Unlock your full potential by mastering the most common Grading and Sampling interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Grading and Sampling Interview

Q 1. Explain the importance of representative sampling.

Representative sampling is crucial because it ensures that the sample accurately reflects the characteristics of the entire population being studied. Imagine trying to understand the average height of all students in a university by only measuring the heights of students in one specific dorm. That wouldn’t be representative! A representative sample allows us to draw valid conclusions about the population based on the analysis of the sample, minimizing bias and errors.

For instance, in the mining industry, if we’re assessing the grade of an ore body, a non-representative sample might lead to inaccurate estimations of the valuable mineral content, potentially resulting in significant financial losses or flawed mine planning.

Q 2. Describe different sampling methods and their applications.

Various sampling methods exist, each with its strengths and weaknesses. The choice depends on the specific context, including the nature of the material, the required accuracy, and cost constraints.

- Simple Random Sampling: Each member of the population has an equal chance of being selected. Think of drawing names out of a hat. This is straightforward but might not be effective for heterogeneous populations.

- Stratified Sampling: The population is divided into strata (subgroups) based on relevant characteristics (e.g., age, location). A random sample is then taken from each stratum. This is useful when dealing with populations with known variations.

- Systematic Sampling: Selecting every nth item from a population after a random starting point. This is efficient but can be problematic if there’s a pattern in the population that aligns with the sampling interval.

- Composite Sampling: Combining multiple samples into one composite sample for analysis. This is cost-effective for large volumes but masks individual sample variations.

- Incremental Sampling: Taking samples at regular intervals during a continuous process. This is ideal for monitoring quality control during production.

For example, in environmental monitoring, stratified sampling might be used to collect soil samples across different land-use types to assess pollution levels accurately. In quality control of manufactured products, systematic sampling is commonly employed to efficiently check for defects.

Q 3. What are the key factors to consider when designing a sampling plan?

Designing a robust sampling plan requires careful consideration of several factors:

- Objective: Clearly define the purpose of the sampling (e.g., estimating the average grade, assessing variability, detecting contamination).

- Population characteristics: Understand the nature of the material, its variability, and any potential spatial or temporal patterns.

- Sample size: Determine the appropriate number of samples needed to achieve the desired level of accuracy and precision. Statistical methods help determine the necessary sample size.

- Sampling method: Select the most suitable sampling method based on the population characteristics and the objective.

- Sample preparation: Outline the steps involved in preparing the samples for analysis (e.g., crushing, grinding, drying). Inconsistent sample preparation can introduce significant errors.

- Analytical methods: Choose appropriate analytical techniques with sufficient sensitivity and accuracy.

- Cost and time constraints: Balance the need for accuracy with practical limitations.

Failing to adequately consider these factors can lead to inaccurate results and potentially costly mistakes.

Q 4. How do you ensure the accuracy and precision of sampling results?

Ensuring accuracy and precision involves a multi-faceted approach:

- Proper sampling techniques: Adhering to rigorous sampling protocols to minimize bias and ensure representativeness.

- Calibration and maintenance of equipment: Regular calibration of instruments and careful maintenance ensure accurate measurements.

- Quality control checks: Implementing quality control measures at each stage of the process, including blind samples and duplicate analysis, helps identify and correct errors.

- Statistical analysis: Using appropriate statistical methods to assess the variability in the data, calculate confidence intervals, and evaluate the precision of the results.

- Documentation: Meticulous record-keeping of all aspects of the sampling and analysis process is essential for traceability and auditability.

For example, in a laboratory setting, regular calibration of balances and other analytical equipment is crucial for ensuring accurate results. Blind samples – samples of known composition analyzed without the analyst knowing the composition – help assess the accuracy and consistency of the analytical process.

Q 5. Explain the concept of sampling bias and how to mitigate it.

Sampling bias occurs when the sample does not accurately represent the population, leading to skewed results. This can arise from various sources, including:

- Selection bias: Non-random selection of samples, favoring certain parts of the population.

- Measurement bias: Inconsistent or inaccurate measurements during sampling or analysis.

- Analytical bias: Errors inherent in the analytical methods used.

Mitigation strategies include:

- Randomization: Employing random sampling techniques to ensure all parts of the population have an equal chance of being selected.

- Blind sampling: Preventing the analyst from knowing the source or identity of the sample during analysis.

- Calibration and quality control: Regularly calibrating equipment and implementing quality control measures to detect and correct errors.

- Stratification: Dividing the population into strata to ensure adequate representation of all subgroups.

Consider a scenario where we’re sampling trees in a forest. If we only sample trees near the road, we might underestimate the average tree height in the entire forest.

Q 6. What are the common errors associated with grading and sampling?

Common errors in grading and sampling include:

- Incorrect sample size: Too few samples leading to insufficient precision.

- Non-representative sampling: Bias introduced by non-random sampling or inappropriate sampling techniques.

- Poor sample preparation: Inconsistent or inadequate sample preparation introducing errors into the analysis.

- Contamination: Introduction of foreign materials affecting the results.

- Incorrect analytical methods: Using inappropriate or poorly calibrated analytical techniques.

- Human error: Mistakes during sampling, handling, or data entry.

- Equipment malfunction: Errors arising from faulty or improperly maintained equipment.

These errors can lead to significant inaccuracies in grading and characterization of materials, affecting decision-making in various industries.

Q 7. How do you handle outliers or anomalies in your sampling data?

Outliers or anomalies in sampling data require careful consideration. They could be genuine variations within the population or the result of errors during sampling or analysis. We shouldn’t automatically discard them.

The approach involves:

- Investigation: Examine the circumstances under which the outlier was obtained. Were there any unusual events during sampling or analysis?

- Data validation: Verify the data’s accuracy. Were there any errors in recording or transcription?

- Statistical analysis: Employ statistical tests to determine if the outlier is statistically significant. Methods like Grubbs’ test can help assess this.

- Robust statistical methods: Use statistical techniques less sensitive to outliers, such as median instead of mean for central tendency.

- Documentation: Record the outlier and the steps taken to investigate and handle it.

If the outlier is determined to be a genuine data point, it should be retained. However, if it’s due to an error, it should be addressed and corrected or removed with proper justification. Simply removing outliers without proper investigation is not good practice and may introduce bias itself.

Q 8. Describe your experience with different types of sampling equipment.

My experience with sampling equipment spans a wide range, encompassing both manual and automated systems. Manual methods often involve tools like shovels, riffles, and scoops for collecting representative samples from bulk materials like ore or aggregates. I’m proficient in using these tools, ensuring proper techniques for minimizing bias and contamination. For instance, when sampling a stockpile, I utilize the ‘cone and quartering’ method to progressively reduce the sample size while maintaining representativeness.

Automated sampling systems are crucial for high-throughput applications. I’ve worked extensively with systems like automatic core samplers for drilling operations, which provide continuous cores for precise analysis of mineral deposits. I also have experience with robotic samplers used in process streams, ensuring accurate representation of material flowing through conveyors or pipelines. Each method requires a different approach to calibration, maintenance, and data logging, which I’m well-versed in.

- Manual Sampling: Shovels, riffles, cores, tubes, scoops

- Automated Sampling: Robotic samplers, automatic core samplers, in-line samplers

Q 9. How do you ensure the chain of custody is maintained during sampling?

Maintaining chain of custody is paramount to ensure the integrity and validity of sampling data. This involves meticulously documenting every step of the sampling process, from sample collection to laboratory analysis. Think of it like a carefully orchestrated relay race: each participant needs to hand off the baton (the sample) accurately and without interruption.

My approach includes using uniquely numbered sample tags or labels affixed to each sample container. These labels include critical information such as sample ID, location, date, time, and the sampler’s signature. A detailed sampling log is maintained, recording all actions, observations (e.g., weather conditions, material characteristics), and any deviations from the sampling plan. This log serves as an irrefutable record. Secure transport and storage of samples are also vital, using tamper-evident seals and appropriate storage conditions to prevent contamination or degradation. Finally, all personnel involved in the process are briefed on their responsibilities in maintaining chain of custody.

Q 10. Explain your experience with statistical analysis of sampling data.

Statistical analysis is the cornerstone of interpreting sampling data accurately and drawing meaningful conclusions. My experience includes applying various statistical techniques to assess sample representativeness, estimate population parameters (e.g., average grade, variability), and determine the confidence level of our findings. This involves understanding and applying techniques like:

- Descriptive Statistics: Calculating means, standard deviations, and variances to summarize the sample data. For instance, calculating the average gold grade from a set of drill core samples.

- Inferential Statistics: Using hypothesis testing to evaluate if there are significant differences between sample groups, or estimating population parameters with confidence intervals. A crucial application in mining is estimating ore reserves based on limited sampling data.

- Geostatistics: This is particularly important in resource estimation, incorporating spatial correlation to model the distribution of valuable components in a deposit. Kriging, a geostatistical technique, is often used to create grade maps and estimate resource volumes.

Understanding the limitations of sampling is crucial; I always strive to account for sampling errors and uncertainty in my interpretations.

Q 11. What software or tools are you familiar with for data analysis in grading and sampling?

My proficiency extends to several software tools crucial for data analysis in grading and sampling. I’m proficient in:

- Spreadsheet software (Excel, Google Sheets): For data entry, basic statistical calculations, and data visualization.

- Statistical software packages (R, Minitab): For more advanced statistical analyses like regression modeling, hypothesis testing, and geostatistical modeling. For example, I use R to perform kriging and create grade estimations maps.

- Geostatistical software (Surpac, Leapfrog Geo): These specialized software are critical for 3D modeling of ore bodies, grade estimation, and resource modeling. I frequently use these in mining projects.

- Database Management Systems (SQL): For managing and querying large datasets efficiently.

The choice of software depends on the complexity of the project and the specific analytical needs. For example, a simple project might only need spreadsheet software, whereas a large mining project will typically use a suite of specialized software.

Q 12. How do you document and report your sampling and grading findings?

Comprehensive documentation and reporting are essential to ensure transparency and traceability of the entire sampling and grading process. My reports typically include:

- Detailed Sampling Plan: Outlining the sampling methodology, locations, number of samples, and sample preparation procedures.

- Chain of Custody Documentation: Recording the handling and transport of samples, with signatures and dates at each stage.

- Laboratory Analysis Results: Summarizing the assay results from accredited laboratories.

- Statistical Analysis Results: Presenting descriptive statistics, inferential statistics, and geostatistical modeling results, including any limitations and uncertainties.

- Maps and Diagrams: Visualizing spatial distribution of grades and other relevant geological data, if applicable.

- Conclusions and Recommendations: Summarizing the findings and providing recommendations based on the data.

The format and content of the report are tailored to the specific requirements of the project and the intended audience. All reports are reviewed internally before submission to ensure accuracy and completeness.

Q 13. Describe your experience with different grading standards (e.g., ASTM, ISO).

My experience encompasses various grading standards, including ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) standards. These standards provide frameworks for consistent and reliable testing methods. Understanding these standards is critical to ensure that our sampling and grading procedures meet industry best practices and that our results are comparable across different projects and laboratories.

For instance, ASTM standards provide detailed guidelines for various aspects of materials testing, including sampling procedures, sample preparation, and analytical techniques. ISO standards cover broader aspects of quality management and laboratory accreditation. My experience includes working with ASTM standards for coal and aggregate sampling, and ISO standards for laboratory quality control in metallurgical analysis. Adherence to these standards ensures the credibility and reliability of our findings.

Q 14. How do you interpret and use grading results to make informed decisions?

Interpreting and utilizing grading results is a crucial aspect of decision-making in various industries. I use the results not just as raw data but as a basis for informed decisions by considering several factors:

- Statistical Significance: Evaluating if observed differences in grades are statistically significant or merely due to random variation. A small difference in grade might not be significant if the variability is high.

- Spatial Context: Considering the spatial distribution of grades to understand the heterogeneity of the material or deposit. This is crucial in resource estimation.

- Uncertainty Analysis: Acknowledging that all grading results have a degree of uncertainty associated with them. This involves understanding the sources of error and quantifying their impact on the final results.

- Economic Considerations: Evaluating the economic viability of different courses of action based on the grading results. For example, a higher grade might justify higher processing costs.

Ultimately, my goal is to translate complex data into actionable insights. This requires a thorough understanding of the underlying statistical principles and the context of the project, enabling stakeholders to make data-driven decisions.

Q 15. How do you ensure compliance with relevant safety regulations during sampling?

Safety is paramount in sampling. Before any sampling activity, I meticulously review the relevant safety data sheets (SDS) for the material being sampled and the area’s specific risk assessment. This includes understanding potential hazards like flammability, toxicity, or reactivity. I then select and use appropriate personal protective equipment (PPE), which might include respirators, safety glasses, gloves, and specialized clothing depending on the risks. I also ensure the sampling location is properly secured and any necessary permits or authorizations are in place. For example, when sampling in a confined space, I’d implement procedures for atmospheric monitoring and ensure a standby person is present. Regular safety briefings and adherence to company safety protocols are crucial elements of my approach.

Furthermore, I maintain a clean and organized workspace to prevent accidents and ensure the integrity of the samples. Proper handling and disposal of waste materials are also critical to environmental protection and worker safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a situation where you had to troubleshoot a problem with sampling equipment.

During a project involving the sampling of a highly viscous polymer, our automated sampler malfunctioned. The auger became clogged, preventing further sampling. My first step was to isolate the equipment, ensuring the safety of personnel. I then systematically investigated the problem, beginning with a visual inspection of the auger and the material itself. We discovered that the polymer’s higher than expected viscosity, coupled with a slight increase in ambient temperature, caused premature solidification within the auger mechanism.

My solution involved a three-pronged approach: 1) We temporarily adjusted the auger’s speed to reduce clogging. 2) We implemented a pre-heating system for the auger to maintain a consistent temperature. 3) We added a lubrication system to reduce the friction between the auger and the polymer. The issue was resolved, and the rest of the sampling proceeded without further incidents. This experience highlighted the importance of understanding the properties of the material being sampled and the need for adaptable solutions when equipment malfunctions occur.

Q 17. How do you manage time effectively when working on multiple sampling projects simultaneously?

Effective time management when juggling multiple sampling projects requires a structured approach. I utilize project management tools to create detailed schedules with clear deadlines and milestones for each project. Prioritization is key; I focus on the projects with the most urgent deadlines or those with the greatest potential impact.

I also break down larger projects into smaller, more manageable tasks. This makes the overall project less daunting and allows for better progress tracking. Regular review meetings help me assess progress, identify potential bottlenecks, and adjust my schedule as needed. Delegation, where possible, is another important strategy for efficient time management. Clear communication with my team ensures everyone understands their responsibilities and can work effectively towards common goals. Finally, I maintain a flexible approach, recognizing that unexpected issues can arise and requiring adjustments to the schedule.

Q 18. Explain your experience with different types of materials you have graded and sampled.

My experience encompasses a broad range of materials, including:

- Agricultural products: Grains (wheat, corn, soybeans), fruits, vegetables – requiring specific techniques to ensure representative sampling and minimize damage.

- Minerals: Ores, aggregates, soils – often involving large-scale sampling and the use of specialized equipment like core drills and riffle splitters.

- Industrial materials: Polymers, chemicals, powders – demanding precise sampling methods to control contamination and maintain sample integrity, often utilizing specialized containers and handling procedures.

- Environmental samples: Water, soil, air – needing adherence to strict protocols for chain-of-custody and accurate representation of the environment being sampled.

Each material presents unique challenges, necessitating the selection of appropriate sampling techniques, equipment, and handling procedures. My experience enables me to adapt my methods to different material properties and sampling environments.

Q 19. How do you communicate technical information effectively to non-technical audiences?

Communicating technical information to non-technical audiences requires a clear and concise approach. I avoid jargon and technical terms whenever possible, substituting them with plain language explanations and relatable analogies. For instance, when explaining stratified random sampling, instead of using statistical terms, I might explain it as dividing a field into sections (strata) and randomly selecting samples from each section to get a better representation of the entire field’s quality. Visual aids, such as charts, graphs, and diagrams, are invaluable in making complex information easier to understand.

I tailor my communication to the audience’s level of understanding, ensuring the information is relevant and pertinent to their needs. Active listening and seeking feedback are also crucial in confirming understanding and addressing any questions or concerns.

Q 20. What are the key differences between grab sampling and composite sampling?

Grab sampling and composite sampling are two distinct methods used in material sampling. Grab sampling involves taking individual samples from various locations in a lot or batch, providing a snapshot of the material’s quality at those specific points. It’s quick and simple but might not be representative of the entire material if there is significant heterogeneity. Think of grabbing a handful of candies from a large bag – you might get a mix of colors and flavors, but it doesn’t necessarily reflect the exact proportion of each in the entire bag.

Composite sampling combines several grab samples to create a single, representative sample. This approach is more suitable for materials with homogenous characteristics, providing a better overall representation of the material’s average quality. This is like mixing all the candies together from the bag and then taking a sample—it’s a more even reflection of the bag’s contents. The choice between the two methods depends on the material’s homogeneity, the desired level of accuracy, and the project’s objectives.

Q 21. Explain your understanding of different statistical sampling methods (e.g., stratified random sampling).

Statistical sampling methods are essential for ensuring representative samples. Stratified random sampling, for example, is particularly useful when dealing with heterogeneous materials. This technique involves dividing the material into distinct subgroups or strata based on relevant characteristics (e.g., size, color, location within a batch). Then, random samples are drawn from each stratum, proportional to its size. This ensures that each stratum is adequately represented in the final sample, improving the overall accuracy and reducing sampling bias. For example, when sampling a field of wheat, stratification might be by soil type or elevation, ensuring the variation across different areas is captured.

Other methods include simple random sampling (selecting samples randomly from the entire population), systematic sampling (selecting samples at regular intervals), and cluster sampling (selecting clusters of samples from different locations). The choice of the optimal statistical sampling method depends on the specific characteristics of the material, the level of variability, and the desired accuracy of the results.

Q 22. How do you handle disputes or discrepancies regarding grading results?

Handling disputes over grading results requires a systematic approach. First, we thoroughly review the initial grading process, checking for any procedural errors. This might involve verifying the calibration of equipment, re-examining the sample preparation techniques, and comparing the results against established standards. If the discrepancy stems from a difference in interpretation of the grading criteria, we refer back to the documented standards and guidelines to ensure consistent application. We may also involve a second, independent grader to perform a blind assessment of the sample. If the discrepancy persists, a detailed report outlining all steps taken, along with photographic or video evidence (if available), is compiled. This report serves as a basis for further discussion or, in extreme cases, for arbitration, depending on the established dispute resolution processes.

For example, in a recent project involving the grading of agricultural produce, a discrepancy arose regarding the size classification of a particular batch. By meticulously reviewing the initial measurement process and recalibrating the sizing equipment, we discovered a slight misalignment which caused the initial error. The issue was resolved swiftly and transparently.

Q 23. Describe your experience with quality control procedures for grading and sampling.

My experience with quality control (QC) in grading and sampling encompasses a wide range of procedures. It begins with rigorous calibration and validation of all equipment used in the sampling and testing process, adhering to documented SOPs (Standard Operating Procedures). This includes regular checks on scales, moisture meters, and other specialized instruments. We maintain detailed records of these calibrations, including dates, results, and technician signatures, ensuring traceability. Furthermore, we employ blind audits, where samples are independently graded by different technicians to assess consistency. We also use control charts to monitor the grading process over time, identifying any trends or deviations that might indicate a problem with the equipment, procedures, or the grader’s performance. Statistical process control techniques are key to identifying and correcting systemic errors before they impact the final results. We maintain a comprehensive database of all QC results and remedial actions, facilitating continuous improvement.

For instance, in a previous role, we used a control chart to monitor the moisture content readings of a particular grain type. An upward trend was detected, highlighting a potential issue with the moisture meter. Prompt recalibration resolved the problem, preventing potentially inaccurate grading of the entire consignment.

Q 24. What are some best practices for sample preservation and storage?

Sample preservation and storage are crucial for maintaining the integrity of samples and ensuring the reliability of grading results. The specific methods depend on the nature of the material being sampled. For example, samples that are susceptible to moisture loss, such as grains or powders, are often stored in airtight containers with desiccants to prevent moisture absorption. Samples prone to microbial growth require refrigeration or freezing, sometimes with the addition of preservatives. For materials sensitive to light degradation, opaque containers or dark storage conditions are essential. All samples are clearly labeled with identifying information including date, time, location of sampling, and the unique sample ID. Chain-of-custody documentation is strictly maintained, and temperature-sensitive materials are monitored with data loggers to track temperature throughout the storage period. Regular inspections are carried out to identify any signs of degradation or contamination.

Imagine a scenario involving soil samples for environmental analysis. To prevent microbial activity and moisture changes, these samples are stored in sealed, refrigerated containers at a specific temperature. This ensures the integrity of the soil chemistry and prevents inaccurate results in subsequent analysis.

Q 25. How do you ensure the traceability of samples throughout the entire process?

Traceability is paramount in grading and sampling. We use a unique identification number (UID) for each sample, which is tracked throughout the entire process. This UID is recorded on all relevant documentation, including sampling records, laboratory reports, and quality control reports. A chain-of-custody document is meticulously maintained, detailing the transfer of the sample from the point of collection to the testing laboratory, and finally to the archive. The UID is entered into a database or software system that allows for the complete tracking of the sample’s journey. Barcodes or RFID tags can enhance the efficiency and accuracy of sample tracking. This ensures that the integrity and authenticity of the sample are maintained at all times, allowing us to confidently trace the sample’s history and identify any potential issues.

For instance, if a discrepancy occurs later in the process, the UID allows us to easily retrace the sample’s path, identifying individuals involved at each stage, and checking the conditions under which the sample was stored and handled.

Q 26. What are the limitations of different sampling methods?

Different sampling methods have inherent limitations. For example, random sampling, while seemingly unbiased, can still lead to inaccurate results if the population is highly heterogeneous. If the variation within the population is large, a large sample size is necessary, increasing cost and time. Stratified sampling, where the population is divided into subgroups, helps to address this by ensuring representation from all strata; however, accurate stratification requires detailed knowledge of the population characteristics. Systematic sampling, selecting samples at fixed intervals, might introduce bias if the population has a cyclical pattern coinciding with the sampling interval. Convenience sampling, though efficient, is prone to significant bias, as it selects samples that are easily accessible, potentially not representative of the overall population. The choice of sampling method always involves a trade-off between accuracy, cost, and time constraints, and the selection depends heavily on the specific context and the nature of the material being sampled.

For example, in sampling a large ore deposit, a systematic grid sampling might miss zones of high-grade ore if the grid spacing doesn’t adequately capture the spatial distribution of the ore. A more refined strategy, such as stratified sampling with higher density in suspected high-grade zones, would be more effective but also more expensive.

Q 27. Describe a situation where you had to adapt your sampling plan due to unforeseen circumstances.

During a project involving the sampling of a large shipment of timber, we faced unforeseen circumstances due to severe weather. The original sampling plan involved accessing the lumber yard directly; however, heavy rains made the ground inaccessible to our equipment. We had to quickly adapt the plan. This involved using aerial photography with drone technology to assess the timber stacks and using a smaller, more agile team with all-terrain vehicles to reach the stacks. While this deviated from our initial plan, we ensured thorough documentation of the modifications, maintaining the integrity of the sampling process and adjusting our sampling techniques accordingly to account for any potential biases from the changed approach. The samples collected provided reliable data for grading despite the initial logistical challenges. This emphasized the importance of flexibility and adaptability in real-world sampling scenarios.

Key Topics to Learn for Grading and Sampling Interview

- Sampling Techniques: Understanding various sampling methods (random, stratified, systematic, etc.) and their applications in different contexts. Consider the biases inherent in each and how to mitigate them.

- Grading Standards and Specifications: Familiarize yourself with industry-specific grading standards and how to accurately assess quality based on defined parameters. Practice applying these standards to hypothetical scenarios.

- Data Analysis and Interpretation: Learn to analyze sampled data, identify trends, and draw meaningful conclusions. Develop skills in using statistical tools to support your assessments.

- Quality Control and Assurance: Understand the role of grading and sampling in maintaining quality control throughout a process. Explore different quality control methodologies and their practical applications.

- Documentation and Reporting: Master the art of clearly and accurately documenting sampling procedures, grading results, and analysis findings. Practice presenting your findings concisely and effectively.

- Problem-solving and Decision-Making: Prepare to discuss situations where sampling results are unexpected or inconsistent. Develop strategies for troubleshooting and identifying root causes of quality issues.

- Software and Tools: Familiarize yourself with any relevant software or tools used in data analysis and reporting within the grading and sampling field. Demonstrate your ability to utilize these effectively.

- Regulatory Compliance: Understand any relevant industry regulations and standards impacting grading and sampling procedures. Demonstrate awareness of legal and ethical considerations.

Next Steps

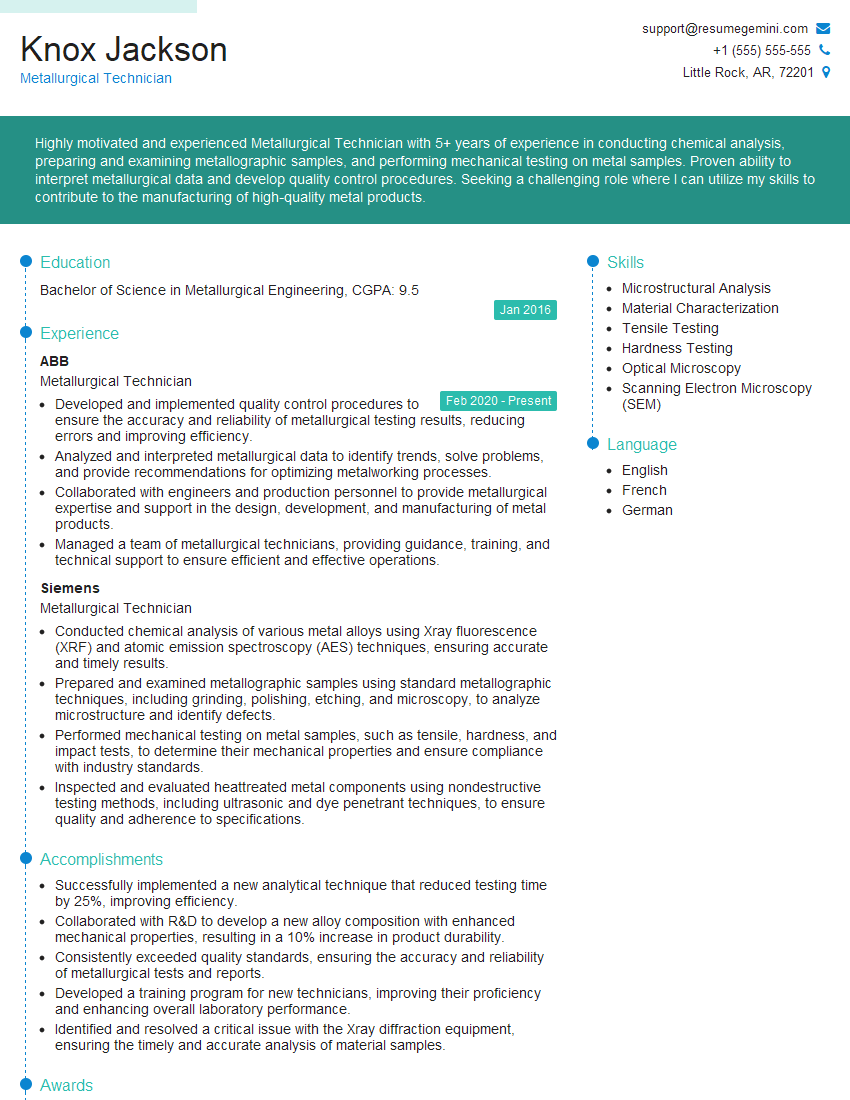

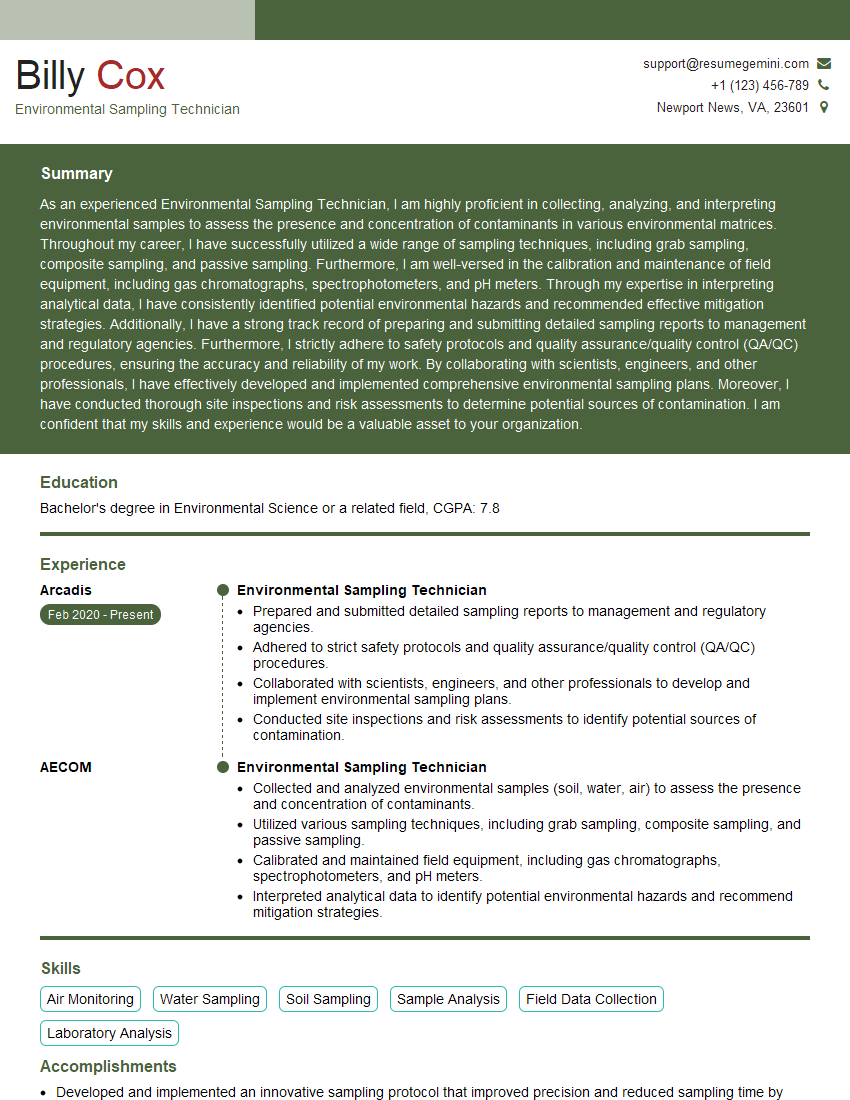

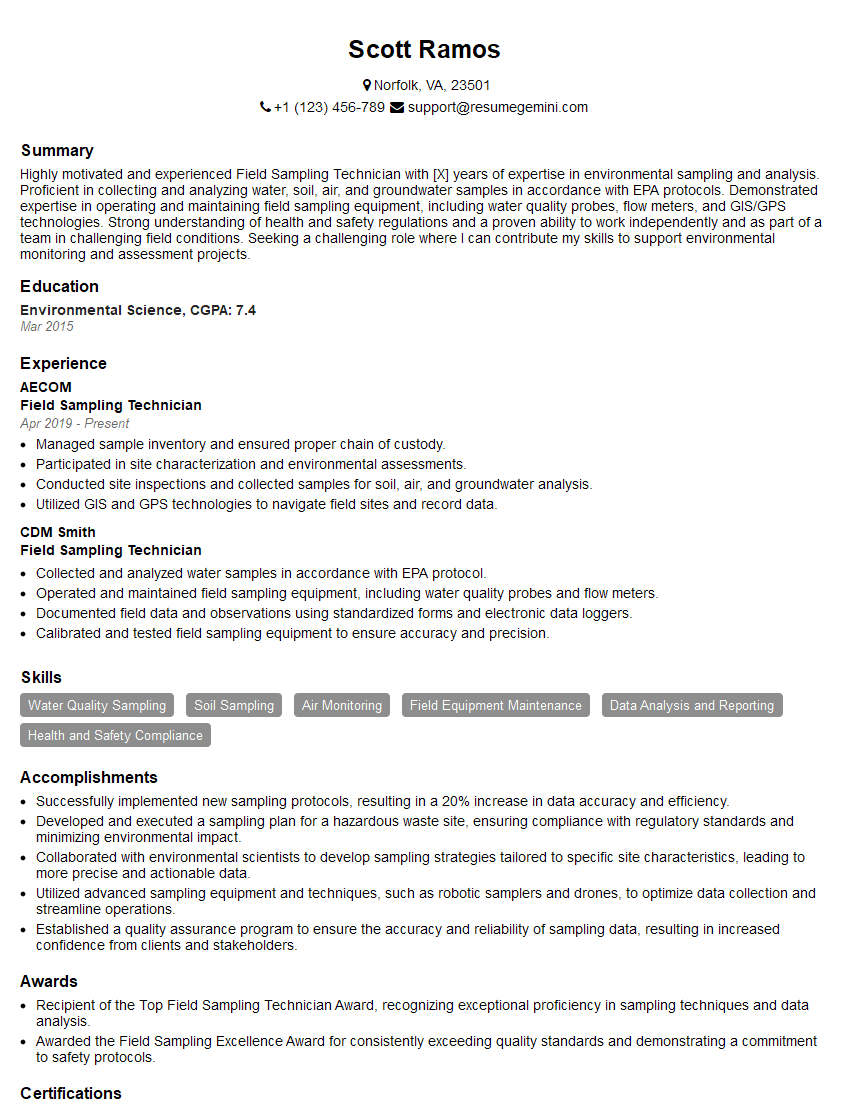

Mastering Grading and Sampling opens doors to exciting career opportunities in various industries demanding high levels of precision and quality control. To significantly boost your job prospects, it’s crucial to craft a compelling and ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific requirements of your target roles. We provide examples of resumes tailored to Grading and Sampling to guide you through the process, ensuring your qualifications shine through to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good