Preparation is the key to success in any interview. In this post, we’ll explore crucial Fruit Thinning Techniques interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Fruit Thinning Techniques Interview

Q 1. Explain the importance of fruit thinning in optimizing fruit yield and quality.

Fruit thinning, the practice of removing excess immature fruits from a tree, is crucial for optimizing both yield and quality. Imagine a tree overburdened with fruit – each fruit receives less nutrients, resulting in smaller, lower-quality produce. Thinning ensures that the remaining fruits receive adequate resources, leading to larger, more flavorful, and marketable fruits. This improves the overall profitability for the grower, leading to higher returns and less waste. In essence, it’s a strategic investment in quality over quantity.

Q 2. Describe the different methods of fruit thinning (hand thinning, chemical thinning, etc.).

Several methods exist for fruit thinning, each with its pros and cons.

- Hand Thinning: This labor-intensive method involves physically removing excess fruits by hand. It allows for precise control and is best for high-value crops where quality is paramount. Think of delicate fruits like peaches or premium apples.

- Chemical Thinning: This method uses plant growth regulators, such as naphthalene acetic acid (NAA) or ethephon, to reduce fruit set. It’s cost-effective for large orchards but requires careful timing and application to avoid harming the tree. The specific chemical and concentration depend heavily on the species and the desired thinning intensity.

- Mechanical Thinning: Less common than the other methods, this involves using machinery to shake branches, causing some fruits to drop. It’s suitable for robust trees and large-scale operations, but it can be less precise than hand thinning and may cause damage to the tree if not used carefully.

Q 3. What are the key factors to consider when choosing a fruit thinning method?

Selecting the right fruit thinning method hinges on several factors:

- Crop type and value: High-value crops like premium cherries often justify the cost of hand thinning, while lower-value crops might benefit from chemical thinning.

- Orchard size and layout: Large orchards might favor chemical or mechanical thinning for efficiency, whereas smaller orchards may allow for hand thinning.

- Labor availability and cost: Hand thinning is labor-intensive and costly, making it unsuitable for situations with limited labor or high labor costs.

- Environmental conditions: Weather conditions influence the timing and effectiveness of chemical thinning. Rainfall, for example, can wash off chemical treatments.

- Tree age and vigor: Young, vigorous trees might require more aggressive thinning than older trees.

Q 4. How do you determine the optimal fruit thinning intensity for a specific orchard?

Determining optimal thinning intensity involves considering several factors: the tree’s age and vigor, the previous year’s crop load, the expected yield, and the desired fruit size. We often use a combination of visual assessment and experience. For example, we might aim for a specific fruit spacing on the branches, ensuring adequate sunlight and air circulation. Detailed yield prediction models, incorporating weather forecasts and historical data, are also increasingly used to optimize thinning decisions.

For instance, an experienced orchardist might aim for a specific number of fruits per cluster or per branch, adjusting the intensity based on the variety and tree condition. This is often calibrated with data from previous years to fine-tune the process for consistent results.

Q 5. Explain how fruit thinning affects fruit size, sugar content, and overall quality.

Fruit thinning profoundly impacts fruit size, sugar content, and overall quality. By reducing the competition for resources, thinning allows the remaining fruits to grow larger and achieve their full potential size. This larger size often translates to higher market value. Similarly, fewer fruits mean more resources are available for sugar accumulation, leading to a sweeter, more flavorful end product. The improved size, color, and flavor all contribute to a significant increase in overall fruit quality.

Q 6. Describe the common challenges associated with fruit thinning and how to address them.

Several challenges accompany fruit thinning. Inconsistent thinning can lead to uneven fruit sizes and reduced yield. This can be mitigated by employing proper training techniques for workers or by using appropriate technology in chemical or mechanical thinning. Cost can be substantial, particularly with hand thinning. Careful planning and consideration of the cost-benefit ratio are crucial. Timing is critical, especially for chemical thinning, where incorrect timing can negatively affect fruit set or even damage the tree. Precise application based on temperature and growth stage is critical to success.

Q 7. How do environmental factors (temperature, rainfall) influence fruit thinning decisions?

Environmental factors significantly impact fruit thinning decisions. High temperatures during the bloom period can affect fruit set, potentially necessitating more aggressive thinning. Conversely, cooler temperatures may reduce fruit set, requiring less thinning. Rainfall can affect the effectiveness of chemical thinning, as rain can wash away the applied chemicals. Therefore, weather forecasts and historical data are critical for making informed decisions about timing and method selection. For example, a rainy period might necessitate delaying chemical thinning or opting for hand thinning instead.

Q 8. What are the economic implications of improper fruit thinning?

Improper fruit thinning has significant economic consequences for fruit growers. Failing to thin adequately results in smaller, lower-quality fruit, reducing overall yield and market value. Overcrowded branches lead to smaller fruit size, poor color development, and increased susceptibility to diseases. This translates directly to lower prices at the market and potentially decreased profit margins. Imagine a tree laden with small, poorly colored apples – they simply won’t fetch the same price as large, vibrant, and evenly sized apples. Conversely, over-thinning can lead to reduced overall yield, impacting profitability as well. The ideal thinning strategy balances yield and quality to maximize economic returns.

For example, a grower failing to thin their apple orchard might experience a 30% reduction in average fruit size, translating into a 20% decrease in total income, even if the number of fruits is high. The cost of harvesting and packaging the inferior fruit also outweighs the potential profit.

Q 9. Explain the relationship between fruit thinning and pest and disease management.

Fruit thinning plays a crucial role in pest and disease management. Proper thinning improves air circulation and light penetration within the canopy, reducing humidity and creating a less favorable environment for fungal diseases like apple scab or powdery mildew. These diseases thrive in damp, shaded conditions, and thinning directly addresses this problem. Furthermore, thinning makes it easier to identify and treat pest infestations. When fruit is spaced adequately, it’s much easier to spot signs of insect damage or disease, enabling timely intervention and preventing widespread infection. Think of it like weeding a garden – if your plants are overcrowded, it’s difficult to spot any weeds that might be harming them.

For instance, in a peach orchard, thinning reduces the incidence of brown rot by improving air circulation around fruits. This reduced humidity creates an environment less suitable for fungal spore germination and growth. Similarly, proper thinning allows better visibility for monitoring pests like codling moths, enabling effective pesticide application only when necessary, reducing pesticide use and its environmental impact.

Q 10. How do you monitor the effectiveness of your fruit thinning strategy?

Monitoring the effectiveness of a fruit thinning strategy involves a multi-pronged approach. First, I visually assess the canopy for even fruit distribution and adequate spacing. Fruit size is measured using calipers at various points within the tree. I also record yield data, focusing not just on the total number of fruits but also the size distribution. Statistical analysis of this data helps determine the effectiveness of the thinning strategy, allowing for adjustments in subsequent years.

For instance, I might track the average fruit weight across different thinning treatments. If one area was thinned more aggressively and the average fruit weight is significantly larger in that area, it indicates a successful thinning strategy. Conversely, if fruit size is consistently small despite thinning, it may suggest a need to refine the technique or address other factors, such as nutrient deficiencies.

Q 11. Describe your experience with hand thinning techniques.

Hand thinning is a labor-intensive but highly precise method that gives growers excellent control. I’ve extensive experience in hand thinning various fruit types, including apples, peaches, and cherries. The process involves selectively removing excess fruit by hand, ensuring adequate spacing between the remaining fruits. This requires trained personnel who understand the importance of spacing and fruit selection. While time-consuming, it allows for careful consideration of fruit quality and position within the tree.

A critical aspect is training personnel to identify and remove undesirable fruit like smaller, damaged, or poorly positioned fruits, while leaving behind well-formed, healthy fruits. I’ve personally found that a well-trained team can significantly improve fruit quality and yield. In my experience, proper training reduces the risks associated with unintentional damage to the tree during the process.

Q 12. What are the benefits and limitations of chemical thinning?

Chemical thinning offers a faster and potentially less labor-intensive alternative to hand thinning, particularly for large orchards. The benefits include reduced labor costs and the ability to treat large areas efficiently. However, it’s crucial to select the appropriate chemical and application timing for optimal results and to minimize potential risks to the tree. Over-application can cause severe fruit drop and harm the tree’s health.

Limitations include the potential for uneven thinning, requiring close monitoring, and the environmental impact of using chemicals. There’s also a risk of fruit injury and the possibility of affecting beneficial insects. Effective chemical thinning needs a precise understanding of chemical efficacy, application techniques, and environmental factors. For example, temperature and humidity can significantly impact the effectiveness of chemical thinning agents. Always follow label instructions carefully.

Q 13. How do you calculate the cost-effectiveness of different fruit thinning methods?

Calculating the cost-effectiveness of different fruit thinning methods requires careful consideration of several factors. These include the cost of labor (for hand thinning), the cost of chemicals and application (for chemical thinning), the increased yield and improved fruit quality obtained from proper thinning, and the potential losses due to insufficient or excessive thinning. A cost-benefit analysis helps compare methods. This involves comparing the net profit generated by each method, accounting for all costs and revenue.

For example, one might calculate the cost per labor hour for hand thinning versus the cost per acre for chemical thinning. Then, they can factor in projected yield increases and changes in fruit prices attributable to improved fruit size and quality. A thorough analysis allows growers to make informed decisions based on their specific orchard conditions and market expectations.

Q 14. What safety precautions do you take during fruit thinning operations?

Safety is paramount during fruit thinning operations. For hand thinning, proper training on safe climbing techniques and the use of personal protective equipment (PPE), such as safety harnesses and gloves, is crucial. For chemical thinning, workers must wear appropriate PPE, including respirators, protective clothing, and eyewear. Adherence to label instructions and careful handling of chemicals are vital to prevent exposure. Furthermore, ensuring adequate ventilation during chemical applications is essential. Pre-application training on the correct procedures and potential hazards is also essential. Regular safety checks and risk assessments should be a routine part of the thinning operations.

Specific examples include conducting daily safety briefings before commencing work, ensuring that all personnel are aware of emergency procedures and communication channels, and having first aid facilities readily available on site.

Q 15. How do you manage labor resources for efficient fruit thinning?

Efficient fruit thinning relies heavily on effective labor management. It’s not just about the number of workers, but about their skill, training, and organization.

- Strategic Planning: Before the thinning season, I carefully estimate the labor needed based on the orchard size, tree density, and the expected fruit set. This often involves analyzing data from previous years and considering the specific variety.

- Team Structure: I organize teams with a mix of experienced and less experienced workers. Experienced workers can train and supervise the newer members, ensuring consistent thinning quality across the orchard. This also boosts efficiency by reducing errors and retraining time.

- Incentive Programs: Offering performance-based incentives, such as piece-rate payments or bonuses for meeting quality targets, can significantly improve worker motivation and productivity. This ensures careful thinning rather than rushing through the job.

- Technology Integration: Where feasible, I incorporate tools that can enhance efficiency, such as pruning shears with ergonomic designs that reduce worker fatigue, or even robotic systems for larger operations. The goal is to streamline the process and minimize worker strain.

- Regular Monitoring and Feedback: I regularly monitor the team’s progress and provide feedback to address any issues, ensuring a consistent level of quality across the entire orchard. This may involve adjusting team size or addressing specific skill gaps.

For example, in a 10-acre apple orchard, I’d divide the work into manageable sections, assigning experienced leads to each team to ensure quality control and even distribution of workload. This approach ensures both speed and precision in thinning.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of fruit load management.

Fruit load management is the practice of controlling the number of fruits a tree produces to optimize fruit size, quality, and overall yield. It’s a balancing act – too many fruits lead to small, low-quality fruit, while too few fruits result in reduced yield.

Effective fruit load management begins with accurate assessment of the tree’s potential, considering factors like tree vigor, age, and previous yields. We aim for the ‘optimum’ fruit load – the number of fruits that will result in the largest, highest-quality fruit while maintaining good tree health. This involves several key elements:

- Pre-thinning Assessment: Before thinning, a careful assessment of fruit set and distribution is crucial. This involves examining individual branches and determining areas requiring thinning.

- Thinning Strategy: Choosing the right thinning method – hand thinning, chemical thinning, or a combination – depends on factors such as tree size, fruit type, and available resources.

- Post-thinning Evaluation: After thinning, it’s important to evaluate the results, ensuring the target fruit load has been achieved. This allows for adjustments in subsequent years based on the outcome.

Think of it like baking a cake – too much batter results in a flat, dense cake, too little and it’s insufficient. Similarly, the right fruit load ensures the tree’s resources are distributed optimally, resulting in high-quality produce.

Q 17. How do you identify and handle fruit with defects during thinning?

Identifying and handling defective fruits during thinning is crucial for maintaining overall fruit quality. This involves careful inspection of each fruit during the thinning process.

- Visual Inspection: I train my team to visually identify fruits exhibiting defects such as bruises, diseases (e.g., scab, brown rot), insect damage, or malformations. This often requires knowledge of the specific fruit variety and common problems in the region.

- Removal Process: Defective fruits are carefully removed during thinning to prevent the spread of diseases and improve the overall quality of the remaining fruits. It’s essential to avoid damaging adjacent fruits during the removal process.

- Disease Management: The removal of infected fruits is a critical component of disease management. Removing diseased fruits helps in preventing the spread of pathogens throughout the orchard, thus protecting the remaining healthy fruits.

- Waste Management: Proper disposal of defective fruits is crucial. It may involve composting or burying infected material to avoid contamination.

For instance, when thinning apples, we carefully remove any fruits with blemishes or signs of apple scab, ensuring that only healthy fruits remain on the tree to maximize fruit quality and minimize disease risk. This requires a sharp eye and experience in recognizing defects at an early stage.

Q 18. What are the signs of over-thinning or under-thinning?

Recognizing the signs of over-thinning or under-thinning is vital for successful fruit load management. Both scenarios have significant negative consequences on fruit yield and quality.

- Over-thinning: This results in reduced yield, despite potentially larger fruit sizes. Signs include excessively large gaps between fruits on the tree, bare or sparsely populated branches, and an overall reduction in the total number of fruits harvested. This often leads to poor economic returns.

- Under-thinning: This results in smaller fruit size, reduced fruit quality, and potentially compromised tree health due to the strain of carrying an excessive number of fruits. Signs include a very high density of fruits on the tree, small fruit size, and potentially a higher incidence of fruit drop due to competition for resources.

Imagine a tree with excessively large apples that were once too numerous. That’s over-thinning. Now, imagine a tree where the apples are tiny and numerous—that’s under-thinning. The goal is to find the balance for optimal yield and fruit quality.

Q 19. How do you adapt your fruit thinning strategy to different fruit varieties?

Adapting fruit thinning strategies to different fruit varieties is essential due to variations in tree growth habits, fruit size, and susceptibility to diseases. Each variety has unique requirements for optimal fruit load.

- Variety-Specific Requirements: Some varieties naturally produce a heavier fruit set than others. Knowing these differences is key to deciding how aggressively to thin. For example, some apple varieties may require more aggressive thinning than others to achieve the desired fruit size.

- Fruit Size and Spacing: The target fruit size for each variety influences the thinning intensity. Larger-fruited varieties generally require more aggressive thinning to ensure sufficient spacing and resource allocation per fruit.

- Branch Structure: The structure of the tree and the distribution of the fruiting spurs influences thinning practices. Trees with densely packed fruiting spurs will often require more meticulous thinning than those with more dispersed fruiting.

- Disease Susceptibility: Varieties prone to certain diseases may require more careful removal of diseased or damaged fruits to minimize the spread of pathogens and maintain overall fruit quality.

For example, when thinning peaches, the goal is often to achieve a smaller, more uniform fruit size than might be targeted for a larger-fruited apple variety. These different approaches reflect the inherent differences in their fruit set, growth habit, and market demands.

Q 20. Describe your experience with using thinning chemicals (if any).

Chemical thinning is a tool used in conjunction with hand thinning, particularly in large-scale operations where hand thinning alone is impractical. I’ve had experience using various chemical thinners, always following label instructions and local regulations meticulously.

The most common chemicals are naphthaleneacetic acid (NAA) and ethephon. The application timing is crucial and depends on the variety and the fruit set. We typically apply these as a foliar spray during a specific growth stage. Factors such as temperature, humidity, and the concentration of the chemical solution are carefully monitored to optimize effectiveness and minimize risk to the trees.

I carefully record the type of chemical used, the application date, the concentration, and the environmental conditions during the application. This meticulous record-keeping helps in evaluating the effectiveness of chemical thinning and refining the strategy for subsequent years.

Q 21. What are the potential risks associated with chemical thinning?

Chemical thinning, while effective, does carry potential risks if not properly managed. It’s crucial to be aware of these risks and implement appropriate mitigation strategies.

- Phytotoxicity: Over-application or application under unfavorable conditions can lead to damage to the tree (phytotoxicity), resulting in leaf scorch or even tree death. This is why careful adherence to label instructions is paramount.

- Environmental Impact: Chemical thinners can affect non-target organisms, such as beneficial insects. Careful selection of chemicals and responsible application techniques help minimize these effects.

- Residue Concerns: Chemical residues on the fruit must be within acceptable limits for human consumption. This necessitates proper timing of application and compliance with pre-harvest intervals specified on the chemical label.

- Uneven Thinning: Inconsistent application can lead to uneven thinning patterns, resulting in an undesirable fruit distribution on the tree. Therefore, maintaining a uniform spray application is crucial.

These risks can be minimized by accurate assessment of fruit load, careful calibration of application equipment, adherence to label instructions, and monitoring the effects of the application. This proactive approach ensures safe and effective chemical thinning.

Q 22. How do you ensure consistent fruit thinning across a large orchard?

Ensuring consistent fruit thinning across a large orchard requires a multi-pronged approach focusing on planning, training, and monitoring. It’s like painting a large canvas – you need a plan, the right tools, and regular checks to ensure even coverage.

Standardized Protocols: We develop detailed protocols outlining thinning targets (e.g., fruits per cluster, fruits per shoot) based on variety, tree vigor, and yield goals. These protocols are documented and distributed to all teams.

Zoning and Task Allocation: The orchard is divided into manageable zones, each assigned to a team with a designated supervisor. This ensures focused effort and allows for easier quality control.

Regular Monitoring and Adjustments: Supervisors conduct frequent checks throughout the thinning process. They use checklists and sampling techniques to verify adherence to protocols. Adjustments to thinning intensity might be made based on the observed progress in different zones.

Technology Integration: We utilize GPS-enabled mapping tools to track progress and identify areas requiring additional attention. This ensures complete coverage and reduces the risk of overlooking sections of the orchard.

Q 23. How do you train and supervise workers during fruit thinning?

Training and supervision are crucial for successful fruit thinning. We invest heavily in both aspects to ensure quality and consistency.

Pre-Season Training: Before the thinning season begins, we conduct comprehensive training sessions covering thinning techniques (hand thinning, chemical thinning), fruit identification, and quality standards. We use practical demonstrations and hands-on exercises.

On-the-Job Supervision: Experienced supervisors are assigned to teams to provide real-time guidance and feedback. They ensure workers understand and apply the established thinning protocols, paying close attention to detail and correcting any inconsistencies.

Performance Evaluation: We regularly evaluate the work of thinning crews through random sampling and quality checks. This feedback loop helps improve techniques and identify areas needing further training.

Incentive Programs: We often employ incentive programs to motivate workers and reward high-quality work. This promotes better performance and ensures higher levels of engagement.

Q 24. What is your experience with using technology (e.g., automated thinning systems) in fruit thinning?

My experience with automated thinning systems is limited, but I’m actively exploring their potential. While existing technologies are not fully mature for all fruit types and orchard setups, I see promising applications for the future.

Robotics: Robotic systems equipped with advanced sensors and AI can potentially automate parts of the thinning process, leading to increased efficiency and consistency.

Sensor-Based Systems: Technologies that assess fruit size and density could inform decision-making about thinning intensity and help optimize resource allocation.

Challenges: Current limitations include high initial costs, the need for specific orchard layouts, and potential difficulties in adapting to variable fruit characteristics and weather conditions.

Q 25. How do you measure the success of your fruit thinning program?

Measuring the success of a fruit thinning program is multifaceted and involves quantitative and qualitative assessments.

Yield: Increased yield per tree, compared to previous years or control plots, is a primary measure of success. We track this data meticulously.

Fruit Size and Quality: We measure average fruit size, weight, and quality parameters (e.g., sugar content, firmness) to evaluate the impact of thinning on fruit development.

Uniformity: Consistent fruit size and maturity across the orchard indicates successful thinning. We use statistical analysis to assess uniformity.

Labor Efficiency: We track the labor hours required for thinning to gauge efficiency improvements and identify areas for optimization.

Economic Return: Ultimately, the success is evaluated by analyzing the economic return on investment. This includes considering increased yields, improved fruit quality, and reduced labor costs.

Q 26. Describe a time you had to troubleshoot a problem related to fruit thinning.

In one instance, we experienced unexpected fruit drop in a specific block of apple trees despite appropriate thinning. We initially suspected improper thinning, but investigation revealed a hidden pest infestation that was weakening the fruit stems.

Problem Identification: We conducted a thorough inspection of the affected trees and discovered evidence of codling moth infestation.

Solution Implementation: We immediately implemented integrated pest management strategies including pheromone traps and targeted insecticide application (following label recommendations).

Monitoring and Evaluation: We closely monitored the infestation levels and adjusted our pest management accordingly. We also improved our pre-thinning orchard inspection protocols to detect such issues early.

Q 27. What are your strategies for dealing with unexpected weather conditions during fruit thinning?

Unexpected weather conditions can significantly impact fruit thinning operations. We employ flexible strategies to mitigate these challenges.

Weather Monitoring: We closely monitor weather forecasts and adjust our schedules accordingly. If extreme heat, rain, or wind is predicted, we may postpone thinning activities to protect both the workers and the trees.

Contingency Planning: We develop contingency plans that include alternative work schedules or task prioritization based on weather conditions.

Protective Measures: We provide workers with appropriate protective gear (e.g., rain gear, hats, sunscreen) to ensure their safety and comfort during adverse weather.

Q 28. How do you stay updated on the latest best practices in fruit thinning?

Staying current with the latest best practices in fruit thinning requires continuous learning and engagement with the industry.

Industry Conferences and Workshops: I actively participate in conferences and workshops related to horticulture and fruit production, where experts share the latest research and best practices.

Peer Networking: I maintain a strong network of colleagues and industry professionals, exchanging knowledge and insights through discussions and collaborations.

Scientific Literature: I regularly review scientific journals and publications on fruit thinning techniques, pest management, and orchard management practices.

Government and University Resources: I use government resources and university extension programs to stay abreast of the latest research findings and recommendations.

Key Topics to Learn for Fruit Thinning Techniques Interview

- Understanding Fruit Development Stages: Knowing the optimal time for thinning based on fruit size, color, and overall plant health is crucial. This includes recognizing signs of stress or disease that might influence thinning strategies.

- Thinning Methods: Mastering various techniques, including hand thinning, mechanical thinning, and chemical thinning, is essential. Understand the pros and cons of each method and their suitability for different fruit types and growing conditions.

- Yield Optimization and Quality Improvement: Learn how proper fruit thinning directly impacts yield, fruit size, sugar content, and overall fruit quality. Be prepared to discuss the economic implications of different thinning strategies.

- Crop Load Management: Understand the concept of crop load and its impact on tree vigor and long-term productivity. This includes knowing how to assess crop load accurately and adjust thinning accordingly.

- Environmental Factors and Their Influence: Discuss the role of weather patterns, soil conditions, and pest/disease pressure on fruit thinning decisions. Be ready to explain how these factors can affect thinning strategies and outcomes.

- Post-Thinning Care and Management: Understand the necessary steps after thinning, such as proper disposal of removed fruit, nutrient management to support remaining fruit, and monitoring for potential problems.

- Safety Procedures and Regulations: Demonstrate awareness of safety protocols associated with various thinning methods, including safe handling of tools and chemicals, and adherence to relevant industry regulations.

Next Steps

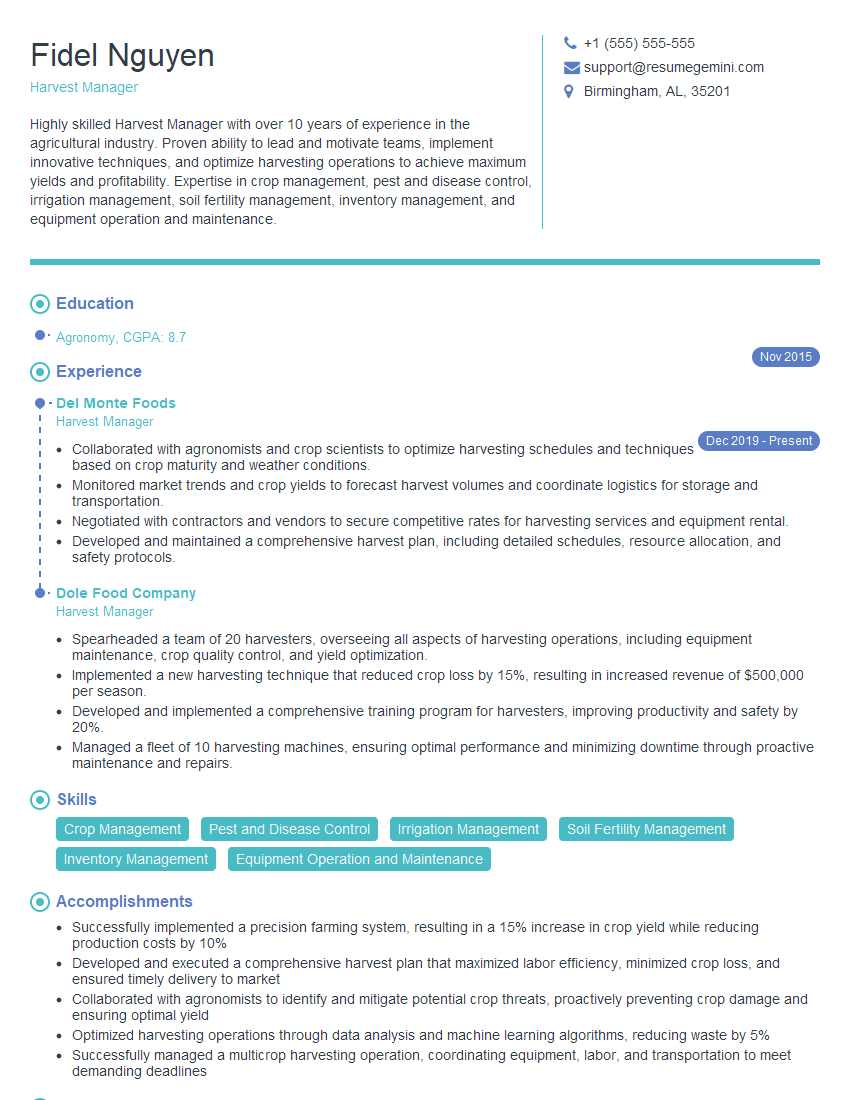

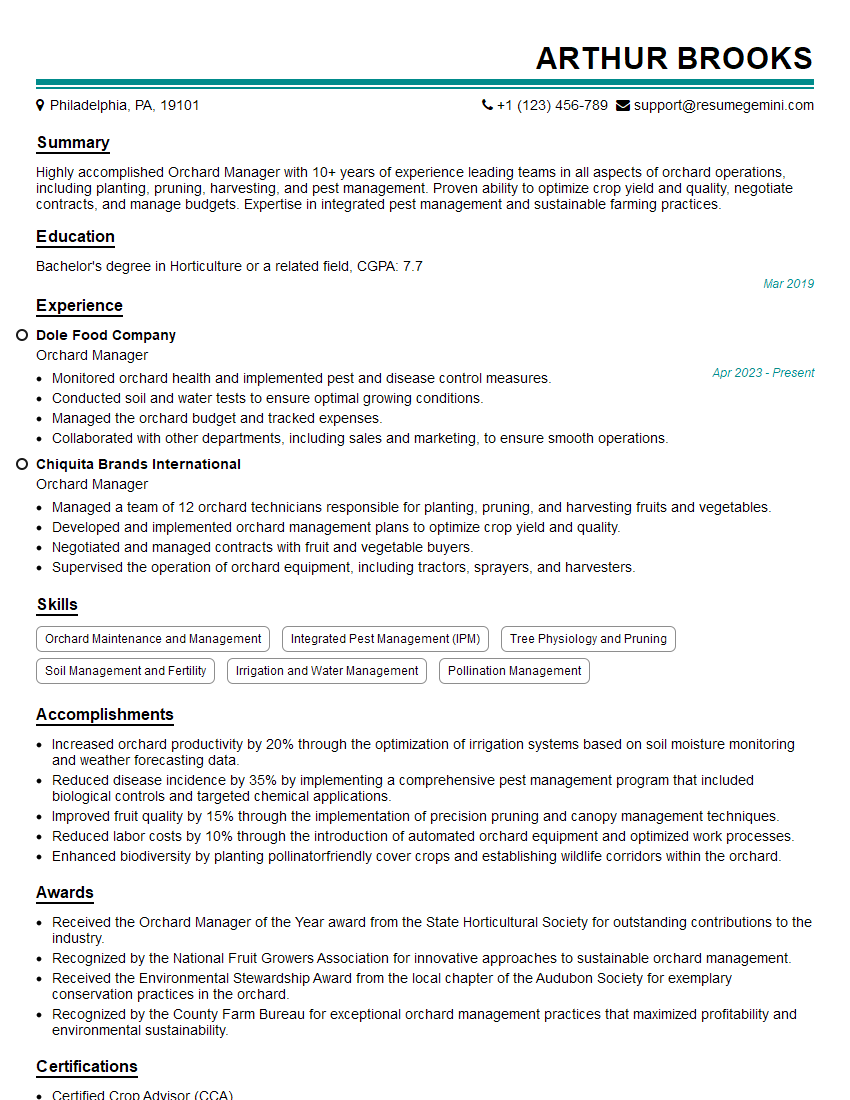

Mastering Fruit Thinning Techniques is vital for career advancement in agriculture and horticulture. A strong understanding of these techniques demonstrates your commitment to quality and efficiency, opening doors to more senior roles and higher earning potential. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume. Examples of resumes tailored to Fruit Thinning Techniques are provided to help you craft a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good