Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Fruit Packing interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Fruit Packing Interview

Q 1. Describe your experience with different fruit packing methods.

My experience encompasses a wide range of fruit packing methods, tailored to the specific fruit type and market demands. For delicate fruits like berries, we utilize gentle tray packing, often with cushioning materials like shredded paper or foam to prevent bruising. Larger fruits, such as apples and oranges, are frequently packed in bulk bins or cartons, sometimes with dividers to keep them separated. For export, we often use specialized techniques like vacuum cooling and modified atmosphere packaging (MAP) to extend shelf life. I’ve also worked with automated packing lines that efficiently sort, grade, and pack fruits at high volumes, significantly increasing throughput compared to manual methods. One particularly challenging project involved packing mangoes for international shipping, requiring specific humidity control and careful selection of packaging to withstand the journey.

Q 2. What are the common quality control checks performed during fruit packing?

Quality control is paramount in fruit packing. Our checks begin at the receiving end, visually inspecting fruits for defects like bruises, blemishes, or insect damage. We use sizing equipment to categorize fruits by size, ensuring uniformity within each package. We also measure key quality parameters such as firmness (using a firmness tester), color (using colorimeters), and sugar content (using a refractometer) to guarantee the final product meets the required standards. Throughout the process, we maintain strict temperature and humidity controls to prevent spoilage. Any fruit failing these checks is immediately diverted to secondary markets or rejected. Regular audits and documentation ensure traceability and compliance with food safety regulations. For example, a batch of apples with excessive bruising would be immediately removed from the production line, and the reason for the damage investigated and addressed.

Q 3. How do you ensure the efficient operation of fruit packing machinery?

Efficient machinery operation relies on a preventative maintenance schedule and a well-trained team. This involves daily inspections for wear and tear, regular lubrication, and timely replacement of worn parts. We utilize predictive maintenance techniques such as vibration analysis to detect potential problems before they lead to breakdowns. Operator training is crucial to ensure proper use and cleaning of equipment, minimizing downtime. For example, a conveyor belt malfunction can be quickly addressed with routine cleaning and lubrication. Proper operator training ensures they can identify and resolve minor issues before they become major problems. We also track machine performance data, such as packing speed and reject rates, to identify areas for improvement and optimization.

Q 4. Explain your experience with different types of fruit packaging materials.

My experience includes working with a variety of packaging materials, each with its pros and cons. We commonly use corrugated cardboard boxes for their strength, affordability, and recyclability. For premium fruits, we might use plastic clamshells or punnets for enhanced visibility and protection. For longer-distance shipping, we often employ specialized films that create a modified atmosphere to extend shelf life. Sustainable materials like biodegradable pulp trays and compostable films are increasingly being incorporated to meet growing environmental concerns. The choice of material is dictated by the type of fruit, transportation distance, and cost considerations. For instance, delicate strawberries often require plastic punnets for individual protection, whereas sturdier apples might be packed in cardboard boxes.

Q 5. How do you handle damaged or substandard fruit during the packing process?

Damaged or substandard fruit is handled separately to prevent contamination and maintain quality standards. It’s typically diverted to a separate processing line for juicing, canning, or other secondary uses. If the damage is extensive, the fruit is discarded according to established waste management protocols. This segregation is vital for preventing the spoilage of good quality fruit. We carefully document the reasons for rejection to analyze and address the root causes of damage, such as issues in harvesting or handling. For instance, slightly bruised apples could be used for applesauce, while heavily bruised ones would be disposed of properly.

Q 6. What are the key safety procedures you follow in a fruit packing environment?

Safety is paramount. We enforce strict adherence to hygiene protocols, including hand washing, use of protective clothing (gloves, aprons, hairnets), and regular sanitation of equipment and work surfaces. Proper lifting techniques are emphasized to prevent musculoskeletal injuries. We also have comprehensive safety training programs to educate workers on hazard identification and emergency procedures. Equipment is regularly inspected to ensure it’s functioning safely. For instance, all machinery is regularly inspected and workers receive training on lockout/tagout procedures to prevent accidental starts during maintenance. We have clear safety signage and emergency procedures prominently displayed.

Q 7. Describe your experience with inventory management in a fruit packing setting.

Efficient inventory management is crucial to avoid spoilage and meet market demands. We utilize inventory management systems to track the quantity and quality of fruit at each stage, from receiving to shipping. This includes real-time updates on stock levels, order fulfillment, and expiry dates. Demand forecasting helps us optimize procurement and packing schedules. Data analytics helps identify trends and predict future demand, enabling us to make informed decisions regarding procurement and resource allocation. For example, we might increase our order for a specific fruit type based on sales data showing increased demand during a specific season. Regular stock rotation ensures that older fruits are used first, minimizing waste.

Q 8. How do you maintain hygiene and sanitation standards during fruit packing?

Maintaining hygiene and sanitation is paramount in fruit packing to ensure food safety and prevent spoilage. It’s like preparing a pristine kitchen before cooking a gourmet meal – every step matters.

- Pre-harvest sanitation: Clean and disinfected tools and equipment are crucial. This includes knives, sorting belts, and washing equipment. We often use approved food-grade sanitizers, following strict dilution ratios.

- Washing and pre-cooling: Fruits are thoroughly washed to remove dirt, debris, and potential contaminants. Pre-cooling rapidly lowers the fruit’s temperature, extending its shelf life and minimizing microbial growth. We might use hydrocoolers or air coolers depending on the fruit type and scale of operation.

- Personal hygiene: All personnel wear clean uniforms, hairnets, and gloves. Regular handwashing with antimicrobial soap is mandatory at designated stations throughout the facility. Hand sanitizer is also readily available.

- Facility sanitation: The packing facility is regularly cleaned and sanitized. We pay close attention to areas where fruits come into contact with surfaces, using appropriate cleaning agents and disinfectants. Routine pest control is vital.

- Regular inspections: We conduct frequent internal audits to verify compliance with hygiene standards. These inspections cover equipment, facilities, and personnel practices.

Failing to adhere to these measures can lead to product contamination, spoilage, and serious health risks for consumers. A robust sanitation program is an investment in product quality and business reputation.

Q 9. How do you ensure the correct labeling and traceability of packed fruit?

Accurate labeling and traceability are essential for ensuring product quality, complying with regulations, and efficiently managing supply chains. Think of it as a fruit’s unique identity card, following it from farm to table.

- Clear labeling: Each package must clearly display information such as the fruit’s name, variety, weight, growing region, packer’s name, and any relevant certifications (e.g., organic). Legibility is crucial.

- Batch codes and lot numbers: Each batch of packed fruit receives a unique code that allows us to trace its origin and track its journey through the supply chain. This is vital in case of recalls or quality control issues.

- Barcode and RFID technology: Advanced systems utilize barcodes or Radio-Frequency Identification (RFID) tags to automate tracking and enhance efficiency. This facilitates real-time monitoring of inventory and distribution.

- Data management systems: We use software to manage and maintain all traceability information, ensuring easy access to data when needed. This is invaluable for regulatory compliance and effective supply chain management.

- Documentation: Detailed records are maintained throughout the entire process, documenting harvest date, packing date, storage conditions, and distribution details. This provides complete transparency and traceability.

Effective labeling and traceability systems safeguard the consumer, enhance brand reputation, and streamline the overall packing process.

Q 10. Describe your experience with different fruit varieties and their specific packing requirements.

My experience spans a wide range of fruit varieties, each presenting unique challenges in terms of handling and packaging.

- Berries (strawberries, blueberries, raspberries): These delicate fruits require gentle handling to avoid bruising. We use special trays and cushioning materials to protect them during packing and transport. Speed is crucial here to maintain freshness.

- Stone fruit (peaches, plums, nectarines): These fruits are relatively firm but still susceptible to bruising. We carefully sort and grade them before packing, ensuring only undamaged produce is included. Proper temperature control is essential during transportation.

- Citrus fruits (oranges, lemons, grapefruits): Citrus fruits have a thicker peel, offering more protection. However, proper washing and sorting to eliminate blemishes are still vital. We often use protective netting for bulk shipments.

- Apples and pears: These fruits require careful handling to prevent bruising and maintain their firmness. Modified atmosphere packaging (MAP) is sometimes used to extend their shelf life. We use sizing equipment to group similarly sized fruits.

- Avocados: Avocados are highly perishable. Proper ripening and careful handling are essential. We use specialized containers and controlled temperature environments to maintain quality.

Understanding the specific characteristics of each fruit variety and adapting packing methods accordingly is essential for maximizing quality and shelf life. I’ve worked with all of these fruits and consistently adapted to the requirements for each.

Q 11. How do you prioritize tasks and manage your time effectively in a fast-paced fruit packing environment?

In the fast-paced world of fruit packing, effective prioritization and time management are crucial. It’s about orchestrating a well-oiled machine to ensure timely and efficient packing.

- Prioritization matrix: I use a prioritization matrix to rank tasks based on urgency and importance. Urgent and important tasks get immediate attention; less urgent tasks are scheduled accordingly.

- Task scheduling: I create detailed schedules and assign tasks to team members based on their skills and availability. This ensures everyone understands their responsibilities and deadlines.

- Continuous monitoring: I regularly monitor progress and identify potential bottlenecks or delays. This allows for proactive adjustments to maintain efficiency.

- Teamwork and communication: Clear communication among team members is essential. Open dialogue and collaboration help resolve issues quickly and efficiently.

- Lean principles: I incorporate lean manufacturing principles to eliminate waste and streamline the packing process. This involves optimizing workflow, minimizing material handling, and reducing downtime.

For example, during peak season, we might prioritize processing the most perishable fruits first to minimize losses. By combining these strategies, we ensure high productivity while maintaining quality.

Q 12. Explain your understanding of cold chain logistics related to fruit packing.

Cold chain logistics is the uninterrupted maintenance of a low-temperature environment during fruit handling, storage, and transportation. Think of it as a crucial lifeline for preserving fruit freshness and quality – essentially preventing spoilage.

- Pre-cooling: Rapidly lowering the temperature of the harvested fruit soon after picking is vital to slow down respiration rates and minimize enzymatic activity that contributes to spoilage.

- Refrigerated storage: Maintaining appropriate storage temperatures is critical, varying depending on the fruit type. We use refrigerated warehouses and controlled-atmosphere storage (CA) where necessary.

- Refrigerated transportation: Fruits are transported in refrigerated trucks or containers to maintain low temperatures throughout the journey. Regular temperature monitoring is implemented to ensure compliance.

- Temperature monitoring and recording: Temperature data is meticulously recorded throughout the cold chain. This information is crucial for tracking and troubleshooting, proving consistency and confirming quality.

- Packaging materials: Selecting appropriate packaging materials that provide insulation and maintain low temperatures is crucial. This may involve using insulated containers and specialized packaging films.

Maintaining a flawless cold chain is a critical aspect of ensuring product quality. Any break in the cold chain can significantly reduce shelf life and increase the risk of spoilage.

Q 13. How do you identify and resolve common issues that occur during fruit packing?

Identifying and resolving issues quickly is essential in fruit packing. It’s like being a detective solving a mystery to preserve the product’s integrity.

- Regular quality checks: Frequent inspections are carried out at various stages of the packing process to identify problems such as bruising, discoloration, or insect infestation.

- Root cause analysis: When an issue is identified, we conduct a root cause analysis to determine the underlying factors. This might involve examining handling techniques, equipment settings, or storage conditions.

- Corrective actions: Once the root cause is identified, appropriate corrective actions are implemented to prevent recurrence. This can range from adjusting equipment settings to retraining staff.

- Preventive measures: We implement preventive measures to minimize the occurrence of common issues. This includes regular equipment maintenance, improved handling procedures, and enhanced sanitation practices.

- Data analysis: Analyzing historical data helps us identify patterns and trends, allowing us to anticipate and proactively address potential problems.

For instance, if we notice an increase in bruised apples, we might investigate whether the harvesting or handling techniques need improvement or if the conveyor belt requires adjustment.

Q 14. What is your experience with using packing line machinery and equipment?

My experience with packing line machinery and equipment is extensive. I am proficient in operating and maintaining a range of automated and semi-automated equipment, ranging from fruit sorters and graders to packing lines and palletizers.

- Fruit sorters and graders: I’m familiar with optical sorters that identify and sort fruits based on size, color, and defects. This ensures uniform product quality.

- Weighing and filling machines: I have experience with automatic weighing and filling systems that ensure accurate product weights and efficient packaging.

- Packaging machines: I can operate a variety of packaging machines, including flow wrappers, tray sealers, and cartoners. I can handle different packaging materials and formats.

- Palletizers: I understand the operation of automated palletizers that efficiently stack packed products onto pallets for transportation. I can adjust settings to handle various pallet sizes and arrangements.

- Maintenance and troubleshooting: I’m able to perform routine maintenance on equipment and troubleshoot minor mechanical problems. I know when to escalate problems to qualified technicians.

I understand the importance of preventative maintenance to minimize downtime and maximize equipment lifespan. Proficiency with these machines ensures high-throughput and efficient fruit packing operations.

Q 15. How do you contribute to a team environment within fruit packing operations?

In fruit packing, teamwork is paramount. I contribute by actively participating in team discussions, sharing my expertise on efficient packing techniques and problem-solving, and offering support to colleagues. For example, during peak season, I’ve often assisted newer team members with mastering specific machinery or quality control procedures. I believe in a collaborative environment where everyone feels valued and can contribute their skills to achieve our shared goals. Open communication and mutual respect are key to effective teamwork; I actively listen to others’ ideas and offer constructive feedback.

Another way I contribute is by proactively identifying and addressing potential bottlenecks. If I notice one line is falling behind, I’ll help redistribute tasks or suggest improvements to the workflow. This proactive approach prevents delays and ensures smooth operations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your problem-solving skills within a fruit packing context.

Problem-solving is a daily occurrence in fruit packing. I approach challenges systematically. Let’s say we experienced a significant increase in bruised fruit. My first step would be to identify the root cause – is it harvesting methods, transportation issues, or a malfunctioning conveyor belt?

I’d then gather data, perhaps by analyzing the location of bruises and correlating it with specific parts of the process. This data-driven approach helps eliminate guesswork. Once the cause is pinpointed, I collaborate with the team to implement solutions. This might involve adjusting harvesting techniques, improving transport refrigeration, or conducting preventative maintenance on the machinery. I document all solutions and their effectiveness to prevent recurring problems.

For instance, we once had issues with packaging sealing. By systematically checking each stage of the sealing process, we discovered a faulty heating element. Replacing this element resolved the problem immediately. This illustrates my ability to diagnose problems quickly and efficiently, using a combination of technical knowledge and practical experience.

Q 17. What is your experience with different types of fruit packaging machinery?

My experience encompasses a wide range of fruit packaging machinery, from automated sorters and graders to filling and sealing machines, and palletizers. I’m proficient in operating and maintaining various types of equipment, including:

- Automated Grading Systems: I’m familiar with optical sorters that identify and sort fruit based on size, color, and defects.

- Filling and Sealing Machines: I have hands-on experience with various types of machines that fill containers (punnets, trays, boxes) and seal them efficiently, ensuring product integrity.

- Palletizing Robots: I understand the operation and safety protocols for robotic systems used for stacking packed fruit onto pallets for efficient storage and transport.

- Conveyor Systems: I have experience working with and troubleshooting different types of conveyor belts and systems used for moving fruit through the packing line.

I’m also adept at identifying and reporting malfunctions, and I understand preventative maintenance schedules to keep the machinery running smoothly. My practical experience allows me to quickly diagnose problems and minimize downtime.

Q 18. How do you ensure the efficient use of packaging materials to minimize waste?

Minimizing waste is a core principle in efficient fruit packing. We employ several strategies to ensure the efficient use of packaging materials. This includes optimizing packaging size to fit the fruit, reducing the use of excess void fill (e.g., using biodegradable options or custom-designed inserts), and carefully planning pallet configurations to reduce wasted space.

We also regularly review our inventory levels to avoid overstocking and ensure that we’re using packaging materials at optimal efficiency. For example, we’ve implemented a system for tracking and monitoring material usage, identifying areas where waste is occurring, and implementing corrective actions. This data-driven approach allows us to make informed decisions about material selection and usage, and to continuously improve our waste reduction efforts.

Furthermore, I’m involved in evaluating sustainable packaging options, such as using recycled or compostable materials, helping the company meet environmental targets.

Q 19. Describe your experience with maintaining accurate records and reporting in fruit packing.

Accurate record-keeping is critical in fruit packing. I’m experienced in maintaining detailed records of production output, material usage, and quality control data. This usually involves using both manual and computerized systems. I’m proficient in using software to track production metrics, such as the number of units packed, the rate of production, and the number of defects identified.

My role often involves generating reports summarizing daily, weekly, or monthly production figures. These reports are crucial for management to track performance, identify areas for improvement, and make informed decisions regarding resource allocation. For instance, I’ve used data on defect rates to highlight issues in the harvesting or handling processes, leading to improved practices and reduced waste.

Maintaining accurate records also helps with inventory management and ensuring traceability in case of quality issues or recalls. I understand the importance of data integrity and follow strict procedures to ensure accuracy and reliability.

Q 20. How do you adapt to changes in production demands in a fruit packing facility?

Adaptability is key in fruit packing, where demand fluctuates depending on the season and market conditions. I’ve successfully adapted to changing production demands by adjusting my work schedule, assisting in different areas of the packing line as needed, and mastering new packing techniques.

For example, during peak seasons, we may receive significantly larger volumes of fruit. I’ve adapted by working extra hours, training new employees, and streamlining our processes to handle the increased workload. Conversely, during slower periods, I’ve helped with inventory management, maintenance tasks, and other support roles.

My ability to learn quickly and efficiently is crucial in adapting to new equipment or processes. I’m always open to training and readily embrace new challenges, ensuring smooth operations regardless of the production demands.

Q 21. How familiar are you with relevant health and safety regulations in fruit packing?

I’m very familiar with relevant health and safety regulations in fruit packing. This includes understanding and adhering to food safety standards (like HACCP principles), proper hygiene practices (handwashing, sanitation of equipment), and safe handling of machinery and equipment. I understand the importance of wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and protective footwear.

I’m also knowledgeable about workplace safety procedures, including emergency response protocols, hazard identification and reporting, and safe lifting techniques. I actively participate in safety training sessions and am committed to maintaining a safe working environment for myself and my colleagues. For instance, I’ve assisted in conducting regular safety checks on machinery and reporting any potential hazards to the supervisor. Compliance with these regulations is not merely a requirement; it’s crucial for ensuring the safety and quality of both our products and our workforce.

Q 22. What is your experience with handling large volumes of fruit efficiently?

Efficiently handling large fruit volumes involves a strategic approach combining optimized processes, advanced technology, and a skilled workforce. My experience includes managing operations processing upwards of 100,000 kg of fruit daily. This involved overseeing the entire process, from receiving and quality control to packing and dispatch. We utilized automated sorting and grading systems to categorize fruit by size and ripeness, significantly accelerating the packing process. We also implemented a just-in-time inventory system, minimizing storage costs and waste while ensuring a continuous flow of product. For example, during peak season for strawberries, we employed an additional conveyor belt system to improve throughput by 25% compared to the previous year. This optimization not only increased our capacity but also minimized product damage and improved overall efficiency.

Q 23. How do you ensure the quality and freshness of packed fruit is maintained?

Maintaining fruit quality and freshness is paramount. We employ a multi-pronged approach: Firstly, careful pre-cooling immediately after harvest slows down respiration and enzymatic activity, extending shelf life. Secondly, we maintain a consistently cool temperature (around 1-2°C) throughout the entire packing and storage process. Thirdly, we meticulously select only the highest quality fruits, discarding any damaged or bruised items. Finally, we use modified atmosphere packaging (MAP) where appropriate. This involves reducing oxygen levels and increasing carbon dioxide and nitrogen levels within the packaging, slowing down deterioration. In the case of highly perishable fruits like blueberries, MAP significantly extended their shelf life by up to 5 days compared to traditional packaging methods.

Q 24. How do you troubleshoot common problems with fruit packing machinery?

Troubleshooting fruit packing machinery requires a methodical approach. I begin by identifying the problem, documenting it precisely, and then working through a diagnostic process. This often starts with a visual inspection, checking for obvious issues like blockages, worn parts, or loose connections. If the problem persists, I refer to the machine’s maintenance manual, often using flow charts to guide troubleshooting steps. For example, if a filling machine underfills the packs, we check for blockages in the hopper or calibrate the filling mechanism. If a conveyor belt stops, we inspect the motor, belts, and sensors. Sometimes it’s as simple as resetting a tripped circuit breaker. In more complex cases, we consult with the machine’s manufacturer or an experienced technician. Regular preventative maintenance, including lubrication and cleaning, drastically reduces the frequency of breakdowns.

Q 25. What are the key performance indicators (KPIs) you focus on in fruit packing?

Key Performance Indicators (KPIs) in fruit packing are crucial for measuring efficiency and quality. We track:

- Throughput: Kilograms of fruit packed per hour, indicating packing line efficiency.

- Waste Rate: Percentage of fruit rejected due to damage or spoilage.

- Line Efficiency: Percentage of time the packing line is operational.

- Defect Rate: Number of defective packs (incorrect weight, damage, etc.) per batch.

- Labor Productivity: Output per worker-hour, reflecting workforce efficiency.

Q 26. How would you handle a situation where a packing machine malfunctions?

A packing machine malfunction requires a swift and organized response. First, we prioritize safety, ensuring all personnel are clear of the affected machine. Then, we assess the situation to determine the severity of the malfunction. If it’s a minor issue, we attempt to troubleshoot the problem using the techniques I’ve described. If we can’t resolve the issue quickly, we immediately contact the maintenance team and inform the production supervisor. In the meantime, we might temporarily divert the fruit flow to a different line or manually pack the fruit until the machine is repaired. The objective is to minimize downtime and maintain production as much as possible. We also document the malfunction, repair process, and any resulting production loss for analysis and preventative measures.

Q 27. Describe your experience working within a team to meet production targets.

Teamwork is essential in fruit packing. I’ve been part of teams ranging from 10 to 50 people. In my previous role, I coordinated the work of packers, quality control inspectors, and maintenance technicians to achieve daily production targets. Effective communication is key – daily briefings, clear role assignments, and open channels for feedback helped us stay aligned. I fostered a collaborative environment through shared goals and mutual support. For example, when we had a particularly challenging period with high order volumes, we established a cross-training program, allowing team members to assist each other with different tasks. This flexibility proved crucial in meeting our targets and maintained morale under pressure.

Q 28. How do you ensure compliance with food safety regulations during fruit packing?

Ensuring compliance with food safety regulations is non-negotiable. This involves adhering to strict hygiene standards, regular sanitation protocols, and employee training. We maintain meticulous records of temperature monitoring, cleaning procedures, and employee certifications. We follow guidelines set by organizations like the FDA (in the US) or equivalent regulatory bodies. For example, we implement HACCP (Hazard Analysis and Critical Control Points) principles to identify and control potential hazards throughout the packing process. This includes implementing measures for pest control, preventing cross-contamination, and ensuring proper handling of allergens. Regular audits and inspections are vital for verifying compliance and continuous improvement in food safety practices.

Key Topics to Learn for Fruit Packing Interview

- Understanding Fruit Handling Techniques: Learn about proper fruit handling to minimize damage and spoilage, including techniques for different types of fruit and their varying sensitivities.

- Quality Control and Sorting: Familiarize yourself with procedures for identifying and sorting fruits based on size, ripeness, quality, and defects. Understand the importance of adhering to industry standards.

- Packing and Packaging Procedures: Master the different packing methods used for various fruits, including techniques for efficient packing, minimizing waste, and ensuring product preservation. Understand different packaging materials and their applications.

- Safety and Hygiene Practices: Review workplace safety procedures, including proper use of equipment, sanitation guidelines, and personal protective equipment (PPE). Understand the importance of maintaining a clean and safe working environment to meet food safety standards.

- Efficiency and Productivity: Learn about methods for maximizing efficiency in the packing process, including workflow optimization, time management strategies, and teamwork techniques.

- Inventory Management and Stock Control: Understand basic inventory management principles, such as tracking stock levels, managing orders, and ensuring adequate supply to meet demand.

- Troubleshooting and Problem Solving: Develop skills in identifying and resolving issues that may arise during the fruit packing process, such as equipment malfunctions, product defects, or logistical challenges.

- Teamwork and Communication: Understand the importance of effective communication and collaboration within a team environment. This includes following instructions, reporting problems, and contributing positively to overall productivity.

Next Steps

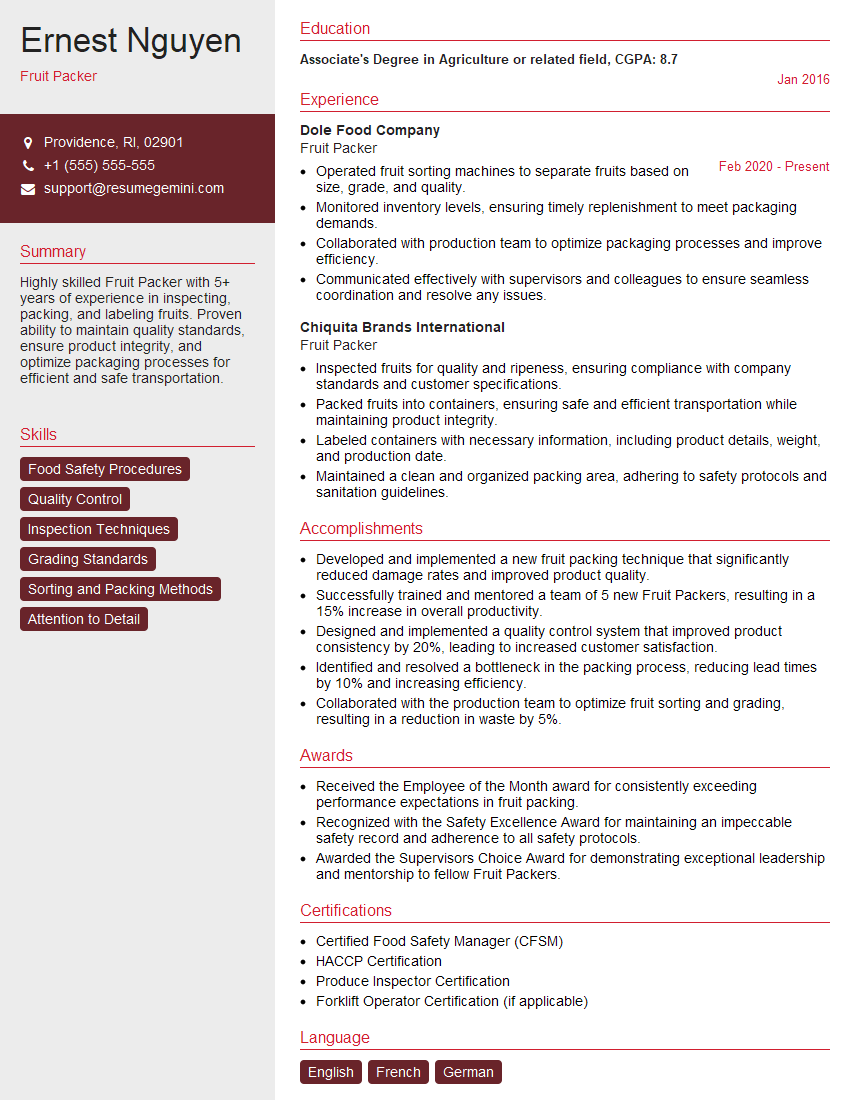

Mastering fruit packing skills opens doors to a rewarding career with opportunities for growth and advancement within the agricultural and food processing industries. A strong resume is crucial for showcasing your abilities and securing your ideal role. To increase your chances of getting noticed by employers, create an ATS-friendly resume that highlights your relevant skills and experience. We strongly recommend using ResumeGemini to build a professional and effective resume. ResumeGemini provides tools and examples to help you craft a compelling resume tailored to the Fruit Packing industry, ensuring your qualifications shine. Examples of resumes tailored to Fruit Packing are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good