Are you ready to stand out in your next interview? Understanding and preparing for Gear Handling interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Gear Handling Interview

Q 1. Describe your experience with different types of gear handling equipment.

My experience encompasses a wide range of gear handling equipment, from basic hand tools like chain blocks and come-alongs to sophisticated machinery such as mobile cranes, forklifts, and overhead cranes. I’m proficient in operating and maintaining various types of lifting slings, including wire rope slings, synthetic webbing slings, and chain slings. I’ve also worked extensively with specialized equipment for handling specific materials, like vacuum lifters for glass panels or magnetic lifters for steel. For example, in a previous role, I managed the safe and efficient movement of large prefabricated modular building sections using a combination of a crawler crane and specialized spreader beams, necessitating careful planning and execution to avoid damage and ensure worker safety.

- Overhead Cranes: Experience operating bridge cranes, gantry cranes, and jib cranes for lifting and moving heavy loads in industrial settings.

- Forklifts: Proficient in operating various forklift types (e.g., counterbalance, reach trucks, order pickers) for efficient material handling in warehousing and logistics.

- Mobile Cranes: Experience with both rough-terrain cranes and all-terrain cranes for lifting and placing loads in various environments.

- Specialized Lifting Equipment: Familiarity with vacuum lifters, magnetic lifters, and other specialized equipment for handling sensitive or unusual materials.

Q 2. What safety procedures do you follow when handling heavy equipment?

Safety is paramount in gear handling. My procedures always begin with a thorough pre-operational inspection of all equipment, including checks for wear and tear, proper lubrication, and functional safety mechanisms. I meticulously follow all relevant safety regulations and company policies. Before any lift, I conduct a risk assessment, considering factors such as load weight, stability of the load, wind conditions, and potential obstructions. I always ensure that appropriate personal protective equipment (PPE) is worn by myself and all personnel involved, including hard hats, safety glasses, gloves, and high-visibility clothing. Communication is key; I use clear hand signals or radio communication to coordinate with the crane operator or other team members to ensure everyone is aware of the lift plan. I never attempt a lift unless I’m confident in its safety and have the necessary equipment and training. Imagine trying to lift a heavy engine – a proper sling, secure rigging, and clear communication with the crane operator are absolutely essential to prevent accidents.

Q 3. Explain your understanding of load capacity and weight distribution.

Load capacity refers to the maximum weight a piece of equipment can safely lift, while weight distribution concerns how that weight is balanced to maintain stability. Exceeding load capacity can lead to catastrophic equipment failure and serious injury. Weight distribution is critical; an unevenly distributed load can cause instability, tipping, or even collapse. For instance, a forklift might tip over if the load is too far forward. I always consult the equipment’s specifications to confirm its load capacity and ensure that the weight is evenly distributed before undertaking a lift. I utilize load charts and calculations to determine the best slinging configurations and placement to optimize weight distribution and ensure the stability of the load. A good analogy is balancing a stack of books: distributing the weight equally helps prevent the stack from toppling over.

Q 4. How do you ensure the safe and efficient loading and unloading of equipment?

Safe and efficient loading and unloading involve careful planning and execution. I begin by assessing the area, ensuring there’s sufficient space for maneuverability and that the ground is level and stable. I use appropriate handling equipment based on the weight and nature of the load. Proper securing methods are essential; loads are always secured using appropriate straps, chains, or other restraining devices to prevent shifting or movement during transit. For example, when loading a container onto a truck, we ensure the container is properly positioned and secured to prevent it from sliding or falling during transport. The unloading process mirrors this, with careful attention to controlled movement and safe positioning of the equipment. I always prioritize the safety of personnel and the prevention of damage to the equipment and the surrounding environment.

Q 5. Describe your experience with inventory management for gear.

My inventory management experience includes utilizing various systems, from simple spreadsheets to sophisticated database software. I track equipment location, condition, maintenance history, and certifications (e.g., crane certifications, sling inspections). This allows for accurate tracking of equipment availability and facilitates preventative maintenance scheduling. Regular audits ensure inventory accuracy and identify any discrepancies or missing items. A robust inventory management system helps optimize the use of existing equipment and identifies potential equipment needs before they impact operations. Imagine a construction site – a well-managed inventory prevents delays caused by missing or damaged equipment.

Q 6. How do you handle damaged or malfunctioning equipment?

Damaged or malfunctioning equipment is immediately taken out of service and clearly marked as such. A thorough inspection is conducted to determine the extent of the damage and the cause of the malfunction. Depending on the severity, repairs might be undertaken in-house or by a specialized contractor. Documentation of the damage, repair, and return-to-service process is meticulously maintained. For example, if a sling shows signs of wear, it is immediately removed from service, inspected, and either repaired or replaced depending on its condition. This ensures the ongoing safety and reliability of our gear handling operations.

Q 7. What is your experience with different types of rigging techniques?

My experience with rigging techniques is extensive, encompassing various methods and configurations to lift and secure loads. I’m familiar with different types of slings, including wire rope slings, chain slings, and synthetic webbing slings, and know how to select the appropriate sling for the given load and application. I understand the principles of load angles and the importance of proper hitching and securing to prevent load slippage or sling failure. For instance, using a choker hitch for a wire rope sling requires careful attention to prevent damage and ensure the load is adequately secured. I’m also proficient in using various rigging hardware, including shackles, turnbuckles, and wire rope clips, always ensuring that they are correctly installed and in good working order. Safety is paramount in rigging; incorrect techniques can lead to serious accidents.

Q 8. How do you prioritize tasks when handling multiple pieces of equipment?

Prioritizing tasks in gear handling involves a systematic approach that balances urgency, importance, and resource availability. Think of it like conducting an orchestra; each instrument (piece of equipment) has a role, and you need to coordinate their actions effectively.

- Urgency: Tasks with immediate deadlines or safety implications take precedence. For example, repairing a faulty crane before it can cause an accident.

- Importance: Consider the impact of each task on the overall project. Critical tasks that significantly impact downstream processes will be given higher priority. This could involve preparing specialized equipment for a time-sensitive operation.

- Resource Availability: Factor in the personnel, tools, and time needed for each task. Sometimes, a less urgent task might need to be postponed if the resources are committed to something more critical. For example, you might delay a preventative maintenance task if a critical repair is required first.

- Prioritization Methodologies: I frequently use methods like the Eisenhower Matrix (urgent/important) or MoSCoW method (Must have, Should have, Could have, Won’t have) to visualize and organize tasks. This provides a clear roadmap for efficient task execution.

By carefully considering these factors, I ensure optimal efficiency and minimize disruptions.

Q 9. Explain your knowledge of relevant safety regulations and compliance standards.

Safety is paramount in gear handling. My knowledge encompasses a wide range of regulations and standards, including OSHA (Occupational Safety and Health Administration) guidelines, ANSI (American National Standards Institute) standards for specific equipment types, and any relevant industry-specific codes. I’m familiar with regulations concerning:

- Personal Protective Equipment (PPE): This includes the appropriate use of hard hats, safety glasses, gloves, and high-visibility clothing depending on the task and environment.

- Safe Operating Procedures (SOPs): Adherence to SOPs for each piece of equipment is crucial to prevent accidents. This includes pre-operation checks, load limits, and emergency procedures.

- Lockout/Tagout (LOTO): I’m trained and experienced in LOTO procedures to ensure equipment is safely de-energized before maintenance or repair.

- Hazard Communication: I understand the importance of identifying and communicating potential hazards to workers, ensuring everyone is aware of safety protocols.

Staying updated on these regulations is ongoing. I regularly attend safety training courses and review updates to ensure compliance and the safety of myself and my team.

Q 10. Describe your experience with pre-trip inspections of equipment.

Pre-trip inspections are fundamental to safe and efficient gear handling. It’s like a health check for your equipment. I meticulously inspect each piece of equipment before use, focusing on key components to prevent malfunctions or accidents. My inspection typically involves:

- Visual Inspection: Checking for any signs of damage, wear and tear, leaks, or loose parts.

- Functional Checks: Testing the functionality of critical components such as brakes, lights, hydraulic systems, and lifting mechanisms.

- Fluid Levels: Verifying the levels of oil, coolant, and other fluids.

- Tire Condition: Inspecting tires for wear and proper inflation.

- Documentation: Recording my findings in a pre-trip inspection form, noting any defects or issues that require attention.

A thorough pre-trip inspection not only prevents costly breakdowns but also minimizes the risk of accidents. For example, a simple leak in a hydraulic system, detected during an inspection, can prevent a catastrophic failure during operation.

Q 11. How do you handle unexpected delays or changes in workload?

Unexpected delays and workload changes are commonplace in gear handling. My approach is to remain adaptable and proactive. I utilize several strategies to address these situations:

- Communication: Immediately communicate the delay or change to relevant stakeholders, explaining the impact and potential solutions.

- Reprioritization: Re-evaluate the task priority list based on the new circumstances. This may involve adjusting schedules or re-allocating resources.

- Problem-Solving: Identify the root cause of the delay and work to find solutions. This may involve finding alternative equipment, resources, or methods.

- Contingency Planning: Having a pre-planned contingency plan helps mitigate the impact of unforeseen events. This might include having backup equipment or personnel on standby.

For instance, if a crucial part for a piece of equipment is delayed, I might explore alternative repair solutions or find a temporary replacement to maintain operation.

Q 12. How do you maintain accurate records of equipment usage and maintenance?

Maintaining accurate equipment records is crucial for effective management and maintenance. I use a combination of digital and physical methods to ensure accurate record-keeping:

- Digital Systems: I leverage computerized maintenance management systems (CMMS) to track equipment usage, maintenance schedules, repairs, and parts inventory. This allows for easy access to information and detailed reporting.

- Physical Logs: I also maintain physical logs and inspection reports for each piece of equipment. This provides a backup and ensures immediate access to vital information even if digital systems are unavailable.

- Data Entry: I meticulously document all relevant information, including dates, times, personnel involved, and any significant observations. Consistent and accurate data entry is key to the integrity of these records.

These detailed records are essential for preventative maintenance scheduling, tracking equipment costs, and complying with regulatory requirements. They also provide valuable data for analyzing equipment performance and identifying areas for improvement.

Q 13. What is your experience with using computerized inventory management systems?

I have extensive experience using computerized inventory management systems. My experience includes using systems like SAP, Oracle, and smaller industry-specific software packages. These systems greatly enhance efficiency and accuracy in managing equipment inventory. Key benefits include:

- Real-time Tracking: Accurate tracking of equipment location, status, and availability.

- Automated Reporting: Generation of reports on equipment usage, maintenance needs, and inventory levels.

- Predictive Maintenance: Using data analysis to predict potential equipment failures and schedule preventative maintenance proactively.

- Improved Efficiency: Streamlining the processes of ordering parts, tracking maintenance, and managing inventory.

For example, using a CMMS, I can easily generate a report showing all equipment due for preventative maintenance in the next month, enabling proactive scheduling and preventing costly downtime.

Q 14. How do you ensure the secure transportation of equipment?

Ensuring secure transportation of equipment is paramount. This requires a multi-faceted approach that considers both the security of the equipment and the safety of those involved in the transportation process. My approach includes:

- Secure Loading and Unloading: Utilizing proper techniques and equipment to prevent damage during loading and unloading.

- Proper Securing: Using appropriate straps, chains, and other securing devices to prevent shifting or movement during transit.

- Route Planning: Choosing suitable routes that avoid hazards and minimize the risk of damage or theft.

- Vehicle Inspection: Ensuring that the transport vehicle is in good condition and suitable for the task.

- Insurance and Documentation: Having proper insurance coverage and maintaining all necessary documentation for the transportation process.

- GPS Tracking (if applicable): Utilizing GPS tracking systems to monitor the location and status of the equipment during transit.

For instance, when transporting heavy machinery, I would ensure it’s properly secured to the trailer using appropriate tie-downs and that the trailer’s load capacity is not exceeded. This prevents accidents during transport and protects the investment in the equipment.

Q 15. Describe your experience with different types of lifting equipment.

My experience with lifting equipment encompasses a wide range, from basic hand-operated chain hoists and lever hoists to complex overhead cranes, forklifts, and specialized lifting devices like vacuum lifters and spider cranes. I’m proficient in operating and maintaining equipment across various load capacities and working environments. For instance, I’ve extensively used overhead cranes in a large manufacturing facility for lifting heavy machinery components, each weighing several tons. The precision and safety protocols required for such operations are second nature to me. With forklifts, my experience covers both counterbalance and reach truck models, adapting my techniques to the specific application and load requirements, such as narrow aisle stacking in a warehouse environment. My familiarity extends to smaller, more specialized equipment like pallet jacks and hand trucks, highlighting my ability to handle a variety of tasks efficiently and safely.

- Overhead Cranes: Experience in operating bridge cranes, gantry cranes, and jib cranes with various load capacities.

- Forklifts: Proficient in operating various types, including counterbalance, reach, and order picker models.

- Hoisting Equipment: Skilled in using chain hoists, lever hoists, and electric hoists.

- Specialized Equipment: Experience with vacuum lifters and specialized rigging techniques.

Career Expert Tips:

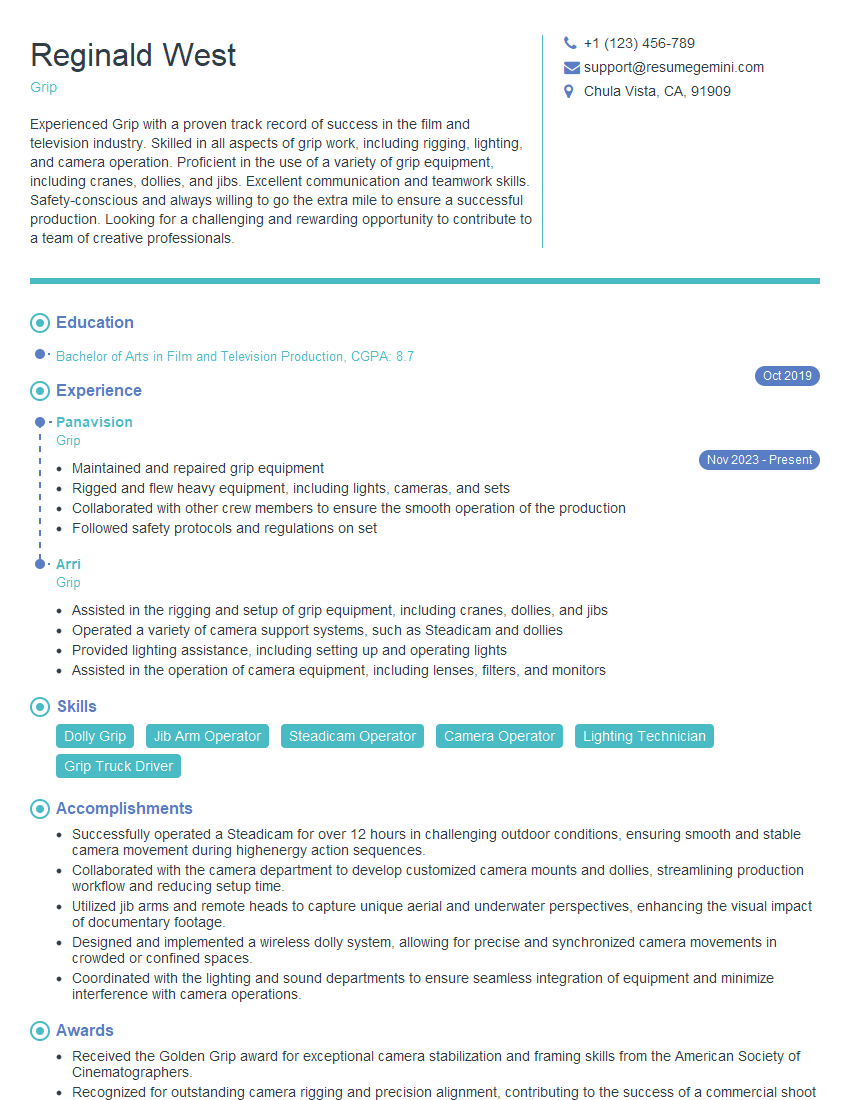

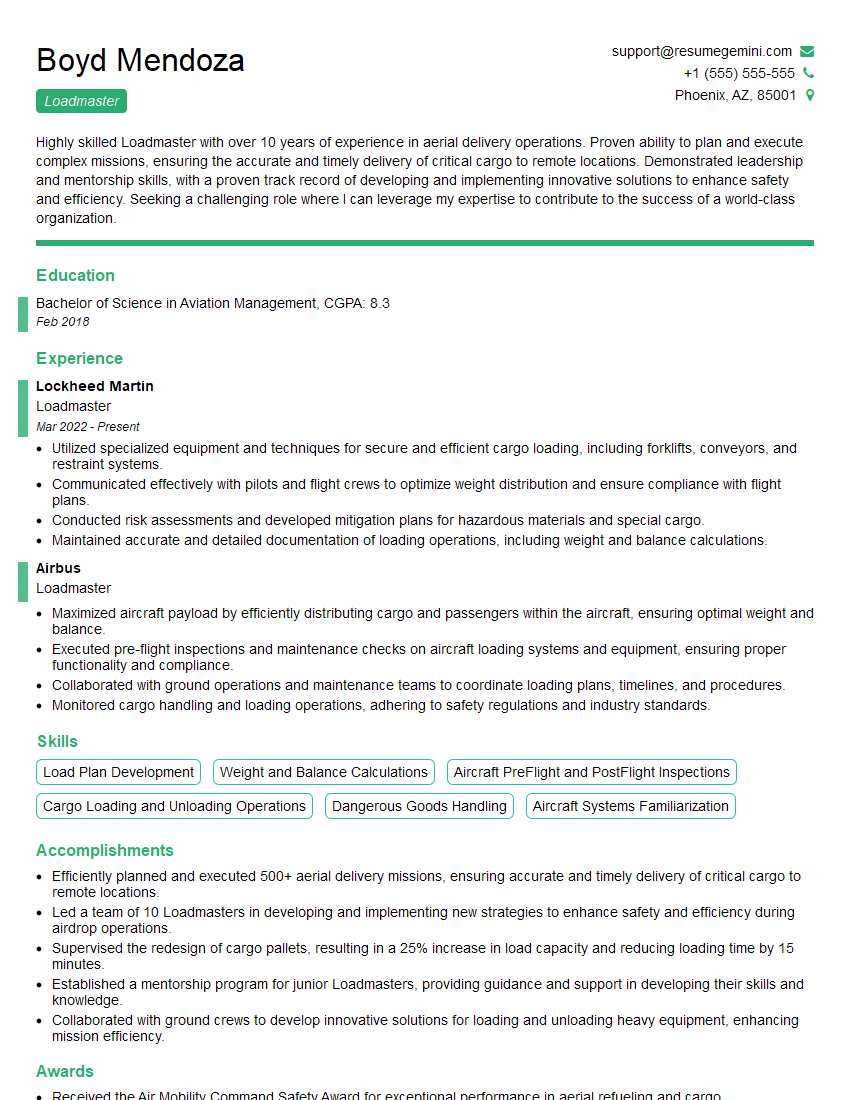

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your understanding of load balancing and stability?

Load balancing and stability are paramount in gear handling. Load balancing ensures the weight is distributed evenly across all lifting points, preventing undue stress on any single point and reducing the risk of equipment failure or load slippage. Instability can lead to accidents. To achieve this, I meticulously assess the load’s center of gravity and ensure appropriate lifting points and sling angles are used. For example, when lifting a large, irregularly shaped object, I might use multiple slings strategically positioned to balance the weight and maintain stability. Stability is also crucial; it involves considering factors such as the ground conditions, the lifting equipment’s capacity, and environmental factors (wind, etc.). I always prioritize safe working loads, and never exceed the equipment’s rated capacity.

Think of it like balancing a seesaw: if you don’t distribute the weight evenly, it will tilt and become unstable. The same principle applies to lifting heavy objects – even distribution and considering all factors are vital for safety.

Q 17. How do you communicate effectively with team members during gear handling operations?

Clear and concise communication is essential during gear handling operations. I utilize a combination of verbal and non-verbal communication techniques. Before starting any lift, I always conduct thorough pre-lift briefings, outlining the task, the procedures, and potential hazards. During the operation, I use hand signals, standardized communication protocols, and two-way radios to ensure everyone is aware of the actions being taken. I actively listen to my team members, address any concerns they may have, and make sure everyone understands the plan. I find that clear, concise language and visual aids (diagrams, checklists) significantly improve team understanding and enhance safety. For instance, when guiding a forklift operator, I use clear hand signals and verbal commands to precisely direct the movement of the load. In situations with multiple team members, a designated signal person ensures everyone is synchronized and aware of the lift’s progress.

Q 18. Explain your experience with troubleshooting equipment malfunctions.

Troubleshooting equipment malfunctions requires a systematic approach. My experience involves identifying the problem, assessing the cause, and implementing the appropriate solution, always prioritizing safety. I begin with a visual inspection, checking for obvious issues like loose connections, hydraulic leaks, or damaged components. Then, I use diagnostic tools, checklists, and manufacturer manuals to identify the source of the problem. If I’m unable to resolve the issue myself, I escalate it to a qualified technician, ensuring the equipment is properly tagged out of service to prevent further damage or injury. For example, if a forklift experiences a sudden loss of power, I would first check the battery charge and connections. If that doesn’t solve the problem, I’d then investigate the engine or electrical systems, utilizing diagnostic equipment as needed. The key is systematic diagnosis and, when necessary, the timely involvement of qualified personnel.

Q 19. How do you perform preventative maintenance on gear handling equipment?

Preventative maintenance is crucial for ensuring the safe and efficient operation of gear handling equipment. My routine includes regular inspections for wear and tear, lubrication of moving parts, and timely replacement of worn components. I meticulously document all maintenance activities, adhering to manufacturers’ recommendations and company policies. This involves checking hydraulic fluid levels, inspecting chains and cables for wear and damage, and ensuring proper functionality of safety devices like limit switches and emergency stops. I use checklists and maintenance logs to track the history and condition of equipment, ensuring that scheduled maintenance is performed consistently. This approach minimizes downtime, reduces the risk of malfunctions, and extends the lifespan of the equipment. For example, for an overhead crane, I’d inspect the hook, cables, and the entire lifting mechanism on a set schedule, documenting each inspection and any necessary maintenance actions.

Q 20. What is your experience with different types of packaging and crating?

My experience with packaging and crating includes various types of materials and techniques, selected to provide appropriate protection during handling and transit. This ranges from simple cardboard boxes and pallets to specialized crates and custom-designed packaging for fragile or oversized items. I’m familiar with different types of cushioning materials, such as bubble wrap, foam, and air pillows, and I understand the importance of proper bracing and securing within crates to prevent shifting during transportation. For example, for delicate electronic equipment, I’d use custom-fit foam inserts and vibration-dampening materials within a sturdy wooden crate. For heavier items, I’d utilize steel strapping and proper pallet placement to ensure stability. Selecting the correct packaging depends on factors such as the item’s fragility, weight, size, and destination.

Q 21. How do you handle hazardous materials during gear handling operations?

Handling hazardous materials requires strict adherence to safety regulations and protocols. I am thoroughly familiar with the relevant safety data sheets (SDS) and proper handling procedures for various hazardous materials. This includes using appropriate personal protective equipment (PPE), such as respirators, gloves, and safety glasses, and ensuring the use of specialized containers and equipment suitable for the specific hazard. I understand the importance of proper labeling, segregation, and containment of hazardous materials throughout the handling process. For example, when handling corrosive chemicals, I’d utilize secondary containment and specialized lifting equipment to prevent spills and ensure operator safety. All activities are documented to maintain a complete record of handling, storage, and disposal of these materials.

Q 22. Describe your understanding of various slinging techniques.

Slinging techniques are crucial for safe and efficient gear handling. The choice of technique depends heavily on the load’s shape, weight, and the available lifting equipment. Incorrect slinging can lead to serious accidents.

- Choker Hitch: This uses a single sling wrapped around the load. It’s simple but places significant stress on the sling, requiring extra caution and careful consideration of the sling’s capacity. Example: Lifting a cylindrical object like a pipe.

- Basket Hitch: Two or more slings are used to form a basket under the load, distributing the weight evenly. This is a very common and generally safe method for loads that have multiple lifting points. Example: Lifting a pallet of materials.

- Vertical Hitch: The sling hangs vertically from the lifting point directly above the load’s center of gravity. Ideal for symmetrical objects to avoid shifting during the lift. Example: Lifting a large rectangular crate.

- Bridle Sling: Multiple slings are attached to a single point on the lifting device, converging at a central point above the load. This offers good stability for heavy or awkwardly shaped objects. The angle of the slings is critical here; a narrower angle increases the stress on the slings. Example: Lifting a large engine block.

Proper sling placement and angle are vital to avoid overloading or damaging slings. Always consult the sling manufacturer’s load charts and adhere to safety guidelines.

Q 23. How do you ensure the proper use and maintenance of personal protective equipment (PPE)?

Personal Protective Equipment (PPE) is non-negotiable in gear handling. My approach involves understanding its purpose, proper usage, regular inspection, and immediate reporting of any damage.

- Inspection: Before each shift, I inspect my PPE (hard hats, safety glasses, gloves, high-visibility clothing, steel-toe boots, and harnesses as needed) for any damage or wear. Any defects are reported immediately.

- Correct Usage: I ensure I use PPE correctly as per the manufacturer’s instructions and company safety procedures. For example, ensuring the harness is correctly fitted and fastened before working at heights.

- Maintenance: I participate in regular PPE training to refresh my knowledge and stay up-to-date on best practices. I understand that damaged PPE is ineffective and needs to be replaced. Gloves should be checked for punctures; helmets for cracks.

- Reporting: If any PPE is damaged or lost, I report it immediately to the supervisor to get a replacement, avoiding potential risks.

The safety of myself and my colleagues is paramount. Proper PPE use is not just a policy, it’s a fundamental part of my work ethic.

Q 24. Explain your experience with working at heights or confined spaces while handling gear.

I have extensive experience working at heights and in confined spaces while handling gear. Safety is always the top priority in these scenarios.

- At Heights: I’m fully trained and certified in fall protection techniques, utilizing appropriate harnesses, lanyards, and anchor points. I meticulously follow all safety protocols, including regular inspections of equipment and awareness of potential hazards such as wind or uneven surfaces. I’ve worked on projects involving crane operations at significant heights, requiring precise communication and adherence to strict safety procedures.

- Confined Spaces: Before entering confined spaces, I always ensure proper ventilation and atmospheric monitoring. I adhere to permit-to-work systems, ensuring colleagues are aware of my entry and location. I’ve handled gear in confined spaces such as ship holds or storage tanks, using appropriate lighting, communication devices, and rescue plans.

My experience has instilled a strong sense of responsibility and attention to detail in high-risk situations. Thorough planning, teamwork, and adherence to safety regulations are crucial.

Q 25. How do you manage your time efficiently to meet deadlines?

Efficient time management is key in gear handling, which often involves multiple tasks and deadlines. My approach involves prioritizing, planning, and using various tools.

- Prioritization: I identify tasks based on urgency and importance, focusing on the most critical aspects first. The most dangerous or time-sensitive tasks get tackled before others.

- Planning: I create detailed plans that break down large projects into smaller, manageable steps. This helps anticipate potential delays and allows for adjustments as needed. I regularly check in to see if I’m on schedule.

- Tools: I utilize tools such as checklists, scheduling software, and communication platforms to track progress and collaborate effectively with my team. We hold regular team briefings to discuss progress and to highlight any potential roadblocks.

Proactive planning and consistent monitoring ensure that I consistently meet deadlines and maintain a high level of productivity.

Q 26. How do you adapt to different work environments and situations?

Adaptability is essential in gear handling, as job sites and tasks can vary significantly. I’ve worked in diverse environments, from industrial plants to construction sites and shipyards.

- Flexibility: I’m comfortable working independently or as part of a team, adjusting my approach based on the project requirements and the expertise of others.

- Problem-Solving: I’m able to quickly assess situations, identify problems, and find effective solutions while always prioritizing safety. Often this involves making on-the-spot decisions.

- Learning: I’m eager to learn new techniques and adapt to different technologies or equipment. This means I can easily handle any new equipment or procedures.

My adaptability comes from a willingness to embrace new challenges and collaborate effectively in various work settings. I’m always looking for ways to improve my efficiency and safety.

Q 27. Describe a time you had to solve a problem related to gear handling.

During a large-scale construction project, a crucial piece of equipment became unexpectedly damaged, delaying the project and causing potential cost overruns. The initial reaction was frustration, but I took a systematic approach.

- Assessment: I first assessed the damage and the extent of the delay it would cause. This involved understanding precisely what the problem was and how it was affecting the project.

- Solutions: I then brainstormed potential solutions, including contacting a repair technician, exploring temporary replacements, or modifying the project schedule. This involved weighing the pros and cons of each option.

- Decision and Execution: After evaluating the options, I chose the most efficient and safe solution – finding a temporary replacement, which had less downtime than the repair.

- Follow-Up: I ensured that all necessary measures were taken to prevent such issues in the future. This involved communicating findings to prevent similar problems.

This situation highlighted the importance of quick thinking, problem-solving skills, and proactive communication in resolving unexpected challenges.

Q 28. What are your salary expectations for this role?

My salary expectations are in line with my experience and the requirements of this role. I’m open to discussing a competitive compensation package based on the full details of the position and benefits offered.

Key Topics to Learn for Gear Handling Interview

- Gear Types and Selection: Understanding different types of gears (spur, helical, bevel, worm) and their applications. Knowing how to select the appropriate gear type for a specific application based on factors like load, speed, and space constraints.

- Gear Design and Manufacturing: Familiarity with gear design principles, including tooth profiles, pressure angles, and module. Understanding common manufacturing processes like hobbing, shaping, and broaching, and their impact on gear quality.

- Gear Train Analysis: Ability to analyze simple and compound gear trains to determine speed ratios, torque transmission, and efficiency. Understanding the concept of gear ratios and their effect on system performance.

- Gear Lubrication and Maintenance: Knowledge of different lubrication methods and their importance in extending gear life. Understanding common gear wear mechanisms and preventative maintenance procedures.

- Troubleshooting and Diagnostics: Ability to identify common gear failures (e.g., wear, breakage, noise) and troubleshoot problems using appropriate diagnostic techniques. Experience with gear inspection and repair methods.

- Safety Procedures: Understanding and adhering to relevant safety regulations and procedures for handling and maintaining gears and related machinery. This includes personal protective equipment (PPE) and lockout/tagout procedures.

- Gear Materials and Properties: Understanding the properties of different gear materials (e.g., steel, plastic, composites) and their suitability for specific applications. Knowledge of material selection criteria for strength, durability, and cost-effectiveness.

Next Steps

Mastering gear handling is crucial for advancement in many engineering and manufacturing roles, opening doors to exciting career opportunities and increased earning potential. To maximize your job prospects, it’s vital to present your skills effectively. An ATS-friendly resume is key to getting your application noticed by recruiters. ResumeGemini is a trusted resource for crafting professional resumes tailored to your specific experience. We provide examples of resumes optimized for Gear Handling roles to help you stand out from the competition. Take advantage of these resources to showcase your expertise and secure your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good