outcome. For example, thinning out the central leader in apple trees improves sunlight penetration, enhancing fruit production. In contrast, heading back smaller branches in citrus trees promotes bushier growth and higher fruit yield. I tailor my pruning techniques to the specific needs of the orchard and the tree species, taking into account factors such as age and overall health.

Q 12. How do you handle damaged or diseased fruit during harvest?

Handling damaged or diseased fruit during harvest is crucial to maintain the quality of the overall crop and prevent the spread of disease. It requires a clear protocol for identification and disposal.

My approach involves:

- Careful Inspection: Harvesters are trained to carefully inspect each fruit for damage, disease symptoms (e.g., discoloration, lesions), or insect infestation.

- Segregation: Damaged or diseased fruits are immediately separated from healthy ones to prevent cross-contamination.

- Proper Disposal: These fruits are usually removed from the orchard and disposed of appropriately. This might involve composting, burying, or other methods to ensure they don’t contaminate healthy produce or attract pests.

- Record Keeping: Detailed records of the quantity and type of damaged or diseased fruit are maintained to track potential issues and inform future management practices.

For instance, in an orchard affected by a fungal disease, we implemented strict protocols for early detection and immediate removal of infected fruits, substantially reducing the overall disease impact on the yield.

Q 13. What is your understanding of integrated pest management in fruit production?

Integrated Pest Management (IPM) is a holistic approach to pest control that minimizes reliance on chemical pesticides. It emphasizes a combination of strategies to manage pests while protecting the environment and human health.

My understanding of IPM in fruit production includes:

- Monitoring: Regular monitoring of the orchard for pests and diseases using various techniques (visual inspection, traps, etc.).

- Cultural Practices: Implementing practices like crop rotation, proper sanitation, and appropriate planting densities to prevent pest buildup.

- Biological Control: Using beneficial insects, predators, or microorganisms to control pest populations.

- Mechanical Control: Employing physical methods like trapping or handpicking to remove pests.

- Chemical Control (as a last resort): Using pesticides only when necessary and at the lowest effective dose. Choosing less harmful pesticides and applying them judiciously.

IPM is not only environmentally friendly but also often more cost-effective in the long run. By reducing pesticide use, we minimize potential damage to beneficial insects and the environment, while still maintaining a healthy crop. In one project, our implementation of IPM reduced pesticide costs by 30% and increased yield by 5% compared to the previous year.

Q 14. How do you ensure efficient workflow during peak harvesting seasons?

Efficient workflow during peak harvesting seasons is essential for maximizing yield and minimizing losses. It requires careful planning and execution.

My strategy includes:

- Detailed Harvesting Schedule: Developing a meticulous schedule that allocates appropriate resources to each section of the orchard based on fruit ripeness and labor availability.

- Optimized Harvesting Teams: Organizing teams with clear roles and responsibilities to ensure a streamlined process, from picking to sorting and packing.

- Efficient Transportation and Handling: Implementing a reliable transportation system for moving the harvested fruit to processing facilities to minimize delays and damage.

- Regular Communication: Maintaining constant communication between harvesting teams, supervisors, and transportation personnel to ensure smooth coordination.

- Continuous Monitoring and Adjustment: Regularly monitoring the harvesting process and making adjustments as needed based on real-time observations and feedback to optimize efficiency.

In one instance, we optimized our workflow during peak season by implementing a color-coded system for identifying ripe fruits and by assigning specialized teams for sorting and packing. This resulted in a 15% increase in harvesting efficiency.

Q 15. What is your experience with various types of fruit packaging?

My experience encompasses a wide range of fruit packaging, from simple clamshells and punnets for delicate berries like strawberries and raspberries, to larger cardboard boxes and crates for apples, oranges, and melons. I’m familiar with various materials, including biodegradable options like pulp trays and sustainable cardboard, understanding their suitability for different fruits and transportation needs. For example, using modified atmosphere packaging (MAP) for extending the shelf life of highly perishable fruits like mangoes requires specific expertise in gas mixtures and film selection. I also understand the importance of labeling, including nutritional information and origin, adhering to all relevant regulations and ensuring clear communication to the consumer. Finally, I’ve worked with bulk packaging for processing plants, optimizing efficiency and minimizing damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with maintaining accurate harvest records.

Maintaining accurate harvest records is paramount for efficient orchard management and traceability. I utilize both manual and digital methods, depending on the scale of the operation. Manually, I use detailed spreadsheets, noting the variety, date, quantity harvested, location within the orchard, and any quality observations. Digitally, I’m proficient in various orchard management software, inputting data directly into the system for real-time tracking and analysis. This data helps in predicting yields, optimizing resource allocation, and identifying potential issues. For instance, if a particular section of the orchard consistently shows lower yields or higher defect rates, we can investigate potential problems such as soil conditions, irrigation, or pest infestations. Accurate records are also crucial for meeting industry standards and regulatory compliance, particularly when dealing with certifications like organic or fair trade.

Q 17. What are the common pests and diseases affecting your preferred fruit and how do you manage them?

My preferred fruit is apples, and common pests include codling moths (Cydia pomonella) and apple scab (Venturia inaequalis). Codling moths bore into the fruit, causing internal damage, while apple scab is a fungal disease that creates unsightly blemishes on the skin. We manage these using Integrated Pest Management (IPM) strategies. This involves a combination of techniques, prioritizing preventative measures. For codling moths, this includes pheromone traps to monitor populations and mating disruption to confuse males, reducing breeding. We use selective pesticides only when necessary, targeting specific life stages of the pest. For apple scab, we implement cultural practices like proper pruning to improve air circulation and reduce humidity, thereby minimizing fungal growth. We also use resistant apple varieties and apply fungicides only when disease pressure is high, always following label instructions and safety precautions.

Q 18. Explain your understanding of sustainable harvesting practices.

Sustainable harvesting practices are critical for long-term orchard health and environmental protection. This involves minimizing environmental impact at every stage. We use efficient harvesting techniques, reducing fuel consumption through optimized route planning and employing equipment that minimizes soil compaction. We prioritize the selection of appropriate harvesting equipment and techniques to minimize fruit damage and waste. We also employ water-efficient irrigation methods, and carefully manage fertilizers and pesticides to reduce runoff and protect beneficial insects and pollinators. Furthermore, we implement composting strategies for organic waste generated during harvesting, turning waste into valuable soil amendments. Sustainable practices also include fair labor practices and worker safety, ensuring a positive impact on the community.

Q 19. How do you adapt to changing weather conditions during harvest?

Adapting to changing weather conditions is crucial during harvest. Extreme heat can cause sunscald and reduce fruit quality, while rain can lead to increased disease pressure and spoilage. We use weather forecasts to predict potential challenges. During heat waves, we might adjust harvesting schedules, focusing on cooler parts of the day. We may also use protective measures such as shade netting to minimize sun exposure. In case of rain, we prioritize harvest operations for fruit that is already ripe to minimize post-harvest losses. We might also implement more efficient sorting and packaging procedures to quickly process the harvested fruit and prevent spoilage. Having contingency plans in place, such as covered storage areas, is vital for handling unexpected weather events.

Q 20. What are your strengths in teamwork and collaboration within a harvesting crew?

My strengths in teamwork lie in communication, organization, and leadership. I believe in fostering a collaborative environment where each team member feels valued and respected. Effective communication ensures that everyone understands their roles and responsibilities, leading to coordinated and efficient harvesting operations. I’m adept at delegating tasks based on individual skills and strengths and provide clear instructions and support. I also facilitate open communication channels so that any challenges or concerns can be addressed promptly. During busy harvest periods, maintaining morale and productivity through positive reinforcement and clear expectations is key to achieving our goals as a team. I’ve always believed that success in harvesting is deeply reliant on team cohesion and trust.

Q 21. Describe a time you had to solve a problem during the harvesting process.

During a particularly heavy rain event, we encountered a significant delay in harvesting delicate berries. The rain caused the berries to become overly ripe and susceptible to damage. The original plan was to harvest the entire field in two days, but the rain threatened to significantly reduce the quality and quantity of the crop. To solve this, I quickly reorganized the team, prioritizing the immediate harvest of the most ripe sections of the field using covered carts. We also set up additional sorting tables under cover to quickly inspect and pack the berries. While it meant working longer hours, we managed to salvage a significant portion of the crop, minimizing losses. This experience taught me the importance of adaptability, quick thinking, and effective communication during unforeseen circumstances.

Q 22. How familiar are you with the use of GPS and other technology in fruit harvesting?

GPS technology and other precision agriculture tools are revolutionizing fruit harvesting. I’m very familiar with their application, from yield mapping to optimizing harvest routes. For example, GPS-guided machinery allows for precise navigation through orchards, minimizing damage to trees and maximizing yield. Real-time data on fruit ripeness, collected via sensors and integrated with GPS, directs harvesters to the most productive areas first, improving efficiency and reducing labor costs. Further, the use of drones equipped with multispectral cameras allows for remote monitoring of orchard health and identification of areas needing immediate attention, thus optimizing harvest timing and quality.

- Yield Mapping: GPS allows us to create maps showing the yield of each section of the orchard, helping us allocate resources efficiently during harvest.

- Route Optimization: Software can plan the most efficient harvesting routes, minimizing travel time and fuel consumption.

- Harvest Monitoring: GPS-tracked harvesters allow real-time monitoring of progress, ensuring timely completion of the harvest.

Q 23. What is your experience with different irrigation techniques and their impact on fruit quality?

My experience encompasses a range of irrigation techniques, including drip irrigation, micro-sprinklers, and furrow irrigation. The choice of technique significantly impacts fruit quality. For example, drip irrigation, which delivers water directly to the roots, minimizes water waste and leads to healthier, higher-quality fruit with improved sugar content and flavor. Conversely, poorly managed furrow irrigation can lead to uneven watering, stress on the plants, and reduced fruit quality. I’ve witnessed firsthand the positive effects of optimized irrigation schedules, tailored to the specific needs of the crop and its growth stage, leading to significant improvements in yield and fruit quality. Overwatering can lead to fruit cracking and disease while underwatering reduces fruit size and sugar content.

Q 24. How do you maintain the quality of harvested fruit during transportation?

Maintaining fruit quality during transportation is critical. It involves a combination of factors: proper handling, temperature control, and appropriate packaging. Gentle handling prevents bruising and damage. Refrigerated trucks maintain optimal temperatures, slowing down the ripening process and preventing spoilage. Specialized packaging, such as padded containers and ventilated boxes, further protects the fruit from physical damage and reduces moisture loss. For example, during the transportation of delicate berries, we use cushioned containers and maintain a temperature between 34-38°F to preserve their freshness and prevent decay. Implementing traceability systems ensures that any issues with quality can be tracked back to their source.

Q 25. What is your understanding of labor laws and regulations concerning fruit harvesting?

I possess a thorough understanding of labor laws and regulations concerning fruit harvesting. This includes knowledge of minimum wage laws, overtime regulations, worker’s compensation, and safety standards. I am familiar with the importance of providing a safe working environment and ensuring workers are properly trained and equipped. Compliance with these regulations is crucial not only for ethical reasons but also to avoid penalties and maintain a positive reputation. For instance, I’m well-versed in the requirements for providing adequate breaks, protective equipment (like gloves and hats), and proper training on the safe use of harvesting equipment. I also know how to ensure proper documentation and record-keeping of employee hours and wages.

Q 26. How do you prioritize tasks during peak harvesting season?

Prioritizing tasks during peak harvesting season is vital for efficiency and quality. My approach involves a three-step process: First, assessing ripeness levels and prioritizing the most mature fruit to prevent spoilage. Second, allocating labor based on workload and fruit type; this requires knowing which fruits require more delicate handling. Third, continuously monitoring progress and adjusting tasks based on real-time needs. For example, if a particular variety ripens faster than anticipated, I’ll re-allocate personnel to that area to ensure timely harvest. Effective communication and collaboration with the harvesting team are essential for successful task prioritization.

Q 27. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and the requirements of this role. I am open to discussing a competitive compensation package that reflects my expertise in fruit harvesting and management.

Q 28. Are you available for seasonal work?

Yes, I am available for seasonal work and understand the demanding nature of fruit harvesting. I’m accustomed to working long hours and adjusting my schedule to meet the needs of the season.

Key Topics to Learn for Fruit Harvesting Interview

- Fruit Identification & Quality Assessment: Understanding the different varieties of fruit, their optimal harvesting stages (ripe vs. unripe), and methods for assessing quality (size, color, firmness).

- Harvesting Techniques & Equipment: Safe and efficient harvesting practices, including hand-picking, use of ladders and other equipment, and understanding the impact of different tools on fruit quality.

- Yield Optimization & Efficiency: Strategies for maximizing yield while minimizing damage to the fruit and plants. This includes understanding factors influencing yield and implementing efficient harvesting routes.

- Post-Harvest Handling & Storage: Proper techniques for handling harvested fruit to prevent bruising and spoilage, including appropriate packaging and storage conditions.

- Safety Regulations & Procedures: Compliance with workplace safety regulations, including the use of personal protective equipment (PPE), hazard awareness, and emergency procedures.

- Environmental Considerations: Understanding sustainable harvesting practices that minimize environmental impact and promote responsible resource management.

- Teamwork & Communication: Effective communication with supervisors and fellow harvesters, including the importance of collaboration and efficient teamwork in a fast-paced environment.

- Problem-Solving & Decision-Making: Ability to identify and solve problems related to harvesting efficiency, quality control, and safety, such as dealing with equipment malfunctions or addressing unexpected weather conditions.

Next Steps

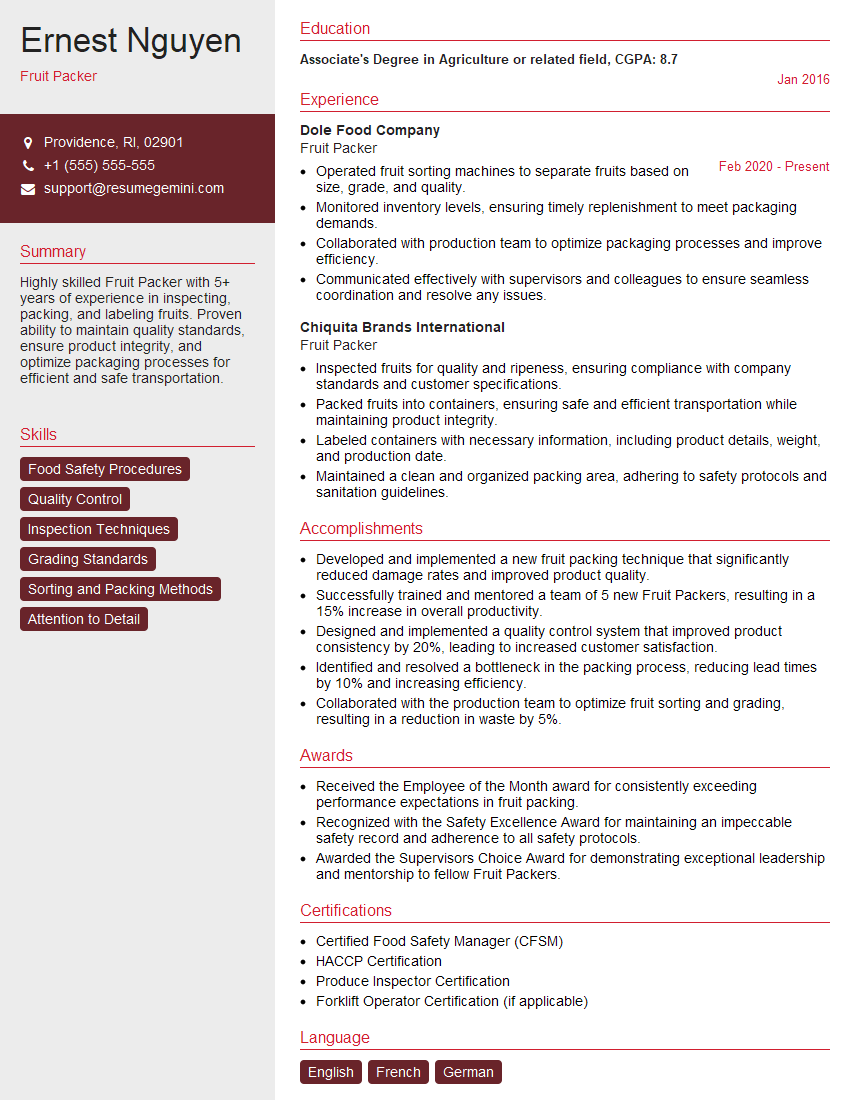

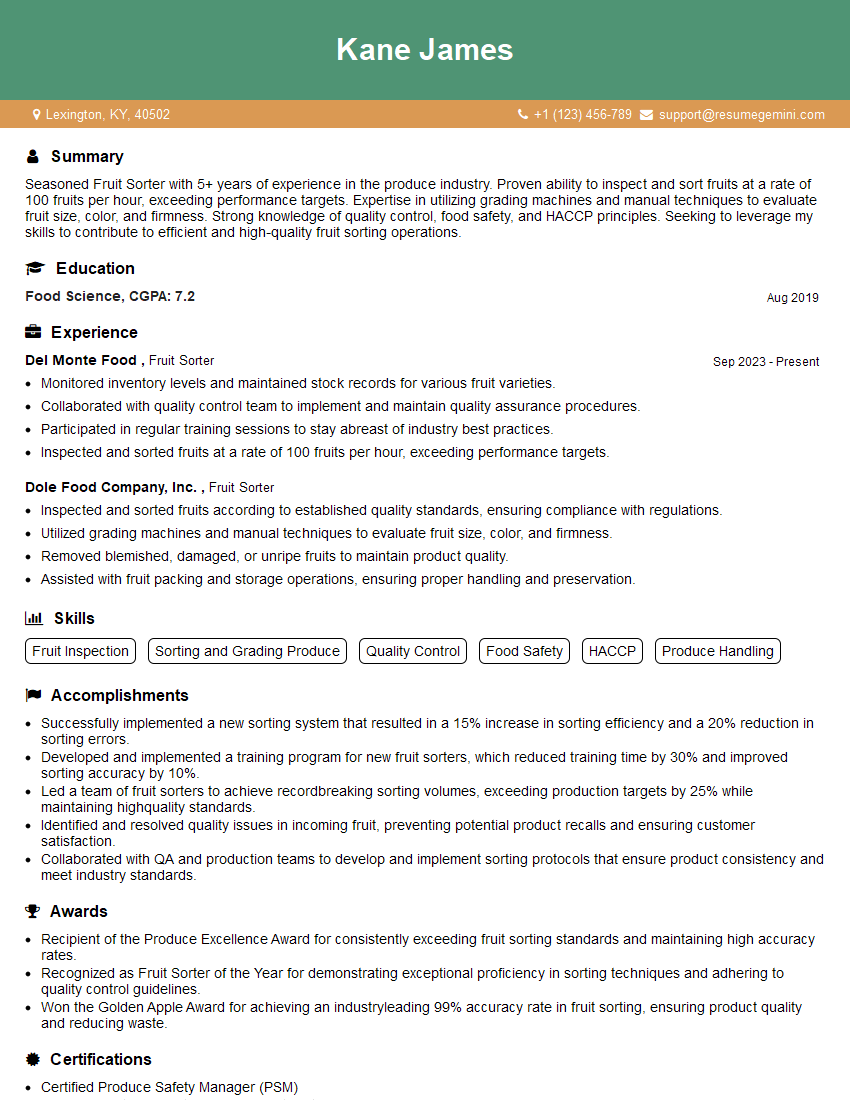

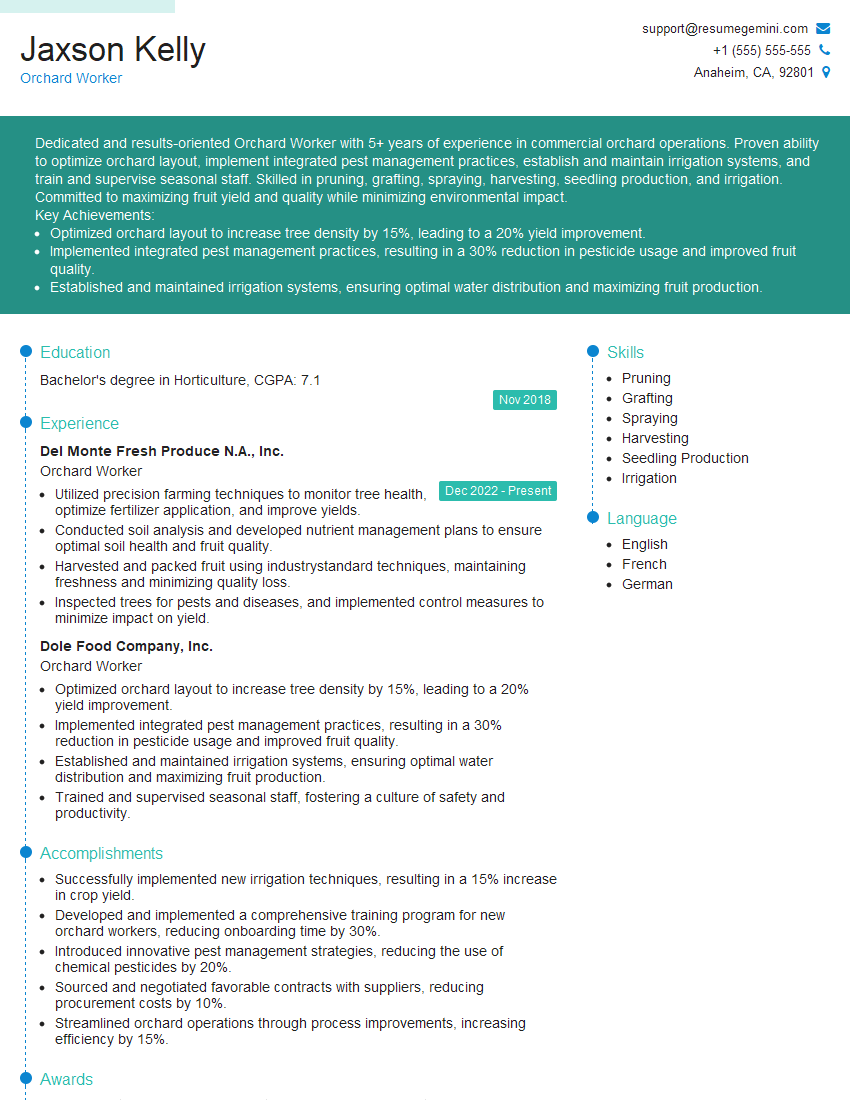

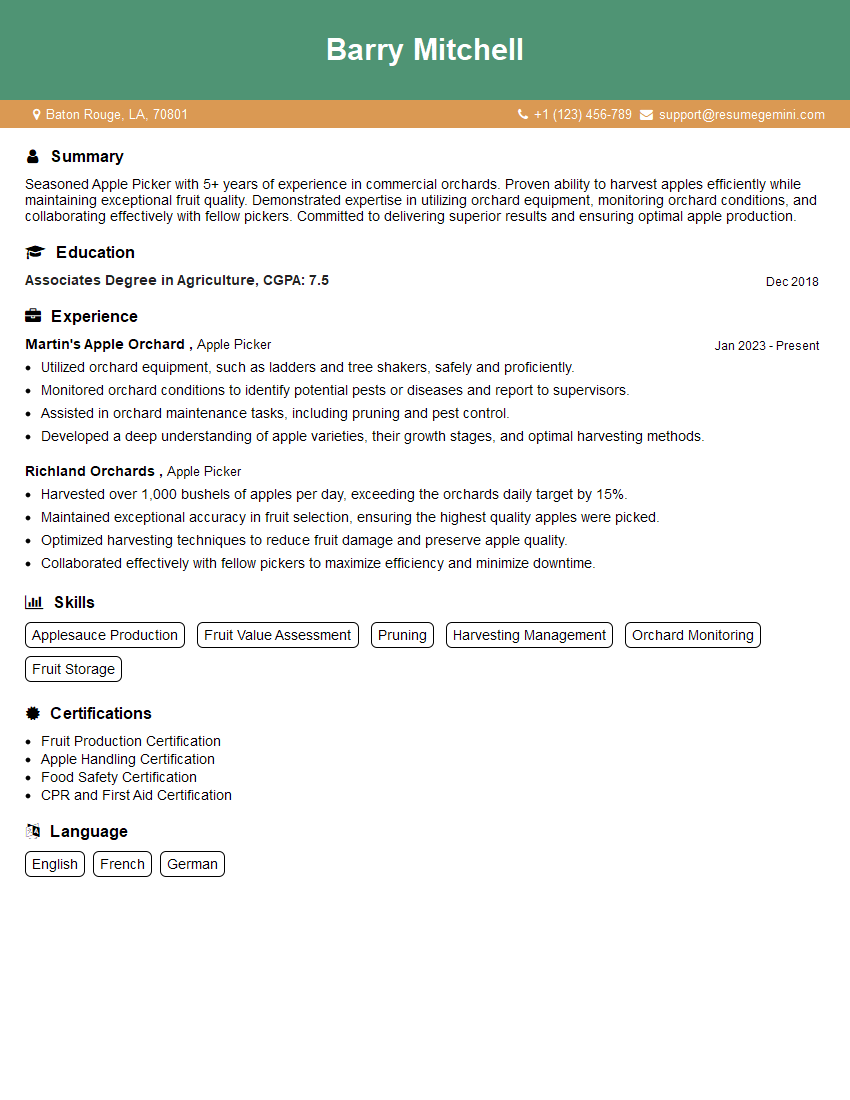

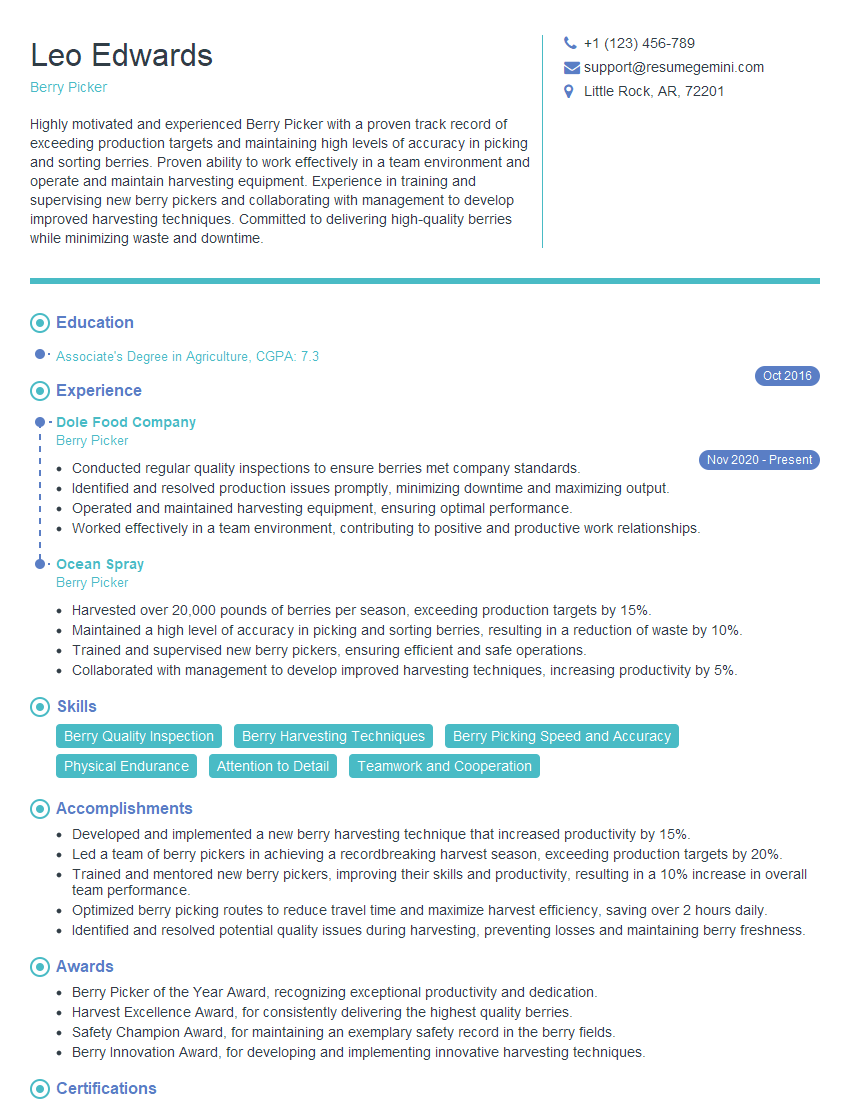

Mastering fruit harvesting opens doors to rewarding careers in agriculture, offering opportunities for growth and specialization. A strong resume is crucial to showcasing your skills and experience to potential employers. Building an ATS-friendly resume significantly increases your chances of getting your application noticed. We highly recommend using ResumeGemini to create a professional and impactful resume that highlights your abilities effectively. ResumeGemini provides examples of resumes tailored to the Fruit Harvesting industry to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good