Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Gas Turbine Operation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Gas Turbine Operation Interview

Q 1. Explain the Brayton cycle and its application in gas turbines.

The Brayton cycle, also known as the Joule cycle, is a thermodynamic cycle that describes the workings of a constant-pressure heat engine. It’s the fundamental principle behind most gas turbine engines. The cycle consists of four main processes:

- Isentropic Compression: Air is drawn into the compressor and compressed adiabatically (without heat transfer), increasing its pressure and temperature.

- Constant-Pressure Heat Addition: The compressed air enters the combustor where fuel is added and burned, significantly raising the temperature at constant pressure.

- Isentropic Expansion: The hot, high-pressure gases expand through the turbine, doing work to drive the compressor and generate power. This expansion is also adiabatic.

- Constant-Pressure Heat Rejection: The exhaust gases exit the turbine at a lower pressure and temperature, completing the cycle.

In gas turbines, the Brayton cycle is implemented using a compressor, combustor, and turbine. The turbine extracts energy from the expanding gases to drive the compressor and, in most cases, also generate shaft power for various applications like electricity generation or propulsion.

Think of it like this: The compressor is like a pump, building up pressure. The combustor is like a furnace, adding energy. The turbine is like a water wheel, harnessing the energy of the flowing gases to generate power. The whole system operates continuously in a loop.

Q 2. Describe the different types of gas turbines (open vs. closed cycle).

Gas turbines are primarily categorized into open and closed cycle systems, differing mainly in how air is handled:

- Open Cycle Gas Turbines: These are the most common type. They draw ambient air into the compressor, combust the fuel within, and then exhaust the hot gases directly into the atmosphere. Most aircraft engines and many power generation turbines use this design due to its simplicity and efficiency (especially at high power levels).

- Closed Cycle Gas Turbines: In closed-cycle systems, a working fluid (usually helium or air) is continuously recirculated within a closed loop. Heat is added to this fluid using an external heat source, such as a nuclear reactor or concentrated solar power, and then the fluid is expanded through the turbine. The exhaust is then cooled and recompressed before re-entering the heat exchanger. This design offers advantages in applications where emissions are critical or high temperature materials are a constraint (e.g., nuclear power plants). Also, there’s no dependence on ambient air conditions.

The choice between open and closed cycle depends heavily on the application and its requirements.

Q 3. What are the key components of a gas turbine engine?

The key components of a gas turbine engine are:

- Air Intake: Filters and guides the incoming air.

- Compressor: Increases the pressure of the incoming air using multiple stages of rotating blades.

- Combustor (or Burner): Where fuel is mixed with compressed air and ignited, producing high-temperature, high-pressure gases.

- Turbine: Extracts energy from the expanding hot gases to drive the compressor and generate power.

- Exhaust System: Directs the hot exhaust gases away from the engine.

Additionally, many gas turbines include components for control systems, lubrication systems, and auxiliary systems for starting and monitoring performance.

Q 4. Explain the function of a compressor in a gas turbine.

The compressor in a gas turbine is crucial for increasing the density of the incoming air. This is vital because a higher density of air means more mass flow into the combustor, resulting in more power generation. The compressor is typically composed of multiple stages of axial and/or centrifugal compressors. Each stage progressively raises the pressure of the air. The compressor is usually driven by the turbine section of the engine.

Imagine blowing air into a balloon. The compressor is like repeatedly blowing into the balloon, increasing the air pressure inside. Higher pressure translates into greater energy release during combustion.

Q 5. Describe the role of the combustor in a gas turbine.

The combustor’s primary function is to efficiently mix and burn fuel with the compressed air from the compressor. This controlled combustion process raises the temperature of the gases dramatically. The design of the combustor is critical for efficient combustion, minimizing emissions, and maintaining stable flame conditions across a wide range of operating conditions. Modern combustors often utilize sophisticated fuel injection and air mixing techniques to optimize performance and reduce pollutants.

Think of it like the kitchen of the engine. It’s where the fuel and air are mixed and “cooked” to create the high energy gases required to power the turbine.

Q 6. Explain the operation of a gas turbine’s turbine section.

The turbine section uses the high-pressure, high-temperature gases exiting the combustor to generate power. This is achieved through multiple stages of turbine blades that harness the kinetic energy of the expanding gases. A portion of the turbine’s power drives the compressor, while the remaining power is available for producing shaft work (to drive a generator or a propeller, for example). The turbine stages are carefully designed to extract energy efficiently while withstanding extreme temperatures and stresses.

It’s like a series of water wheels. The high-pressure gas flows over the turbine blades, causing them to spin, thereby generating power. The power generated is what makes the gas turbine useful.

Q 7. What are the different types of gas turbine fuels?

Gas turbines can utilize various fuels, each with its advantages and disadvantages:

- Natural Gas: Widely used due to its abundance, relatively clean burning characteristics, and high energy density. It is a common choice in power generation applications.

- Distillate Fuels (Jet Fuel, Diesel): These liquid fuels are commonly used in aircraft and some land-based applications, offering high energy density and ease of storage and handling.

- Crude Oil: Can be used in specialized gas turbines, but it requires more complex fuel preparation systems due to its varied composition.

- Biofuels: Sustainable alternatives that are increasingly being developed and tested. The challenge is to achieve the same performance and reliability as conventional fuels.

- Syngas (Synthetic Gas): Produced from coal gasification or biomass, it offers a potential pathway to cleaner power generation from carbon-intensive sources.

Fuel selection depends on factors such as availability, cost, environmental regulations, and the specific requirements of the gas turbine application.

Q 8. How does a gas turbine achieve speed control?

Gas turbine speed control is primarily achieved by regulating the fuel flow to the combustion chamber. Think of it like controlling the gas pedal in a car. More fuel means more combustion, resulting in higher gas velocity and higher turbine speed. This is typically managed by a sophisticated control system that considers various parameters like load demand, turbine inlet temperature, and compressor pressure ratio. The system uses actuators to adjust fuel flow based on these factors, keeping the turbine speed within safe and efficient operating limits. For example, during a sudden increase in load demand, the control system would automatically increase fuel flow to accelerate the turbine to meet the new power requirement. Conversely, if the load decreases, fuel flow is reduced to prevent overspeeding. Several methods exist to modulate fuel flow, including variable area nozzles, fuel metering valves, or even sophisticated digital control systems incorporating advanced algorithms. The goal is always to maintain a balance between power output and turbine health.

Q 9. Explain the concept of gas turbine efficiency.

Gas turbine efficiency refers to the effectiveness of converting the energy of the fuel into useful shaft work. It’s expressed as a percentage and represents how much of the fuel’s energy is actually used to produce power, as opposed to being lost as heat. A highly efficient gas turbine will produce a higher power output for the same amount of fuel compared to a less efficient one. This efficiency is influenced by numerous factors, including the turbine’s design, operating conditions, and maintenance. Higher turbine inlet temperatures, advanced compressor designs with higher pressure ratios, and efficient combustion systems contribute to higher efficiency. Think of it like a car’s fuel economy: a more efficient car gets more miles per gallon. Similarly, a more efficient gas turbine will generate more power per unit of fuel consumed. Various efficiency metrics exist, such as thermal efficiency (how much heat energy is converted to work) and isentropic efficiency (comparing the actual work done to the ideal work in an isentropic process).

Q 10. What are common gas turbine performance parameters?

Common gas turbine performance parameters provide a comprehensive overview of the turbine’s operational health and efficiency. Key parameters include:

- Turbine Inlet Temperature (TIT): Measures the temperature of the gas entering the turbine. Crucial for efficiency and component life. High TIT indicates more energy extraction, but also higher stress on the turbine blades.

- Compressor Pressure Ratio (CPR): Ratio of the compressor outlet pressure to inlet pressure. Higher CPR indicates more efficient compression, but also higher compressor work.

- Exhaust Gas Temperature (EGT): Temperature of the gas exiting the turbine. Indicates the efficiency of the energy extraction process.

- Power Output: The actual power generated by the turbine, measured in kW or MW.

- Fuel Flow: The amount of fuel consumed per unit time, indicative of power output and efficiency.

- Compressor Discharge Pressure: Measures the pressure at the compressor outlet.

- Vibration Levels: Monitoring vibration levels of various components is critical to detecting potential failures.

- Efficiency: Overall thermal efficiency, reflecting the effectiveness of fuel conversion into power.

Regular monitoring and analysis of these parameters are essential for proactive maintenance and ensuring optimal performance.

Q 11. Describe different methods for gas turbine starting.

Gas turbine starting procedures are critical and vary depending on the specific turbine design and application. Common methods include:

- Air Start: A high-pressure air supply is used to rotate the turbine to a speed sufficient to ignite the fuel. This is like manually cranking a car engine. This requires a dedicated air compressor system.

- Electric Motor Start: A powerful electric motor is directly coupled to the turbine shaft, accelerating it to the self-sustaining speed. This is more common for smaller turbines.

- Gas Start: A smaller gas turbine or a dedicated gas starter can provide the initial rotational speed. This is more efficient and less space consuming than air start for larger turbines.

- Steam Start: A steam turbine is used to bring the gas turbine up to speed. This is less common, often found in combined cycle power plants.

The chosen starting method depends on various factors including the turbine size, environmental conditions, and auxiliary equipment availability. Safety protocols are crucial during startup to prevent damage to the turbine or associated equipment.

Q 12. Explain the importance of lubrication in gas turbines.

Lubrication in gas turbines is absolutely critical for their reliable operation and longevity. The high speeds and temperatures involved place immense stress on bearings and other rotating components. Lubrication serves several vital functions:

- Reducing Friction and Wear: Lubricant minimizes friction between moving parts, reducing wear and extending component lifespan. This is essential given the high rotational speeds of the turbine.

- Cooling: Lubricants help to cool critical components, particularly bearings, preventing overheating and damage.

- Corrosion Protection: Lubricants provide a protective barrier against corrosion, especially in the presence of high temperatures and contaminants.

- Cleaning: The lubricant helps to remove small debris and contaminants from the system.

The type of lubricant used is carefully selected to withstand the harsh operating conditions, and regular oil analysis is crucial for detecting potential problems early on. Insufficient or degraded lubrication can lead to catastrophic failure and significant downtime.

Q 13. What are some common gas turbine faults and troubleshooting methods?

Gas turbines can experience various faults, requiring diligent troubleshooting. Some common faults include:

- Compressor Fouling: Build-up of dirt or other contaminants on compressor blades reducing efficiency and airflow. Cleaning or replacement might be necessary.

- Combustion Instability: Erratic combustion leading to vibrations and potential damage. This might require adjustments to fuel injection or combustion chamber design.

- Turbine Blade Erosion or Degradation: High-temperature and high-velocity gas flow can erode turbine blades over time. Regular inspection and potential replacement are needed.

- Bearing Failures: High loads and temperatures can damage bearings. Early detection through vibration monitoring is crucial. Replacement of bearings is usually required.

- Fuel System Malfunctions: Issues in fuel delivery, metering, or ignition can prevent proper operation. Diagnostic tests and repair or component replacement are needed.

Troubleshooting typically involves a combination of data analysis from sensors (temperature, pressure, vibration, etc.), visual inspection, and potentially specialized diagnostic tools. Systematic analysis helps isolate the problem, ensuring timely and effective repairs, minimizing downtime, and preventing cascading failures.

Q 14. Describe the process of gas turbine maintenance and inspection.

Gas turbine maintenance and inspection are crucial for ensuring safe and efficient operation. A structured maintenance program is essential, combining preventive and corrective measures. This program typically involves:

- Regular Inspections: Routine visual inspections, including checking for signs of wear, corrosion, or damage on various components.

- Oil Analysis: Periodic testing of lubricating oil to detect contaminants, degradation, or potential bearing wear.

- Vibration Monitoring: Continuously monitoring vibration levels to detect imbalances or other problems affecting rotating components.

- Performance Monitoring: Tracking key performance parameters (as described earlier) to identify deviations from optimal operating conditions.

- Major Overhauls: Planned overhauls are conducted at predetermined intervals, typically involving detailed inspections, repairs, and component replacements.

The specific maintenance schedule is determined by factors such as operating conditions, turbine type, manufacturer guidelines, and regulatory requirements. Effective maintenance ensures the gas turbine’s continued performance, reliability, and extends its overall lifespan, preventing unexpected downtime and costly repairs.

Q 15. What is the role of a gas turbine control system?

The gas turbine control system is the brain of the operation, responsible for maintaining optimal performance and safety. Think of it as the pilot of an airplane, constantly monitoring and adjusting parameters to ensure a smooth and efficient flight. It manages fuel flow, air intake, exhaust, and other critical components, dynamically adjusting to changing conditions and load demands. This ensures that the turbine operates within its designed parameters, preventing damage and maximizing efficiency.

Career Expert Tips:

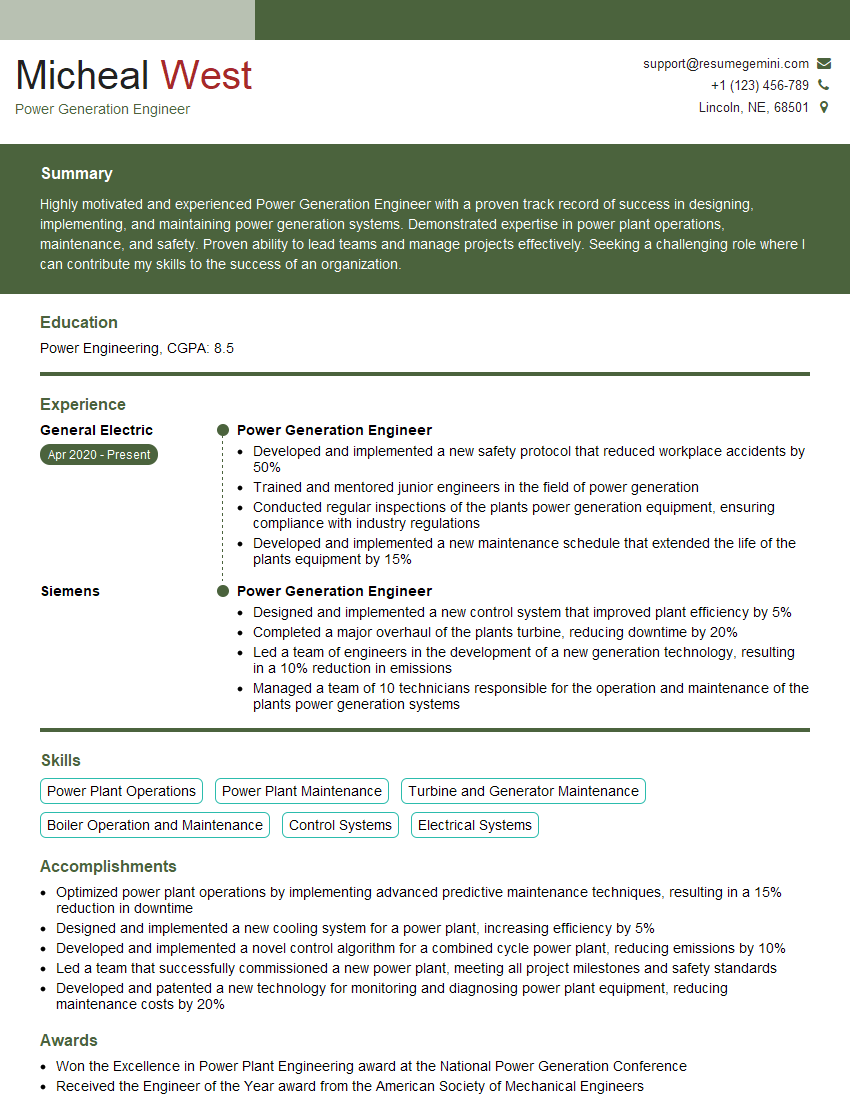

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain different types of gas turbine control systems.

Gas turbine control systems can be broadly categorized into several types. The most common are:

- Electronic Control Systems (ECS): These are the most prevalent today, utilizing sophisticated microprocessors and software to precisely manage all aspects of the turbine’s operation. They offer advanced features like adaptive control, predictive maintenance capabilities, and improved diagnostics. Many modern ECS utilize PID (Proportional-Integral-Derivative) control algorithms for precise regulation of parameters.

- Hydraulic Control Systems: While less common now, these systems use hydraulic pressure to control fuel flow and other parameters. They are robust and reliable but less flexible and precise than electronic systems. They were prevalent in older gas turbine designs.

- Electromechanical Control Systems: These systems use a combination of electrical and mechanical components. They are generally simpler and less costly than fully electronic systems but offer less precise control. They might be found in some smaller or less demanding applications.

The choice of control system depends on factors like the size and complexity of the turbine, the required level of precision, and the budget. For instance, a large power generation turbine will almost certainly use an advanced ECS, while a smaller auxiliary power unit might utilize a simpler electromechanical system.

Q 17. What are the safety precautions when working with gas turbines?

Safety is paramount when working with gas turbines, which operate at extremely high temperatures and pressures. Key precautions include:

- Lockout/Tagout Procedures: Before any maintenance or repair, always follow strict lockout/tagout procedures to prevent accidental startup. This involves isolating power and other energy sources to the turbine.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including heat-resistant clothing, gloves, eye protection, and hearing protection. High temperatures and noise levels necessitate this.

- Hot Gas Path Awareness: Never approach a running turbine or components that are still hot after shutdown without proper safety measures and time for cooling. The exhaust gases can cause severe burns.

- Confined Space Entry Procedures: If working in confined spaces around the turbine, follow strict confined space entry procedures, including atmospheric monitoring and proper ventilation.

- Emergency Shutdown Procedures: Be thoroughly familiar with the emergency shutdown procedures and the location of emergency shut-off switches.

- Regular Inspections and Maintenance: Regular inspections and maintenance are critical to preventing failures and ensuring safe operation.

A single lapse in safety protocol can lead to severe injury or fatality, so adherence to safety regulations is non-negotiable.

Q 18. How do you ensure the efficient operation of a gas turbine?

Efficient gas turbine operation relies on several factors:

- Regular Maintenance: Scheduled maintenance, including cleaning, inspections, and component replacements, is vital. Think of it like a car – regular oil changes and tune-ups extend its life and improve fuel economy.

- Optimized Operating Parameters: The control system should be configured to maintain optimal operating parameters based on the load demand and ambient conditions. This ensures maximum efficiency and minimizes fuel consumption.

- Clean Air Intake: A clean air intake system is critical to prevent damage to the compressor and maintain peak efficiency. Dust and debris can significantly impact performance.

- Fuel Quality: Using fuel of the correct specification is essential for optimal combustion and reduced emissions. Using substandard fuel can lead to component damage and increased maintenance costs.

- Effective Monitoring: Continuous monitoring of key parameters, such as temperature, pressure, and vibration, allows for early detection of potential problems.

By attending to these aspects, you can significantly improve the efficiency and longevity of your gas turbine.

Q 19. Describe your experience with gas turbine diagnostics.

Throughout my career, I’ve extensively utilized various diagnostic techniques for gas turbines. This includes analyzing data from the turbine’s control system, examining vibration signatures using sensors, and interpreting exhaust gas analysis. For instance, I was once involved in troubleshooting a turbine experiencing unexpectedly high exhaust gas temperatures. By carefully analyzing the data from the ECS, I identified a gradual decrease in compressor efficiency, which eventually pointed to a problem with the compressor blades. This was confirmed through a borescope inspection.

I have experience with both online and offline diagnostic tools and techniques, and I am proficient in interpreting data from various sensors and monitoring systems. My expertise also extends to the use of specialized software packages designed for gas turbine diagnostics. I’m accustomed to working collaboratively with maintenance teams and engineers to pinpoint issues and recommend effective solutions.

Q 20. How do you perform performance testing on a gas turbine?

Performance testing of a gas turbine is a systematic process to evaluate its efficiency and identify any deviations from expected performance. It usually involves:

- Data Acquisition: Gathering data on various parameters, including fuel consumption, power output, exhaust gas temperatures, and pressure ratios, at different operating points.

- Ambient Condition Measurement: Precise measurement of ambient temperature, pressure, and humidity is critical since they significantly affect performance.

- Performance Curve Generation: Plotting the collected data to create performance curves which illustrate the turbine’s power output, efficiency, and fuel consumption across its operating range.

- Comparison with Baseline Data: Comparing the test results with baseline data or manufacturer specifications to identify any performance degradation or discrepancies.

- Diagnostic Analysis: If discrepancies are found, a thorough diagnostic analysis is performed to identify the root cause.

The testing method and the level of detail will depend on the type of gas turbine and the objective of the testing. For example, ISO standards provide detailed guidelines for gas turbine performance testing.

Q 21. Explain the impact of ambient conditions on gas turbine performance.

Ambient conditions significantly impact gas turbine performance. Higher ambient temperatures reduce air density, leading to lower mass flow into the compressor, resulting in reduced power output. Conversely, lower ambient temperatures increase air density, leading to increased power output. Ambient pressure also plays a role; higher pressure increases air density, leading to improved performance. Humidity also affects performance, as it reduces the effective air density and can lead to increased corrosion. To account for these effects, gas turbine performance is often corrected to standard atmospheric conditions, allowing for a fair comparison of performance across various locations and weather conditions. The control system usually compensates for some of these effects, but the overall efficiency is impacted nevertheless.

Q 22. How do you manage emissions from a gas turbine?

Managing emissions from a gas turbine involves a multi-pronged approach focusing on minimizing pollutants like NOx, CO, and particulate matter. This is achieved through a combination of advanced combustion techniques and emission control systems.

Combustion Optimization: Lean premixed combustion, for example, reduces NOx formation by ensuring a more complete and efficient burn of fuel. This technique precisely mixes fuel and air before entering the combustor, resulting in lower temperatures and thus lower NOx. Other techniques involve staged combustion and dry low NOx combustors.

Selective Catalytic Reduction (SCR): SCR systems inject a reducing agent, usually ammonia, into the exhaust stream. This agent reacts with NOx in the presence of a catalyst, converting it into harmless nitrogen and water vapor. Imagine it like a chemical sponge soaking up the unwanted NOx.

Water Injection: Water injection helps lower combustion temperatures, which directly reduces NOx emissions. The added water also helps in removing some particulate matter. However, it increases the volume of exhaust gases, requiring careful consideration in the design and operation.

Exhaust Gas Recirculation (EGR): EGR introduces a portion of the exhaust gas back into the combustor, diluting the fuel-air mixture. This lowers the combustion temperature and reduces NOx formation. Think of it as cooling down the combustion process.

The specific techniques employed depend on factors such as the gas turbine’s design, fuel type, and environmental regulations. Regular monitoring of emissions using sophisticated instrumentation is crucial for ensuring compliance and optimizing the emission control strategies.

Q 23. Describe your experience with gas turbine overhaul and repair.

My experience with gas turbine overhaul and repair spans over 10 years, encompassing various models and manufacturers. I’ve led teams in both planned overhauls and emergency repairs. A typical overhaul involves a meticulous process:

Inspection: This starts with a comprehensive visual inspection, followed by detailed non-destructive testing (NDT) such as borescope inspections, ultrasonic testing, and dye penetrant testing to identify cracks, erosion, or corrosion in critical components.

Component Cleaning and Repair: Components are meticulously cleaned, and damaged parts are repaired or replaced. This might include machining, coating, or replacing blades, vanes, combustor liners, or seals.

Assembly and Testing: Once repaired components are reassembled, rigorous testing is performed to ensure that the turbine operates within its specified parameters. This includes functional testing, balancing of rotating components, and leak checks.

I’ve also been involved in troubleshooting and repairing unexpected failures, such as hot gas path issues leading to compressor or turbine blade damage. In such cases, quick and accurate diagnosis is critical to minimizing downtime and ensuring safe operation. I’m adept at using diagnostic tools and leveraging historical data to identify root causes and prevent future occurrences.

One particularly challenging case involved a sudden increase in turbine vibrations. Through meticulous analysis of vibration data and engine parameters, we traced the root cause to a damaged bearing. Swift action prevented catastrophic failure.

Q 24. What are the advantages and disadvantages of using gas turbines for power generation?

Gas turbines are valuable for power generation, but like any technology, they have both advantages and disadvantages.

Advantages:

High Power Output: Gas turbines offer high power density relative to their size, making them suitable for peak power generation and applications requiring rapid start-up.

Fast Start-up Times: They can be started and brought up to full power within minutes, an advantage during peak demand periods or emergency situations.

Modular Design: They are relatively modular and can be easily scaled up or down to meet specific power requirements.

Clean Burning Fuels (Potentially): Modern designs are increasingly efficient and capable of burning cleaner fuels, reducing emissions.

Disadvantages:

Lower Efficiency: Compared to steam turbines, gas turbines have lower thermodynamic efficiency, especially at base load operation.

Higher Operational Costs: High operating temperatures lead to faster component degradation, necessitating more frequent maintenance and higher replacement costs.

Emissions: Although emissions control systems are improving, gas turbines can still produce significant pollutants, especially NOx.

High Initial Cost: The initial capital investment for gas turbines can be relatively high.

The suitability of gas turbines depends heavily on the specific application. Their advantages make them ideal for peak shaving, emergency power generation, and combined cycle power plants, where their waste heat is used to generate steam for improved overall efficiency.

Q 25. Explain the concept of gas turbine blade cooling.

Gas turbine blades operate at extremely high temperatures, exceeding the melting point of the blade material. Blade cooling is essential to prevent catastrophic failure. Several methods are employed:

Internal Cooling: This involves intricate internal passages within the blade, where a portion of the compressor air is circulated to cool the blade from the inside. This creates a thermal barrier, reducing the blade’s surface temperature.

Film Cooling: Tiny holes on the blade surface inject a layer of cool air that forms a protective film, insulating the blade from the hot gas stream. This film acts as a shield, reducing heat transfer.

Convection Cooling: Heat is transferred from the blade surface to the cooling air flowing through the internal passages by convection. The design of the internal passages is crucial for effective heat transfer.

Impingement Cooling: Cool air is directed at high velocity onto the blade surface to enhance the cooling effect. This targeted cooling is particularly effective in regions experiencing the highest temperatures.

The specific cooling techniques used depend on the blade location, material, and operating conditions. The effectiveness of cooling is vital for extending blade life and enhancing the performance of the gas turbine.

Q 26. Describe different types of gas turbine combustor designs.

Gas turbine combustors are designed to efficiently burn fuel and produce a hot, high-velocity gas stream. Different designs are used to optimize performance, emissions, and durability:

Can Annular Combustor: This design features a cylindrical combustion chamber with multiple fuel injectors arranged around the circumference. This provides a stable, evenly distributed flame, beneficial for larger engines.

Can Combustor: Several cylindrical cans, each containing a burner, are arranged around the central axis. This is a more modular design, easier to replace individual components.

Annular Combustor with Rich-Quench-Lean (RQL) Staging: This advanced design aims to reduce NOx emissions by using a staged combustion process. It involves a rich combustion zone followed by a quench zone (to lower the temperature) and a lean combustion zone for complete fuel oxidation.

Premixed Combustor: Fuel and air are premixed before entering the combustion chamber, leading to a more efficient and cleaner combustion process, significantly reducing NOx emissions. However, this design necessitates careful control of the fuel-air mixture to prevent combustion instability.

The choice of combustor design is influenced by factors such as engine size, fuel type, desired emissions levels, and overall performance goals.

Q 27. How do you address gas turbine vibrations?

Gas turbine vibrations can be detrimental to engine health and longevity. Addressing them requires a systematic approach:

Monitoring: Regular vibration monitoring using accelerometers and advanced diagnostics helps to detect abnormal vibrations early on. The frequency and amplitude of vibrations provide clues about their source.

Root Cause Analysis: Once abnormal vibrations are detected, a thorough investigation is necessary to identify the root cause. This may involve reviewing operational data, conducting visual inspections, or employing advanced diagnostic techniques.

Corrective Actions: The corrective action depends on the source of the vibration. This could range from simple adjustments, such as correcting misalignment, to more extensive repairs, including replacing damaged bearings or balancing rotating components.

Preventive Measures: Implementing preventive measures is essential to avoid future vibration problems. This includes regular maintenance, adherence to operating procedures, and optimized engine balancing.

For instance, a high frequency vibration might indicate a problem with a bearing, while a low frequency vibration could point towards a foundation issue. Early detection and effective corrective actions are crucial to prevent catastrophic damage and ensure safe operation.

Q 28. What are your experiences with predictive maintenance for gas turbines?

Predictive maintenance for gas turbines leverages data analysis and advanced diagnostics to anticipate potential problems before they occur. This shifts from reactive maintenance (fixing problems after they occur) to proactive maintenance, minimizing downtime and optimizing maintenance schedules.

Data Acquisition: Sensors throughout the gas turbine collect various data points such as temperature, pressure, vibration, and emissions.

Data Analysis: Advanced analytics and machine learning algorithms analyze the collected data to identify patterns and anomalies that indicate potential problems. This could involve comparing real-time data with historical data or utilizing fault diagnostic models.

Predictive Modeling: Based on the analysis, predictive models estimate the remaining useful life of critical components and predict the likelihood of failures.

Maintenance Scheduling: This information informs optimized maintenance scheduling, allowing for repairs or component replacements before they lead to major failures.

For example, by analyzing vibration data, we can predict the impending failure of a bearing well in advance, allowing us to schedule a replacement during a planned outage, rather than facing an emergency shutdown. This approach leads to reduced maintenance costs, increased equipment availability, and improved overall operational efficiency.

Key Topics to Learn for Gas Turbine Operation Interview

- Thermodynamics of Gas Turbines: Understanding the Brayton cycle, its components, and efficiency calculations. Practical application includes analyzing performance curves and identifying potential inefficiencies.

- Gas Turbine Components and Operation: Detailed knowledge of compressors, combustors, turbines, and their interactions. Practical application involves troubleshooting malfunctions based on operational data and sensor readings.

- Control Systems and Instrumentation: Familiarity with various control strategies, instrumentation systems, and their role in maintaining optimal operating parameters. Practical application includes interpreting control panel displays and responding to alarms.

- Maintenance and Troubleshooting: Understanding preventative maintenance schedules, common failure modes, and diagnostic techniques. Practical application includes identifying potential problems through data analysis and implementing effective solutions.

- Safety Procedures and Regulations: Thorough understanding of safety protocols, emergency procedures, and relevant industry regulations. Practical application includes demonstrating safe work practices and adhering to safety guidelines.

- Emissions and Environmental Considerations: Knowledge of emission control technologies and environmental regulations impacting gas turbine operation. Practical application includes analyzing emission data and optimizing operation for reduced environmental impact.

- Advanced Gas Turbine Technologies: Familiarity with modern advancements such as advanced materials, digital twin technology, and predictive maintenance. Practical application includes discussing the benefits and limitations of these technologies.

Next Steps

Mastering Gas Turbine Operation opens doors to exciting and rewarding careers in power generation, aerospace, and other high-tech industries. A strong understanding of these principles is highly sought after, leading to greater career advancement opportunities and higher earning potential. To increase your chances of landing your dream job, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional, impactful resumes that get noticed. We provide examples of resumes tailored to Gas Turbine Operation to help you showcase your expertise. Take the next step towards your ideal career – craft a compelling resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good