Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Furniture Assembly and Disassembly interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Furniture Assembly and Disassembly Interview

Q 1. What types of tools are essential for furniture assembly and disassembly?

The essential tools for furniture assembly and disassembly vary depending on the furniture’s complexity and materials, but a well-equipped toolkit should include:

- Screwdrivers: Phillips head and flathead screwdrivers in various sizes are crucial for handling different screw types. I always carry a magnetic tip screwdriver to prevent dropped screws.

- Wrenches: Adjustable wrenches and socket wrenches are needed for nuts and bolts, especially for metal furniture.

- Hammer: A claw hammer is useful for driving nails (though less common in modern furniture) and removing stubborn parts.

- Allen Wrenches (Hex Keys): These are essential for assembling many types of modern furniture that use Allen bolts.

- Measuring Tape: Accurate measurements are vital for aligning parts correctly and ensuring the furniture is assembled square.

- Level: Ensuring furniture is level is crucial for stability and aesthetics. A small level is a must-have.

- Pliers: Needlenose pliers can help grip small parts, while slip-joint pliers are useful for a wider range of tasks.

- Putty Knife or scraper: Useful for removing old adhesive or paint.

- Safety Glasses: Always protect your eyes from flying debris.

Beyond these basics, power tools like drills (with various drill bits) can significantly speed up assembly, especially for larger projects. However, safety with power tools is paramount and requires proper training.

Q 2. Describe your experience with different types of assembly hardware.

My experience with assembly hardware is extensive, encompassing a wide range of fasteners. I’m proficient with:

- Cam Locks: These are common in flat-pack furniture and involve inserting a cam into a hole to secure two parts. I know how to ensure they are properly seated to prevent wobbling.

- Dowels: Wooden dowels are used to join pieces of wood; I’m skilled in accurately aligning dowel holes for a strong, stable joint. Often glue is needed here.

- Wood Screws: I’m familiar with various sizes and types, and I understand the importance of pre-drilling pilot holes to prevent wood splitting.

- Metal Screws: I have experience with different thread types and understand their application in different materials like metal or wood.

- Nuts and Bolts: I use various sizes and types of nuts and bolts, understanding the differences between machine screws, carriage bolts, and others. I’m adept at choosing the appropriate wrench size and tightening to the correct torque.

- Fasteners with Concealed Hardware: This is particularly important for maintaining the aesthetic of high-end furniture where visible hardware is undesirable.

Understanding the strengths and weaknesses of each type of hardware is key to successful assembly, ensuring the final product is durable and functional.

Q 3. How do you handle damaged or missing parts during assembly?

Dealing with damaged or missing parts requires a systematic approach. First, I carefully review the assembly instructions and inventory the existing parts. If a part is missing, I document it immediately, taking photos for clarity. I then contact the manufacturer or retailer to request a replacement. For minor damage, like a small scratch, I might try a simple repair (e.g., wood filler for minor wood damage). However, if the damage compromises structural integrity, the entire piece might need to be replaced.

Example: I once assembled a bookshelf where one of the support dowels was broken. I carefully documented the damage and contacted the seller for a replacement. In the meantime, I devised a temporary fix using strong wood glue and a carefully cut wooden dowel, ensuring the bookshelf remained safe until the replacement arrived.

Q 4. Explain your process for safely disassembling furniture.

Safe disassembly starts with careful planning. I begin by examining the furniture to identify the assembly method and the order of disassembly. I then:

- Document the process: I take pictures or make notes of how each component is attached, noting the position of parts.

- Loosen fasteners gradually: I begin by loosening rather than removing fasteners, allowing me to undo mistakes. I never force anything.

- Organize disassembled parts: I place removed screws, bolts, and other parts into labeled containers or bags to prevent loss and maintain organization.

- Protect surfaces: I use protective material, like cardboard, to shield finished surfaces from scratches.

- Handle heavy pieces carefully: I use proper lifting techniques and request assistance for especially heavy furniture items.

By following a methodical approach and prioritizing safety, I ensure efficient and damage-free disassembly, ready for future reassembly or disposal.

Q 5. What safety precautions do you take when handling power tools during furniture assembly?

Safety is paramount when using power tools. My precautions include:

- Using appropriate safety equipment: This always includes safety glasses, hearing protection (especially with drills), and work gloves. I also often use a dust mask when working with wood.

- Ensuring the tool is in good working order: I always check the power cord, blades/bits, and other components for any damage before use.

- Maintaining proper posture and balance: I use a secure work surface and maintain stable footing while operating power tools.

- Working in a well-lit area: Good visibility minimizes the risk of accidents.

- Keeping the work area clean and organized: A clutter-free environment prevents tripping and improves safety.

- Never reaching over the tool while it’s running: I always switch off and unplug tools before making adjustments or cleaning.

Always remember: power tools can be dangerous if not used correctly; proper training and adherence to safety regulations are essential.

Q 6. How do you manage your time when assembling multiple pieces of furniture?

Managing time efficiently when assembling multiple pieces of furniture involves careful planning and prioritization. I begin by assessing all items, noting their complexity and required tools. I then group similar items together (e.g., all items requiring the same type of hardware). This reduces the need for frequent tool changes and improves workflow. I create a prioritized list based on urgency and complexity. For example, I might start with the simplest pieces to gain momentum and build confidence.

I also take short breaks to prevent fatigue and maintain accuracy. Most importantly, I avoid rushing; quality over speed always leads to a more satisfying outcome and reduces the likelihood of mistakes that could lead to costly rework.

Q 7. Can you explain your experience with different types of furniture materials (wood, metal, etc.)?

My experience spans various furniture materials, each with its unique characteristics and assembly considerations:

- Wood: I work with various types of wood (solid wood, plywood, particleboard, MDF), understanding their different strengths, weaknesses, and appropriate fastening methods. For example, pre-drilling pilot holes is crucial when working with hardwoods to prevent splitting.

- Metal: My metal furniture experience includes steel, aluminum, and wrought iron. I am familiar with different joining methods, including welding (though not typically part of assembly work, I understand the process for repair), bolting, and riveting.

- Glass: I understand the importance of handling glass with care and using appropriate protective measures during assembly and disassembly to avoid breakage. I am experienced in the proper use of specialized clamps and fasteners for glass.

- Plastic and Composite Materials: These materials often require specialized fasteners, and I understand the techniques to avoid cracking or stripping.

Adaptability is key—understanding the properties of each material allows for safe and efficient assembly, preventing damage and ensuring durability.

Q 8. Describe your experience with reading and interpreting assembly instructions.

Reading and interpreting assembly instructions is fundamental to successful furniture assembly. It involves not just understanding the diagrams, but also deciphering the textual instructions, identifying parts, and understanding the sequence of steps. My approach is methodical. First, I thoroughly review all diagrams and instructions, noting the total number of parts and comparing them to the actual components received. I then look for any special tools or hardware required, ensuring I have them ready before beginning. I focus on understanding the step-by-step instructions, often visualizing the process before physically starting. This prevents errors and saves time. For instance, I recently assembled a complex bookshelf with numerous dowels and cam locks. By carefully examining the diagrams, numbering each component, and laying them out in order of assembly, I completed the process efficiently and accurately.

- Step 1: Inventory Check: Compare the parts list to the actual parts.

- Step 2: Diagram Review: Carefully study diagrams and instructions, noting the sequence of assembly.

- Step 3: Tool Preparation: Gather all necessary tools and hardware.

- Step 4: Visualize: Mentally walk through the steps before starting the physical assembly.

Q 9. How do you troubleshoot common problems encountered during assembly?

Troubleshooting is a critical skill in furniture assembly. Common problems include missing parts, damaged pieces, or unclear instructions. My approach begins with a careful re-examination of the instructions and a visual check of all parts. I always double-check the inventory against the parts list. If a part is missing or damaged, I contact the manufacturer or retailer immediately. If the instructions are unclear, I use online resources or consult similar assembly guides to find clarification. For example, if a screw won’t go in, I investigate whether the hole is obstructed or if the screw is the correct size and type. Sometimes, a slightly different approach, such as pre-drilling a pilot hole, can solve the problem. Another time, I discovered that a seemingly misplaced part actually required assembly in a different orientation than initially suggested by the picture, a situation resolved by carefully comparing the written instructions to the illustrations.

- Step 1: Re-examine Instructions: Double-check all steps.

- Step 2: Part Verification: Compare actual parts to the parts list.

- Step 3: Seek Clarification: If instructions are ambiguous, consult online resources or experts.

- Step 4: Adjust Approach: Adapt the assembly approach as needed, such as pre-drilling holes or adjusting part orientations.

Q 10. What is your experience with flat-pack furniture assembly?

Flat-pack furniture assembly is my specialty. I have extensive experience assembling various types of flat-pack furniture, from simple bookshelves and desks to complex wardrobes and entertainment centers. My proficiency includes understanding and utilizing various joining mechanisms such as cam locks, dowels, screws, and other hardware. I’m adept at handling different materials like particleboard, MDF, and solid wood, aware of their specific strengths and weaknesses in relation to assembly techniques. My experience includes dealing with variations in instruction clarity and overcoming potential challenges inherent to flat-pack construction, such as alignment issues and pre-drilled holes that don’t quite align. I approach each assembly with precision, focusing on accuracy to ensure a strong and stable final product.

Q 11. How do you ensure the stability and safety of assembled furniture?

Ensuring the stability and safety of assembled furniture is paramount. I achieve this through careful attention to detail throughout the assembly process. This includes using the correct hardware, following instructions precisely, and ensuring all joints are secure and properly aligned. I double-check the stability of the finished piece, testing for wobbles or weak points. For example, when assembling a tall bookshelf, I ensure that all shelves are evenly spaced and securely fastened to the vertical supports. I also check for any potential hazards, such as sharp edges or protruding screws, and address them immediately by filing them down or covering them with protective caps. Finally, I always advise clients on proper usage and weight limits to avoid accidents.

- Step 1: Accurate Assembly: Follow instructions precisely and use correct hardware.

- Step 2: Joint Security: Ensure all joints are secure and aligned.

- Step 3: Stability Check: Test for wobbles or weak points.

- Step 4: Hazard Mitigation: Check for sharp edges or protruding parts.

- Step 5: Usage Advice: Inform client about proper use and weight limits.

Q 12. Describe a time you had to improvise a solution during furniture assembly.

During the assembly of a custom-built media console, I encountered a situation where one of the pre-drilled holes was slightly misaligned. This prevented me from inserting one of the critical connecting dowels. Instead of forcing it, which could have caused damage, I carefully assessed the situation. I realized that a slight adjustment in the position of one of the side panels would solve the problem. I used a mallet and soft padding to carefully realign the panel, ensuring it wouldn’t damage the delicate wood finish. Once realigned, the dowel fit perfectly, and the assembly proceeded smoothly. This demonstrates my ability to think critically and find creative solutions to unexpected problems.

Q 13. What is your experience with different furniture styles (modern, traditional, etc.)?

My experience encompasses a wide range of furniture styles, including modern, traditional, transitional, and contemporary designs. Each style presents unique assembly challenges. Modern furniture often involves minimalist designs with sleek lines and innovative joining techniques. Traditional furniture frequently incorporates more complex joinery methods and often requires more specialized tools. Contemporary pieces might incorporate mixed materials or unusual designs, requiring adaptation and problem-solving skills. Regardless of style, my approach is always consistent: meticulous attention to detail, careful adherence to instructions, and a willingness to adapt my technique as needed to accommodate the specific requirements of each style and piece.

Q 14. How do you handle customer complaints regarding furniture assembly?

Handling customer complaints regarding furniture assembly requires patience, empathy, and effective communication skills. My approach begins by actively listening to the customer’s concerns and acknowledging their frustration. I then attempt to understand the specific problem they are facing. This might involve asking clarifying questions and even remotely viewing the assembled furniture through photos or video calls. Once I understand the issue, I collaboratively work towards a solution. If the problem stems from a mistake in assembly, I will offer guidance and support, and in some cases, I can even offer a remote troubleshooting session or a site visit to rectify the situation. If the problem arises from faulty parts or unclear instructions, I will work with the manufacturer or retailer to ensure a fair resolution for the customer, either through repair, replacement, or a full refund. The goal is always to resolve the issue quickly and amicably, ensuring customer satisfaction.

Q 15. Explain your experience with furniture disassembly for relocation or disposal.

Disassembling furniture for relocation or disposal requires a methodical approach. My experience encompasses a wide range of furniture types, from simple bookcases to complex, multi-piece bedroom sets. I begin by carefully examining the piece to identify the type of joinery used – are we dealing with screws, dowels, cam locks, or mortise and tenon joints? This informs my disassembly strategy. I always start by removing any visible screws or fasteners, taking note of their size and location for reassembly later (if needed). I use the appropriate tools – screwdrivers, wrenches, and sometimes even specialized furniture disassembly tools – to avoid damaging components. For pieces with complex joinery, like those utilizing cam locks or dowels, I work slowly and methodically, taking photographs of each step to aid reassembly. For example, when disassembling a large armoire, I’d first remove the doors, carefully noting their hinges and how they attach, then systematically disassemble the carcass, keeping track of all screws, dowels, and other hardware in clearly labeled bags. This organized approach ensures that components are protected and easily reassembled if necessary, or easily sorted for disposal.

I’ve handled many situations requiring careful disassembly, including antique furniture where preserving original components is crucial. In those cases, extra care is taken, and often photographic documentation of each stage is created for reference.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you properly dispose of disassembled furniture components?

Proper disposal of disassembled furniture components is crucial for environmental responsibility and adherence to local regulations. My process starts with sorting the materials. Wood components, if in good condition, can often be donated to charities, used for crafting projects, or repurposed. Metal components are typically recycled at designated scrap metal facilities. For plastics and other materials, I follow local guidelines for waste disposal, often separating them into appropriate recycling bins or taking them to designated recycling centers. Any upholstery or fabrics are disposed of responsibly according to local regulations, often requiring specific disposal methods to manage potentially harmful materials. In some cases, I might even contact local recycling or waste management companies to inquire about specific options for unusual or hard-to-dispose-of materials.

For example, I recently disassembled a large, old sofa. The wood frame was donated to a local carpenter, the metal springs were recycled, and the foam padding and fabric went to a facility specializing in textile recycling. This approach helps minimize the environmental impact while adhering to all relevant regulations.

Q 17. Describe your experience with working from blueprints or diagrams.

I’m highly proficient at working from blueprints and diagrams. My experience includes interpreting both simple assembly instructions and detailed technical drawings for complex furniture pieces. I’ve used this skill extensively in both assembly and disassembly projects. Understanding the relationship between different parts, viewing them in two and three dimensions, is key. For instance, I recently assembled a custom-designed entertainment center using detailed blueprints. The drawings showed not just the individual pieces but also the joinery method and precise measurements. I cross-referenced the dimensions against the actual components, ensuring accurate alignment and preventing any mismatches. Any ambiguities were resolved by careful analysis of the plans and by employing appropriate problem-solving strategies, often involving checking for potential errors before proceeding.

When dealing with older pieces lacking instructions, I often use my experience to deduce the assembly method by examining existing joinery techniques and comparing to similar pieces. This ability to interpret visual information and understand construction principles is crucial in this field.

Q 18. What is your experience with using pneumatic tools for furniture assembly?

I have significant experience using pneumatic tools for furniture assembly, particularly for tasks involving driving screws or fastening components quickly and efficiently. Pneumatic tools, like impact drivers and nail guns, offer greater power and speed compared to manual tools, especially when dealing with large or heavy pieces. Safety is paramount when using these tools. I always ensure I’m wearing appropriate safety glasses and hearing protection. Proper training and understanding of the tool’s operation are essential, and I’m always careful to control the tool’s power setting to prevent overdriving fasteners or damaging the wood. For instance, when assembling a large kitchen cabinet unit, the use of a pneumatic driver allows for the quick and secure fastening of numerous screws, significantly reducing the assembly time while maintaining high-quality results. In some instances, adjusting the air pressure or choosing the correct bit is crucial for precise work.

I also understand the importance of regular maintenance for pneumatic tools, ensuring they are correctly lubricated and maintained to avoid malfunction or injury.

Q 19. How do you maintain your tools and equipment?

Maintaining my tools and equipment is a top priority. Proper care extends their lifespan and ensures safety and efficiency. After each use, I clean my tools thoroughly, removing any sawdust, debris, or adhesive residue. I lubricate moving parts as needed, according to the manufacturer’s recommendations. Screwdrivers are kept organized and sharp, ensuring a precise fit for various screw heads. Pneumatic tools require regular lubrication and maintenance to ensure efficient air flow. I regularly inspect my tools for any signs of damage or wear, and I promptly replace or repair any damaged components. My workspace is also kept clean and organized, ensuring easy access to tools and efficient workflow. This proactive approach minimizes downtime, prevents accidents, and optimizes the overall efficiency of my work.

Regular sharpening of blades and proper storage of all equipment are vital for quality work and safety.

Q 20. How familiar are you with different types of joinery?

My familiarity with different types of joinery is extensive. I’m proficient in identifying and working with various methods, including:

- Dowel joints: Simple, strong, and widely used for aligning and joining components.

- Screw joints: Versatile and efficient, used extensively in modern furniture.

- Cam locks: Quick and easy to assemble, often found in flat-pack furniture.

- Mortise and tenon joints: Traditional joinery requiring precision and skill, producing strong and durable connections.

- Biscuit joints: Often used in conjunction with glue for increased strength and stability.

- Pocket hole joinery: Creates strong, concealed joints with a simple tool system.

Understanding these different types of joinery allows me to accurately assess the structural integrity of furniture, to disassemble pieces safely and effectively, and to select the appropriate tools and techniques for both assembly and repair.

Q 21. What is your process for inspecting furniture before and after assembly?

Inspecting furniture before and after assembly is crucial for quality control. Before assembly, I carefully check all components for any damage, such as scratches, dents, or missing parts. I verify that all parts match the instructions or blueprints and that the materials are of appropriate quality. After assembly, I thoroughly inspect the finished piece for structural integrity, ensuring all joints are secure and that the furniture is stable and functional. I check for any alignment issues, ensuring drawers slide smoothly, doors close properly, and there are no gaps or wobbles. I also check for any damage incurred during the assembly process. If any issues are detected, I address them immediately. This thorough inspection process guarantees that the final product meets the required quality standards and is safe for use.

For example, before assembling a chair, I check if all the legs are identical and free from cracks. After assembling it, I make sure it is sturdy and does not wobble. This ensures the client receives a high quality, functional piece of furniture.

Q 22. How do you handle complex or intricate assembly tasks?

Tackling complex furniture assembly requires a methodical approach. I begin by meticulously studying the instructions, often multiple times, to fully grasp the overall structure and the sequence of steps. I then visually inspect all components, identifying any potential issues or missing parts early on. For intricate joinery, like dovetail or mortise and tenon joints, I use a combination of visual inspection and gentle force to understand how the pieces interlock. If a step seems unclear, I’ll often refer to online resources or manufacturer support to avoid mistakes.

For example, when assembling a grandfather clock, the intricate pendulum mechanism and its precise alignment required careful attention to detail and multiple checks throughout the assembly process. I use clamps strategically during assembly to ensure stability and proper alignment before driving in screws or using other fasteners. Think of it like building a Lego castle—you wouldn’t just slap the pieces together; you’d carefully follow the instructions and ensure each section is properly aligned to create a stable structure.

Q 23. What is your experience with using measuring tools (tape measure, level, etc.)?

Accurate measurements are crucial for successful furniture assembly and disassembly. I’m proficient in using tape measures, levels, and squares to ensure precise alignment and avoid errors. My experience includes using both standard and metric measurements, and I understand the importance of double-checking measurements before making any cuts or permanent adjustments. I regularly utilize a level to ensure surfaces are perfectly horizontal or vertical, preventing wobbly or unstable furniture. For instance, when assembling a bookshelf, accurate measurements guarantee shelves are evenly spaced and level, ensuring both aesthetics and functionality. I’ve even had to adjust measurements slightly when working with uneven floors to ensure stability.

Q 24. How do you prioritize tasks when faced with multiple assembly projects?

Prioritizing multiple assembly projects involves a systematic approach. I begin by evaluating the urgency of each project, considering deadlines and client needs. Then I assess the complexity of each task, prioritizing simpler projects that can be completed quickly to free up time for more challenging ones. I also consider the availability of necessary tools and materials, ensuring I have everything I need before starting a project. I often use a project management system (even a simple to-do list) to keep track of deadlines and progress, which keeps me organized and efficient. For instance, if I have a rush order for a small desk and a larger, more complex entertainment center, I’d prioritize the desk to meet the client’s deadline and then tackle the entertainment center.

Q 25. How do you ensure the quality of your work during assembly and disassembly?

Quality assurance is paramount in furniture assembly and disassembly. I meticulously check each step of the process, ensuring all joints are secure, screws are tightened properly, and all components are correctly aligned. I frequently inspect for any damage to the furniture during the assembly or disassembly process. I carefully handle components to avoid scratches or dents. After completion, I perform a final inspection, checking for any loose parts, wobbly sections, or cosmetic imperfections. For instance, before delivering a disassembled item, I make sure all components are properly wrapped and labeled to avoid damage during transportation. This methodical approach ensures the client receives a well-constructed and aesthetically pleasing piece of furniture.

Q 26. Describe your experience working independently and as part of a team.

I’m comfortable working both independently and collaboratively. When working independently, I’m self-motivated and efficient, capable of managing my time and resources effectively. My experience includes managing several projects simultaneously, meticulously tracking progress and ensuring timely completion. When working in a team, I’m a strong communicator and collaborator, able to contribute effectively to group discussions and problem-solving. I value teamwork, actively sharing knowledge and expertise to achieve a common goal. For example, on a large-scale office relocation, we worked as a team to efficiently disassemble and reassemble numerous pieces of furniture, coordinating our efforts to meet a tight deadline.

Q 27. Explain your understanding of different furniture construction techniques.

My understanding of furniture construction techniques is extensive. I’m familiar with various joinery methods, including dowel joints, mortise and tenon joints, dovetail joints, and various screw and bolt fastenings. I understand the different types of wood and other materials used in furniture construction, and I know how their properties impact assembly and durability. I’m also knowledgeable about different furniture styles and their characteristic construction methods, from traditional joinery in antique pieces to modern techniques used in mass-produced furniture. Knowing these techniques allows me to troubleshoot effectively and make informed decisions during assembly and disassembly. For example, understanding the strength of different wood types allows me to choose the right tools and techniques to avoid damaging the furniture.

Q 28. How do you adapt to different assembly instructions and styles?

Adaptability is key in furniture assembly. I’ve worked with a wide variety of assembly instructions and styles, from detailed diagrams and step-by-step guides to minimal instructions and pictorial representations. My approach involves carefully reviewing all instructions provided and cross-referencing them with the components. If I encounter ambiguities, I use my experience and knowledge of furniture construction to deduce the correct procedure. I’m not afraid to ask for clarification or seek additional resources if needed, ensuring a high-quality outcome regardless of the instruction style. Think of it like learning a new recipe—the presentation may be different, but the underlying principles remain the same.

Key Topics to Learn for Furniture Assembly and Disassembly Interview

- Understanding Assembly Instructions: Interpreting diagrams, exploded views, and written instructions accurately and efficiently. Practical application includes identifying different joinery techniques and recognizing potential assembly issues from the instructions themselves.

- Tool Knowledge and Usage: Demonstrating proficiency with essential tools (screwdrivers, wrenches, power drills, etc.), understanding their proper use, safety precautions, and maintenance. Practical application includes selecting the appropriate tool for a specific task and efficiently using it to achieve a high-quality assembly.

- Joinery Techniques: Familiarity with various joinery methods (e.g., dowel joints, cam locks, screw fasteners, etc.) and their respective strengths and weaknesses. Practical application includes identifying the type of joint used in a piece of furniture and understanding the best approach for assembling or disassembling it.

- Problem-Solving and Troubleshooting: Identifying and resolving common assembly issues, such as misaligned parts, damaged components, or missing hardware. Practical application involves demonstrating creative problem-solving skills to overcome unexpected challenges during assembly or disassembly.

- Safety Procedures: Understanding and adhering to workplace safety protocols, including proper lifting techniques, use of personal protective equipment (PPE), and safe handling of tools and materials. Practical application includes explaining safe practices and demonstrating an understanding of risk mitigation during the assembly process.

- Efficiency and Time Management: Optimizing assembly and disassembly processes for speed and accuracy while maintaining high quality. Practical application includes outlining strategies for efficient workflow and minimizing wasted time and materials.

- Material Knowledge: Understanding different furniture materials (wood, metal, particle board, etc.) and their properties, including strengths, weaknesses, and appropriate handling techniques. Practical application includes knowing how to work with various materials safely and effectively.

Next Steps

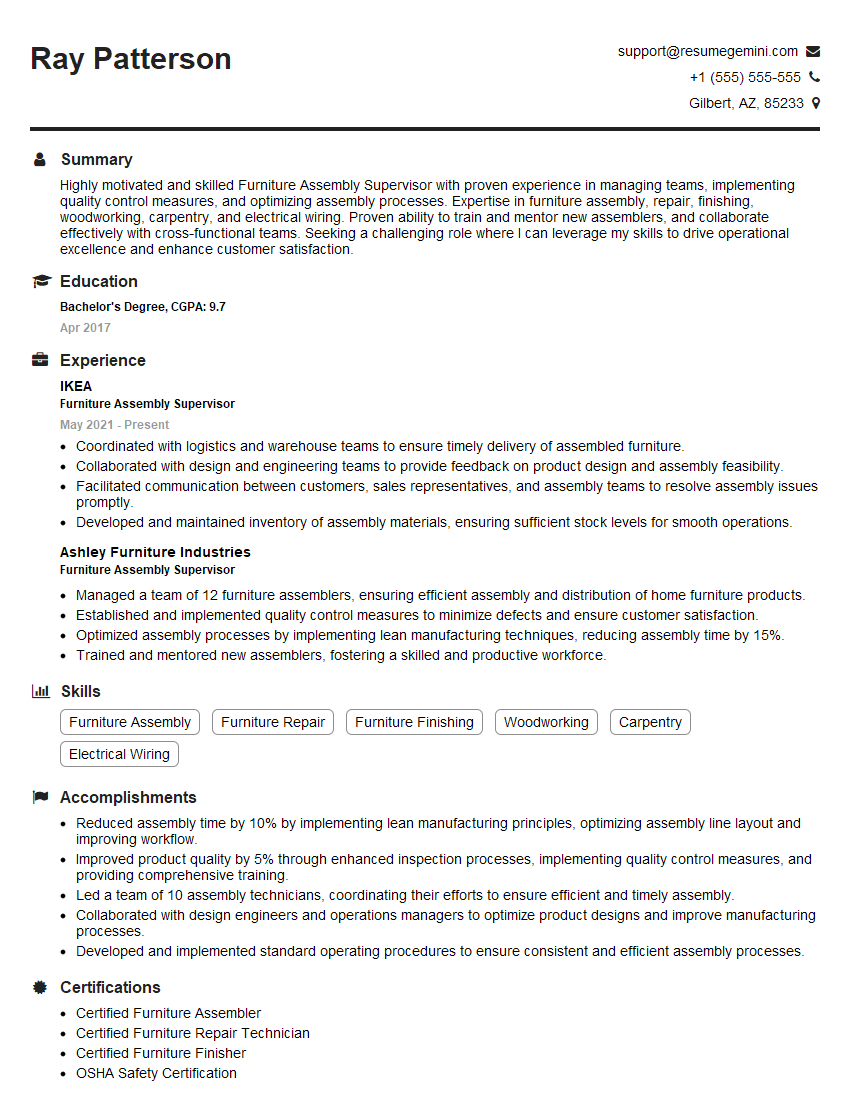

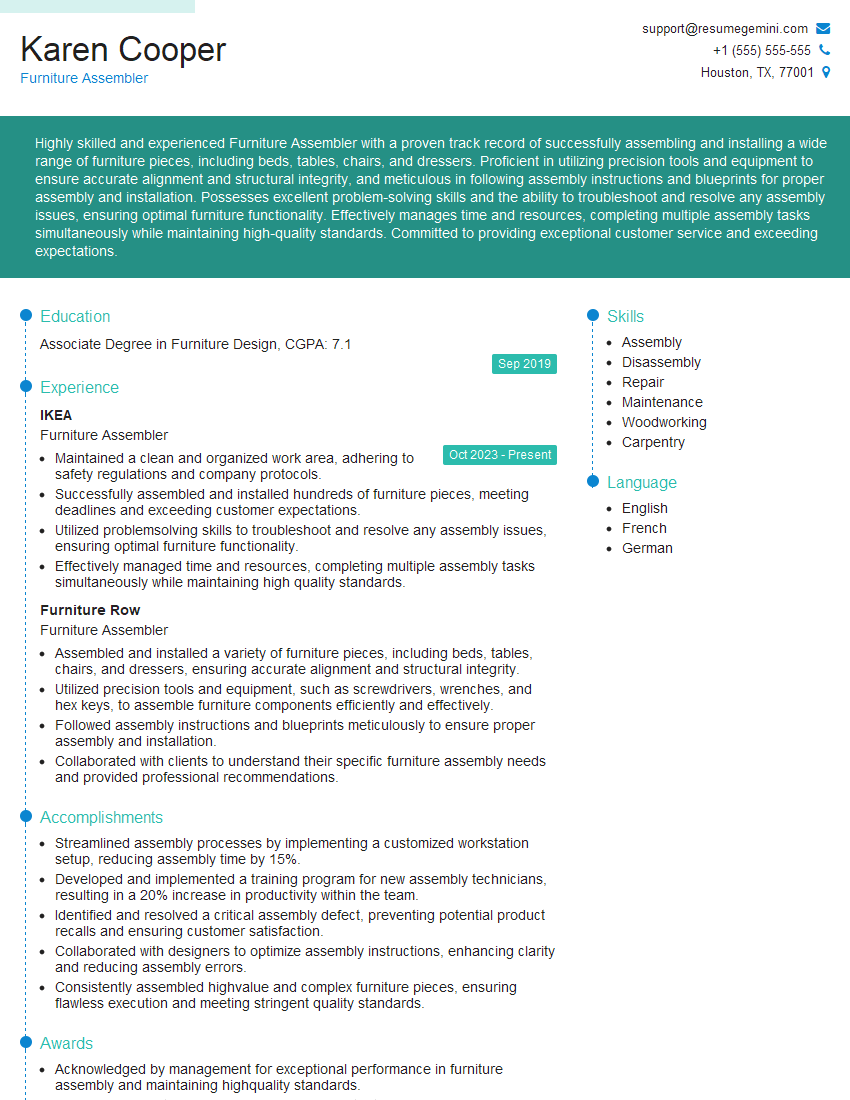

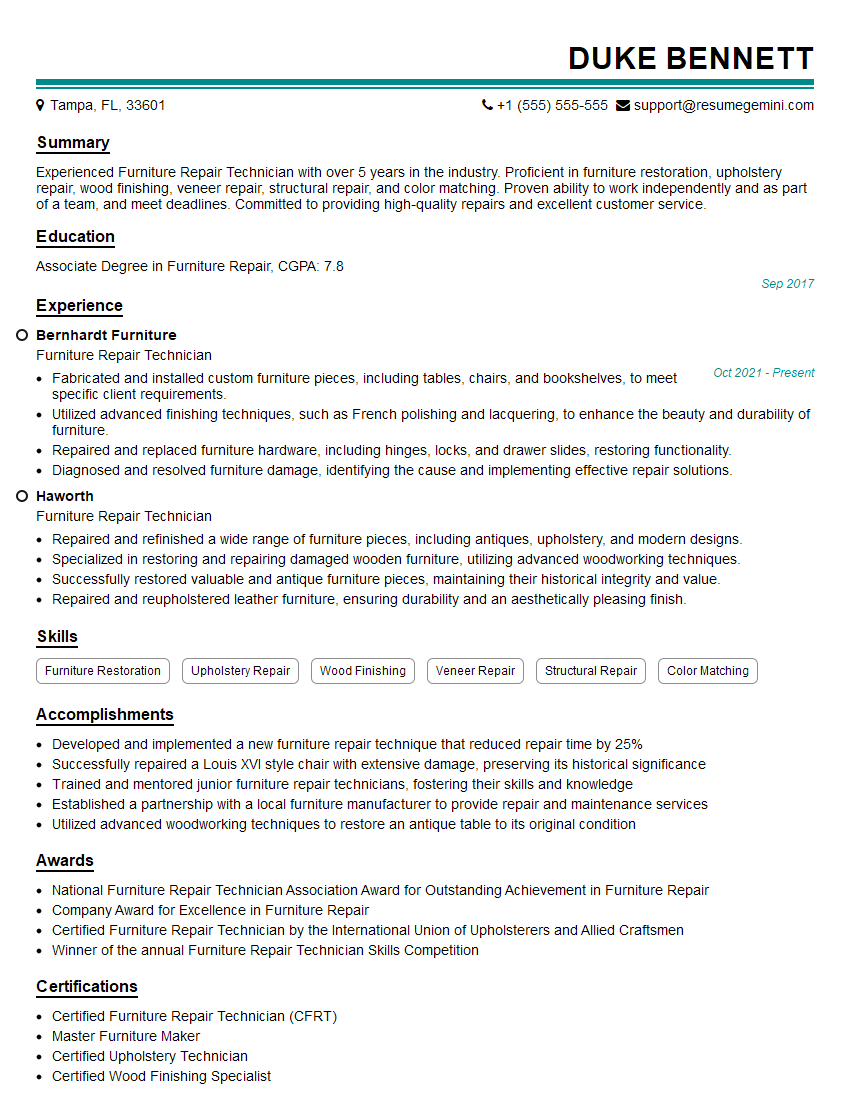

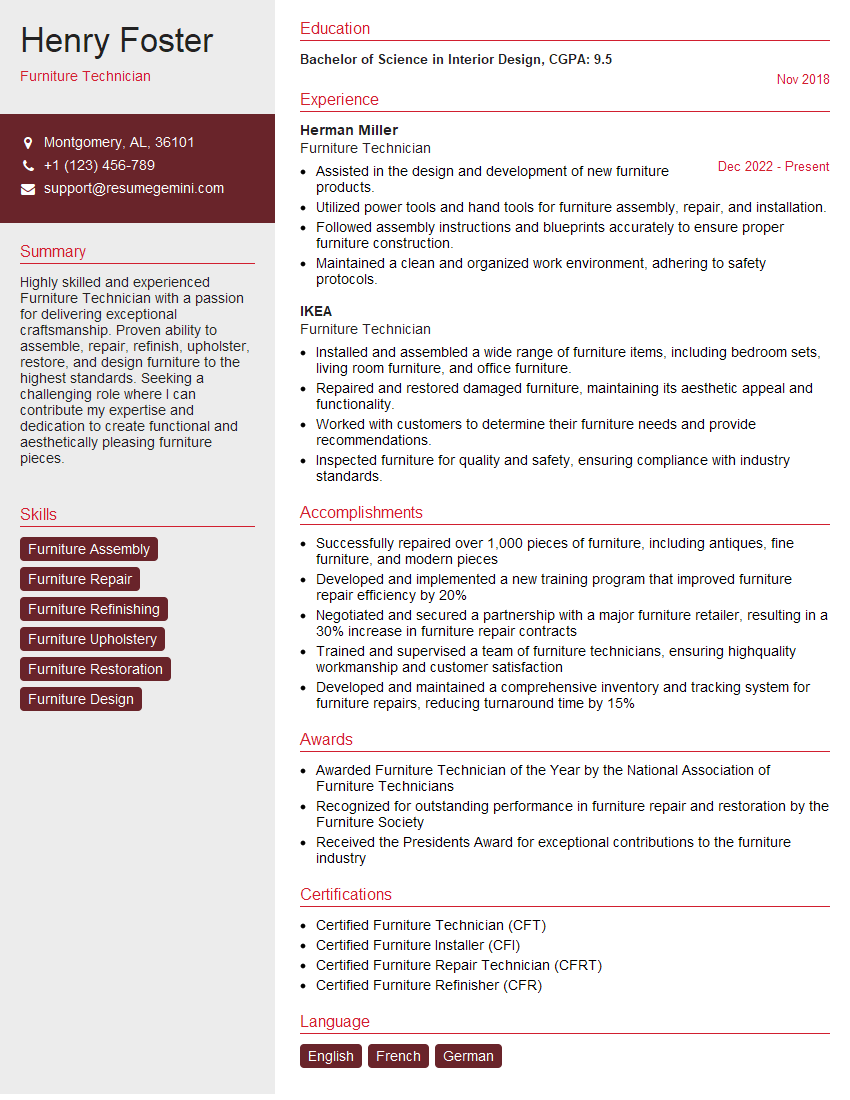

Mastering furniture assembly and disassembly opens doors to diverse roles within the furniture industry, from retail and warehousing to manufacturing and repair. A strong understanding of these skills significantly enhances your employability and potential for career growth. To make the most of your job search, creating an ATS-friendly resume is crucial. This ensures your application gets noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to build a professional and effective resume that showcases your skills and experience. ResumeGemini provides examples of resumes tailored to Furniture Assembly and Disassembly, helping you create a document that stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good