Preparation is the key to success in any interview. In this post, we’ll explore crucial Glass Drawing interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Glass Drawing Interview

Q 1. Describe your experience with different glassblowing techniques (e.g., flameworking, lampworking, furnace working).

My experience encompasses a wide range of glassblowing techniques. Flameworking, also known as lampworking, is my primary focus. This involves using a torch to melt small amounts of glass, allowing for intricate detail and precise control. I’ve created everything from delicate jewelry to small sculptural pieces using this method. Furnace working, on the other hand, uses a larger furnace to melt and shape larger quantities of glass. This technique is ideal for producing larger scale sculptures or functional pieces like bowls and vases. My experience with furnace working includes both the gathering and shaping of molten glass, and the use of various tools for manipulating the glass during the process. While I haven’t extensively worked with other techniques like glassblowing using a blowpipe and gather, I have a good foundational understanding of the principles involved.

Q 2. Explain the process of selecting and preparing glass for a project.

Selecting and preparing glass is crucial for a successful project. The choice of glass depends heavily on the intended application and desired aesthetic. For instance, borosilicate glass, known for its heat resistance, is excellent for functional pieces, while soda-lime glass, though less heat-resistant, offers a wider range of colors and is more easily worked with for certain techniques. I carefully consider the coefficient of thermal expansion (CTE), ensuring compatibility between different glass types if I’m using multiple colors or rods in one piece. Preparation involves cleaning the glass rods or tubes thoroughly to remove any dust or debris that could contaminate the molten glass and affect its clarity or integrity. This often includes wiping it down with isopropyl alcohol before working. Sometimes, depending on the desired color, I’ll prepare the glass further by applying a colored frit (crushed glass) before melting.

Q 3. What types of furnaces are you familiar with, and what are their respective advantages and disadvantages?

I’m familiar with several types of glass furnaces, each with its own advantages and disadvantages. Electric furnaces provide precise temperature control and are relatively easy to operate. However, they can be expensive to purchase and maintain, and their heating element may be vulnerable to damage from shock. Gas furnaces are generally more affordable upfront but offer less precise temperature control and require a steady gas supply. They also have potential safety hazards associated with gas leaks. For smaller-scale work, I often use benchtop electric furnaces, which offer good control and portability. The choice of furnace really depends on the scale and type of project I’m working on and my budget. For really large pieces, a larger, possibly industrial, furnace is necessary.

Q 4. How do you maintain the temperature of a glass furnace?

Maintaining consistent furnace temperature is critical. With electric furnaces, this is achieved through programmable controllers that allow for precise temperature settings and gradual heating and cooling cycles. I regularly monitor the temperature using both the furnace’s built-in pyrometer and an independent thermocouple. For gas furnaces, maintaining temperature is more challenging and often requires adjustments to the gas flow rate based on the ambient temperature and the size of the glass being melted. Even with careful control, gradual temperature changes can still occur, so it’s important to closely watch the glass during the working process. Sudden temperature changes can cause the glass to crack or shatter, so careful control is essential.

Q 5. Describe your experience working with different types of glass (e.g., borosilicate, soda-lime).

My experience spans several glass types. Borosilicate glass, like Pyrex, is a favorite due to its low thermal expansion coefficient, making it resistant to thermal shock. This is ideal for creating durable and functional pieces that won’t easily crack when exposed to temperature changes. Soda-lime glass, on the other hand, is more common in mass-produced items; it’s more readily available and less expensive, however, it’s more prone to cracking with temperature changes. I’ve also worked with lead glass, known for its brilliance, but its toxicity requires extra safety precautions. Choosing the right glass is paramount, and the choice depends entirely on the final application and desired characteristics of the finished product.

Q 6. How do you troubleshoot issues that may arise during the glassblowing process?

Troubleshooting is an essential part of glassblowing. A common issue is the glass becoming too cold, resulting in a rough surface. In this situation, I’ll return the glass to the furnace to reheat it. Another problem can be the formation of bubbles in the glass caused by impurities or overheating. Careful cleaning of the glass and precise temperature control are critical to avoid this. Cracks can develop from sudden temperature changes, stress, or insufficient annealing (slow cooling). Careful annealing is key to preventing this. If a piece becomes misshapen, I can often reheat it and reform it carefully, relying on my experience to estimate how the glass will flow. Each problem requires a different approach, and experience and attention to detail play crucial roles in resolving them.

Q 7. What safety precautions do you take when working with glass and high temperatures?

Safety is paramount in glassblowing. I always wear safety glasses, ideally with side shields, to protect my eyes from flying glass fragments or intense heat. Heat-resistant gloves are a must to prevent burns. I work in a well-ventilated area, especially when using gas furnaces to avoid inhalation of fumes. I ensure proper personal protective equipment (PPE) including long sleeves and closed-toe shoes. The workspace should be clean and organized to avoid accidents. The furnace should be placed on a stable and fire-resistant surface, far from flammable materials. In case of a glass breakage, I’m ready with appropriate equipment to safely clear the debris. I always remember that safety is not optional but a critical part of this profession.

Q 8. Explain your process for designing and creating a glass piece from initial concept to finished product.

My glassblowing process begins with a clear concept, often sketched and refined numerous times. I consider the overall form, the interplay of light and color, and the desired texture. This initial design phase is crucial for visualizing the final piece and anticipating potential challenges. Then comes the gathering of the molten glass from the furnace, a process requiring precise timing and temperature control. I shape the molten glass using various tools like blowpipes, marvers (for shaping and smoothing), jacks (for holding and manipulating), and various punty rods (for supporting the piece). I might use different techniques depending on the design, such as flameworking for intricate detail or lampworking for smaller items. Each step—from adding color, shaping the form, and creating textures—is carefully considered to achieve the intended design. Finally, the piece is carefully annealed in a kiln to slowly cool it down, preventing cracking. Post-annealing, I may perform any final polishing or finishing.

For example, for a recent commission of a complex vase with intricate swirling patterns, I first created a detailed 3D model to visualize the flow and transitions. This allowed me to plan my glass gathering and shaping strategies effectively. I then employed a combination of techniques such as gathering different colored glass rods and swirling them within the molten blob to create the desired effect. The annealing process was particularly important for this piece due to its complex form and internal stresses.

Q 9. How do you handle challenging designs or complex projects?

Challenging designs often require a multi-faceted approach. I start by breaking down the complex project into smaller, manageable tasks. This allows for methodical progress and easier troubleshooting. For example, if a design involves intricate layered patterns, I might first create each pattern component separately and then integrate them carefully. Detailed planning, including creating scaled drawings and 3D models, is also essential. I also rely heavily on experimentation and iterative processes. This may involve several trial runs with smaller glass pieces to test techniques and perfect the design elements before working on the final piece. Collaboration with other skilled glass artists or engineers is sometimes beneficial, particularly when dealing with particularly complex structural requirements.

For instance, while creating a large, free-standing sculpture incorporating multiple glass panels, I collaborated with a structural engineer to calculate the required thickness and support system to prevent breakage. This collaborative effort ensured both artistic integrity and structural stability.

Q 10. Describe your experience with different glassblowing tools and equipment.

My experience encompasses a wide range of glassblowing tools and equipment. This includes various sizes and types of blowpipes, both metal and graphite, each suited for different glass weights and shapes. I’m proficient with different marvers, from wooden ones for initial shaping to polished steel ones for finer detail work. I am familiar with different types of punty rods and jacks, which are essential for handling and manipulating the glass during shaping. I’m also skilled in utilizing various kilns for annealing and other heat-treating processes, and I understand the differences between different furnace types and their temperature control capabilities. I also regularly employ specialized tools like shears for cutting glass, and various shaping tools, from wooden paddles to metal tongs. My understanding extends beyond just the tools themselves; I understand how the material properties of each tool influence the final outcome, allowing me to work effectively.

For example, I prefer using graphite blowpipes for working with delicate borosilicate glass, as it helps to retain heat more efficiently than metal, preventing premature cooling and cracking.

Q 11. How do you ensure the quality and consistency of your work?

Maintaining quality and consistency involves meticulous attention to detail at every stage of the process. This starts with using high-quality materials, selecting appropriate glass types for the desired outcome and ensuring the furnace is at the correct temperature. Consistent technique is crucial; years of practice have honed my skills in glass gathering, shaping and manipulating molten glass. I maintain detailed records of each step, including material properties, temperature settings, and time durations. This helps track potential improvements and maintain consistency. Regular inspection and quality checks throughout the process, before and after annealing, are integral in identifying potential flaws early on. Consistent annealing cycles ensure even stress distribution, minimizing the risk of cracking.

For example, I regularly check the glass’s viscosity during the shaping process to ensure I’m working within the optimal temperature range. This helps achieve the desired consistency and prevents issues such as uneven thickness or structural weaknesses.

Q 12. What are your preferred methods for finishing and polishing glass pieces?

Finishing and polishing glass pieces often involve a series of steps. For initial smoothing, I may use various abrasive materials, starting with coarser grits and gradually moving to finer ones. This could involve using wet/dry sandpaper, followed by polishing compounds and felt wheels. For finer detail work, I may use diamond polishing compounds or specialized polishing tools. Depending on the desired finish, I may choose to leave some textured areas or opt for a perfectly smooth, reflective surface. The type of glass also dictates the finishing process; softer glasses require gentler approaches. The final finish might also include cleaning agents to remove any residues and enhance clarity.

For example, for a piece requiring a highly polished finish, I use diamond polishing compounds followed by a final polish with a very fine felt wheel and polishing compound, resulting in a mirror-like finish.

Q 13. Explain your knowledge of annealing and its importance in glassblowing.

Annealing is a crucial post-processing step in glassblowing. It involves slowly cooling the glass in a controlled environment within a kiln. This slow cooling process relieves internal stresses created during the shaping process. Without annealing, the rapid cooling can create internal stresses that lead to spontaneous cracking or shattering. The temperature and time of the annealing cycle vary depending on the type of glass and the size and complexity of the piece. A typical annealing schedule involves a slow decrease in temperature over several hours, followed by a final period at a lower temperature for stabilization. Failure to properly anneal a piece can result in a structurally compromised and potentially dangerous piece.

Think of it like tempering steel – a slow cooling process increases the strength and durability.

Q 14. How do you measure and control the temperature of molten glass?

Measuring and controlling the temperature of molten glass is vital for success. Most furnaces use pyrometers, which measure the temperature via infrared sensors and provide a digital readout. This allows for precise control of the furnace temperature. Additionally, I use visual cues to assess the glass’s viscosity—its resistance to flow—which is closely related to its temperature. Experience plays a significant role in visually gauging the glass’s temperature. However, pyrometers offer a more precise and reliable measurement. Beyond furnace temperature, I also monitor the temperature of individual glass pieces during the shaping process by observing color changes and the flow of the molten material. Maintaining consistency is key, and meticulous monitoring ensures the optimal temperature range throughout.

For instance, I might use a pyrometer to maintain the furnace at 2200°F (1204°C) for working with borosilicate glass, but I would also visually assess the molten glass’s viscosity before gathering it, ensuring the right temperature for shaping.

Q 15. Describe your experience working with different types of kilns (e.g., electric, gas).

My experience encompasses both electric and gas kilns, each with its own advantages and challenges. Electric kilns offer precise temperature control, making them ideal for delicate work and achieving consistent results. Think of it like baking a cake – you need a precise oven temperature. I frequently use electric kilns for annealing, a crucial step to prevent cracking in finished glass pieces. Gas kilns, on the other hand, provide a more intense, direct heat, which is beneficial for larger-scale projects or when working with thicker glass. The intense heat is like a blacksmith’s forge, allowing for rapid shaping and manipulation. For instance, I prefer a gas kiln for slumping large sheets of glass into molds because of its efficient heating capacity. My proficiency with both types allows me to choose the most appropriate kiln for each project, ensuring optimal results.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain and clean your glassblowing equipment?

Maintaining and cleaning glassblowing equipment is crucial for both safety and longevity. After each session, I meticulously clean the torch and associated components. This involves removing any residual glass with specialized tools, avoiding harsh chemicals that could damage the equipment. For example, a wire brush is perfect for removing excess glass from the torch tip. The work area also requires regular cleaning to prevent the accumulation of glass shards and dust, which pose a safety hazard. Regular inspections of the kiln are essential, checking for cracks or malfunctions to prevent accidents. Lubrication of moving parts on equipment like shears is also crucial to maintain functionality. Think of it like maintaining a car – regular maintenance prevents costly repairs down the line. Prevention is key to keeping everything in top condition and safe to use.

Q 17. What software or design programs are you proficient in?

In addition to my hands-on skills, I’m proficient in several software programs vital to my work. I use Adobe Illustrator and Photoshop for designing intricate patterns and generating templates for my glass pieces. This allows me to create detailed designs, even before starting the glassblowing process. Think of it like architectural blueprints for glass. I also utilize CAD software to design more complex, three-dimensional forms, ensuring precise measurements and structural integrity. This is critical for constructing elaborate installations or sculptural pieces. Proficiency in these programs allows me to translate my artistic vision into reality with precision and efficiency.

Q 18. Describe your experience with different glass colors and their properties.

My experience with glass colors is extensive. I work with a wide range of frit, powders, and color rods, each offering unique properties. For instance, some colors are more vibrant and opaque, while others are translucent or iridescent. Certain colors react differently to heat, affecting their final appearance. Understanding these properties is essential for achieving the desired aesthetic. For example, using a specific cobalt blue frit can achieve a deep, rich color, while a different frit might yield a lighter, pastel tone. I also consider the chemical composition of the colorants to ensure compatibility with the glass type and to prevent issues like devitrification (crystallization) during the firing process.

Q 19. How do you create specific textures or effects in your glass pieces?

Creating textures and effects in glass is where I really get to express my creativity. Techniques range from using textured molds to applying various surface treatments. For example, I can create a hammered look by using specialized tools to strike the hot glass, or I can achieve a bubbly effect by adding specific chemicals to the molten glass. I can also incorporate various materials like metallic powders, which create sparkling inclusions within the glass. I might even use techniques like fusing different colored glasses together to produce a mosaic effect. The possibilities are virtually limitless, depending on the desired outcome.

Q 20. What are some common challenges you face when working with glass, and how do you overcome them?

Working with glass presents inherent challenges. One common issue is thermal shock – rapid temperature changes can cause cracks or breakage. To overcome this, I employ slow and controlled cooling techniques, particularly during the annealing process. Another challenge is achieving consistent color and clarity, particularly when working with complex compositions. Careful attention to temperature control, and understanding the properties of each glass type and colorant is key. Finally, achieving the precise form of intricate shapes sometimes requires multiple attempts. This just requires patience, skill, and learning from each iteration.

Q 21. Describe your experience working collaboratively with other artists or craftspeople.

Collaboration is a significant part of my work. I’ve had the pleasure of working with other artists and craftspeople on large-scale installations and projects where different skill sets are required. For instance, I collaborated with a sculptor on a project where I created the glass elements and they created the supporting metal structure. This collaborative approach allowed us to produce a far more complex and interesting piece than either of us could have done alone. Open communication and a shared vision are essential for successful collaboration in glass art.

Q 22. What are your strengths and weaknesses as a glass artist?

My greatest strength as a glass artist lies in my meticulous attention to detail and my ability to translate complex designs into three-dimensional glass forms. I’m also adept at problem-solving, often improvising techniques to overcome unexpected challenges during the glassblowing process. For instance, I once had to adapt a complex marvering technique mid-blow to correct an unexpected slump in a delicate vase. My weakness, however, is sometimes getting overly invested in perfectionism, which can slow down my production. I’m actively working on improving my time management to find a balance between artistic integrity and efficient workflow.

Q 23. How do you stay current with new trends and techniques in glassblowing?

Staying current in glassblowing requires a multi-pronged approach. I regularly attend workshops and conferences, such as those hosted by the Glass Art Society, to learn from master glassblowers and network with peers. I actively subscribe to relevant journals like Glass Quarterly and follow glass artists on social media platforms like Instagram and YouTube, observing their creative processes and innovative techniques. Furthermore, I actively seek out new glass suppliers to explore different types of glass and their unique properties, constantly experimenting with new compositions and processes in my own studio.

Q 24. Describe a time you had to adapt your techniques to meet a specific design challenge.

A client once commissioned a large-scale sculpture incorporating intricate internal detailing. My initial approach, relying on traditional techniques, proved too cumbersome and risked compromising the sculpture’s structural integrity. To overcome this, I developed a multi-stage process. First, I created the sculpture’s core using a simpler, more robust technique. Then, I employed a series of carefully planned additions, using a combination of flameworking and hot glass techniques, to build up the intricate internal details. This layered approach allowed me to maintain structural integrity while achieving the desired level of detail. This project taught me the importance of flexible planning and creative problem-solving in glassblowing.

Q 25. Explain your understanding of different glassblowing styles and historical influences.

My understanding of glassblowing styles spans various historical periods and geographical influences. I’m familiar with the Venetian tradition, known for its elaborate, ornate forms and the use of millefiori (thousand flowers) techniques. I also appreciate the minimalist aesthetics of Scandinavian glassblowing and the bold, expressive forms of contemporary American glass artists. The influence of ancient Roman glasswork, with its techniques like cameo glass, is also apparent in my understanding of layering and carving techniques. Each style has shaped my understanding of glass as a medium, enriching my artistic vocabulary and approach.

Q 26. How do you market and sell your glass art?

Marketing my glass art involves a multifaceted strategy. I maintain a professional website showcasing my work, utilizing high-quality photography and detailed descriptions. I participate in juried art shows and craft fairs, both locally and nationally, to connect directly with potential buyers. My online presence extends to social media, where I share images and videos of my creative process, engaging with followers and building a community around my work. Building relationships with galleries is also crucial; these partnerships provide valuable exposure to a wider audience. Word-of-mouth referrals from satisfied clients are also a significant source of new commissions.

Q 27. How do you price your glass work?

Pricing my glasswork is a careful calculation considering several factors. Firstly, I assess the cost of materials, including the type and quantity of glass used. Secondly, I factor in the time spent on the project, including design, fabrication, and finishing. This includes accounting for the complexity of the design and any specialized techniques involved. Thirdly, I consider my experience and artistic reputation, alongside the market value of similar pieces. Finally, I factor in profit margin to ensure the financial viability of my business. This approach results in fair pricing that reflects the value and craftsmanship inherent in my work.

Q 28. Describe your experience with different types of glass enclosures and their applications.

My experience encompasses a range of glass enclosures. I’m proficient in creating simple, clear glass domes for smaller pieces, offering protection without obscuring the artwork’s aesthetic. For larger sculptures, I frequently work with custom-fabricated wooden or metal bases and enclosures, designed to complement the piece’s style and provide optimal protection during transport and display. I’ve also worked with bespoke acrylic enclosures for fragile or highly detailed work, allowing for better visibility and protection from environmental factors. The choice of enclosure depends entirely on the nature of the artwork, its fragility, and intended display environment.

Key Topics to Learn for Glass Drawing Interview

- Glass Properties & Behavior: Understanding the thermal, chemical, and physical properties of different glass types (e.g., soda-lime, borosilicate) and how they influence drawing processes.

- Drawing Techniques & Processes: Mastering various glass drawing techniques, including hand drawing, machine drawing, and specialized methods. Understanding the parameters affecting the final product (e.g., temperature, speed, viscosity).

- Equipment & Technology: Familiarity with different types of glass drawing equipment, from basic hand tools to automated systems. Knowledge of relevant technologies like furnaces, annealing ovens, and quality control instruments.

- Quality Control & Inspection: Understanding quality control measures for glass drawing, including defect detection, dimensional accuracy, and surface finish assessment. Experience with various inspection methods.

- Safety Procedures & Regulations: A thorough understanding of safety protocols and regulations related to high-temperature processes and handling of molten glass. This includes personal protective equipment (PPE) and emergency procedures.

- Troubleshooting & Problem-Solving: Ability to identify and troubleshoot common problems encountered during the glass drawing process, such as defects, breakage, and inconsistencies. Experience in implementing corrective actions.

- Design & Engineering Principles: Applying principles of design and engineering to optimize the glass drawing process and create desired shapes and dimensions. Understanding of material science and its application to glass.

Next Steps

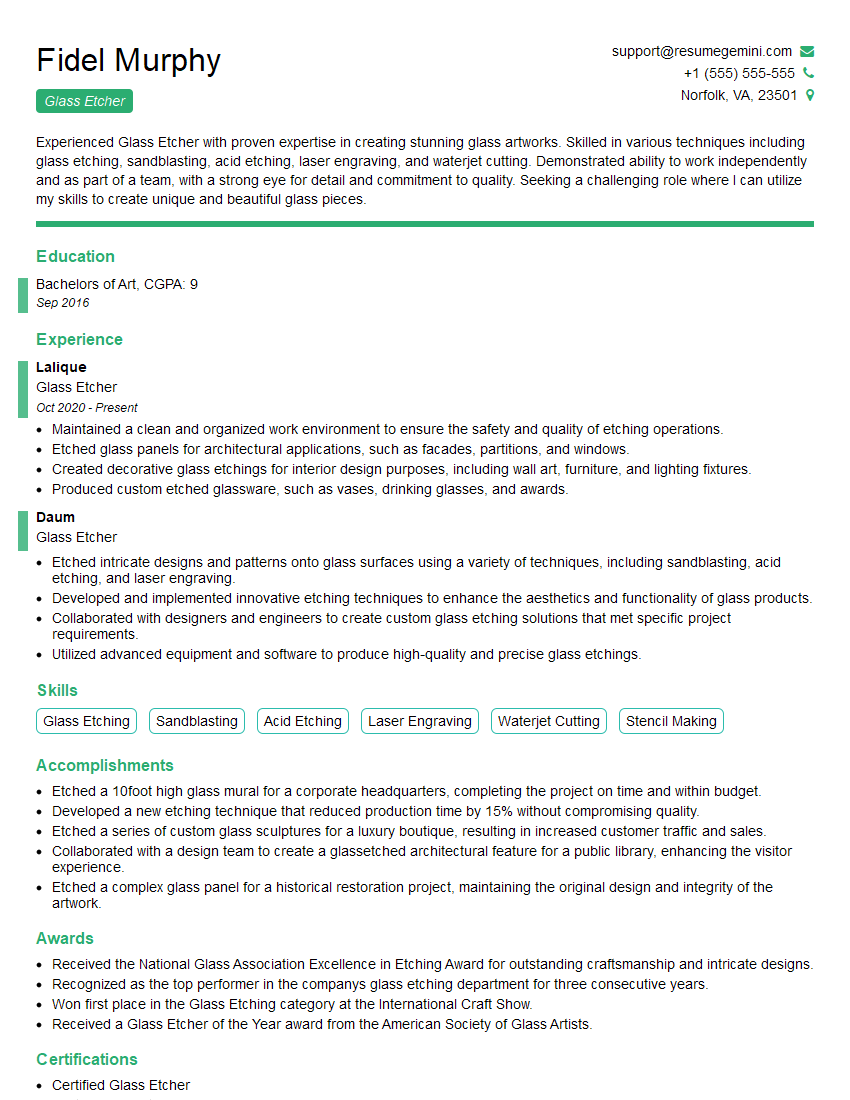

Mastering glass drawing opens doors to exciting career opportunities in manufacturing, research, and development within the glass industry. To maximize your job prospects, creating a compelling and ATS-friendly resume is crucial. ResumeGemini offers a trusted platform to build a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored to the Glass Drawing industry to help you craft a standout application. Invest the time to showcase your expertise and land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).