Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Fur Tailoring interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Fur Tailoring Interview

Q 1. What types of fur are you most experienced in working with?

My expertise spans a wide range of furs, but I’m particularly experienced with luxury furs like mink, sable, fox, and chinchilla. I also have extensive experience working with more readily available furs such as rabbit, shearling, and raccoon. Each fur has unique properties – mink, for instance, is known for its lustrous sheen and delicate texture, requiring a gentle approach, while fox fur’s density and thickness necessitates different handling and stitching techniques. My experience allows me to adapt my methods to the specific needs of each fur type.

- Mink: Requires precise stitching and careful handling due to its delicate nature.

- Sable: Demands meticulous attention to detail because of its rich color and luxurious feel.

- Fox: Needs robust stitching and careful consideration of the fur’s thickness.

- Rabbit: A more versatile fur, it can be handled in a variety of ways, depending on the desired outcome.

Q 2. Describe your experience with fur pattern making.

Fur pattern making is a highly specialized skill that combines traditional pattern-making techniques with a deep understanding of fur’s unique characteristics. Unlike fabric, fur has a distinct nap (the direction of hair growth) and a three-dimensional structure. My approach involves creating a base pattern, usually on a muslin mock-up, then meticulously adjusting it to account for the fur’s drape and pile. I use specialized tools to mark the grain and nap direction precisely on the pelts before cutting. I often need to grade patterns, particularly when working with large pelts like those used in coats, making sure the pattern pieces are aligned correctly to minimize waste and maximize the fur’s beauty. One example of a unique consideration is that patterns for garments featuring fur panels might need to be modified to seamlessly integrate the pelts, potentially creating an illusion of continuous fur across multiple seams. This often requires careful planning and manipulation of the fur’s grain direction.

Q 3. Explain your process for repairing damaged fur garments.

Repairing damaged fur garments requires patience, precision, and a keen eye for detail. My process begins with a thorough assessment of the damage. This includes identifying the type of damage (tear, burn, missing fur, etc.) and evaluating its extent. For minor tears, I carefully stitch the fur back together using specialized needles and thread, matching the fur’s nap to ensure an invisible repair. More extensive damage may require patching or replacing sections of fur, using pelts as close as possible in color and texture to the original garment. I often use techniques like fur grafting, which involves carefully transplanting individual hairs from a donor pelt to the damaged area to create a seamless blend. For example, a small burn mark might be meticulously repaired by carefully blending in hairs from a similar donor pelt. This process necessitates not only sewing expertise but also a strong understanding of the fur’s structure and how to create a natural-looking transition.

Q 4. How do you select the appropriate stitching method for different fur types?

The choice of stitching method is crucial for achieving a durable and aesthetically pleasing result. Different fur types have varying thicknesses and densities, dictating the appropriate needle size and stitch type. For delicate furs like mink, I use a very fine needle and a small, almost invisible stitch, often a slipstitch to avoid puncturing the pelt and damaging the fur. For thicker furs like fox, a stronger stitch is necessary, like a backstitch, to ensure the seams can withstand the wear and tear of daily use. In essence, the balance lies between achieving sufficient strength to hold the fur pieces together while minimizing the visible impact of the stitching on the finished piece. It’s a delicate dance between the functional integrity and the aesthetic beauty of the garment.

Q 5. What are the common challenges faced in fur cleaning and how do you address them?

Fur cleaning presents unique challenges due to the delicate nature of the fur fibers. Common issues include matting, oil staining, and insect infestation. Matting can be addressed through careful brushing and combing, using specialized tools to gently separate the tangled fur. Oil stains require careful cleaning with appropriate solvents, always testing on a hidden area first. Insect infestations necessitate professional cleaning using specialized treatments that target the specific pest while protecting the fur’s integrity. A critical aspect is understanding the fur type, as certain furs are more sensitive to certain cleaning methods than others. I always pre-test any cleaning solution on an inconspicuous area of the garment to avoid damaging the fur.

Q 6. Describe your knowledge of different fur stretching techniques.

Fur stretching techniques are essential for shaping and restoring the form of fur garments. They are often necessary after cleaning or to reshape garments that have been compressed or distorted. I utilize various techniques, including the use of specialized stretching frames and boards. The process often involves carefully pinning the fur to the frame, using dampening techniques to ensure the fur remains pliable, and gradually stretching it to its desired dimensions over several days. For example, a mink stole that has lost its shape after being stored might be stretched gently using a frame, pinned in carefully measured increments to achieve a uniform, natural drape. The skill involves recognizing the limits of the fur’s elasticity and understanding how much stretching it can withstand without damage.

Q 7. How do you ensure the quality of fur garments throughout the manufacturing process?

Maintaining quality throughout the manufacturing process requires rigorous attention to detail at every stage. This begins with the selection of high-quality pelts, ensuring they are free from damage and imperfections. Each stage of the process, from pattern making and cutting to sewing and finishing, is carefully monitored to ensure adherence to the highest standards. Regular quality checks are implemented, and any defects are promptly identified and rectified. Once a garment is completed, a final inspection is conducted to ensure it meets the required standards of quality, aesthetics, and durability. This commitment to quality control guarantees that the finished product is of the highest caliber, reflecting the value and artistry inherent in fur tailoring.

Q 8. What are the key considerations when designing a fur garment?

Designing a fur garment requires meticulous consideration of several factors to achieve both aesthetic appeal and durability. It’s a balancing act between the inherent beauty of the fur and the functionality of the garment.

- Fur Type and Quality: The choice of fur—be it mink, fox, sable, or another—dictates the garment’s drape, texture, and overall look. Higher-quality furs with denser underfur and longer guard hairs offer superior warmth and luxury. For example, a luxurious sable coat will require a different design approach compared to a more casual fox vest.

- Pattern Design and Cutting: The pattern must be carefully drafted to minimize waste and maximize the use of the pelts. Fur has a natural direction (the lie), and the pattern must account for this to ensure the fur flows smoothly and looks natural. Incorrect pattern placement can lead to uneven texture and unsightly breaks in the fur flow.

- Construction Techniques: Specific stitching techniques are crucial for fur. We often use specialized fur sewing machines and hand-stitching to avoid damaging the delicate fur fibers. Incorrect stitching can cause damage or loss of fur. The construction must also account for the weight and bulk of the fur.

- Functionality and Style: The intended use and overall aesthetic of the garment must be carefully considered. A full-length coat demands a different construction and design than a small fur stole. The style must complement the fur type and its natural characteristics.

- Sustainability and Ethics: Increasingly, clients are mindful of the ethical and sustainable sourcing of furs. We need to consider the origin of the furs and whether they come from responsible and sustainable practices.

Q 9. Explain your experience with fur grading and sorting.

Fur grading and sorting is a critical initial step in fur garment production. It involves meticulously examining and categorizing pelts based on several key characteristics. My experience involves years of hands-on work with various fur types.

- Grading: This assesses the overall quality of the pelt, considering factors such as fur density, length, luster, and uniformity of color. Pelts are ranked according to established grading systems, and any imperfections like scars or damage are carefully noted. I’ve worked with grading systems for various fur types, each with its unique criteria.

- Sorting: After grading, pelts are sorted into groups of similar quality. This ensures consistency in the final garment. Matching pelts in terms of color, luster, and size is crucial for a cohesive and visually appealing result. For example, in a mink coat, we carefully sort to minimize color variations and create a smooth, uniform appearance.

- Practical Application: Precise grading and sorting are essential to creating high-quality garments. Without it, the final product might exhibit inconsistencies in color, texture, or density which severely diminishes the value and aesthetic appeal of the piece. Imagine a mink coat with mismatched pelts – it would lack the luxurious uniformity expected of such a garment.

Q 10. How do you identify different fur types and their characteristics?

Identifying fur types relies on a combination of visual inspection, tactile examination, and knowledge of characteristic features. Years of experience have honed my ability to distinguish between various furs.

- Visual Inspection: This involves examining the fur’s color, luster, guard hair length, and underfur density. For instance, mink typically has a short, dense underfur and lustrous guard hairs, while fox fur has longer, more prominent guard hairs.

- Tactile Examination: Feeling the fur’s texture—its softness, suppleness, and overall hand—provides valuable information. The texture can significantly differ between species. Sable, for example, has an incredibly soft and luxurious feel, markedly different from the coarser texture of a coyote.

- Characteristic Features: Each fur type possesses unique characteristics. For example, the characteristic ‘guard hair’ and ‘underfur’ ratio is a key identifier. Knowing these distinct features and comparing them to samples and reference materials is crucial for accurate identification. Certain furs have specific markings or patterns that are helpful identifiers.

- Microscopic Examination: In some cases, microscopic examination of the fur fibers can be used to confirm identification. This is especially helpful when dealing with processed or dyed furs.

Q 11. What are the different methods of fur finishing and their applications?

Fur finishing encompasses various techniques that enhance the fur’s appearance, feel, and durability. The choice of technique depends on the fur type and the desired effect.

- Shearing: This process involves trimming the guard hairs to create a uniform length and texture. It’s frequently used to create a more even, plush look. For example, shearing might be used to create a smooth, velvety finish on a mink coat.

- Plucking: This involves selectively removing guard hairs to create a lighter, more open texture. It’s often used to achieve a specific design element or to enhance the visibility of the underfur.

- Dyeing: Fur dyeing is a common method to alter the fur’s color, creating a wider array of options for designers and clients. The dye process needs to be carefully controlled to avoid damaging the fur.

- Glazing: This involves applying a special finish to enhance the fur’s luster and shine, giving it a more polished look. It is frequently used on dark furs.

- Leathering: This method involves treating the leather side of the pelt to improve its flexibility and durability. This is crucial for garments that require shaping and flexibility.

Q 12. Describe your experience with working with different fur dyeing techniques.

My experience encompasses a wide range of fur dyeing techniques, each requiring precise control and expertise. Incorrect dyeing can ruin the fur.

- Natural Dyes: These dyes offer subtle color changes and are environmentally friendly, although the color range is more limited. I’ve worked with natural dyes derived from plants and minerals, achieving beautiful, muted tones.

- Synthetic Dyes: Synthetic dyes allow for a broader range of colors and often provide more vibrant results. However, careful control of the dyeing process is crucial to avoid damaging the fur fibres.

- Dip Dyeing: This involves immersing the pelts entirely into the dye bath, achieving a consistent color throughout. This is common for even coloring.

- Brush Dyeing: This technique allows for more intricate designs and color variations. It’s often used to create highlights or ombré effects, requiring a high level of skill and precision.

- Color Matching: A crucial aspect of my work involves color matching to client specifications or to achieve a consistent look throughout a garment, especially important in creating pieces from multiple pelts.

Q 13. How do you handle delicate furs during the alteration process?

Handling delicate furs during alterations requires utmost care and precision. The goal is to modify the garment without compromising the integrity or appearance of the fur.

- Careful Assessment: Before starting any alteration, a thorough assessment is crucial to determine the best approach and potential challenges. Knowing the type of fur and its characteristics is key to avoiding damage.

- Specialized Tools: Specialized tools such as fine needles, sharp shears, and specialized fur-sewing machines are crucial. Using blunt instruments can easily damage delicate fur fibers.

- Gentle Handling: The fur should be handled gently and with minimum stress to prevent damage or breakage of fibers. Avoid harsh pulling or stretching, and support the fur as you work.

- Test Patches: Before performing alterations on the main garment, I often test on a small, inconspicuous area to ensure compatibility of the fur with the chosen alteration techniques.

- Stitching Techniques: Specialized stitching techniques minimize the risk of damaging the fur fibers. Hand-stitching is often preferred for delicate areas to ensure maximum control and precision. Proper knotting is also important to prevent damage.

Q 14. What safety precautions do you follow while working with furs?

Safety is paramount when working with furs. Several precautions are routinely followed to ensure a safe working environment and to protect both myself and the material.

- Proper Ventilation: Many fur dyeing and finishing processes involve chemicals. Excellent ventilation is critical to minimize exposure to fumes and other airborne particles. We always work in well-ventilated areas.

- Protective Gear: Safety glasses, gloves, and respirators are worn when handling chemicals or sharp tools. This protects the skin and eyes from potential irritants and injuries.

- Sharp Tool Handling: Sharp tools like needles and shears are handled with care to avoid accidental cuts and injuries. Tools are kept sharp to avoid extra force which can damage the fur.

- Chemical Handling: Chemicals are handled and stored according to manufacturer’s instructions. Proper disposal procedures are followed to avoid environmental contamination.

- Ergonomics: Good posture and ergonomic practices are followed to avoid repetitive strain injuries. We take breaks to avoid fatigue which can lead to mistakes and accidents.

Q 15. How do you maintain and store fur garments to prevent damage?

Proper storage and maintenance are crucial for extending the lifespan of fur garments. Think of it like caring for a delicate antique – it requires attention to detail. Neglect can lead to irreversible damage, such as moth infestations or irreversible matting.

- Cleaning: Professional cleaning is recommended annually. At-home spot cleaning should only be done with specialized fur cleaners, avoiding harsh chemicals or excessive moisture.

- Storage: Store fur garments in a cool, dry, and well-ventilated area away from direct sunlight and heat sources. Use breathable garment bags made of cotton or muslin, never plastic, to allow for air circulation. Cedar chips or sachets are effective natural moth repellents. Properly stuffing the garment with acid-free tissue paper helps to maintain its shape.

- Handling: Always handle fur with care, avoiding harsh pulling or stretching. If a garment becomes wet, allow it to air dry naturally away from direct heat. Never use a hair dryer.

- Protection: During storage, it’s advisable to use protective covers to prevent dust and minor damage. For especially valuable pieces, climate-controlled storage might be necessary. Regular inspection for any signs of damage (holes, pests, or discoloration) is recommended.

For example, I once restored a vintage mink coat that had been improperly stored. It had developed moth damage and was significantly matted. Through meticulous cleaning, repair, and restyling, I was able to restore it to its former glory.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the ethical considerations involved in the fur industry?

The ethical considerations in the fur industry are multifaceted and complex. It’s a highly sensitive area, with strong opinions on both sides. The primary concern is animal welfare. Sustainable and humane practices are paramount.

- Animal Husbandry: The ethical sourcing of fur necessitates ensuring animals are raised in humane conditions, free from cruelty and unnecessary suffering. This includes factors such as appropriate living space, diet, and veterinary care.

- Trapping Practices: Trapping methods used to harvest wild furs must adhere to strict regulations and prioritize minimizing pain and suffering for the animals. Quick and humane killing methods are crucial.

- Transparency and Traceability: Ethical fur producers prioritize transparency throughout the supply chain. This enables consumers to trace the origin of the fur and verify that ethical practices were followed.

- Alternatives and Sustainability: The industry is exploring sustainable fur farming methods and is increasingly aware of the need for environmentally friendly practices to minimise the environmental impact of fur production. The use of recycled fur is also becoming more prominent.

I believe strongly in supporting fur farms and trappers who are committed to these standards, which ultimately leads to a more sustainable and ethical industry. As a tailor, selecting ethically sourced materials is a core part of my work.

Q 17. Describe your experience with using specialized fur-sewing machines.

My experience with specialized fur-sewing machines spans over 15 years. These machines aren’t your standard sewing machines; they require a delicate touch and specialized knowledge. They are designed to handle the unique challenges posed by fur, such as its thickness, texture, and delicate nature.

- Walking Foot Machines: I’m proficient with walking foot machines, which are essential for ensuring even stitching on thick fur. The dual feed mechanism prevents slippage and ensures consistent seam alignment.

- Specialized Needles: The type of needle used is crucial. Fur-specific needles are designed to minimize damage to the fur fibers during stitching. Using the wrong needle can result in broken needles or damage to the fur.

- Stitch Types: I utilize various stitch types, including blindstitching, which is crucial for invisible seams. My selection of stitch type depends on the fur type, garment design and the desired aesthetic outcome.

- Machine Maintenance: Regular maintenance is key. This involves cleaning, oiling, and adjusting the machine’s settings to ensure optimal performance and prevent damage to both the machine and the fur.

For example, I recently used a specialized walking foot machine to construct a bespoke chinchilla jacket, The machine’s ability to handle the delicate and luxurious chinchilla pelt flawlessly was essential in creating a beautiful, high-quality garment.

Q 18. How do you troubleshoot common issues encountered during fur garment construction?

Troubleshooting during fur garment construction requires patience and a keen eye for detail. Common issues include uneven stitching, broken needles, and slipped seams.

- Uneven Stitching: This can be caused by improper needle selection, incorrect machine tension, or an uneven feed of the fabric. The solution involves checking and adjusting the machine’s settings, potentially changing the needle, and ensuring the fabric is properly fed.

- Broken Needles: This is usually due to using the incorrect needle type or hitting a hard object. The remedy involves replacing the needle with a suitable one and carefully checking the fabric for any pins or other objects before sewing.

- Slipped Seams: This can be caused by improper handling of the fur or insufficient stitch density. The solution often involves reinforcing the seam with additional stitching or using a different stitch type. Sometimes hand stitching is necessary for added security.

- Damage to Fur: Using inappropriate tools or techniques can lead to fur fiber damage. This can require skillful repair techniques to avoid noticeable flaws.

I always approach troubleshooting systematically. I start by identifying the cause of the issue, then choose the best solution, keeping in mind the delicate nature of the material and the overall integrity of the garment. Experience allows for rapid assessment and swift resolution.

Q 19. How familiar are you with different fur types and their regional origins?

I possess extensive knowledge of various fur types and their regional origins. This knowledge is essential for selecting the right fur for a specific garment and for understanding its properties. Fur types vary greatly in terms of texture, density, length, and durability.

- Mink: Known for its luxurious sheen and versatility, mink comes in various colors and originates from North America, Europe, and Scandinavia.

- Fox: Fox fur is known for its vibrant colors and dense texture. Different species of fox, such as red fox and silver fox, originate from various regions across the globe.

- Sable: Highly prized for its deep luster and luxurious feel, sable originates primarily from Siberia.

- Chinchilla: Renowned for its incredibly soft and dense texture, chinchilla is native to the Andes Mountains in South America.

- Rabbit: A more economical choice, rabbit fur is widely used and comes in various textures and colors.

Understanding the origin helps me understand the characteristics of the fur, its potential durability, and any specific care requirements. For example, the thickness of a Siberian sable differs from that found in other regions, thus influencing the construction techniques.

Q 20. What are the key differences between natural and faux fur?

The key differences between natural and faux fur lie in their origin, texture, feel, and environmental impact. The choice often depends on ethical considerations, budget, and desired aesthetic.

- Origin: Natural fur comes from animals, while faux fur is synthetically produced.

- Texture and Feel: Natural fur has a unique texture, often with variations in length and density. Faux fur tries to mimic this but usually lacks the same softness and natural variations.

- Durability: High-quality natural fur can last for decades with proper care, while faux fur tends to shed, matt, and wear out more quickly.

- Ethical Considerations: Natural fur raises ethical concerns about animal welfare and sustainability. Faux fur avoids these issues but raises concerns about its environmental impact from its production.

- Cost: Natural fur is generally more expensive than faux fur.

I frequently advise clients on the pros and cons of each. A natural fur garment represents a significant investment, offering unparalleled luxury and longevity. Faux fur provides a more affordable and ethically less challenging alternative, particularly with advancements in producing more realistic textures.

Q 21. Explain your knowledge of fur regulations and standards.

My understanding of fur regulations and standards is extensive, encompassing both international and local laws. These regulations are crucial for ensuring ethical sourcing, proper labeling, and safe handling of fur products.

- International Trade Regulations: I’m familiar with CITES (Convention on International Trade in Endangered Species), which regulates the international trade of endangered animal species and their products, including certain fur types.

- National and Regional Laws: I keep abreast of national and regional regulations regarding fur farming, trapping, and the labeling of fur garments. These laws often specify labeling requirements, such as stating the type of fur used and its country of origin.

- Animal Welfare Standards: I am aware of the animal welfare standards and certifications that some countries and organizations have adopted, such as those concerning animal husbandry, transport and slaughter.

- Health and Safety Regulations: I’m knowledgeable of the safety standards related to the handling of furs, particularly addressing issues such as potential allergies or the safe disposal of fur waste.

Staying updated on these regulations is crucial for my business. It ensures that all my work is conducted ethically, legally, and safely, ultimately contributing to the integrity and sustainability of the fur industry.

Q 22. Describe your experience with creating custom fur designs from client sketches.

Transforming a client’s sketch into a stunning fur garment is a multi-stage process that demands precision and artistry. I begin by carefully studying the sketch, noting details like the desired silhouette, fur type, length, and any unique design elements. This initial consultation often involves discussions about the client’s vision, budget, and the practicality of their design. For instance, a highly intricate design might require more time and a specific type of fur with the necessary drape and texture.

Next, I create a technical drawing, refining the sketch into a precise pattern that accounts for the unique characteristics of fur. This includes considerations for grain direction (the way the fur lies naturally), the stretch and give of the pelt, and optimal seam placement to minimize fur damage. I might even create several pattern variations to explore different options before selecting the best one. Once approved, I then cut the pelts, taking extra care to ensure the pattern is precisely followed and there is minimal waste. The sewing process requires specialized techniques and tools to handle fur without damaging the delicate hairs and create a smooth, professional finish.

For example, I once worked with a client who sketched a dramatic, floor-length cape with intricate detailing. We spent considerable time discussing fur type—eventually settling on a luxurious fox fur for its lustrous texture and drape. Adapting the sketch to account for the fox fur’s natural variation in density required several pattern iterations. The final product beautifully demonstrated the client’s vision, showcasing my ability to translate a simple sketch into a high-end, bespoke piece.

Q 23. How do you manage multiple projects simultaneously in a fast-paced environment?

Managing multiple projects simultaneously in a fast-paced environment requires meticulous organization and prioritization. I utilize a project management system that allows me to track deadlines, client communication, and the status of each project. I break down large projects into smaller, manageable tasks, assigning realistic timelines to each. This allows me to maintain a clear overview of all my commitments and allocate my time effectively.

Prioritization is key. I focus on tasks with the most imminent deadlines first, ensuring that urgent projects always receive the attention they need. I also communicate proactively with clients, providing regular updates and addressing any potential delays early on. This prevents misunderstandings and keeps projects moving smoothly. Think of it like a conductor leading an orchestra – each instrument (project) has its own part, but the conductor ensures everything comes together harmoniously.

For example, I might be working on three projects concurrently: a custom fur coat, a series of fur trims for a fashion house, and a complex repair job. My system allows me to track the progress of each, keeping all materials and deadlines clearly organized so I can seamlessly transition between the varying demands of each project.

Q 24. What are your methods for dealing with client complaints or concerns?

Client satisfaction is paramount. When dealing with complaints or concerns, I approach the situation with empathy and a commitment to finding a solution. I begin by actively listening to the client, ensuring I fully understand their concerns before offering any solutions. I avoid becoming defensive and instead focus on finding a resolution that meets their expectations.

My approach involves a thorough review of the situation. If there’s a genuine defect in my work, I accept responsibility and offer a repair or replacement as appropriate. I might also offer a partial refund or a discount on future services, depending on the circumstances. If the complaint is based on a misunderstanding, I work to clarify the situation and ensure the client’s concerns are addressed.

For instance, a client once complained about the color of a fur vest. It turned out there was a slight variation in color due to the natural variations within the pelt, something I should have better explained upfront. I apologized for the oversight, provided detailed information on natural fur variations and offered a minor discount as a gesture of goodwill, preserving the relationship and maintaining professional integrity.

Q 25. What software or CAD programs are you proficient in using for fur design?

While traditional pattern-making remains a cornerstone of my process, I also utilize digital design tools to enhance efficiency and accuracy. I am proficient in using Adobe Illustrator for creating detailed technical drawings, vectorizing sketches, and experimenting with different design elements. This allows for precise pattern manipulation and adjustments, leading to a more accurate final product. I also use specialized CAD software that is tailored for apparel design, taking into account the specific draping properties of fur and minimizing fabric waste.

Although there isn’t a universally accepted CAD program specifically designed for fur, many general apparel design software can be adapted for this purpose. For example, I use software that offers features like 3D modeling, allowing me to visualize how different fur types drape and fit before committing to the actual cutting and sewing. This step can save a significant amount of time and material, particularly when dealing with expensive fur pelts.

Q 26. How do you stay updated on the latest trends and techniques in the fur industry?

Staying current in the ever-evolving fur industry requires a multi-faceted approach. I regularly attend industry trade shows and conferences, where I network with other professionals, learn about new techniques, and explore new materials. These events provide valuable insights into emerging trends and technologies. I also subscribe to industry publications and online forums, keeping abreast of the latest innovations and design styles.

Furthermore, I actively engage with online communities and follow influential designers and furriers on social media platforms. This allows me to stay informed about current trends in fashion, particularly concerning fur applications. Online tutorials and educational resources also provide valuable insight into new techniques and best practices. Continuously learning and adapting is crucial for remaining competitive and delivering cutting-edge designs.

Q 27. Explain your understanding of different fur pelt preparation methods.

Proper pelt preparation is fundamental to creating high-quality fur garments. The method depends on the type of fur and the desired outcome. Common methods include:

- Fleshing: Removing excess fat and tissue from the skin side of the pelt. This process is crucial for preventing rot and preserving the hide’s flexibility.

- Tanning: This is a chemical process that transforms the raw hide into leather, making it durable and resistant to decay. Different tanning methods exist, each impacting the fur’s final look and feel. Chrome tanning is a common modern method, but traditional vegetable tanning is also used for specific effects.

- Dressing: Softening and conditioning the leather to make it supple and easy to work with. This often involves applying oils and other treatments.

- Dyeing: This process involves adding color to the fur, either before or after tanning. Various techniques are used, depending on the desired outcome. Consideration must be given to how different dyes interact with the type of fur.

- Finishing: This final step involves processes like shearing, plucking, or brushing to achieve the desired texture and density.

The selection of the preparation method must be carefully matched to the fur type and the intended use. For instance, a luxurious sable pelt requires a delicate approach to avoid damage to the fine hairs, whereas a more robust fur like mink might tolerate more aggressive processing. Understanding these nuances is vital for creating durable and aesthetically pleasing finished products.

Q 28. How would you handle a complex fur repair project requiring multiple techniques?

A complex fur repair project often necessitates a combination of techniques, each demanding precision and experience. My approach to such projects is methodical and systematic.

Step 1: Assessment: I begin with a thorough examination of the damage, identifying the extent and nature of the problem. This involves determining the type of fur, the cause of the damage (e.g., tears, moth damage, wear and tear), and the feasibility of repair. Photography and detailed notes are essential at this stage.

Step 2: Planning: Based on the assessment, I develop a repair plan, outlining the specific techniques required. This might involve techniques such as patching, grafting (using fur pieces from a donor area), letting (replacing damaged sections with new fur pieces), or using specialized stitching to minimize visible repairs. I determine the most suitable matching fur for replacements.

Step 3: Execution: I meticulously execute the repair plan, ensuring the repair seamlessly blends with the existing garment. This requires precision stitching and careful consideration of fur direction. Specialized tools and adhesives are crucial for creating an invisible repair.

Step 4: Finishing: Once the repair is complete, I perform a final inspection and apply any necessary finishing touches to ensure the garment’s overall aesthetic quality. This might include brushing or cleaning to restore the fur’s original luster.

For example, a repair might involve patching a tear in a vintage fur coat while simultaneously addressing moth damage to certain areas. This requires expertise in selecting suitable replacement fur, delicate patching, and even specialized moth-proofing treatments.

Key Topics to Learn for Your Fur Tailoring Interview

- Fur Types & Properties: Understanding the characteristics of different fur types (e.g., mink, fox, sable) – their durability, texture, and suitability for various garments.

- Pattern Making & Cutting: Mastering techniques for creating accurate patterns and cutting fur efficiently to minimize waste and maximize the use of pelts.

- Sewing Techniques: Proficiency in specialized sewing methods for fur, including hand-sewing techniques and the use of appropriate sewing machines and needles.

- Fur Handling & Care: Knowing how to properly handle and care for fur pelts to maintain their quality and prevent damage during the tailoring process.

- Design & Aesthetics: Understanding the principles of design as they apply to fur garments – considering factors like style, silhouette, and overall aesthetics.

- Quality Control & Finishing: Inspecting finished garments for quality, addressing any imperfections, and executing finishing touches to ensure a high-quality product.

- Industry Standards & Regulations: Familiarity with ethical sourcing, industry best practices, and any relevant regulations concerning the fur trade.

- Problem-Solving & Troubleshooting: Demonstrating the ability to identify and solve problems that may arise during the fur tailoring process (e.g., pattern adjustments, material imperfections).

- Maintenance & Repair: Understanding common fur garment maintenance procedures and how to repair minor damages.

Next Steps

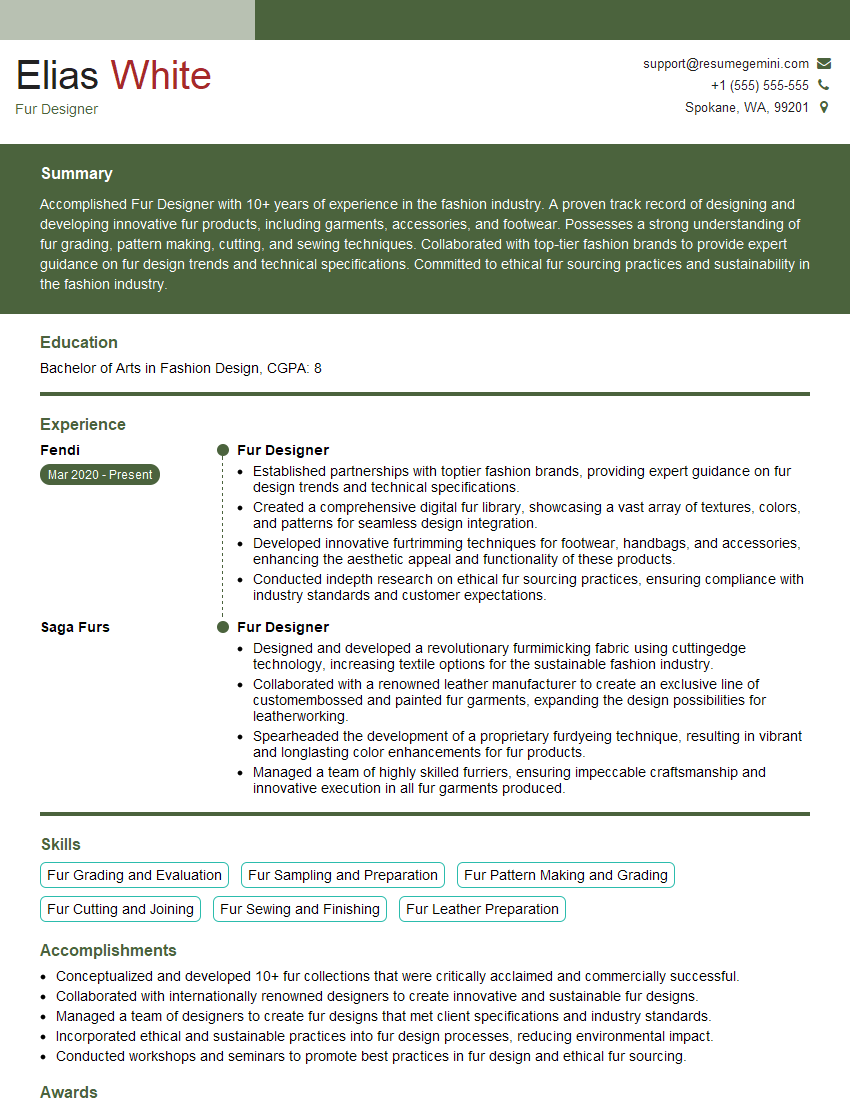

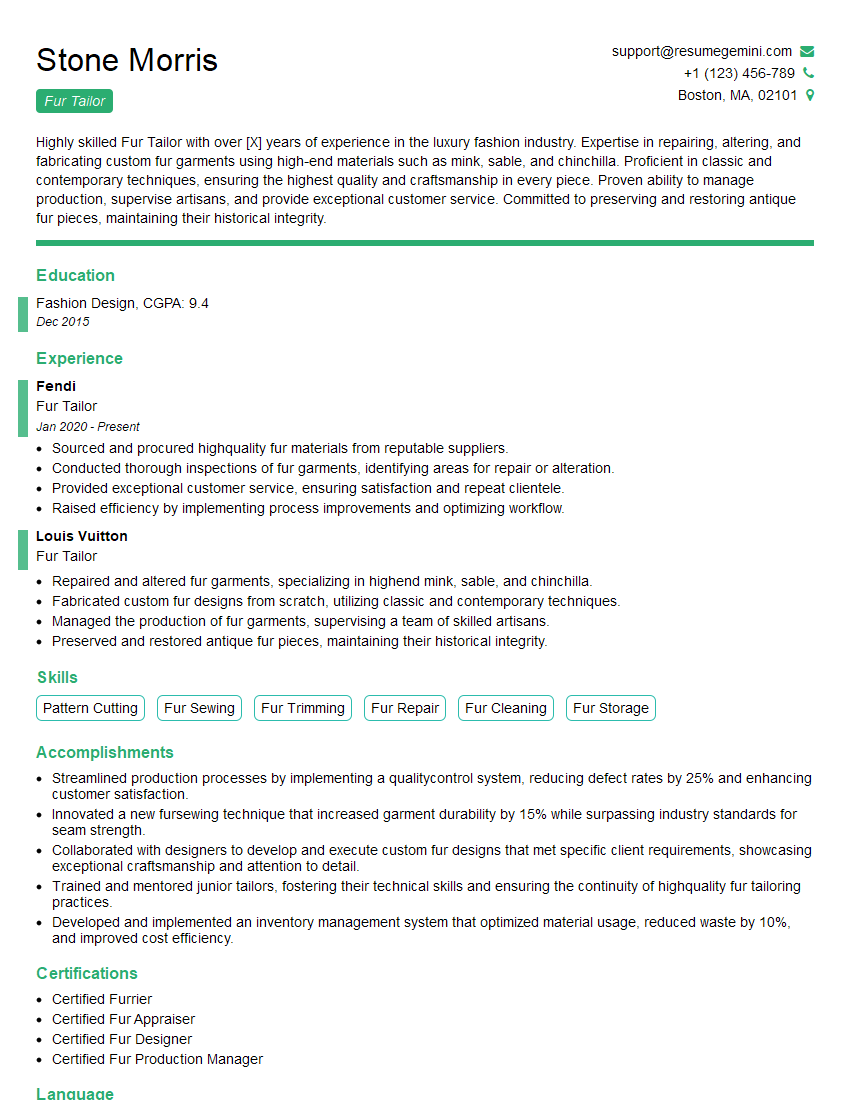

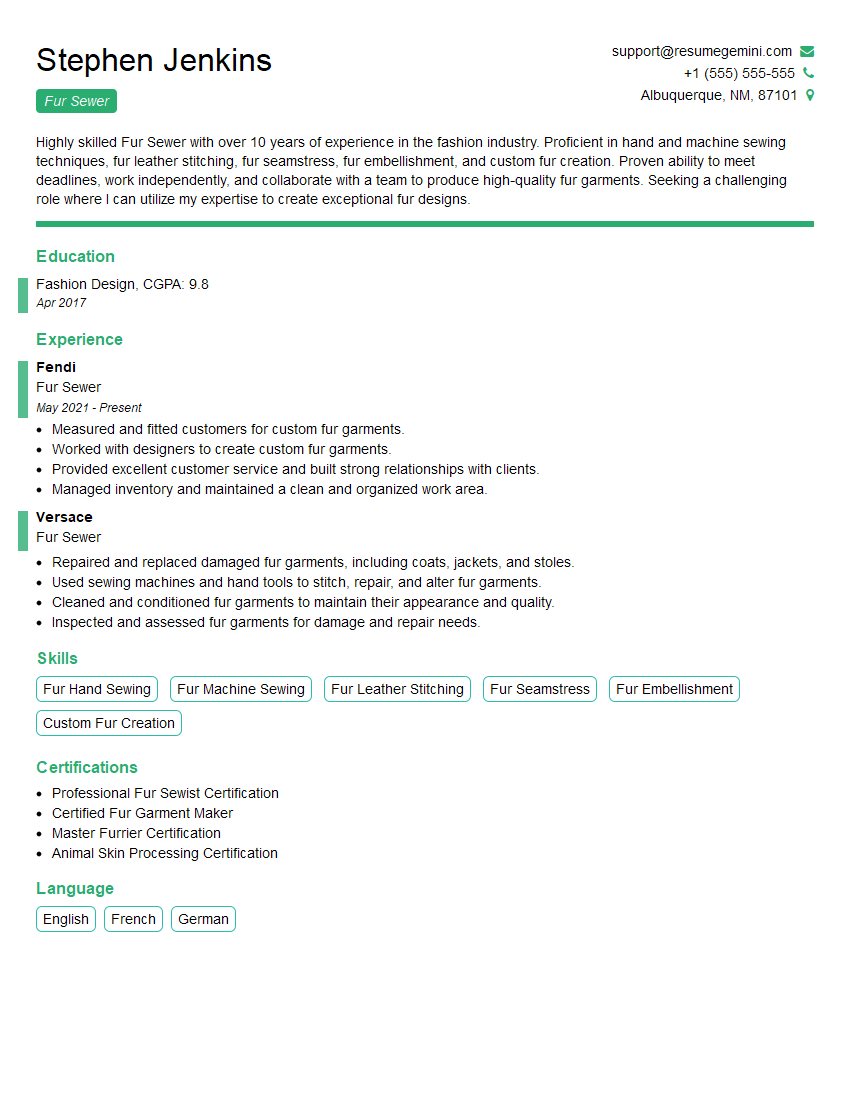

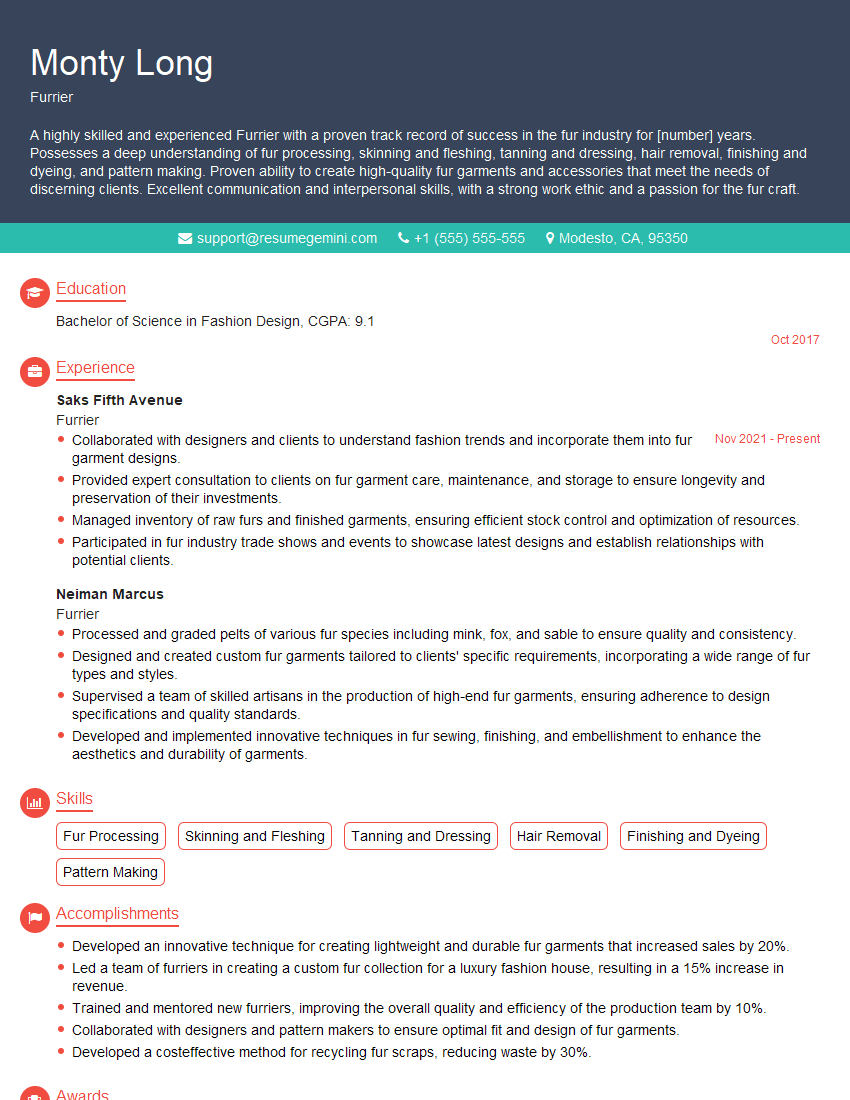

Mastering fur tailoring opens doors to a rewarding career with opportunities for creativity, precision, and high-level craftsmanship. To stand out, a strong resume is crucial. Creating an ATS-friendly resume is key to ensuring your application gets noticed by potential employers. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to the fur tailoring industry are available to help guide your process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good