Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Garment Alteration interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Garment Alteration Interview

Q 1. Describe your experience with various sewing machine types.

My experience encompasses a wide range of sewing machine types, from basic mechanical machines to advanced computerized models. I’m proficient with both industrial and domestic machines, understanding their unique capabilities and limitations. For example, I use industrial machines for heavy-duty tasks like working with multiple layers of denim or leather, appreciating their robust construction and powerful motors. Domestic machines, on the other hand, are perfect for intricate detail work on delicate fabrics like silk or chiffon, allowing for greater control and precision. I’m familiar with features like adjustable stitch length and width, differential feed (crucial for preventing puckering on stretchy fabrics), and various presser feet for specialized tasks like zippers and buttons. My experience allows me to select the most appropriate machine for any given project, optimizing efficiency and quality.

Q 2. Explain your process for taking accurate body measurements.

Accurate body measurements are the foundation of successful garment alterations. My process begins with a clear explanation to the client, emphasizing the importance of relaxed posture and proper alignment. I use a flexible measuring tape, ensuring it lies flat against the body without pulling or stretching. I take multiple measurements at each point to account for variations and ensure accuracy. Key measurements include bust, waist, hip, shoulder width, sleeve length, back width, and garment length. For example, when measuring the bust, I instruct the client to stand comfortably with arms relaxed at their sides, measuring around the fullest part of the chest. I record all measurements in a standardized format, noting any asymmetries or unique body features that might require adjustments to the pattern.

Q 3. How do you handle difficult fabrics like leather or silk?

Working with difficult fabrics like leather and silk requires specialized techniques and tools. For leather, I use heavier-duty needles, such as a leather needle, and adjust the machine settings accordingly to prevent skipped stitches or damage to the material. A walking foot is essential to maintain even feeding and prevent slippage. Pre-punched holes or a specialized stitching method called ‘stitch-in-the-ditch’ are employed for seams that need to be invisible. Silk, on the other hand, is prone to slippage and snagging. I use a fine needle, a sharp blade for clean cuts, and a light touch during stitching. I might use a special silk presser foot and a lower machine speed to prevent damage. I’ll always test any stitching on a scrap of the same fabric beforehand to check stitch tension and needle suitability.

Q 4. What are your preferred methods for hemming different garment types?

Hemming techniques vary depending on the garment type and fabric. For pants, I prefer a blind hem stitch, creating a nearly invisible finish that keeps the hem flat and clean. For skirts or dresses with a heavier fabric, I might use a rolled hem or double-fold hem, depending on the desired look and finish. Delicate fabrics like chiffon often benefit from a hand-sewn hem for a more refined finish. Before any hemming, I always carefully press the fabric to ensure a crisp, even hem. A consistent seam allowance is key to a professional finish, and I carefully press the seam to ensure a clean look. The choice of hem depends on factors including the garment style, weight of the fabric, desired aesthetics, and available time.

Q 5. Describe your experience with pattern adjustments and alterations.

Pattern adjustments and alterations are a significant part of my work. I have extensive experience in adjusting patterns to fit different body types and styles. For example, I might need to widen or narrow shoulders, adjust the waistline, or lengthen or shorten sleeves. I am proficient in various techniques like adding darts, easing curves, or letting out seams. I use a variety of tools, including pattern rulers, French curves, and tracing paper, to make precise adjustments. I always test my adjustments on a muslin fabric sample first, making sure the fit is perfect before working on the actual garment. This iterative process guarantees a flawless final product. Understanding the fundamental principles of garment construction is key to successful pattern adjustment.

Q 6. How do you troubleshoot common sewing machine problems?

Troubleshooting sewing machine problems is a crucial skill. A common issue is skipped stitches, which can often be solved by checking the needle, thread tension, and bobbin winding. A broken needle is easily replaced, and thread tension can be adjusted using the machine’s controls. Another common problem is uneven feeding, which can be addressed by cleaning the machine and checking the presser foot and feed dogs. Sometimes, the problem might stem from a blunt or incorrectly inserted needle, a poorly wound bobbin, or even tangled thread within the machine’s mechanism. A systematic approach, starting with the most common causes and gradually investigating more complex issues, is essential to efficient troubleshooting.

Q 7. Explain your understanding of different stitch types and their applications.

My understanding of stitch types and their applications is comprehensive. A straight stitch is the workhorse for most seams. A zigzag stitch is used for finishing edges to prevent fraying and is also excellent for sewing stretchy fabrics. An overlock stitch, often achieved with a serger, provides a professional finish that is both strong and aesthetically pleasing. Blind hem stitches create nearly invisible hemming. Other specialized stitches include buttonhole stitches and decorative stitches. The choice of stitch type is paramount in achieving the desired strength, durability, and visual appeal of a garment. It depends on factors like fabric type, stress points on the garment, and the final aesthetic finish.

Q 8. How do you determine the appropriate seam allowance for various garments?

Seam allowance, the distance between the stitching line and the raw edge of the fabric, is crucial for a well-fitting garment. It varies depending on the garment type, fabric weight, and desired style. For example, a heavier fabric like denim might require a larger seam allowance (e.g., 5/8 inch) for strength and durability, while a delicate silk might use a smaller allowance (e.g., 1/4 inch) to minimize bulk.

I determine the appropriate seam allowance by considering these factors:

- Garment type: A tailored jacket will typically have different seam allowances than a casual dress.

- Fabric weight: Heavier fabrics need more seam allowance to support their weight and prevent tearing.

- Style details: Detailed seams or construction might demand adjusted allowances.

- Pattern instructions: Commercial patterns always specify the required seam allowance.

I often use a combination of experience and the pattern instructions as a starting point, adjusting as necessary during the fitting process. For instance, if a seam is too tight after the initial stitching, I know to add a bit more allowance in subsequent alterations.

Q 9. What techniques do you use to achieve a professional finish on alterations?

Achieving a professional finish in garment alterations requires attention to detail throughout the process. I prioritize clean stitching, precise cutting, and proper seam finishing techniques.

- Clean Stitching: Consistent stitch length and straight seams are paramount. I use a variety of stitches depending on the fabric and the specific alteration.

- Precise Cutting: Accurate cutting eliminates wonky seams and ensures a smooth, professional look. I always double-check my measurements before cutting.

- Seam Finishing: Raw edges are never left exposed; I use techniques like serging, pinking, or French seams to prevent fraying and add durability. The choice of finishing technique depends on the fabric and the visibility of the seam.

- Pressing: Proper pressing is crucial. I use steam and a pressing cloth to ensure crisp seams and prevent shine. Pressing as I go is important, not just at the end.

For example, when hemming trousers, I use a blind hem stitch to create an invisible finish. For delicate fabrics, I might use a hand-stitched rolled hem. Each alteration calls for a technique appropriate for the specific fabric and visual result desired.

Q 10. Describe your experience with zipper replacement and installation.

I have extensive experience with zipper replacement and installation. This includes various zipper types, from invisible zippers to metal and plastic coil zippers. My process involves careful measurement, precise cutting, and meticulous stitching.

The steps typically include:

- Removing the old zipper: Carefully unpicking the old zipper without damaging the surrounding fabric.

- Preparing the fabric: Ensuring clean edges and accurately measuring for the new zipper.

- Installing the new zipper: Using appropriate stitch length and tension to create a secure and even seam.

- Finishing: Pressing the seams and checking for any loose threads or irregularities.

I’ve worked on countless zipper replacements, from simple dress zippers to complex jacket zippers, always ensuring a smooth, functional, and aesthetically pleasing result. I am proficient in installing zippers invisibly, which requires extra precision and expertise.

Q 11. How do you handle customer requests that are technically challenging?

Handling technically challenging customer requests requires a combination of skill, communication, and problem-solving. I start by having a thorough conversation with the customer to understand their vision and any concerns. We discuss the feasibility of the alteration, outlining any limitations and potential complications.

If the alteration is beyond my immediate skill set, I will honestly explain this to the client and suggest alternative solutions or refer them to a specialist if necessary. Transparency is paramount.

For example, if a customer asks for a significant alteration to a complex couture garment, I might need to conduct a detailed assessment, including taking precise measurements, and possibly performing a trial alteration before proceeding with the final work. This allows me to anticipate and address potential challenges before they become major issues.

Q 12. How do you manage your time effectively when faced with multiple alterations?

Effective time management is crucial in my profession. I use a combination of techniques to manage multiple alterations effectively.

- Prioritization: I prioritize alterations based on urgency and complexity. Urgent repairs or alterations requiring a short turnaround time take precedence.

- Scheduling: I use a scheduling system (digital or physical) to track deadlines and allocate time for each alteration.

- Batching: I group similar tasks, such as hemming multiple pairs of pants, together to streamline the process.

- Delegation (if applicable): If I have a large workload or particularly complex projects, I might consider delegating tasks to an assistant or colleague (if available).

By staying organized, anticipating potential delays, and efficiently using my time, I can deliver high-quality work within reasonable timeframes.

Q 13. Explain your experience with taking alterations from written instructions.

I have extensive experience working from written instructions, whether they come from a customer, designer, or pattern. This involves carefully interpreting the instructions and converting them into actionable steps.

My process includes:

- Thorough Reading: I carefully read the entire instruction document to get a clear understanding of the desired outcome.

- Measurement Verification: I verify all measurements against the garment before proceeding.

- Step-by-Step Execution: I follow the instructions precisely, paying close attention to detail and technique.

- Regular Checks: I regularly check my progress against the instructions to ensure accuracy.

Clear communication is key; if I have questions or encounter ambiguities, I always clarify with the source of the instructions before continuing to ensure the final result meets expectations. I find that detailed written instructions, including diagrams, are extremely helpful in complex alterations.

Q 14. What are your methods for quality control during alterations?

Quality control is an integral part of my alteration process. I implement several methods to ensure high-quality results:

- Pre-alteration Check: I carefully examine the garment before starting any alteration to identify potential issues.

- Mid-process Inspection: I regularly check my work for accuracy and identify any issues early on.

- Final Inspection: After completion, I conduct a thorough final inspection for quality, stitching, and overall fit.

- Trial Fitting (where applicable): For alterations involving significant changes to the garment’s fit, I always conduct trial fittings to ensure the alterations meet the customer’s expectations.

- Documentation: I keep detailed records of each alteration, including measurements and techniques used, for future reference and quality tracking.

My goal is to deliver alterations that not only meet but exceed customer expectations. Proactive quality control prevents rework and ensures client satisfaction.

Q 15. Describe your experience with different types of closures (buttons, hooks, snaps).

Closures are a crucial aspect of garment alteration. My experience encompasses a wide range of fastening methods, each demanding a specific approach.

- Buttons: I’m proficient in replacing buttons, sewing on shank buttons (for a more comfortable fit and to avoid pressure points), and creating buttonholes using various techniques – hand-sewing, machine sewing with a buttonhole attachment, or even blind-stitching for a nearly invisible finish. I carefully consider the button’s size, material, and the fabric’s weight when selecting the appropriate thread and stitching technique. For instance, delicate silk requires a finer needle and thread than heavy denim.

- Hooks and Eyes: These require precision placement to ensure a smooth closure and a neat appearance. I have experience with various types – including metal and plastic – and understand how to choose the right size and type based on the garment’s weight and stress points. I meticulously hand-sew these to prevent them from pulling or tearing the fabric. I often use a small stitch length for strength and durability.

- Snaps: These are ideal for quick closures, particularly in children’s clothing or areas experiencing frequent use. I am experienced with both hand-setting snaps using a specialized tool and using machine-applied snaps for a consistent, factory-like finish. I carefully consider the placement of snaps, always testing the strength and ease of use post-installation. For delicate fabrics, I often opt for small, lightweight snaps to minimize damage.

Choosing the right closure is essential; it’s about both functionality and aesthetics. I always consider the overall design of the garment and the client’s preferences to select the most appropriate option.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and repair common garment defects?

Identifying and repairing garment defects requires a keen eye for detail and a thorough understanding of construction. My process involves a systematic approach:

- Careful Inspection: I begin by thoroughly examining the garment, identifying the location, type, and extent of the damage. This includes looking for tears, holes, broken seams, missing buttons, or uneven hems.

- Determining the Cause: Understanding the cause of the defect is critical for effective repair. Was it due to wear and tear, a manufacturing flaw, or an accident? Knowing the cause guides the repair strategy.

- Selecting the Right Repair Technique: Different defects require different solutions. A small tear might be mended with invisible mending or a simple patch. A larger tear might need more extensive repairs, possibly including fabric replacement or patching. Broken seams are repaired by carefully resewing the seam, often using a reinforcing stitch for added strength.

- Matching Fabric and Thread: This is crucial for achieving an invisible repair. For minor repairs, I often use a fabric remnant from a hidden seam. For more extensive repairs, I might need to source a matching fabric. Thread selection is critical – it needs to be the same colour and weight as the original.

- Testing and Finishing: After the repair, I test the garment’s functionality and ensure the repair is secure and durable. I finish with a light pressing to restore the garment’s shape and appearance.

For example, I once repaired a significant tear in a silk evening gown by carefully patching the back with a similar silk and using invisible mending techniques. The client was thrilled with the result, barely noticing the repair.

Q 17. Explain your understanding of different fabrics and their properties.

A deep understanding of fabrics and their properties is paramount in garment alteration. Different fabrics behave differently when sewn, pressed, and altered. My knowledge spans various fiber types, weaves, and finishes:

- Natural Fibers: I’m familiar with cotton (its absorbency and tendency to shrink), linen (its texture and wrinkling), wool (its elasticity and drape), silk (its delicacy and slippage), and cashmere (its softness and luxury). I know how to handle each fiber type during alterations – for instance, pre-washing cotton to avoid shrinkage after altering and using special techniques for delicate silks.

- Synthetic Fibers: I’m experienced with polyester (its durability and crease resistance), nylon (its strength and water resistance), and rayon (its drape and softness). Synthetic fabrics often require different needle and thread types compared to natural fibers.

- Fabric Weaves: I understand the difference between weaves like twill, satin, and plain weave and how they affect the drape and durability of the garment. This impacts my choice of stitch type and seam finish.

- Fabric Finishes: I’m knowledgeable about various finishes such as water resistance, stain resistance, and wrinkle resistance. These impact the alterations possible and the care needed during the process.

This understanding allows me to choose appropriate techniques and prevent damage during alterations. For example, I would use a different seam finish for a lightweight silk than for a heavy denim jacket.

Q 18. What is your experience with working with different types of needles?

Selecting the correct needle is critical for a clean, even stitch and to avoid damaging the fabric. My experience with needles covers a range of types and sizes:

- Needle Size and Type: I use different needle sizes (numbered from 8 to 18, with smaller numbers indicating finer needles) based on the fabric’s weight and type. A fine needle is used for delicate fabrics like silk, while a heavier needle is necessary for thick fabrics like denim.

- Needle Points: Different needle points are designed for different fabrics: sharp points for woven fabrics, ball points for knits to avoid snagging, and microtex or stretch needles for knits and lycra.

- Needle Materials: I understand the benefits of different needle materials, such as stainless steel for general use and titanium needles for superior strength and durability.

For example, when altering a cashmere sweater, I use a ball-point needle to prevent snagging the delicate fabric. Incorrect needle choice can lead to skipped stitches, broken needles, or even fabric damage, highlighting the importance of this seemingly small detail.

Q 19. How do you address client concerns or dissatisfaction with alterations?

Client satisfaction is paramount. Addressing concerns or dissatisfaction requires empathy, clear communication, and a commitment to finding a solution. My approach includes:

- Active Listening: I carefully listen to the client’s concerns, allowing them to fully express their dissatisfaction. I ask clarifying questions to understand the specific issue.

- Empathetic Response: I acknowledge their feelings and validate their concerns, ensuring they feel heard and understood.

- Problem Solving: I collaboratively explore solutions, presenting options and explaining the potential outcomes of each. This may involve adjustments to the alteration, offering a remake or providing a partial refund.

- Clear Communication: I communicate my plan of action transparently and clearly. I provide realistic expectations for the timeframe and the outcome of the proposed solution.

- Follow-up: I follow up with the client to ensure their satisfaction with the resolved issue. I often seek feedback to improve my service in the future.

Maintaining open and honest communication helps to build trust and resolve disagreements effectively, creating positive relationships with clients.

Q 20. What safety precautions do you follow when operating sewing machines?

Safety is my top priority when operating sewing machines. My safety protocols include:

- Machine Maintenance: Regularly checking and cleaning the machine to ensure smooth operation and prevent jams or accidents.

- Proper Use of Attachments: Correctly attaching and using any additional attachments or presser feet according to the manufacturer’s instructions.

- Finger Guard: Always using the finger guard or other safety features provided on the sewing machine to prevent accidental needle pricks.

- Sharp Needles and Proper Disposal: Using sharp needles only and disposing of used needles safely in a designated container.

- Electrical Safety: Ensuring the sewing machine is properly grounded and the power cord is not frayed or damaged.

- Machine Placement: Positioning the machine on a stable surface in a well-lit area, free from clutter or obstructions.

- No Loose Clothing: Wearing clothing that is not loose-fitting or dangling around the moving parts of the machine to avoid entanglement.

These precautions are not just about preventing minor injuries; they protect against serious accidents and ensure a safe working environment.

Q 21. How do you maintain your sewing equipment and tools?

Maintaining sewing equipment and tools is vital for their longevity, efficiency, and safety. My maintenance routine includes:

- Regular Cleaning: I regularly clean my sewing machine, removing lint, dust, and thread trimmings from the bobbin case, feed dogs, and other moving parts. This prevents jams and prolongs the machine’s lifespan.

- Lubrication: I lubricate the sewing machine’s moving parts according to the manufacturer’s instructions to keep them running smoothly.

- Needle and Thread Management: I replace sewing machine needles regularly, especially when working with heavy fabrics or noticing a decrease in stitch quality. I store my needles safely to prevent loss or damage.

- Tool Maintenance: I regularly clean and sharpen my scissors, seam rippers, and other hand tools. Sharp tools improve accuracy and efficiency.

- Storage: I store my sewing machine and tools in a clean, dry place to protect them from dust and moisture.

This preventative maintenance ensures the equipment is in optimal working condition, preventing costly repairs and downtime.

Q 22. What experience do you have with bridal alterations?

Bridal alterations are a significant part of my expertise, requiring meticulous attention to detail and a deep understanding of fabric behavior. I’ve worked on countless gowns, from simple A-line silhouettes to intricate, heavily embellished designs. My experience encompasses a wide range of alterations, including:

- Hemming: Precisely adjusting the length of the gown, accounting for the train and ensuring a flawless drape.

- Bustle alterations: Creating or modifying bustles to achieve the desired look and functionality.

- Bodice adjustments: Altering the fit around the bust, waist, and shoulders for a perfect, comfortable fit. This often involves intricate adjustments to seams and darts.

- Train alterations: Shortening or reshaping the train, while preserving its aesthetic integrity.

- Seam adjustments: Taking in or letting out seams to achieve a flattering fit, often working with delicate fabrics and beading.

For instance, I once worked on a gown with exceptionally delicate lace. The bride needed a significant alteration to the bodice, which required careful seam ripping, re-fitting, and precise re-stitching to avoid damaging the lace. The result was a perfectly fitted gown that met the bride’s expectations and celebrated the beauty of the original design.

Q 23. What is your experience with menswear alterations?

Menswear alterations demand precision and a strong understanding of tailoring techniques. My experience encompasses a range of garments, from suits and tuxedos to shirts and trousers. I regularly perform alterations such as:

- Jacket adjustments: Altering the shoulders, sleeves, waist, and overall fit of jackets for a sharp, tailored look.

- Trouser alterations: Hemming trousers, tapering legs, adjusting the waist, and making other necessary fit modifications.

- Shirt adjustments: Altering the collar, sleeves, and body of shirts to ensure a comfortable and flattering fit.

- Repair and restoration: Repairing rips, tears, and other damages to menswear garments, preserving their integrity.

One memorable project involved altering a vintage tuxedo for a client’s wedding. The tuxedo needed significant adjustments to the fit, as well as repairs to several minor damages. The careful restoration and tailoring resulted in a stunning garment that reflected both the client’s style and the tuxedo’s original elegance.

Q 24. What is your experience with womenswear alterations?

Women’s wear alterations form a significant part of my expertise, requiring versatility and a keen eye for detail. I handle a diverse range of styles, fabrics, and alterations, including:

- Dress alterations: Adjusting the fit of dresses of all styles, from casual sundresses to formal gowns, paying attention to details like necklines, sleeves and hems.

- Pant alterations: Hemming, tapering, and adjusting the waistbands of trousers, skirts and jeans.

- Jacket and coat alterations: Modifying the fit of jackets and coats, including shoulder, sleeve, and body adjustments.

- Special occasion wear alterations: Working with delicate fabrics and embellishments on prom dresses, cocktail dresses, and other special event garments.

For example, I recently worked on a client’s favorite silk dress that was slightly too large. Through careful adjustments to the seams and darts, I was able to create a perfect fit without compromising the drape or elegance of the dress. This involved precise measurements and an understanding of how the fabric would respond to the alterations.

Q 25. Describe your experience with altering denim garments.

Altering denim garments requires specialized techniques due to the fabric’s weight and construction. I’m proficient in various denim alterations, including:

- Hemming: Creating a clean, even hem on jeans and other denim items, often using techniques like serging to prevent fraying.

- Tapering: Adjusting the leg width of jeans, often requiring precise seam ripping, reshaping, and re-stitching.

- Waist adjustments: Taking in or letting out the waist of denim pants, considering the unique construction of denim.

- Repair and distressing: Repairing rips and tears, or creating intentional distressing to achieve a specific style.

The challenge with denim is maintaining the original look and feel of the garment while making the necessary alterations. One technique I frequently use when hemming jeans is to subtly match the existing stitching to ensure a seamless and professional finish.

Q 26. What software or technology are you familiar with for creating patterns or designs?

While I primarily rely on my expertise and experience for pattern making, I am familiar with several design software programs. My experience includes using:

- Adobe Illustrator: For creating and editing technical drawings and patterns.

- Photoshop: For manipulating images and creating design concepts.

While my primary focus is the hands-on alteration process, these digital tools allow me to create detailed sketches and refine designs to communicate ideas to clients or collaborators effectively.

Q 27. What is your understanding of industry standards for garment alterations?

Industry standards for garment alterations emphasize accuracy, durability, and aesthetic consistency. Key aspects include:

- Precise Measurements: Accurate measurements are crucial to ensure a proper fit. I utilize standard measurement techniques and tools to obtain precise measurements.

- Seam Construction: Seams should be strong, even, and appropriately finished to ensure durability. I use various techniques based on the garment type and fabric.

- Finishing Touches: Details like pressing, cleaning, and maintaining the garment’s original style are essential for a professional finish.

- Client Communication: Effective communication with the client is critical to understanding their needs and expectations and achieving the desired outcome.

For example, industry standards for hemming trousers typically involve a 1/4 inch seam allowance, while using a blind hem stitch to keep the seam hidden. My practice always adheres to these standards, ensuring the quality and longevity of the altered garment.

Q 28. How do you adapt your techniques to work with different garment styles?

Adapting my techniques to different garment styles involves understanding the specific construction and fabric properties of each item. This involves considering:

- Fabric Type: Different fabrics require different handling techniques; delicate fabrics necessitate gentler techniques, while heavier fabrics may need more robust methods.

- Construction Details: The garment’s construction, such as darts, seams, linings, and closures, dictates the best approach to alteration.

- Style and Design: The overall style and design of the garment influence the alteration strategy; a vintage garment, for instance, may require special attention to preserve its historical character.

Think of it like cooking—you’d adjust your approach based on whether you’re making a delicate soufflé or a hearty stew. Similarly, altering a silk blouse requires a different approach than altering a pair of heavy denim jeans. My adaptability ensures I can successfully alter a wide range of styles and fabrics.

Key Topics to Learn for Garment Alteration Interview

- Understanding Fabric Types and Properties: Knowing how different fabrics (e.g., silk, cotton, wool) behave during alterations is crucial for successful adjustments. This includes understanding drape, stretch, and shrinkage potential.

- Mastering Basic Alteration Techniques: Demonstrate your proficiency in common alterations like hemming pants, taking in seams, adjusting waistlines, and altering sleeve lengths. Be prepared to discuss your approach to these tasks.

- Advanced Alteration Techniques: Showcase your expertise in more complex alterations such as fitting adjustments, dart manipulation, and pattern adjustments. Consider discussing your experience with various types of closures (zippers, buttons, hooks).

- Using Sewing Machines and Equipment: Interviewers will likely assess your familiarity with different types of sewing machines, sergers, pressing equipment, and other tools of the trade. Be ready to explain your experience with specific machines and techniques.

- Pattern Making and Adjustment: A strong understanding of pattern alteration techniques is essential for precision and accuracy. Be prepared to discuss your skills in adjusting existing patterns or creating new ones.

- Problem-Solving and Troubleshooting: Garment alteration often involves unexpected challenges. Be ready to discuss how you approach and resolve problems, such as fabric damage or fitting issues, in a professional and efficient manner.

- Client Communication and Consultation: Effective communication with clients is critical. Describe how you assess client needs, explain alteration options, and manage expectations.

- Quality Control and Finishing: Highlight your commitment to producing high-quality results with attention to detail in stitching, finishing techniques, and overall garment presentation.

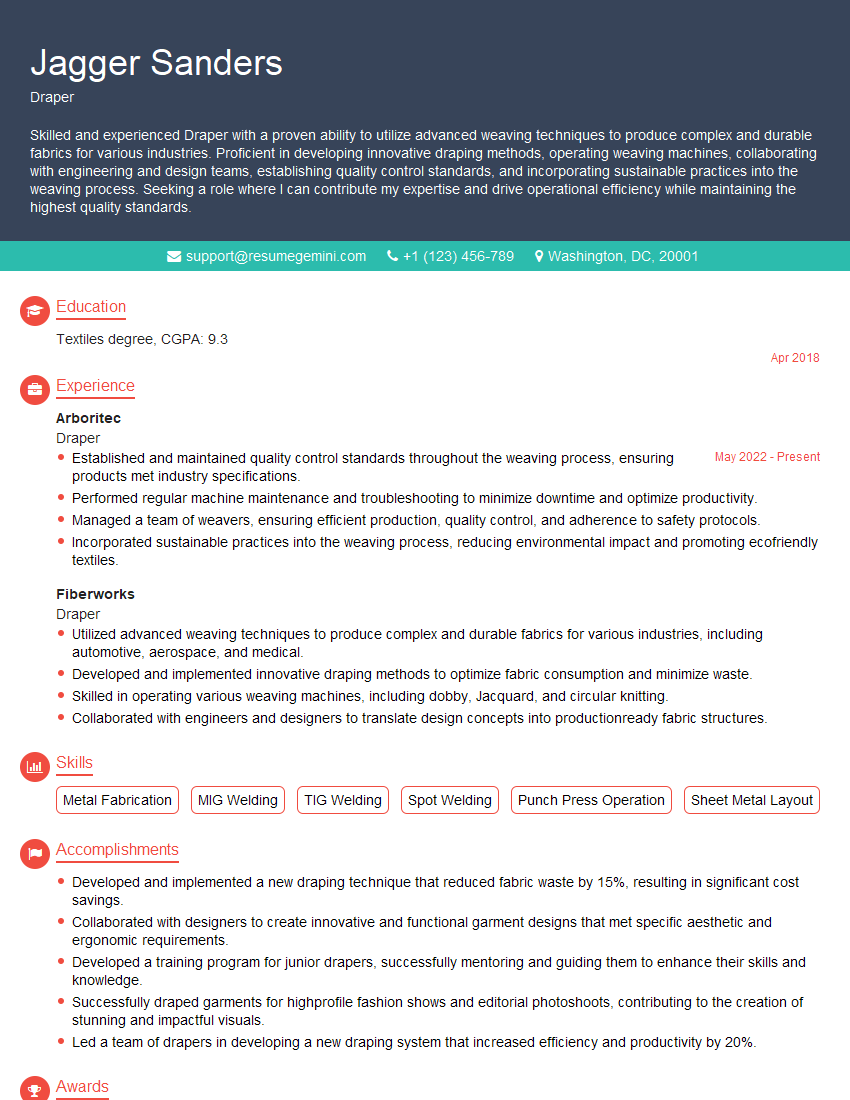

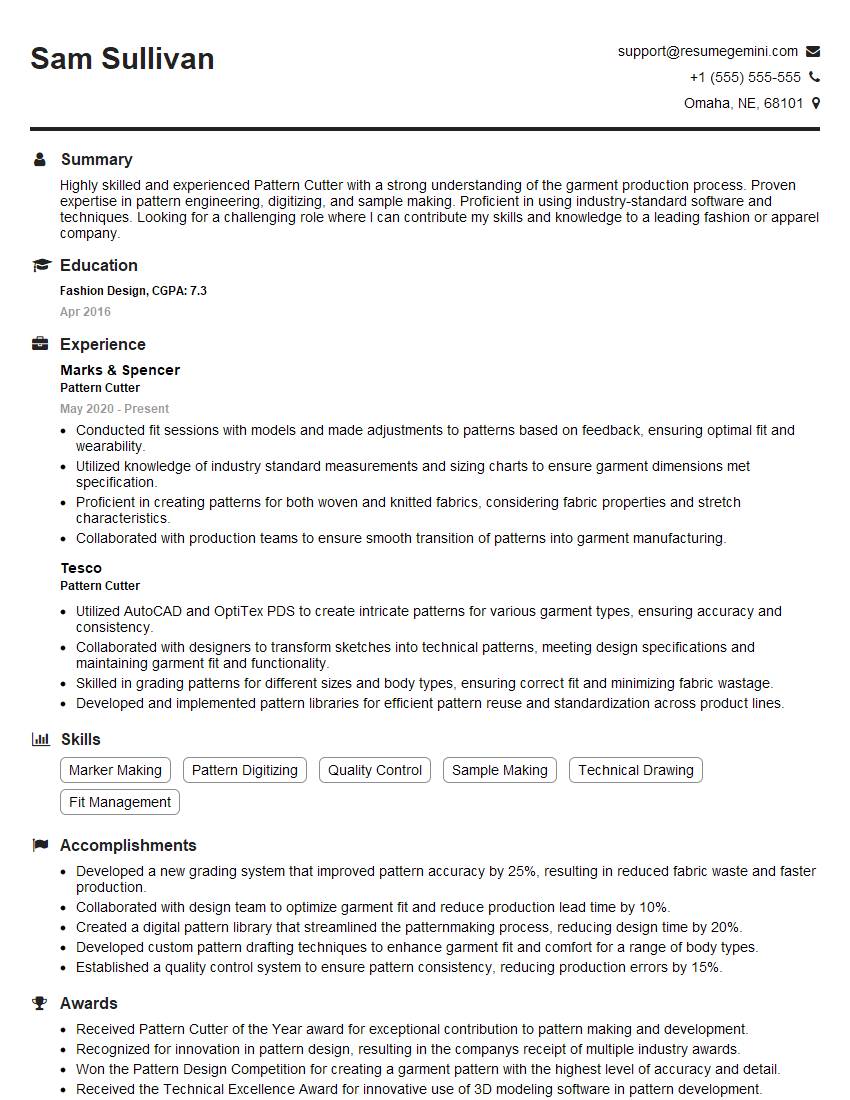

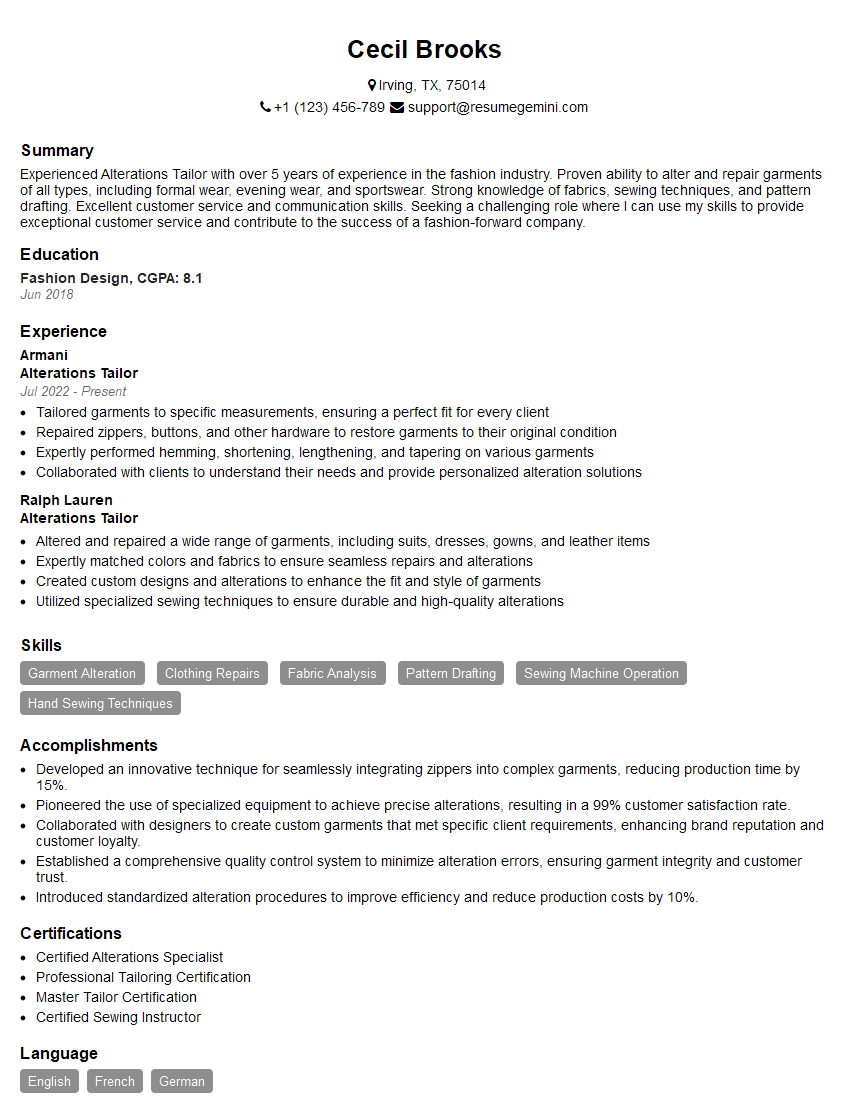

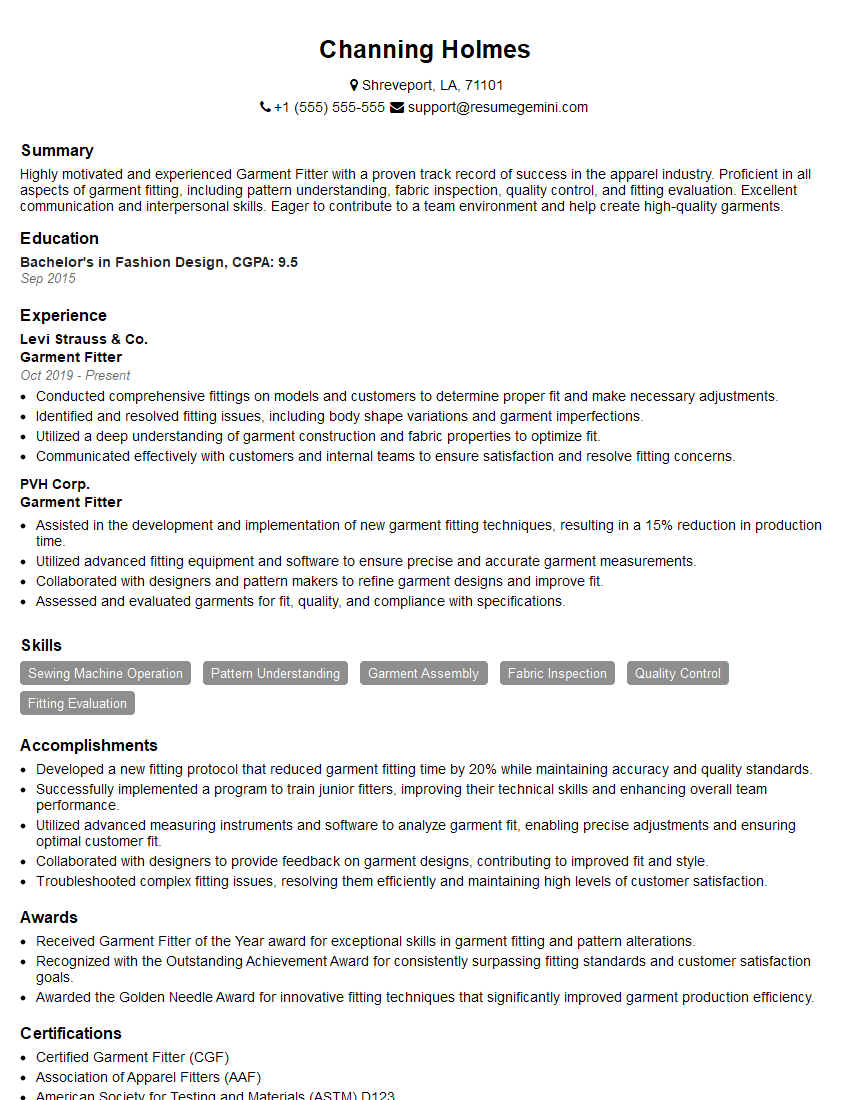

Next Steps

Mastering garment alteration opens doors to exciting career opportunities, offering a blend of creative expression and technical skill. To maximize your job prospects, crafting an ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, significantly increasing your chances of landing your dream job. Examples of resumes tailored specifically to the Garment Alteration field are available within ResumeGemini to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good